Admixture for improving mechanical properties of cement-based materials and preparation method of admixture

A cement-based material and admixture technology, which is applied in the field of admixtures for cement-based material modification, can solve the problems of complex preparation process of the admixture, lowering the strength of the cement-based material, and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

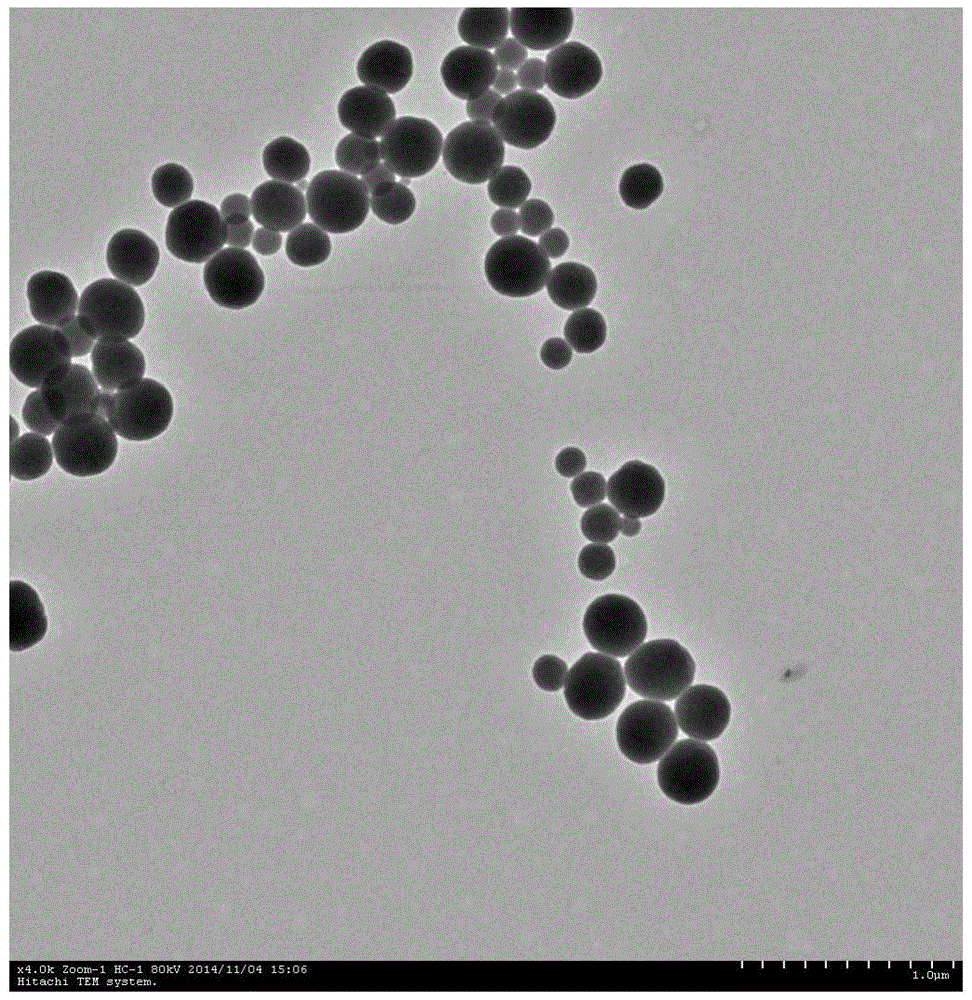

Image

Examples

Embodiment 1

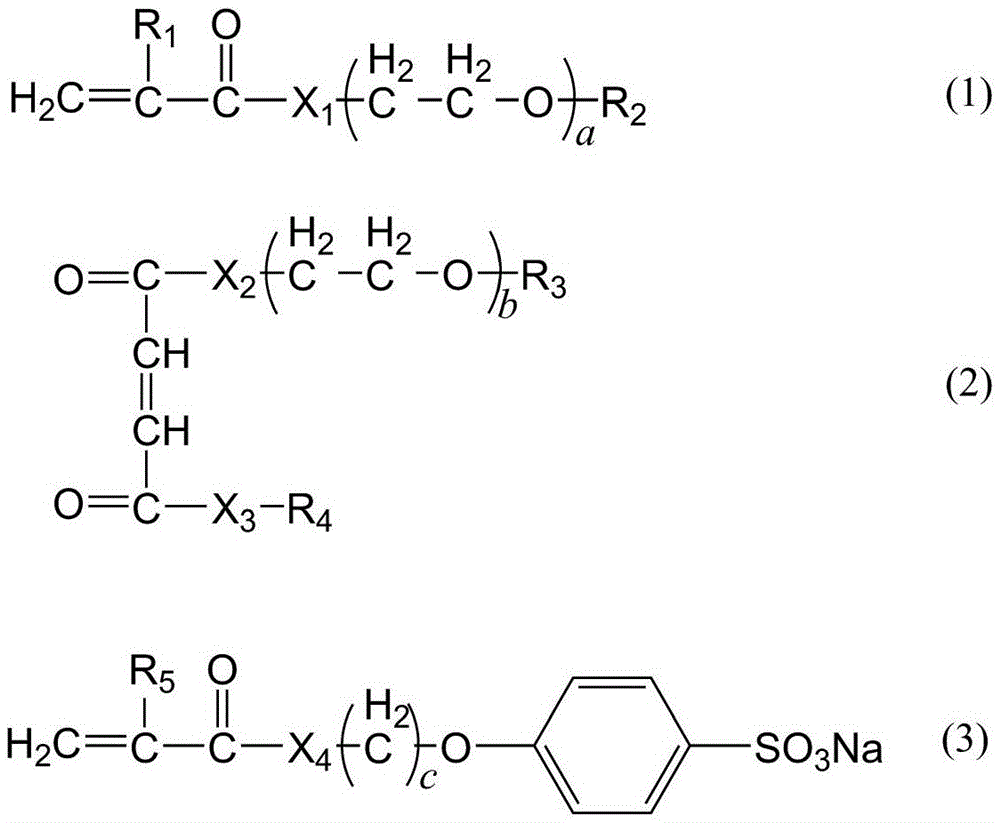

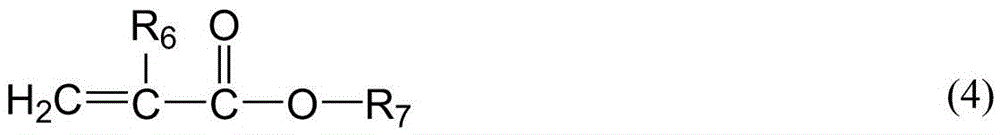

[0110] (1) Add polymerizable monomer A (code A1, polyethylene glycol methacrylate, -CH in the polyethylene glycol chain) to the reactor 2 CH 2 O-the average number of repeating units is 6, the terminal group is a hydroxyl group, and the dosage is 0.4 parts), polymerizable monomer B (4 parts of styrene (St)), siloxane D (8.09 parts of tetramethoxysilane (TMOS) and Tetraethoxysilane (44.30 parts of TEOS) and 270 parts of water, adjust the pH of the mixed solution to 10 with 1mol / LNaOH, fully stir and mix; logical N in the mixed solution 2 Divide O 2 , the temperature of the reactor was raised to 80°C, and the initiator (0.1 parts of ammonium persulfate APS dissolved in 29.9 parts of water) was added to the reactor under stirring conditions to initiate polymerization, and at the same time, the dropwise addition of siloxane D was started to the reactor. The remaining part (TMOS72.81 parts and TEOS398.66 parts) and polymerizable monomer E (St36 parts), timing since the initiator ...

Embodiment 2

[0113] (1) Add polymerizable monomer A (number A2, polyethylene glycol monomethyl ether acrylate, -CH in the polyethylene glycol chain) to the reactor 2 CH 2 O-the average number of repeating units is 22, the terminal group is methyl, and the dosage is 4 parts), polymerizable monomer B (methyl methacrylate (MMA) 50 parts), crosslinking agent C (number C2, ethylene glycol Diacrylate, -CH 2 CH 2 O-the average number of repeating units is 45, 2 parts), 6 parts of APS and 270 parts of water, fully stir and mix; use 1mol / LNaOH to adjust the pH of the mixed solution to 10, and pass N into the mixed solution 2 Divide O 2 , the temperature of the reactor was raised to 70°C, and the siloxane D (TEOS326.11 parts), the polymerizable monomer E (butyl acrylate (BA), 50 parts) and the initiator were evenly added dropwise to the reactor under stirring conditions. The solution (3.28 parts of sodium bisulfite SBS dissolved in 26.72 parts of water) initiates the polymerization. When the ini...

Embodiment 3

[0116] (1) Add polymerizable monomer A (code A3, polyethylene glycol monomethyl ether methacrylate, -CH in polyethylene glycol chain) to the reactor 2 CH 2 O-the average number of repeating units is 45, and the dosage is 10.00 parts), polymerizable monomer B (lauryl acrylate (LA) 160 parts), crosslinking agent C (divinylbenzene (DVB) 4 parts, commercial DVB contains position and para isomers), siloxane D (24.19 parts of phenyltriethoxysilane (PhTEOS) and 45.10 parts of TEOS) and 270 parts of water, stir and mix thoroughly; use 1mol / LH 2 SO 4 Adjust the pH of the mixture to 3, pass N into the mixture 2 Divide O 2 , the temperature of the reactor was raised to 60°C, and the initiator (2 parts of azobisisobutylamidine hydrochloride V50 dissolved in 28 parts of water) was added to the reactor under stirring conditions to initiate polymerization, and the reaction was started from the addition of the initiator The timer was used to react for 12 hours, and then the protection of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com