Fiber compound regenerative asphalt concrete

A composite technology of recycled asphalt and fiber, which is applied in the field of building materials, can solve the problems of limited performance of the mixture material and its failure to play a good role.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

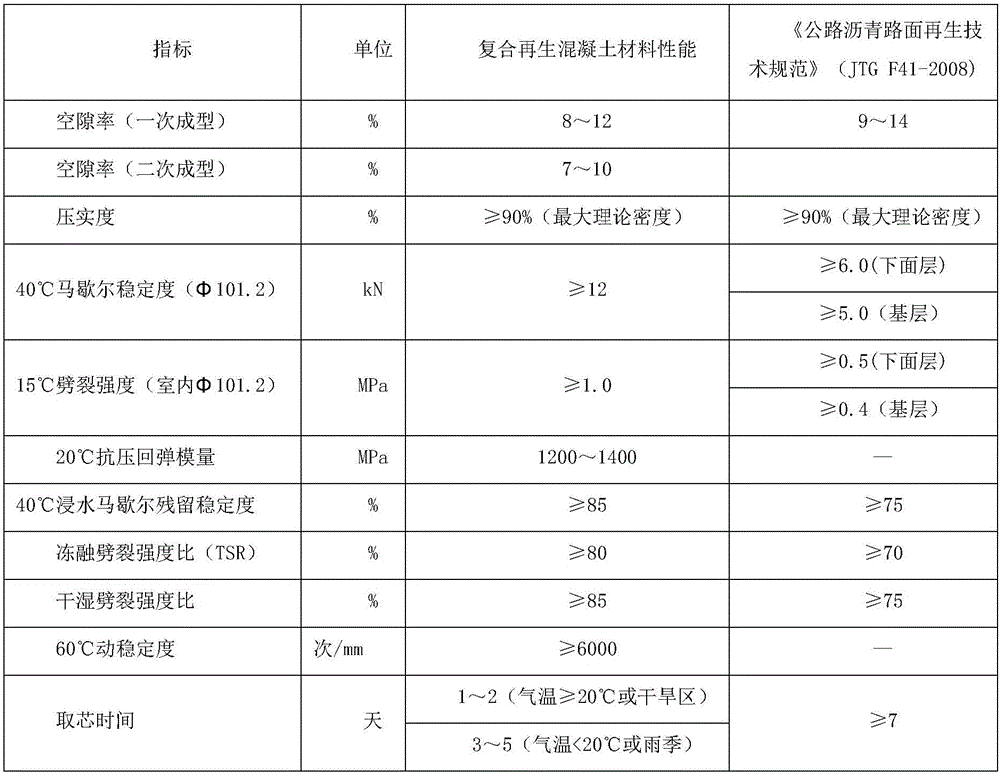

Image

Examples

Embodiment 1

[0020] A fiber composite recycled asphalt concrete prepared from the following components by weight:

[0021] 30 parts of 0-5mm recycled asphalt concrete RAP, 25 parts of 5-10mm recycled asphalt concrete RAP, 28 parts of 10-30mm recycled asphalt concrete RAP, 15 parts of 10-30mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, And 1 part of regeneration agent, and 1.2 parts of glass fiber.

[0022] In the fiber composite recycled asphalt concrete, the length of the glass fiber is 6 mm.

[0023] In the described fiber composite recycled asphalt concrete, the regeneration agent includes the following components by weight:

[0024] Waste tire refining 30 parts, cement 5 parts, asphalt phase solvent 5 parts, aggregate surface hydrophobic agent 0.02 parts, emulsifier 2.0 parts; stabilizer 0.2 parts, water 30 parts, hydrochloric acid 1 part, modified asphalt 54 parts.

[0025] In the described fiber composite recycled asphalt concrete, ...

Embodiment 2

[0033] A fiber composite recycled asphalt concrete prepared from the following components by weight:

[0034] 30 parts of 0-5mm recycled asphalt concrete RAP, 25 parts of 5-10mm recycled asphalt concrete RAP, 28 parts of 10-30mm recycled asphalt concrete RAP, 15 parts of 10-30mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, And 1 part of regeneration agent, and 1.2 parts of glass fiber.

[0035] In the fiber composite recycled asphalt concrete, the length of the glass fiber is 6mm.

[0036] In the described fiber composite recycled asphalt concrete, the regeneration agent includes the following components by weight:

[0037] Waste tire refining 40 parts, cement 25 parts, asphalt phase solvent 50 parts, aggregate surface hydrophobic agent 5 parts, emulsifier 3.0 parts; stabilizer 1.0 parts, water 38 parts, hydrochloric acid 4 parts, modified asphalt 62 parts.

[0038] In the described fiber composite recycled asphalt concrete, t...

Embodiment 3

[0046] A fiber composite recycled asphalt concrete prepared from the following components by weight:

[0047] 30 parts of 0-5mm recycled asphalt concrete RAP, 25 parts of 5-10mm recycled asphalt concrete RAP, 28 parts of 10-30mm recycled asphalt concrete RAP, 15 parts of 10-30mm new aggregate, 2 parts of mineral powder, 1.5 parts of cement, 4 parts of emulsified asphalt, And 1 part of regeneration agent, and 1.2 parts of glass fiber.

[0048] In the fiber composite recycled asphalt concrete, the length of the glass fiber is 6 mm.

[0049] In the described fiber composite recycled asphalt concrete, the regeneration agent includes the following components by weight:

[0050] Waste tire refining 35 parts, cement 13 parts, asphalt phase solvent 21 parts, aggregate surface hydrophobic agent 0.8 parts, emulsifier 2.4 parts; stabilizer 0.6 parts, water 34 parts, hydrochloric acid 2 parts, modified asphalt 56 parts.

[0051] In the described fiber composite recycled asphalt concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com