Motor stator slot portion insulation structure

An insulation structure and motor stator technology, applied in the shape/style/structure of winding insulation, electrical components, electromechanical devices, etc., can solve the high insulation performance requirements of the stator slot, it is difficult to meet the operation requirements of the unit, and the stator slot is easy to appear Corona and other problems, to achieve the effect of increasing the sealing and insulation effect, saving resources, and good anti-corona effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

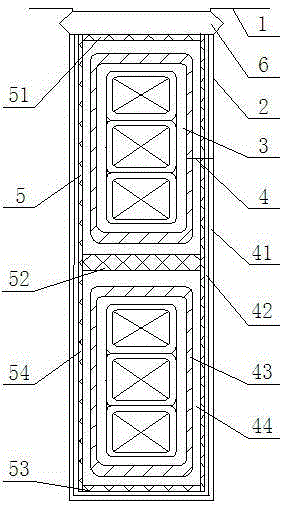

[0018] Such as figure 1 As shown, a motor stator slot insulation structure, which includes a stator core 1, a stator slot 2 is arranged on the stator iron core 1, a coil 3 is arranged in the stator slot 2, and a slot wedge 6 is arranged at the opening of the stator slot 2 , Slot wedge 6 adopts F-level two-way extraction wedge or H-level two-way extraction wedge. The wedge has high anti-split strength and regular cavity size, which can well meet the assembly requirements, and has little waste and saves resources. Usually, it is used 3240 or 3248 laminate processing.

[0019] A slot insulation structure 4 and a coil fixing structure 5 are arranged between the coil 3 and the stator slot 2. The slot insulation structure 4 includes an insulating glue layer 41, a low-resistance pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com