High performance concrete containing composite fiber

A high-performance concrete and composite fiber technology, which is applied in the field of building materials, can solve the problems of weakening the toughness of matrix concrete, increasing the range of tensile toughness and bending toughness of hybrid fiber concrete, and improving the comprehensive mechanical properties and cost performance. , the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

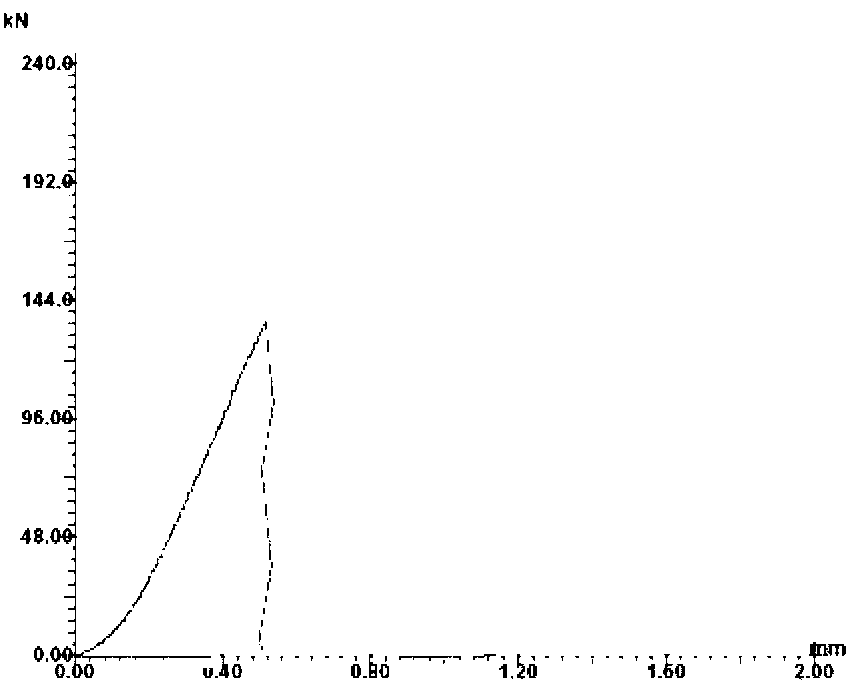

Image

Examples

Embodiment Construction

[0029] Composite fiber composition:

[0030] Arched steel fibers and corrugated steel fibers are purchased from Wuhan Xintu Engineering Fiber Manufacturing Co., Ltd. Among them, the arched steel fibers are multi-anchor arched steel fibers. The cross-section is flat and has transverse notches. Due to the repeated transformation of the cross-section shape, there is a main anchor point at each end, and four auxiliary anchor points are also produced, which can significantly improve the adhesion between the fiber and the matrix. Knot and anchoring ability; plastic steel fiber is provided by Wuhan Zhongding Development Co., Ltd., the surface of the fiber is corrugated, has excellent hydrophilicity, and is easy to disperse evenly in the matrix; polypropylene fiber is selected from concrete produced by Hill Brothers Chemical Company of the United States The special-purpose polypropylene monofilament bundle fiber, DURAFIBER, was purchased from Wuhan Henglu Trading Co., Ltd. The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com