Patents

Literature

216 results about "Tert-butyl peroxybenzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Butyl peroxybenzoate (TBPB) a chemical compound from the group of peresters (compounds containing the general structure R 1-C(O)OO-R 2) which contains a phenyl group as R 1 and a tert-butyl group as R 2.

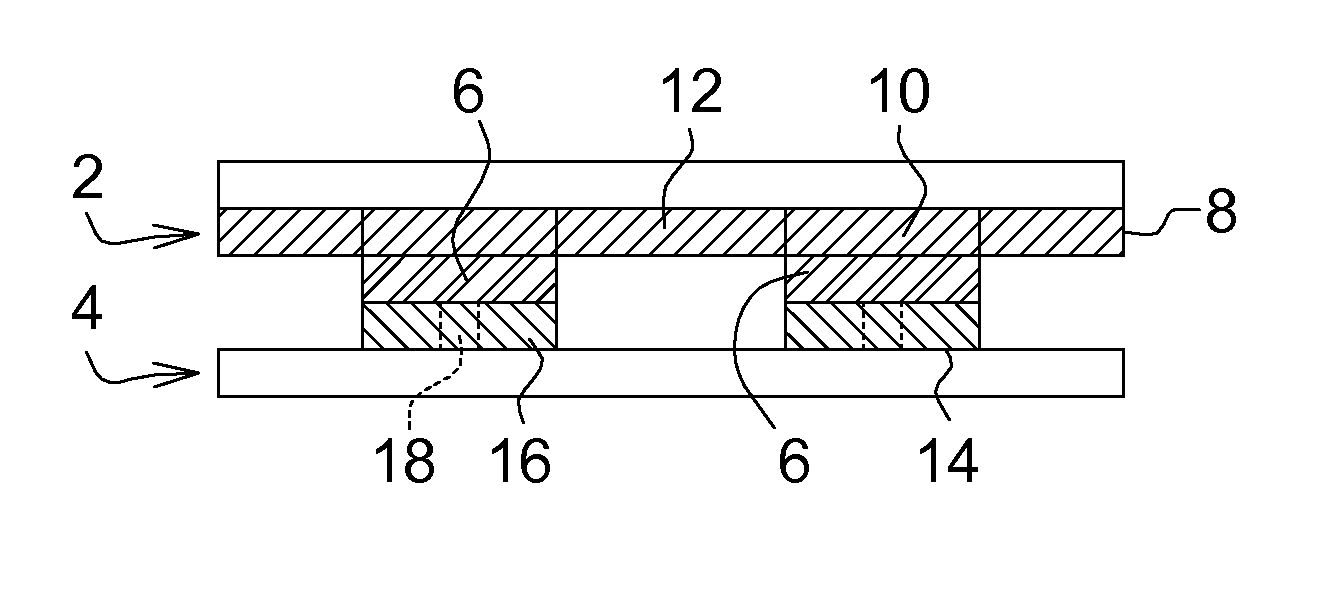

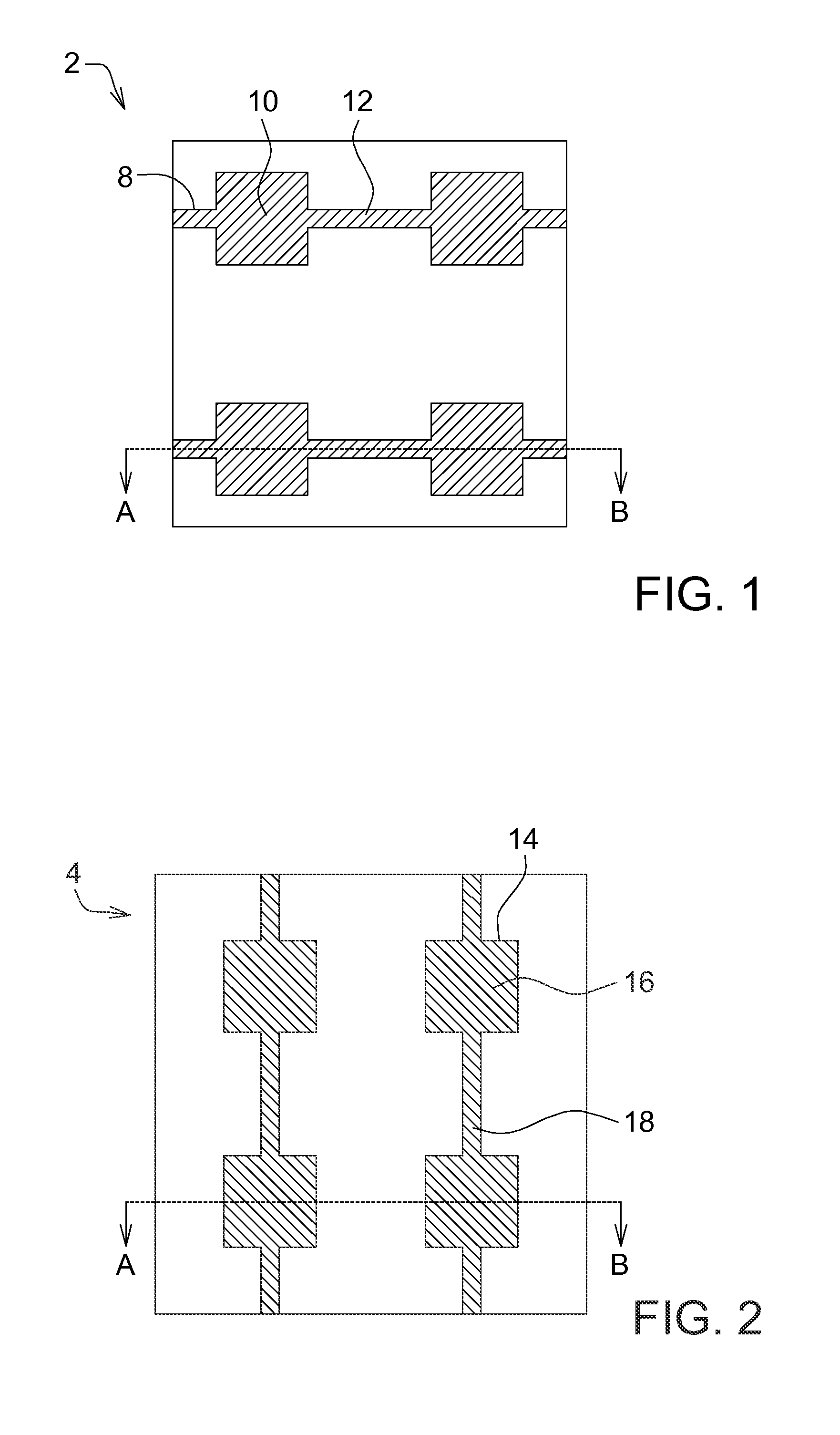

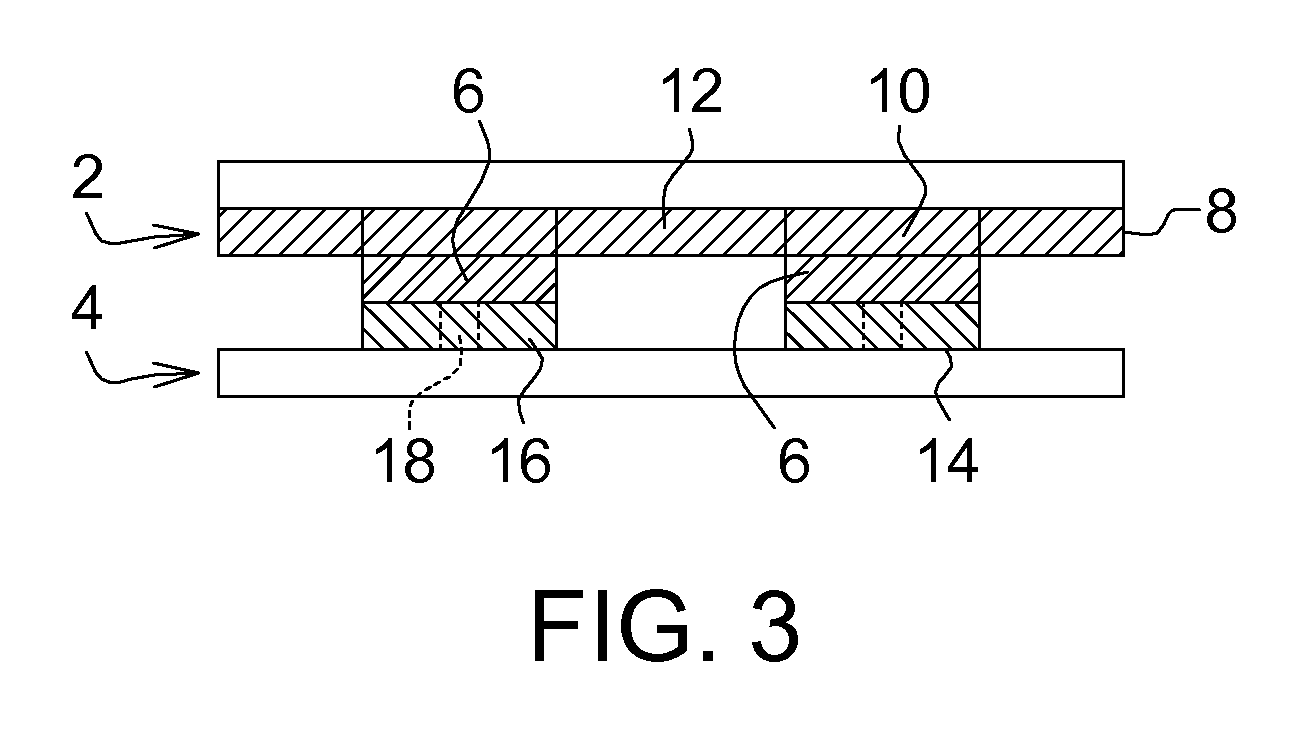

Method for manufacturing piezoresistive material, piezoresistive composition and pressure sensor device

A method for manufacturing a piezoresistive material, a piezoresistive composition and a pressure sensor device are provided. The piezoresistive composition includes a conductive carbon material, a solvent, a dispersive agent, an unsaturated polyester and a crosslinking agent. The conductive carbon material is selected from a group consisting of multi-wall nanotube, single-wall carbon nanotube, carbon nanocapsule, graphene, graphite nanoflake, carbon black, and a combination thereof. The solvent is selected from a group consisting of ethyl acetate, butyl acetate, hexane, propylene glycol mono-methyl ether acetate and a combination thereof. The dispersive agent includes block polymer solution with functional groups providing the affinity. The unsaturated polyester is selected from a group consisting of an ortho-phthalic type unsaturated polyester, an iso-phthalic type unsaturated polyester, and a combination thereof. The crosslinking agent is selected from a group consisting of ethyl methyl ketone peroxide, cyclohexanone diperoxide, dibenzoyl peroxide, tert-butyl peroxybenzoate and a combination thereof.

Owner:IND TECH RES INST

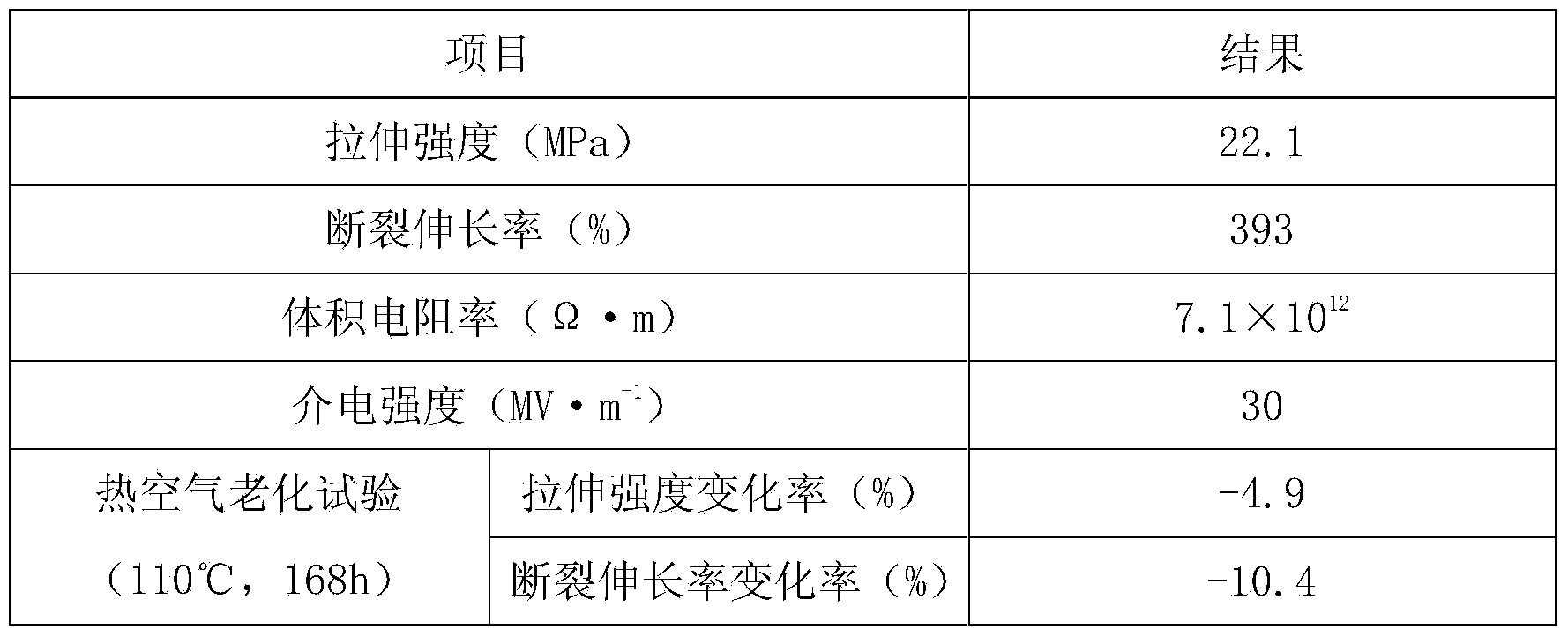

Sheath material for signal controlling cable and preparation method thereof

ActiveCN103524843ANo deformationNot brokenPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneControl signal

The invention discloses a sheath material for a signal controlling cable and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 65-75 parts of low density polyethylene, 20-30 parts of SG-3 type polyvinyl chloride, 15-25 parts of styrene butadiene rubber, 5-10 parts of HIPS, 10-15 parts of nano calcium carbonate, 8-12 parts of nano kaolin, 5-10 parts of an ultrafine mica powder, 3-6 parts of naphthenic oil, 2-3 parts of sulfur, 1-2 parts of an accelerant M, 1-2 parts of zinc oxide, 3-4 parts of stearic acid, 4-8 parts of phenolic resin, 2-3 parts of an anti-aging agent 1010, 0.5-1 part of tert-butyl peroxybenzoate, 3-5 parts of oxidized polyethylene wax, 4-6 parts of rosin pentaerythrityl ester, 1-2 parts of an accelerant TMTD, 5-10 parts of diisobutyl phthalate, 8-12 parts of dioctyl nylon acid ester, 3-6 parts of a composite filler. The sheath material has good high and low temperature resistance and high tensile strength, also has excellent abrasion resistance, acid and alkali resistance, oil resistance, ozone aging resistance, and ultraviolet radiation resistance, extends the service life of a sheath to a great extent, and widens the application scope.

Owner:滁州三界外信息科技有限公司

Fabric coloring agent

The invention discloses a fabric coloring agent. The fabric coloring agent is prepared from the following constituents in parts by weight: 2-3 parts of sodium pyrophosphate, 1-2 parts of dibutyl phthalate, 4-5 parts of calcium sulphate, 6-7 parts of magnesium sulfate, 1-2 parts of aluminium oxide powder, 3-4 parts of iron blue, 4-5 parts of dinitrosopentatetramine, 4-5 parts of dimethyl formamide, 5-6 parts of diethylaminoethyl methacrylate, 3-4 parts of tert-butyl peroxybenzoate, 8-9 parts of an initiator, 8-9 parts of hexamethoxymethylmelamine, 8-9 parts of water, and 1-2 parts of glycerol. The fabric coloring agent disclosed by the invention is easy to color and low in possibility of color fading.

Owner:江苏金牛华尔车服饰有限公司

Anticorrosive cable sheath material for oil well

ActiveCN103788426AImprove anti-corrosion performanceLow toxicityRubber insulatorsPlastic/resin/waxes insulatorsEngineeringPolyphenylene oxide

The invention discloses an anticorrosive cable sheath material for an oil well. The anticorrosive cable sheath material comprises the following raw materials in parts by weight: 20 to 25 parts of natural rubber, 13 to 20 parts of chlorosulfonated polyethylene, 15 to 20 parts of chlorinated polyethylene, 20 to 30 parts of modified polyphenylene oxide resin, 0.8 to 1.3 parts of tert-butyl peroxybenzoate, 2 to 3.5 parts of DCP (dicumyl peroxide), 1.5 to 2 parts of DBP (dibutyl phthalate), 15 to 21 parts of lead oxide, 1.5 to 3 parts of HVA-2, 15 to 20 parts of channel black, 30 to 40 parts of quartz powder, 2 to 4 parts of aluminum hydroxide, 1.5 to 3 parts of magnesium hydroxide, 4 to 7 parts of light magnesium oxide, 1 to 4 parts of triethanolamine, 20 to 24 parts of calcined clay, 0.5 to 1.5 parts of anti-aging agent ODA, 1 to 2.5 parts of anti-aging agent 4010NA and 0.3 to 1.2 parts of accelerator TMTD. The anticorrosive cable sheath material for the oil well is high in anticorrosive performance and flame retardant property, low in toxicity and long in service life.

Owner:安徽华海特种电缆集团有限公司

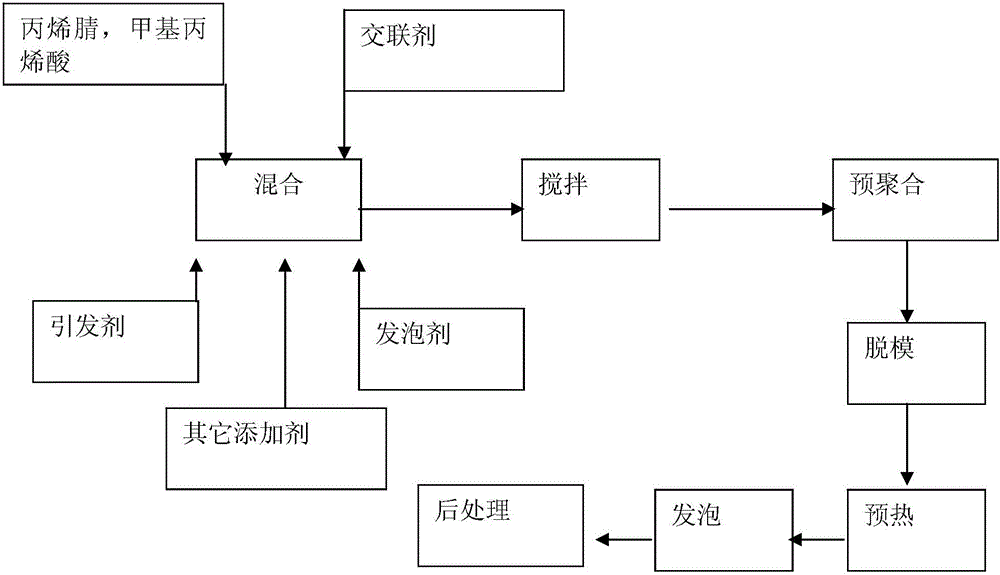

Acrylonitrile-based polymethacrylimide foam and preparation method therefor

ActiveCN105111354AImprove heat resistanceHigh heat distortion temperatureAcrylonitrileDibenzoyl Peroxide

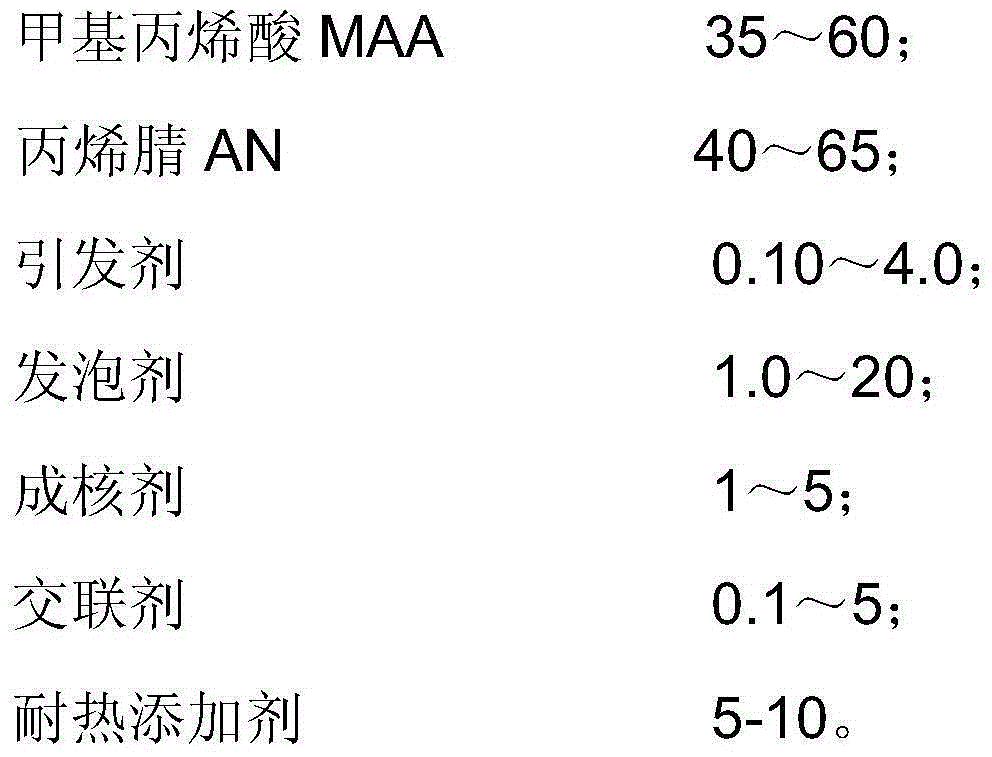

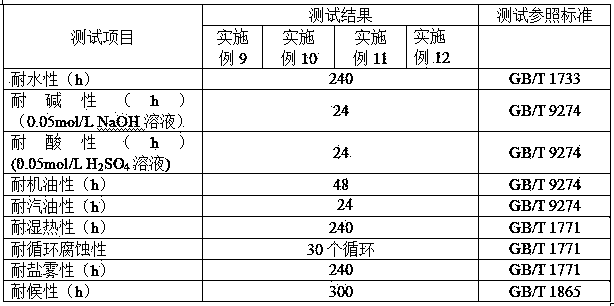

The invention relates to acrylonitrile-based polymethacrylimide foam which comprises the following components in parts by mass: 35-60 parts of methacrylic acid MAA, 40-65 parts of acrylonitrile AN, 0.10-4.0 parts of an initiator, 1.0-20 parts of a foaming agent, 1-5 parts of a nucleating agent, 0.1-5 parts of a crosslinking agent and 5-10 parts of a heat resisting additive, wherein the initiator is an azo compound or a mixture of the azo compound and a peroxide and the initiator at least comprises three different compounds at the same time; the azo compound is azobisisobutyronitrile AIBN, azobisisoamylonitrile or 2,2'-azobisisoheptonitrile; the peroxide is dibenzoyl peroxide, lauroyl peroxide, tert-butyl peroxyoctoate or tert-butyl peroxybenzoate. The acrylonitrile-based polymethacrylimide foam provided by the invention is good in heat resistance, high in heat deformation temperature which is greater than 220 DEG C and excellent in mechanical property.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

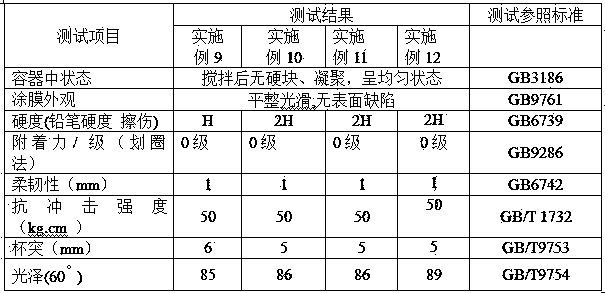

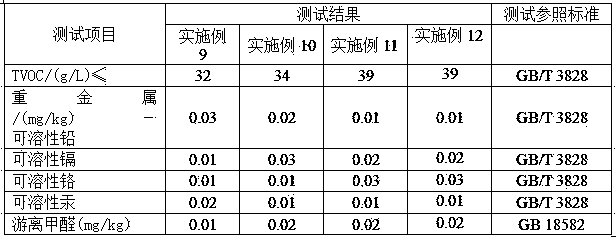

High-solid low-VOC (volatile organic compound) benzene-free solvent-type acrylic resin

The invention relates to a 3C paint, particularly a high-solid low-VOC (volatile organic compound) benzene-free solvent-type acrylic resin. The high-solid low-VOC (volatile organic compound) benzene-free solvent-type acrylic resin is a benzene-free system and is composed of a component A, a component B and a component C. The component A is composed of butyl acetate and propylene glycol methyl ether acetate. The component B is composed of methyl methacrylate, styrene, 2-hydroxypropyl acrylate, butyl methacrylate, butyl acrylate, acrylic acid and tert-butyl peroxybenzoate. The component C is composed of tert-butyl peroxybenzoate and butyl acetate. When being used as a finish paint matched with the primer for 3C electronic products, the resin has the advantages of favorable matching property, higher hardness, higher wear resistance, excellent alcohol resistance, excellent chemical resistance, excellent artificial sweat resistance, excellent cold / heat shock resistance, excellent high-temperature / high-dampness resistance, excellent artificial aging resistance and the like. The resin has high solid content, low viscosity and lower VOC, is more environment-friendly when being used as a benzene-free system, and has higher market competitiveness.

Owner:NANXIONG RISING CHEM IND

Nonaqueous electrolyte of lithium ion battery and lithium ion battery

The invention provides nonaqueous electrolyte of a lithium ion battery and the lithium ion battery. The nonaqueous electrolyte is prepared from an organic solvent, lithium salt and an additive. The nonaqueous electrolyte is characterized that the additive is prepared from tris(trimethylsiloxy)boron, tert-butyl peroxybenzoate and trimethylsilyldiethylamine. According to the nonaqueous electrolyte of the lithium ion battery, disclosed by the invention, by jointly adding the tris(trimethylsiloxy)boron, the tert-butyl peroxybenzoate and the trimethylsilyldiethylamine into the nonaqueous electrolyte, the side reaction between an electrode and electrolyte is greatly reduced; meanwhile, the prepared battery shows good high-temperature storage ability and high-temperature cycling performance.

Owner:BYD CO LTD

Polylactate polyamide ultrafine composite fiber and preparation method thereof

ActiveCN106917161AFeel comfortableIncrease elasticityFilament manufactureConjugated synthetic polymer artificial filamentsFiberPhosphate

The invention discloses polylactate polyamide ultrafine composite fiber. The polylactate polyamide ultrafine composite fiber comprises the following components in parts by weight: 50-60 parts of ultrafine polyamide, 40-50 parts of polylactic acid fiber, ultrafine polyamide is taken as a core wire, the core wire is coated with polylactic acid fiber; the ultrafine polyamide comprises 85-95 parts of chinlon-6 chips, 5-7 parts of active carbon and 6-10 parts of nano silica; polylactic acid fiber comprises 100 parts of polylactic acid, 5-10 parts of a maleic anhydride grafting compatilizer, 1-2 parts of tert-butyl peroxybenzoate, 5-8 parts of citric acid, 10-16 parts of tert-butyl alcohol, 2-6 parts of zinc oxide, 2-5 parts of vinyl polydimethyl silane, and 0.2-0.5 parts of phosphate. The prepared composite fiber has the characteristics of comfortable hand feeling, good elasticity, degradable performance, egradable performance, and certain antibacterial property, by tight coating of core wire and polylactic acid fiber, the composite fiber has the advantages of high intensity and difficult fracture, and a preparation method is simple and feasible.

Owner:广东坚达聚纤科技实业有限公司

Dyeing agent for nylon fabric

ActiveCN103709785AEasy to cleanImprove bindingOrganic dyesDyeing processButyl methacrylateTert-butyl peroxybenzoate

The invention discloses a dyeing agent for a nylon fabric. The dyeing agent is prepared from the following raw materials in parts by weight: 2-8 parts of aluminium oxide powder, 10-13 parts of mica powder, 20-30 parts of butyl methacrylate, 10-20 parts of tert-butyl peroxybenzoate, 30-40 parts of dibutyl phthalate, 20-30 parts of magnesium sulfate, 20-30 parts of zinc stearate, 40-50 parts of blocked isocyanates, 5-10 parts of titanium dioxide, 10-30 parts of dinitroso pentamethylene tetramine, 10-20 parts of polyurethane, 20-25 parts of ferric oxide, 10-15 parts of initiating agent, 7-20 parts of additive and 20-40 parts of water. After the nylon fabric is dyed by the dyeing agent, the soaping fastness is 4.5-5.0 level, the dyeing is not easily cleaned, the bonding is firm, the K / S value is up to 8.168 and the dyeing performance is good.

Owner:NANTONG WANG&SHENG TEXTILES

Colored degradable anti-bacterial polylactic acid elastic fiber and preparation method thereof

ActiveCN106884226AHigh color fastnessHas antibacterial propertiesSpinnerette packsMelt spinning methodsFiberPhosphate

The invention discloses a colored degradable anti-bacterial polylactic acid elastic fiber. The colored degradable anti-bacterial polylactic acid elastic fiber is prepared from the following raw materials in parts by mass: 100 parts of polylactic acid, 5 to 10 parts of maleic anhydride grafting compatilizer, 1 to 2 parts of tert-butyl peroxybenzoate, 8 to 12 parts of antibacterial agent, 5 to 8 parts of citric acid, 10 to 16 parts of tert-butyl alcohol, 2 to 5 parts of vinyl polydimethylsilane, 0.2 to 0.5 part of phosphate, and 6 to 8 parts of master batch, wherein the antibacterial agent is prepared from 20 parts of nanometer cerium oxide, 75 parts of nanometer zinc oxide, and 5 parts of modified activated carbon; the master batch is prepared from 65 parts of carrier, 12 parts of color powder, 3 parts of chitosan, 2 parts of silicon dioxide, and 5 parts of PP (polypropylene) compatilizer. The colored degradable anti-bacterial polylactic acid elastic fiber has the advantages that the toxicity is avoided or is hardly avoided, and the green chemical principle is met; the prepared colored degradable anti-bacterial polylactic acid elastic fiber has the characteristics of degradability, high elasticity, high color fixation rate and antibacterial property; the preparation method is simple and feasible.

Owner:NINGBO SANBANG MICROFIBER

Degradable antibiosis polylactic acid elastic fiber and preparation method thereof

ActiveCN106917157AHas antibacterial propertiesEasy to prepareMonocomponent polyesters artificial filamentArtifical filament manufactureFiberCerium nitrate

The invention discloses degradable antibiosis polylactic acid elastic fiber. The polylactic acid elastic fiber comprises 100 parts of polylactic acid, 5-10 parts of a maleic anhydride grafting compatilizer, 1-2 parts of tert-butyl peroxybenzoate, 8-12 parts of an antiseptic, 5-8 parts of citric acid, 10-16 parts of tert-butyl alcohol, 2-5 parts of vinyl polydimethyl silane, and 0.2-0.5 parts of phosphate. The antiseptic comprises the following components in parts by mass: 20 parts of nano cerium oxide, 75 parts of nano zinc oxide and 5 parts of modified active carbon, wherein the modified active carbon comprises the following components: 80 parts of active carbon, 5 parts of cerium nitrate, 5 parts of starch, and 10 parts of a citric acid solution with concentration of 3 mol / L. The used raw materials are nontoxic and nearly non-toxic, accords with a composite green chemistry principle, the obtained fiber is the degradable antibiosis polylactic acid elastic fiber having the characteristics of degradable performance, large elasticity and antibacterial property, and a preparation method is simple and feasible.

Owner:NINGBO SANBANG MICROFIBER

Resin composition for water-based high-performance color gloss coating and preparation method of resin composition

The invention discloses a resin composition for a water-based high-performance color gloss coating and a preparation method of the resin composition. The resin composition is prepared from 30%-60% of water-based castor oil-modified alkyd resin and 40%-70% of water-based acrylic resin, wherein the water-based castor oil-modified alkyd resin is mainly prepared from castor oil, trimethylolpropane, phthalic anhydride, trimellitic anhydride, butoxyethanol, n-butyl alcohol and xylene; and the water-based acrylic resin is prepared from a solvent, methyl methacrylate, butyl acrylate, styrene, hydroxyethyl methylacrylate, crylic acid, benzoyl peroxide, tert-butyl peroxybenzoate, ammonium hydroxide and water. The pigment disclosed by the invention is easily dispersed to below 10 microns, and is stable in storage; the prepared coating performance is excellent; and the glossiness of a film is not reduced during adding water and diluting.

Owner:肇庆千江高新材料科技股份公司

Underground power cable sheath tube

InactiveCN105778300AGood resistance to salt, heat and coldGood compatibilityInsulated cablesPower cablesEngineeringBrucite

The invention belongs to the field of power materials and discloses an underground power cable sheath tube. The underground power cable sheath tube is prepared from kaolin, magnesium hydroxide, tert-butyl peroxybenzoate, calcium stearate, N,N-dimethylaminoethyl acrylate, zeolite, sodium humate, triphenyl phosphate, polyvinylpyrrolidone, nanometer silicon carbide, sepiolite, brucite, aluminum nitride, quartz sand, phenolic resin, polyethylene and ethylene-propylene-diene monomer. The underground power cable sheath tube is simple and feasible in preparation technology, low in raw material cost and high in corrosion resistance and mechanical strength.

Owner:国网山东省电力公司费县供电公司 +2

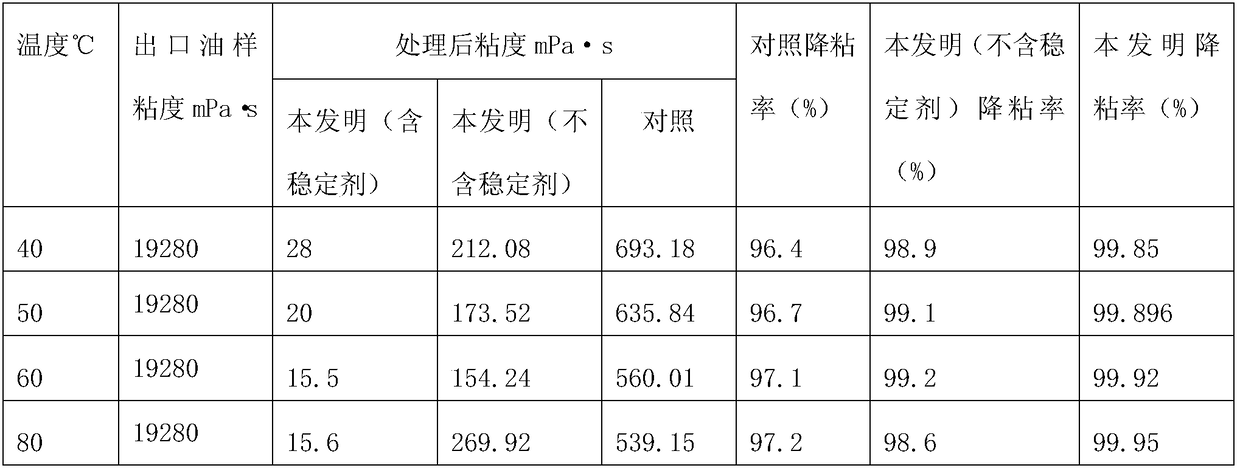

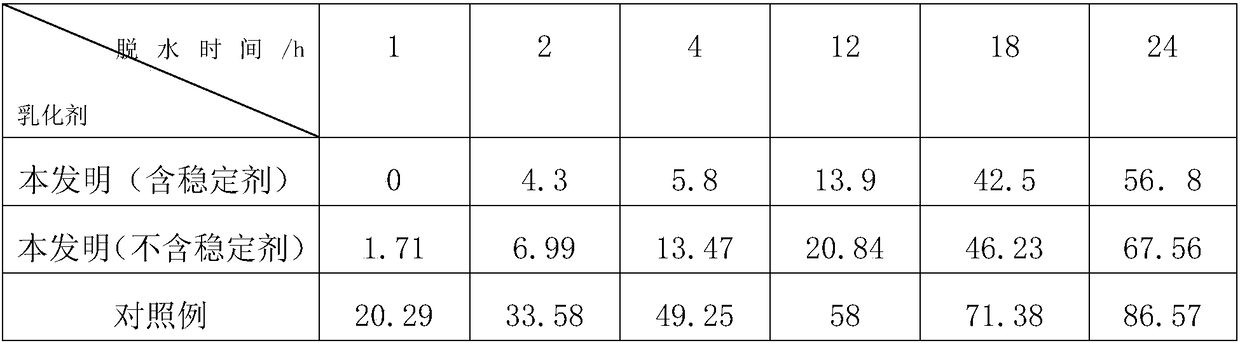

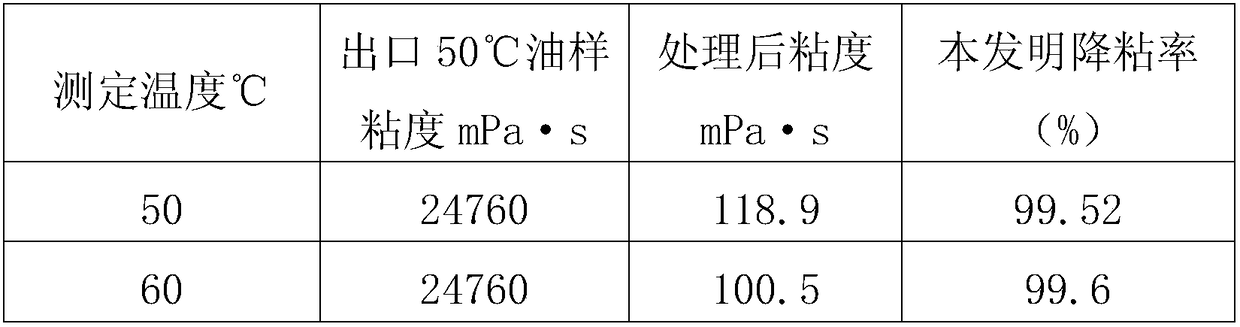

Self-emulsifying heavy oil viscosity reducer as well as preparation method and application thereof

InactiveCN108559470AGood dispersionTo achieve the purpose of reinforcementFluid removalDrilling compositionOil viscositySelf emulsifying

Owner:山东安捷宇石油技术服务有限公司

Reinforcing glass fiber reinforced plastics coating material and preparation method thereof

The invention discloses a reinforcing glass fiber reinforced plastics coating material. The material is characterized by being prepared by the following raw materials in parts by weight: 40-45 parts of phenolic resin, 6-8 parts of epoxy resin, 5-7 parts of amino resin, 5-8 parts of rosin, 10-13 parts of acrylic acid, 8-10 parts of tert-butyl peroxybenzoate, 9-13 parts of methyl methacrylate, 4-6 parts of paraffin, 3-4 parts of bentonite, 2-3 parts of dicyandiamide, 3-4 parts of aluminum stearate, 4-7 parts of zinc oxide, 2-3 parts of methyl trioctyl ammonium chloride, 28-33 parts of chopped glass fiber, and 1-2 parts of additive. Due to the addition of additive, the material has good physical property and mechanical property; zinc oxide is taken as a reinforcing agent, thus increasing the strength of the material; due to the flame-retardant effect of zinc oxide, the prepared material has long service life, is fireproof, has low cost, is tough, can be produced on a large scale, is applicable to popularization and application, and is suitable for manufacturing into different shapes.

Owner:WUHU BAOYI AMUSEMENT EQUIP

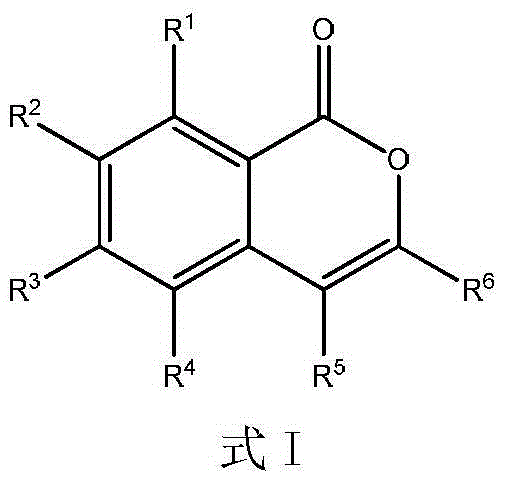

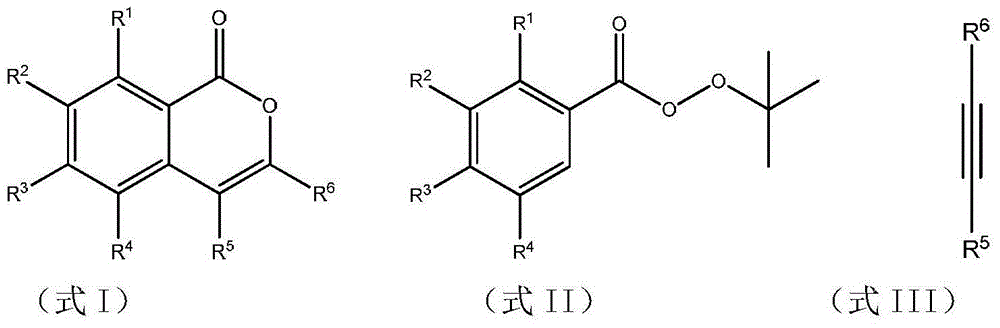

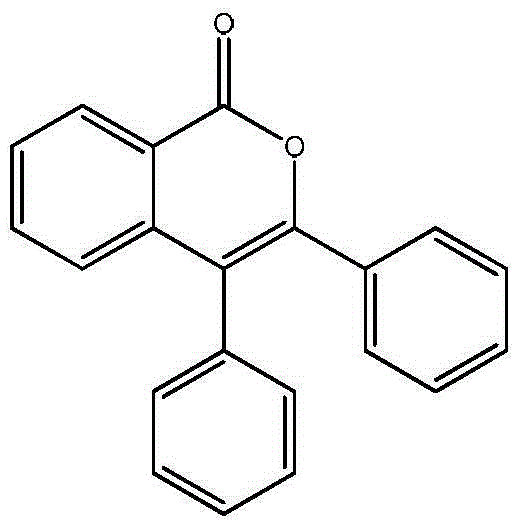

Multi-substituent isocoumarin derivative and preparation method thereof

The invention discloses a multi-substituent isocoumarin derivative and a preparation method thereof. According to the preparation method, substituted tert-butyl peroxybenzoate represented by a formula II, 1,2-disubstituted acetylene represented by a formula III, a catalyst, alkali, acid and a solvent are uniformly mixed and are heated under the protection of nitrogen for a cyclization reaction, and a compound represented by a general structure formula I is obtained after the reaction. According to the method, the reaction conditions are mild, the reaction time is short, the substrate range is wide, the reaction specificity is high, the yield is high, the post-processing is simple and convenient, and the multi-substituent isocoumarin derivative which cannot be synthesized with other methods can be synthesized and has a wide application.

Owner:HUAQIAO UNIVERSITY

Halogen-free flame-retardant nitrile rubber/nylon thermoplastic elastomer and preparation method thereof

The invention relates to the field of thermoplastic elastomers, and discloses a halogen-free flame-retardant nitrile rubber / nylon thermoplastic elastomer and a preparation method thereof, wherein thethermoplastic elastomer contains a nitrile rubber, nylon, a flame retardant, a vulcanizing agent, an anti-aging agent, an antioxidant and an auxiliary agent, the vulcanizing agent is an organic peroxide, and the organic peroxide is at least one selected from dicumyl peroxide, bis(t-butylperoxyisopropyl)benzene, t-butyl cumene peroxide, 2,5-bis(t-butyl peroxy)-2,5-dimethyl-3-hexyne, 2,5-bis-(tert-butyl peroxy)-2,5-dimethyl hexane, dibenzoyl peroxide, tert-butyl peroxybenzoate, and di-tert-butyl peroxide. According to the present invention, the nitrile rubber / nylon thermoplastic elastomer has characteristics of high elasticity, easy processing, repeated processing, good flame retardant performance and the like, and can be used for vehicle oil pipelines and sealing members.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antibacterial modified fluororubber composite material

The invention discloses an antibacterial modified fluororubber composite material. The antibacterial modified fluororubber composite material comprises fluororubber, polycaprolactone, nylon, EPDM, liquid butadiene-acrylonitrile rubber, ethylene-octene copolymer, gas-phase white carbon black, kaoline, modified nano silver, nano zinc oxide, nano titanium dioxide, tert-butyl peroxybenzoate, dibenzoyl peroxide, triallyl cyanurate, epoxy silkworm chrysalis butyl oleate, an accelerant, an anti-aging agent, N-beta-(aminoethyl)-gamma-aminopropyltrimethoxysilane, alpha, omega- dihydroxyl polydimethylsiloxane, and 3-chloro-2-hydroxypropyltrimethylammonium chloride. The antibacterial modified fluororubber composite material possesses excellent antibacterial properties, heat resistance, and aging resistance, and long service life.

Owner:ANHUI JINYANG FLUORINE CHEM

Special modified expandable polystyrene copolymer particles for lost foam and production method for copolymer particles

ActiveCN104804119AQuality improvementReduce carbon deficiency problemsFoundry mouldsFoundry coresBenzoyl peroxidePolystyrene

The invention discloses special modified expandable polystyrene copolymer particles for lost foam. The modified expandable polystyrene copolymer particles comprise the following components in parts by weight: 90-100 parts of styrene, 3-8 parts of methyl methacrylate, 100-140 parts of de-ionized water, 0.2-0.5 parts of benzoyl peroxide, 0.2-0.5 parts of dicumyl peroxide, 0.1-0.5 parts of tert-butyl peroxybenzoate, 0.001-0.01 parts of an anionic surfactant, 1-2 parts of a suspending agent, 5.0-10.0 parts of a foaming agent, 0.1-0.4 parts of a nucleating agent, 0.2-2 parts of organic bromine, 0.01-0.1 parts of a molecular weight modifier with an effect of increasing molecular weight and 0.3-0.5 parts of a surface coating agent. The special modified expandable polystyrene copolymer particles for the lost foam and a production method for the copolymer particles effectively solve a problem of no special EPS (expandable polystyrene) for lost foam costing at present and have the advantages of capabilities of reducing carbon defects of castings during casting and increasing the molecular weight.

Owner:ZHEJIANG CASTCHEM NEW MATERIAL CO LTD

Preparation method of modified expanded polystyrene

The invention discloses a preparation method of modified expanded polystyrene. The preparation method of the modified expanded polystyrene comprises the following steps: adding di(dioctyl phosphite) tetraisopropyl titanate into acetone, uniformly stirring, then adding carbon nano tubes for carrying out ultrasonic dispersion, and drying to obtain a nucleating agent; adding water, barium stearate, activated calcium phosphate, nekal, a defoaming agent, an antioxidant, a flame retardant and styrene into a reaction container, uniformly stirring, then sequentially adding dibenzoyl peroxide, tert-butyl peroxybenzoate, dicumyl peroxide and the nucleating agent, uniformly stirring, heating up to the temperature of 90 DEG C, and carrying out heat preservation for 3-4 hours, so that polystyrene is obtained; adding liquid butadiene-acrylonitrile rubber and melamine formaldehyde resin into a reaction container containing polystyrene, heating up to the temperature of 100-110 DEG C, uniformly stirring, adding a foaming agent, and carrying out heat preservation for 3-4 hours, wherein pressure in a heat preservation process is 1-1.2MPa; and cooling to room temperature, and filtering, so that the modified expanded polystyrene is obtained.

Owner:芜湖市京桥精密智造有限公司

Aramid fiber indoor optical fiber cable strengthening core preparation method

The invention discloses an aramid fiber indoor optical fiber cable strengthening core preparation method which is characterized by comprising the following steps: carrying out yarn directing on aramid fiber by the use of a yarn directing plate, merging piled yarns into one string, entering an oven of 200-250 DEG C to preheat for 1-2min, entering an immersion trough for immersion, carrying out molding treatment by the use of preheat molded orifices, entering a heating die of 150-250 DEG C to carry out heat-curing for 1-5min, pulling out the strengthening core from the die by a dragger, and rolling, wherein an immersion liquid in the immersion trough contains: by weight, 100 parts of vinylite, 1-3 parts of dibenzoyl peroxide, 1-3 parts of tert-Butyl peroxybenzoate, 2-4 parts of a release agent and 10-20 parts of a filling material. The preparation method provided by the invention has the following advantages: the prepared strengthening core has low density, high strength, good flexibility and a certain rigidity; and if the strengthening core is broken, tensile strength of the strengthening core still remains more than 1400 Mpa.

Owner:南通和泰通信科技有限公司 +1

Nitrile rubber/nylon thermoplastic elastomer and preparation method thereof

The invention relates to the field of thermoplastic elastomers, and discloses a nitrile rubber / nylon thermoplastic elastomer and a preparation method thereof, wherein the thermoplastic elastomer contains a nitrile rubber, nylon, a vulcanizing agent, an anti-aging agent, an antioxidant and an auxiliary agent, the vulcanizing agent is an organic peroxide, and the organic peroxide is at least one selected from dicumyl peroxide, bis(t-butylperoxyisopropyl)benzene, t-butyl cumene peroxide, 2,5-bis(t-butyl peroxy)-2,5-dimethyl-3-hexyne, 2,5-bis-(tert-butyl peroxy)-2,5-dimethyl hexane, dibenzoyl peroxide, tert-butyl peroxybenzoate, and di-tert-butyl peroxide. According to the present invention, the nitrile rubber / nylon thermoplastic elastomer has characteristics of high elasticity, easy processing, repeated processing and the like, and can be used for vehicle oil pipelines and sealing components.

Owner:CHINA PETROLEUM & CHEM CORP +1

Epoxy modified electroplated silver resin and preparation method thereof

The invention discloses epoxy modified electroplated silver resin, comprising a first component, a second component, a third component and a fourth component, wherein ingredients of the components and the weight percentage of each ingredient in the epoxy modified electroplated silver resin are as follows: the first component comprises toluene and butyl acetate; the second component comprises methyl methacrylate, tert-butyl methacrylate, lauryl methacrylate, hydroxyethyl methacrylate, glycidyl methacrylate, an AB-4 monomer and tert-butyl peroxybenzoate; the third component comprises butyl acetate and tert-butyl peroxybenzoate; and the fourth component comprises methyl isobutyl ketone. The invention further discloses a preparation method of the epoxy modified electroplated silver resin.

Owner:东莞市比翼新材料科技有限公司

Vinyl acetate-acrylate-ethylene multipolymer emulsion and preparation method thereof

ActiveCN109517102AUniform polymerizationImprove the single-pot conversion rateMonocarboxylic acid ester polymer adhesivesHyposulfiteSodium sulfate

The invention relates to the field of emulsion polymerization and discloses a vinyl acetate-acrylate-ethylene multipolymer emulsion and a preparation method thereof. The method comprises the followingsteps: under an emulsion polymerization reaction condition, (1) in the presence of an oxidization-reduction initiating system, carrying out a first polymerization reaction on a part of mixed monomercontaining a vinyl acetate monomer and an acrylate monomer and vinyl monomer, wherein in the oxidization-reduction initiating system, the oxidizing agent is tert-butyl hydroperoxide and the reducing agent is zinc formaldehyde sulfoxylate and / or sodium formaldehyde hyposulfite; and (2) adding the vinyl monomer and residual part of the mixed monomer into the system after the first polymerization reaction for a second polymerization reaction, wherein in the second polymerization reaction, tert-butyl peroxybenzoate is added into the reaction system. The content of acrylics in the copolymer emulsion obtained by the method is obviously higher than those in common modified EVA in the prior art, and the emulsion is good in bonding strength.

Owner:北京东方石油化工有限公司

Epoxy resin and polyurethane composite heat transfer printing adhesive and preparation method thereof

ActiveCN103275666AImprove antioxidant capacityImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention discloses an epoxy resin and polyurethane composite heat transfer printing adhesive. The adhesive is prepared from the following raw materials in parts by weight: 20-25 parts of polyurethane resin (KL-540E), 8-10 parts of E-12 epoxy resin, 10-12 parts of sorbitan fatty acid ester, 5-6 parts of polyglycerol fatty acid ester, 3-5 parts of epoxidized triglyceride, 2-3 parts of epoxy tetrahydrodioctyl phthalate, 5-8 parts of silane coupling agent KH550, 4-6 parts of ethylene glycol, 2-3 parts of tert-butyl peroxybenzoate, 5-8 parts of alkylphenol ethoxylate, 1-2 parts of antioxidant DLTP, 2-3 parts of antioxidant DSTP, 2-3 parts of 1-hydroxyethyl-2-oleic imidazoline, 1-2 parts of HDI tripolymer, 1-2 parts of propane diamine, 35-40 parts of acetone and 60-65 parts of dimethylbenzene. Compared with the prior art, the adhesive has the advantages that the adhesive is firm in bonding and enables the product not to break, shed or yellow easily, and has the effect on improving the product quality. The antioxidants are added in the formula, thus greatly improving the oxidation resistance of the heat transfer pattern and improving the weatherability. 1-hydroxyethyl-2-oleic imidazoline enables the corrosion resistance to be greatly improved.

Owner:ANHUI YICAI GLASSWARE

Flame-retardant computer cable sheath material with excellent mechanical properties

InactiveCN105199166AGood mechanical propertiesFlame retardant with excellent mechanical propertiesRubber insulatorsPlastic/resin/waxes insulatorsPolypropyleneTert-butyl peroxybenzoate

The invention discloses a flame-retardant computer cable sheath material with excellent mechanical properties, comprising, by weight: 30-50 parts of polypropylene, 30-60 parts of acrylonitrile-butadiene rubber, 20-40 parts of ethylene-propylene-diene monomer rubber, 1-3 parts of tert-butyl peroxybenzoate, 1-2 parts of bis(2, 4-dichlorobenzoyl) peroxide, 0.2-0.6 part of sodium ammonium dichromate, 2-2.6 parts of promoter DM, 10-18 parts of carbon fiber, 20-40 parts of diatomite, 5-15 parts of nano silicon dioxide, 40-60 parts of modified cotton staple, 0.5-1.5 parts of an anti-ageing agent, 1-3 parts of polyvinyl butyral, 2-4 parts of stearic acid, 0.5-2.5 parts of trioctyl phosphate, and 0.5-2.5 parts of aromatic hydrocarbon oil. This material has good flame retardance and excellent mechanical properties.

Owner:ANHUI LAND GRP

Dyeing technology of anti-static wool tops

The invention discloses a dyeing technology of anti-static wool tops. The dyeing technology comprises the following steps that 1, 0.7 part by weight of ethylene diamine tetramethylene phcsphonic acid sodium, 1.4 parts by weight of epoxy chloropropane, 2.6 parts by weight of tert-butyl peroxybenzoate, 1.4 parts by weight of methylene dinaphthyl sulfonate, 11 parts by weight of natural plant pigments, 0.5 part by weight of sodium hexametaphosphate, 1.7 parts by weight of nonyl phenol ethoxylate carboxylate and 32 parts by weight of water are added into a dye vat and stirred to be uniform; 2, wool tops are steeped in the dye vat for 60 min; 3, the steeped wool tops are dried at 85 DEG C; 4, the dried wool tops are immersed in clear water to be rinsed for 40 min; 5, the rinsed wool tops are taken out and naturally dried. According to the dyeing technology of the anti-static wool tops, the color fastness of the dyed wool tops is high, the uniformity of dyeing is good, and dyeing defects do not exist.

Owner:常熟市新华源有色毛条厂

Waterproof coating with corrosion resistance and preparation method thereof

InactiveCN108641501AHigh activityLarge specific surface areaAnti-corrosive paintsRare earthMaterials science

The invention discloses waterproof coating with corrosion resistance. The waterproof coating comprises the following raw materials in parts by weight: 32-38 parts of modified styrene-acrylic emulsion,22-28 parts of fly ash, 14-18 parts of graphene oxide powder, 12-18 parts of mixed rare earth ore, 6-10 parts of mixed metal oxides, 4-8 parts of mica powder, and 1-3 parts of a dispersing agent; themodified styrene-acrylic emulsion comprises the following raw materials in parts by weight: 28-34 parts of tyrene-acrylic emulsion, 14-28 parts of polystyrene microspheres, 4-8 parts of tert-butyl peroxybenzoate, 1-3 parts of a silane coupling agent KH-560, and 12-18 parts of ethanol. The invention aims at providing waterproof paint with corrosion resistance, the paint is applied to metal surface, the paint has excellent corrosion resistance and good adhesion on a metal surface, and the product has high use value and good application prospects.

Owner:合肥市晨雷思建筑材料科技有限公司

Flexible particle diverter and preparation method thereof

The invention belongs to a flexible particle diverter and a preparation method thereof. The diverter is prepared from the following raw materials in parts by weight: 30-40 parts of polyacrylate liquid rubber, 100-120 parts of bisphenol A epoxy resin, 0.05-0.1 part of a peroxide initiator and 0.5-2 parts of an epoxy resin curing agent, wherein the polyacrylate liquid rubber is prepared from the following raw materials: n-butyl alcohol, butyl acrylate, ethyl acrylate, glycidyl acrylate, azodiisobutyronitrile and nitrogen; the peroxide initiator is either benzoyl peroxide or tert-butyl peroxybenzoate; the epoxy resin curing agent is one of polysebacic polyanhydride, polyazelaic polyanhydride, maleic anhydride and tung oil anhydride. The flexible particle diverter, which has flexible particles, has the advantages of no toxicity, good plugging effect on narrow cracks, temperature resistant, mineralization resistant and excellent in shearing resistance.

Owner:北京国海能源技术研究院

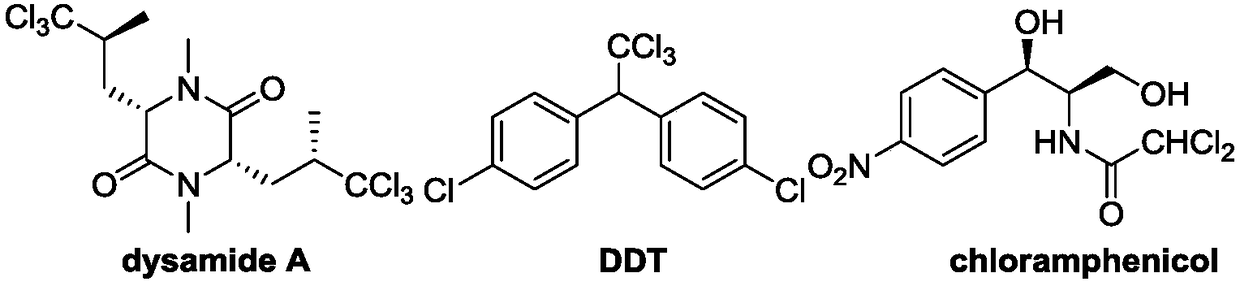

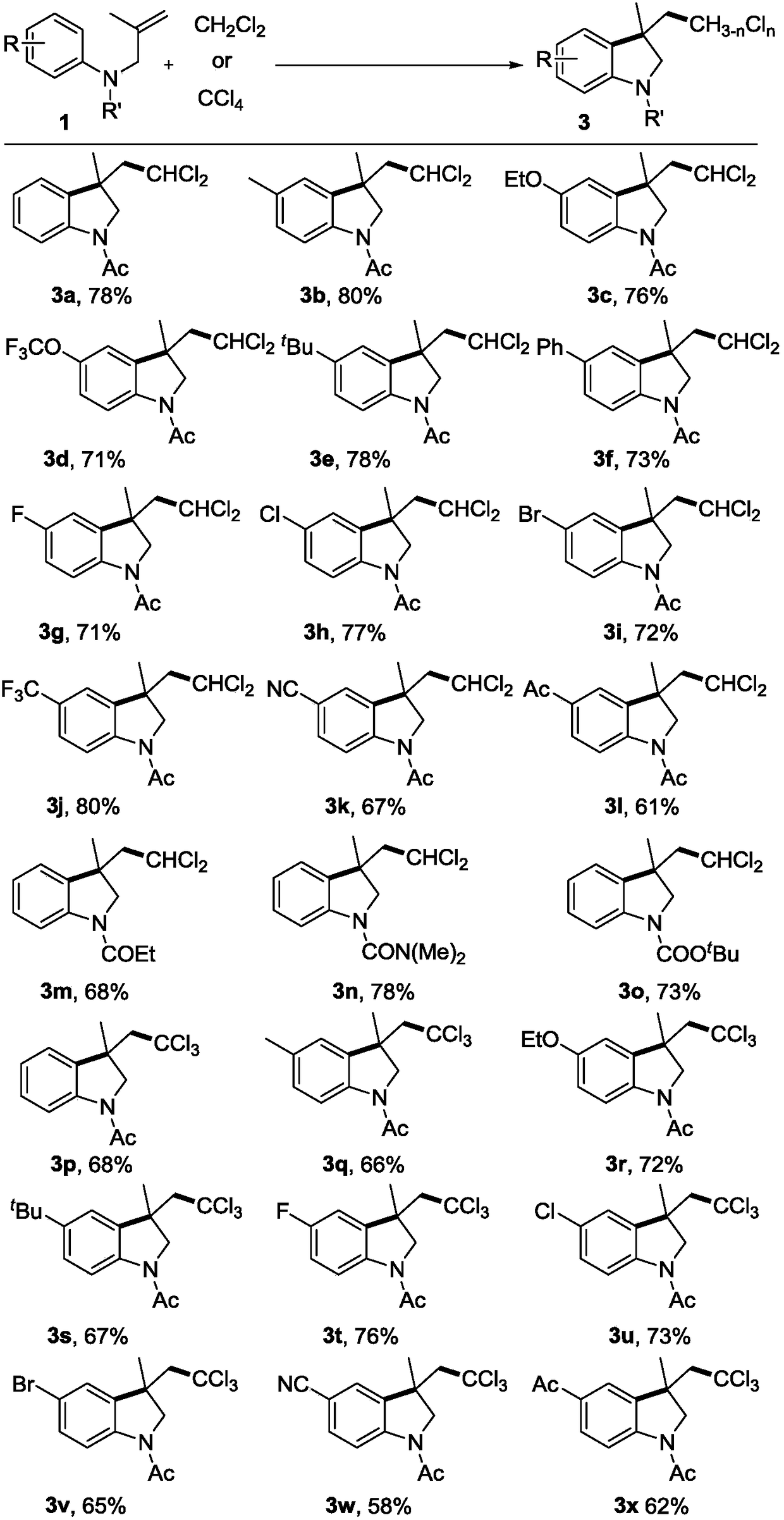

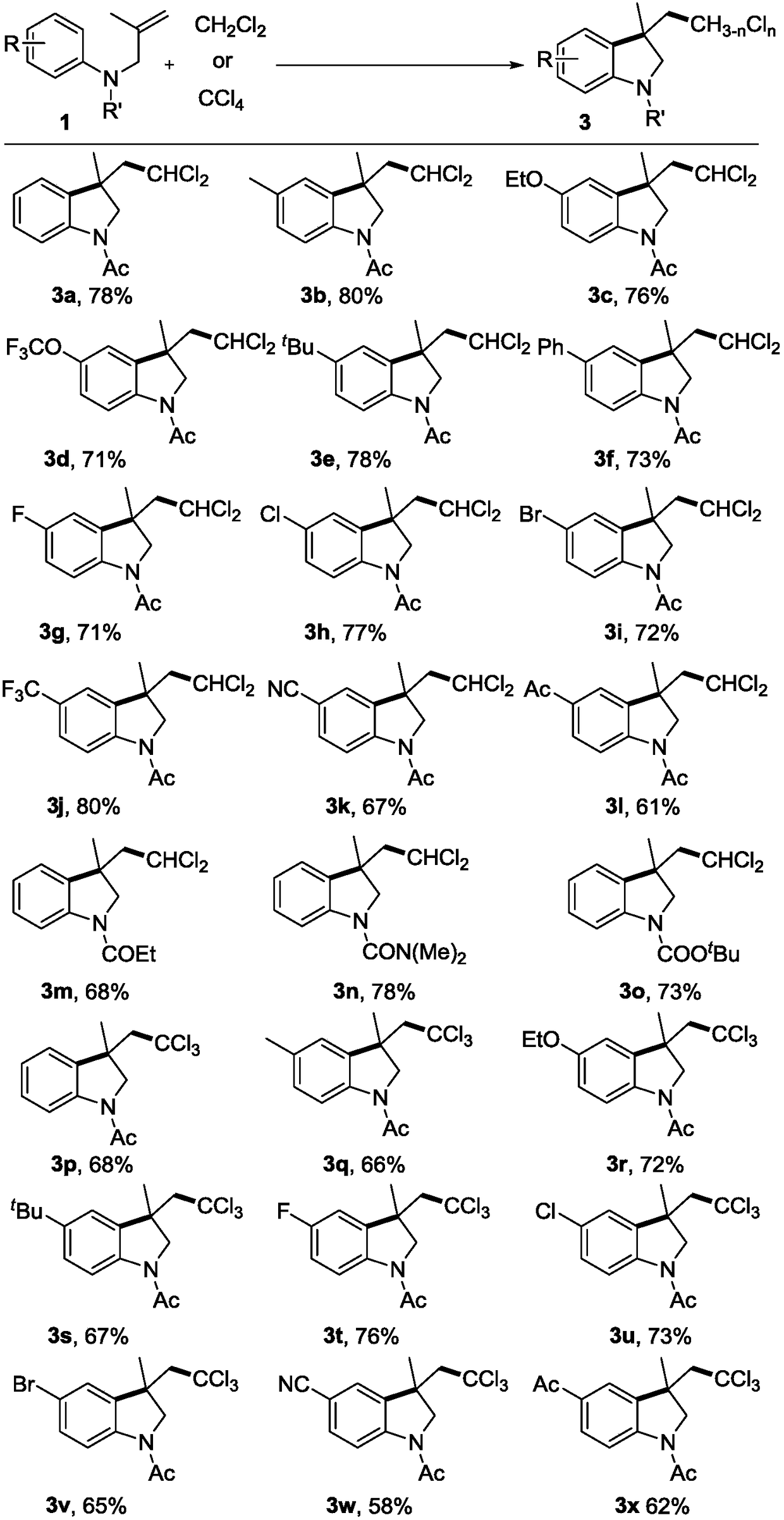

Polychloromethyl-substituted indoline compound and synthetic method and application thereof

ActiveCN108947886AEasy to handleAchieve synthesisAntipyreticOrganic chemistry methodsDi-tert-butyl peroxideMethyl group

The invention relates to a polychloromethyl-substituted indoline compound and a synthetic method and an application thereof, and specifically relates to the synthetic method of a 3-dichloromethyl and3-trichloromethyl-substituted indoline compound, which relates to the field of medicines, organic chemicals and fine chemicals. According to the method, N-(2-methylallyl)-acylarylamine compounds are utilized as raw materials, dichloromethane and carbon tetrachloride are utilized as sources of dichloromethyl and trichloromethyl, and a 3-dichloromethyl or 3-trichloromethyl-substituted N-acyl indoline compound is synthesized under catalysis of peroxide. Specific reaction conditions are that: tert-butyl hydroperoxide, tert-butyl peroxybenzoate, lauric aldehyde peroxide, di-tert-butyl peroxide, andbenzoyl peroxide are utilized as catalysts and free radical initiators under heating and stirring conditions. A reaction does not require participation of transition metal, an addition cyclization process of a free radical process is undergone, and post-treatment is simple, which is an effective way to synthesize the 3-dichloromethyl or 3-trichloromethyl-substituted N-acyl indoline compound.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com