One step synthesis of polymerized aluminum-iron sulfurate from industrial waste slags

A technology of polymerizing aluminum ferric sulfate and inorganic polymers, which is applied in aluminum sulfate, flocculation/precipitation water/sewage treatment, aluminum sulfur compounds, etc. , can not achieve the polymerization effect and other problems, to achieve excellent water purification performance, simple operation, increase the effect of suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

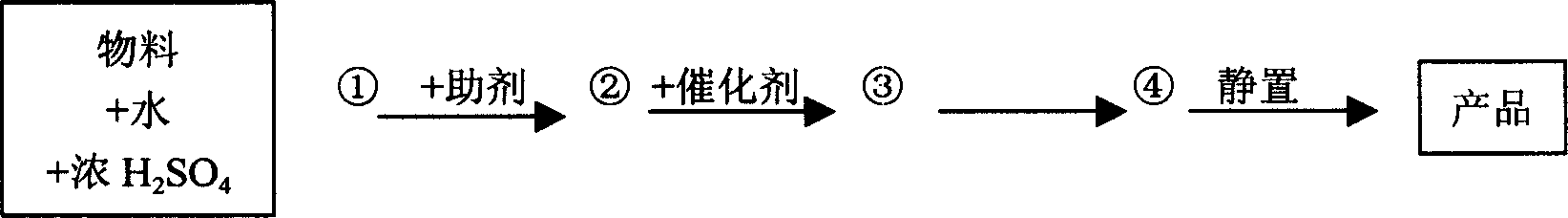

[0029] As shown in Figure 1, a one-step synthesis method is adopted, and different industrial waste residues (material 1, material 2, and material 3) are used as main agents to control SO 4 2- / Fe (molar ratio) 1.3 ~ 1.6, to prepare polyaluminum ferric sulfate with different basicity. During the process, the measured fly ash is added as an auxiliary agent. On the one hand, it is used as an insoluble suspending agent to make the polymer stable and easy to separate; on the other hand, it provides the aluminum ions required by the polymer to obtain the product.

[0030] 1. Raw materials:

[0031] Material 1: steelmaking waste slag, reddish-brown powder, particle size 300 mesh;

[0032] Material 2: aluminum plant waste slag, gray black powder, kaolin, soil red, particle size 200 mesh;

[0033] Material 3: Fly ash of electrostatic precipitator in power plant, black, particle size 300 mesh;

[0034] Sulfuric acid for industrial use.

[0035] 2. Synthesis:

[0036] Put 100g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com