Integral stripping type sugarcane leaf stripping machine

A leaf stripper and leaf stripping technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of low production efficiency and work quality, high labor intensity, etc., achieve high work efficiency, reduce labor intensity, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

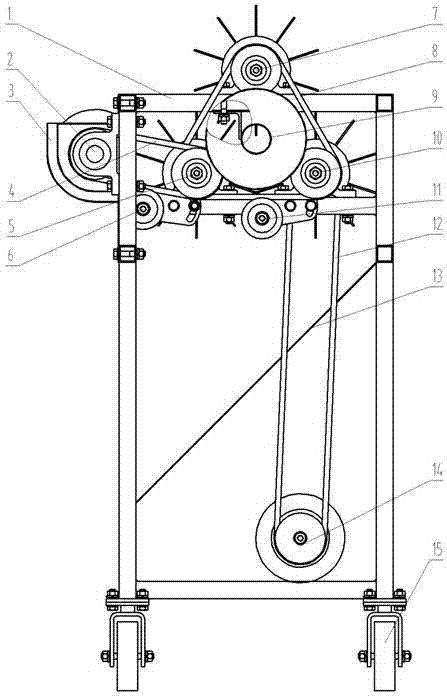

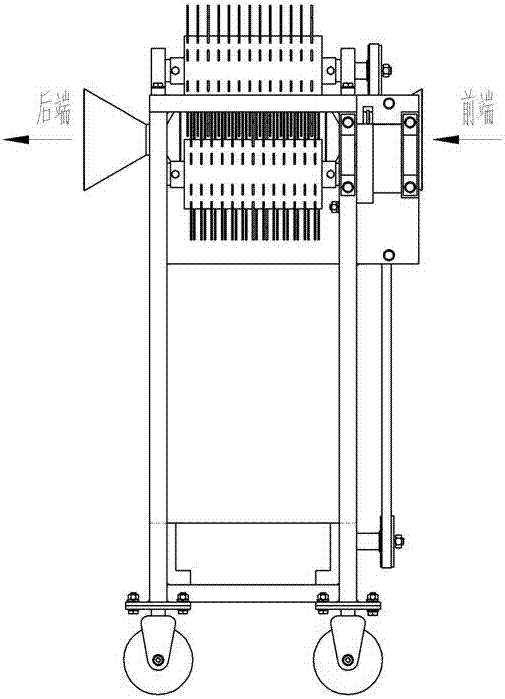

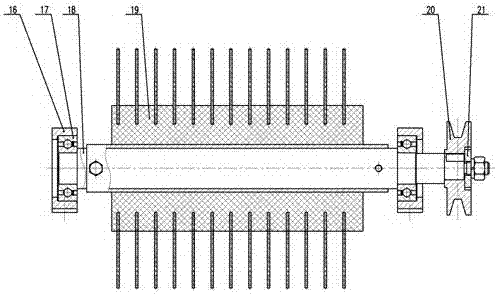

[0029] Embodiment 1: as Figure 1-8 As shown, a whole-bar sugarcane leaf stripper includes a bracket 1, a cutting part 2, a cover plate 3 for the cutting part, a belt I4, a leaf stripping roller brush part I5, a tension wheel part I6, and a leaf stripping roller brush part Ⅱ7, belt Ⅱ8, guide part 9, leaf stripping roller brush part Ⅲ10, tension wheel part Ⅱ11, belt Ⅲ12, baffle plate 13, motor 14, universal wheel 15; said cutting part 2, leaf stripping roller brush part Ⅰ5, leaf stripping roller brush part II7, leaf stripping roller brush part III10 and the guide parts 9 at the front and rear ends are all connected to the bracket 1, leaf stripping roller brush part I5, leaf stripping roller brush part II7 and leaf stripping roller brush part III10 There are roller brushes inside, and the inner belt Ⅱ8 is assembled in the belt groove of leaf stripping roller brush part Ⅱ7 and the inner belt groove of leaf stripping roller brush part Ⅰ5 and leaf stripping roller brush part Ⅲ10; b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com