Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

An ultra-high-purity, process-based technology, applied in the field of fly ash production of ultra-high-purity alumina and its comprehensive utilization, can solve the problems of large energy consumption and resource consumption, high production costs, and many process links, and achieve energy consumption And the effect of large resource consumption, high iron removal efficiency, and many process links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

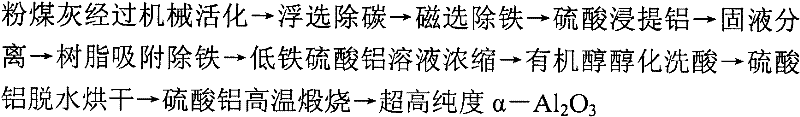

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: raw material fly ash is composed of: Al 2 o 3 Content 37.7%, Fe 2 o 3 Content 4.38%, CaO content 3.74%, MgO content 0.54%, SiO 2 The content is 49.9%, and the loss on ignition is 1.92%. The raw fly ash can also use other components and their corresponding amounts.

[0050] Mill the fly ash in a ball mill for 1 hour to perform mechanical activation; add water according to the mass ratio of fly ash to water of 1:3, fully stir, and remove unburned carbon through flotation; then remove iron oxide through magnetic separation; The fly ash residue after flotation carbon removal and magnetic separation iron removal and concentrated sulfuric acid are formulated into a mixed solution with a sulfuric acid concentration of 40%. The solid-liquid ratio of the fly ash and the mixed solution is controlled to be 1:8. Heat and pressurize the reaction equipment for 3 hours, the highest temperature of the reaction is 240 ° C; after the reaction cools down, add water acco...

Embodiment 2

[0056] Embodiment 2: Press the obtained aluminum sulfate crude liquid into a resin column equipped with JK008 macroporous cationic resin with a corrosion-resistant pump to remove iron. The treatment temperature is 90° C., and the flow rate of the aluminum sulfate crude liquid is 2 times the volume of the resin during processing. / h to obtain a low-iron aluminum sulfate solution.

[0057] When the macroporous cationic resin is adsorbed and saturated, the resin can recover its adsorption capacity through elution and regeneration. The elution conditions are as follows: the eluent adopts hydrochloric acid with a concentration of 8%, the elution temperature is 30° C., and the flow rate of hydrochloric acid is 2 times the resin volume / h, a total of 1 times the resin volume of hydrochloric acid was used for elution; the concentration of 8% hydrochloric acid was used for regeneration, the temperature was 20°C, and the flow rate of hydrochloric acid was 2 times the resin volume / h, a tot...

Embodiment 3

[0060] Embodiment 3: with the fly ash in embodiment 1, ball mill 3h in ball mill, carry out mechanical activation; According to the mass ratio of fly ash and water is 1: 2, add water, fully stir, remove unburned net through flotation carbon; then remove iron oxide through magnetic separation; the fly ash residue after flotation carbon removal and magnetic separation iron removal and concentrated sulfuric acid are made into a mixed solution with a sulfuric acid concentration of 80%, and the concentration of fly ash and the mixed solution is controlled. The solid-liquid ratio is 1:6, and the heating and pressurizing reaction is carried out in the acid-resistant reaction equipment for 5 hours, and the maximum temperature of the reaction is 240°C; , to obtain a filter cake by suction filtration, and wash it with water with a mass ratio of fly ash to water of 1:2 to obtain a crude aluminum sulfate solution with a pH value of 1. The extraction rate of aluminum analyzed was 74%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com