Patents

Literature

87 results about "Multi-Walled Nanotube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A nanotube consisting of single-walled nanotubes layered inside each other.

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

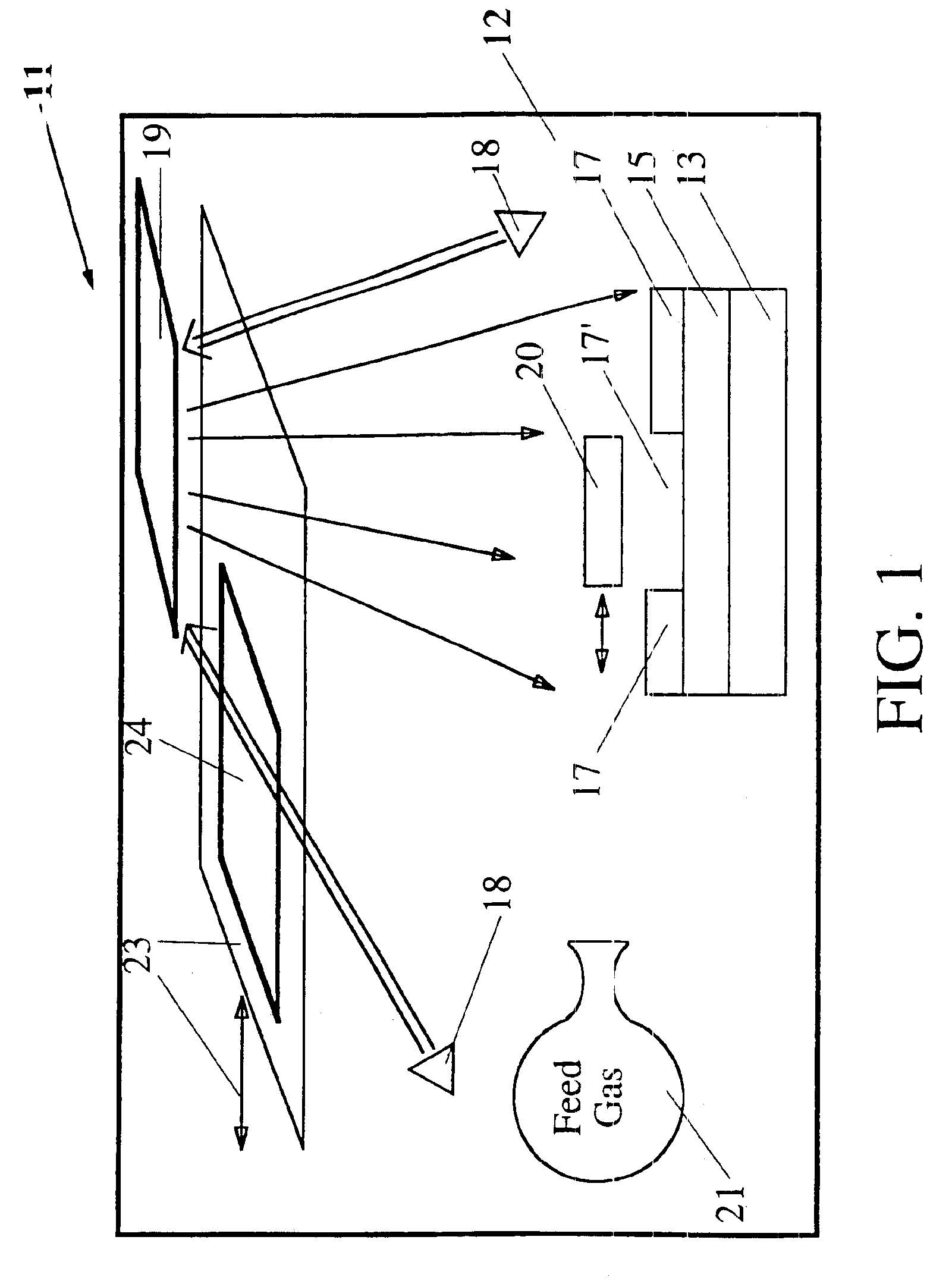

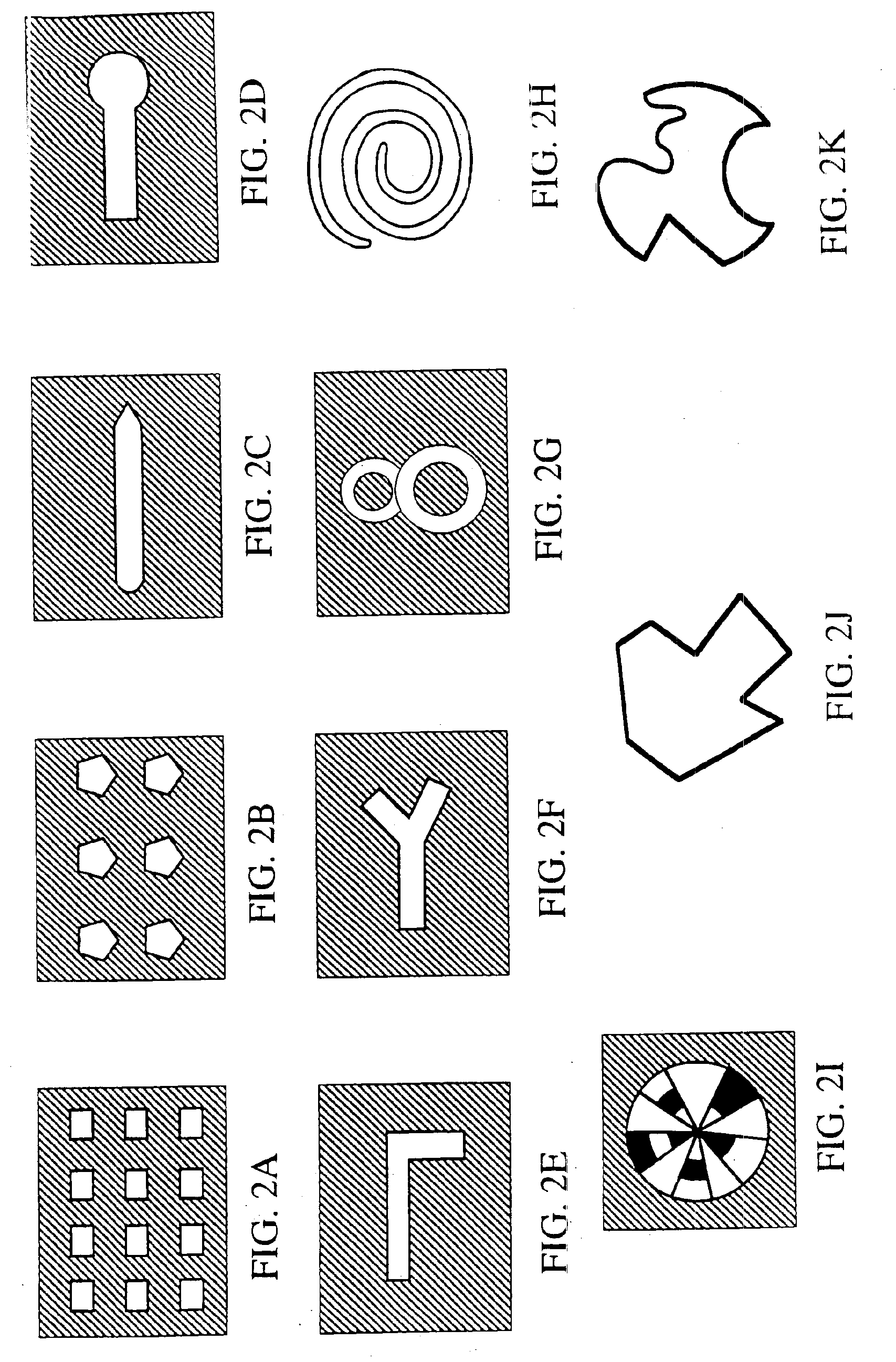

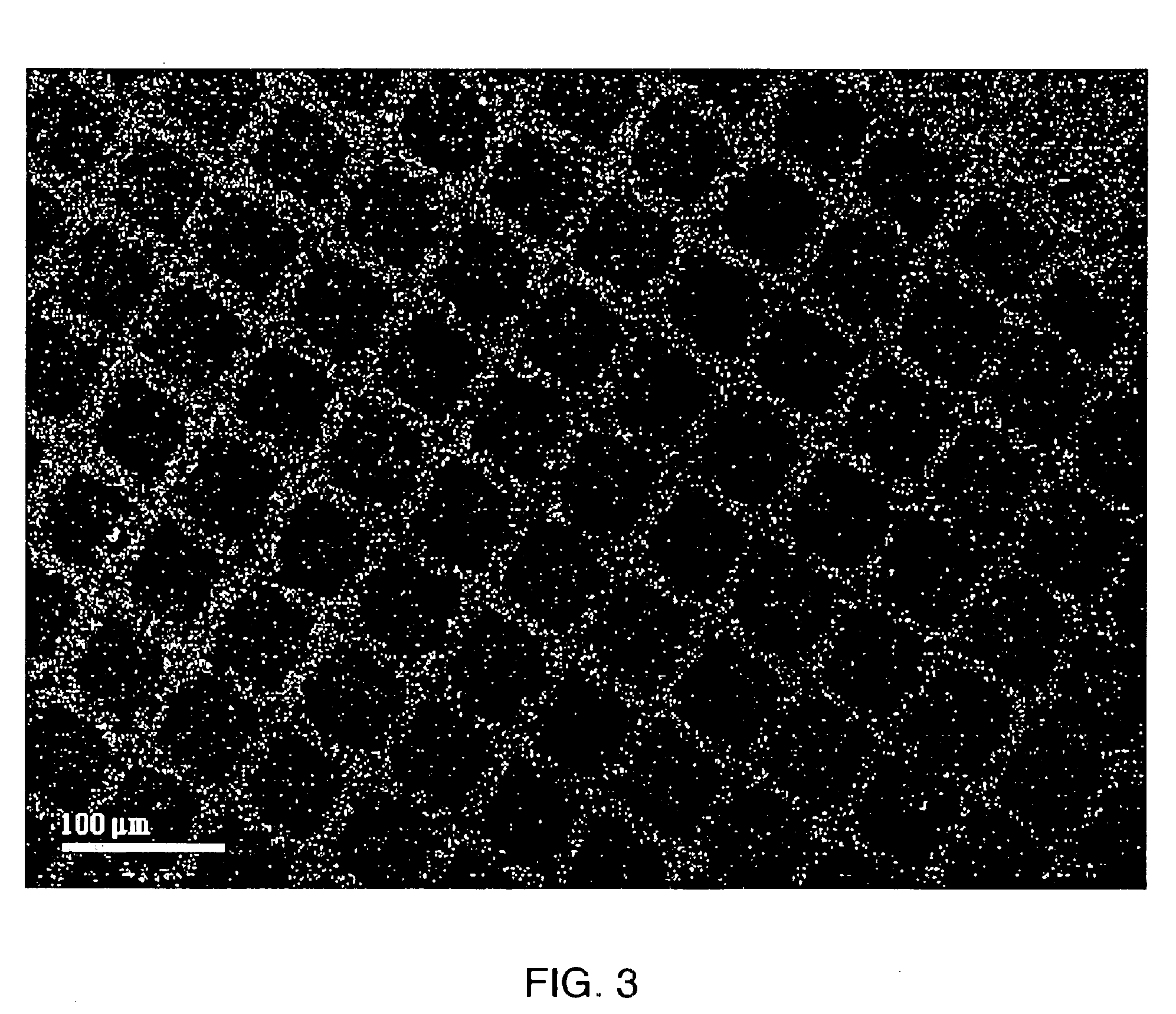

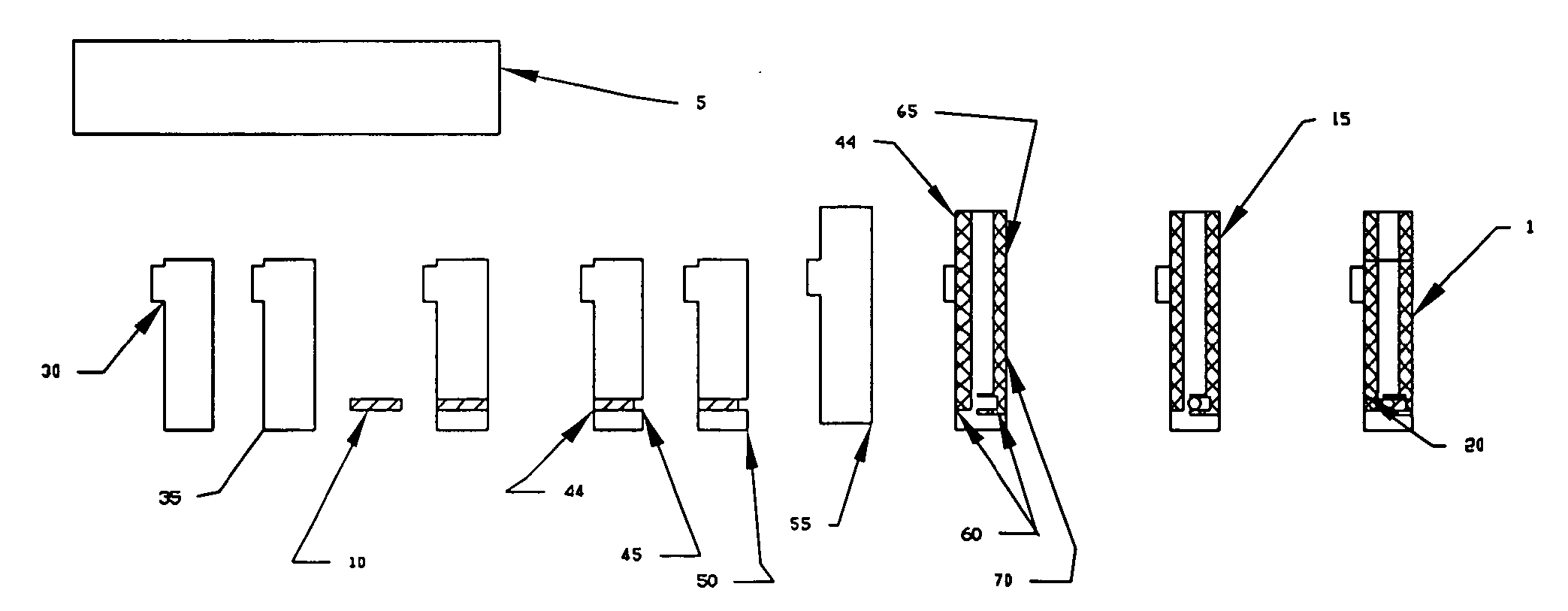

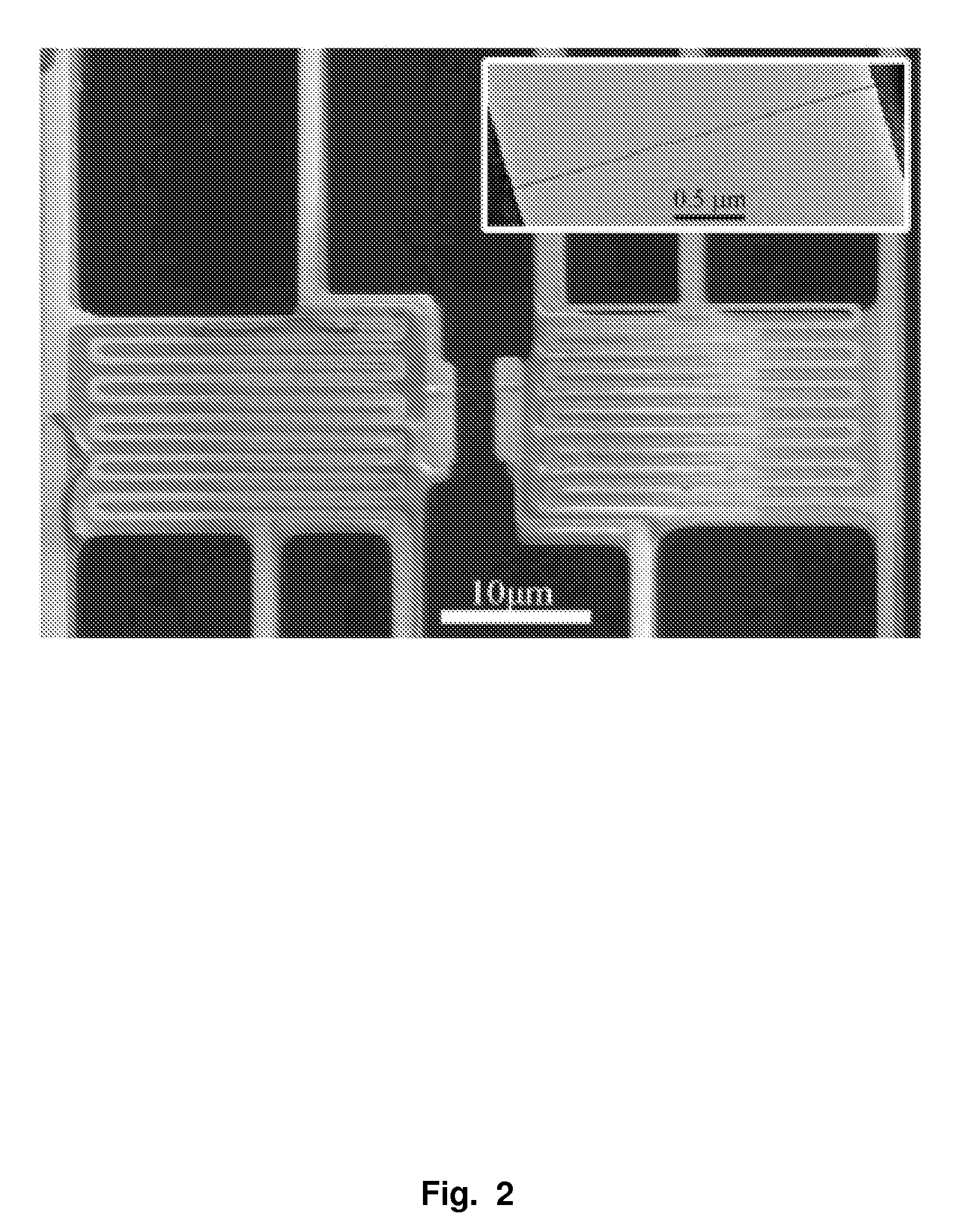

Controlled patterning and growth of single wall and multi-wall carbon nanotubes

Method and system for producing a selected pattern or array of at least one of a single wall nanotube and / or a multi-wall nanotube containing primarily carbon. A substrate is coated with a first layer (optional) of a first selected metal (e.g., Al and / or Ir) and with a second layer of a catalyst (e.g., Fe, Co, Ni and / or Mo), having selected first and second layer thicknesses provided by ion sputtering, arc discharge, laser ablation, evaporation or CVD. The first layer and / or the second layer may be formed in a desired non-uniform pattern, using a mask with suitable aperture(s), to promote growth of carbon nanotubes in a corresponding pattern. A selected heated feed gas (primarily CH4 or C2Hn with n=2 and / or 4) is passed over the coated substrate and forms primarily single wall nanotubes or multiple wall nanotubes, depending upon the selected feed gas and its temperature. Nanofibers, as well as single wall and multi-wall nanotubes, are produced using plasma-aided growth from the second (catalyst) layer. An overcoating of a selected metal or alloy can be deposited, over the second layer, to provide a coating for the carbon nanotubes grown in this manner.

Owner:NASA +1

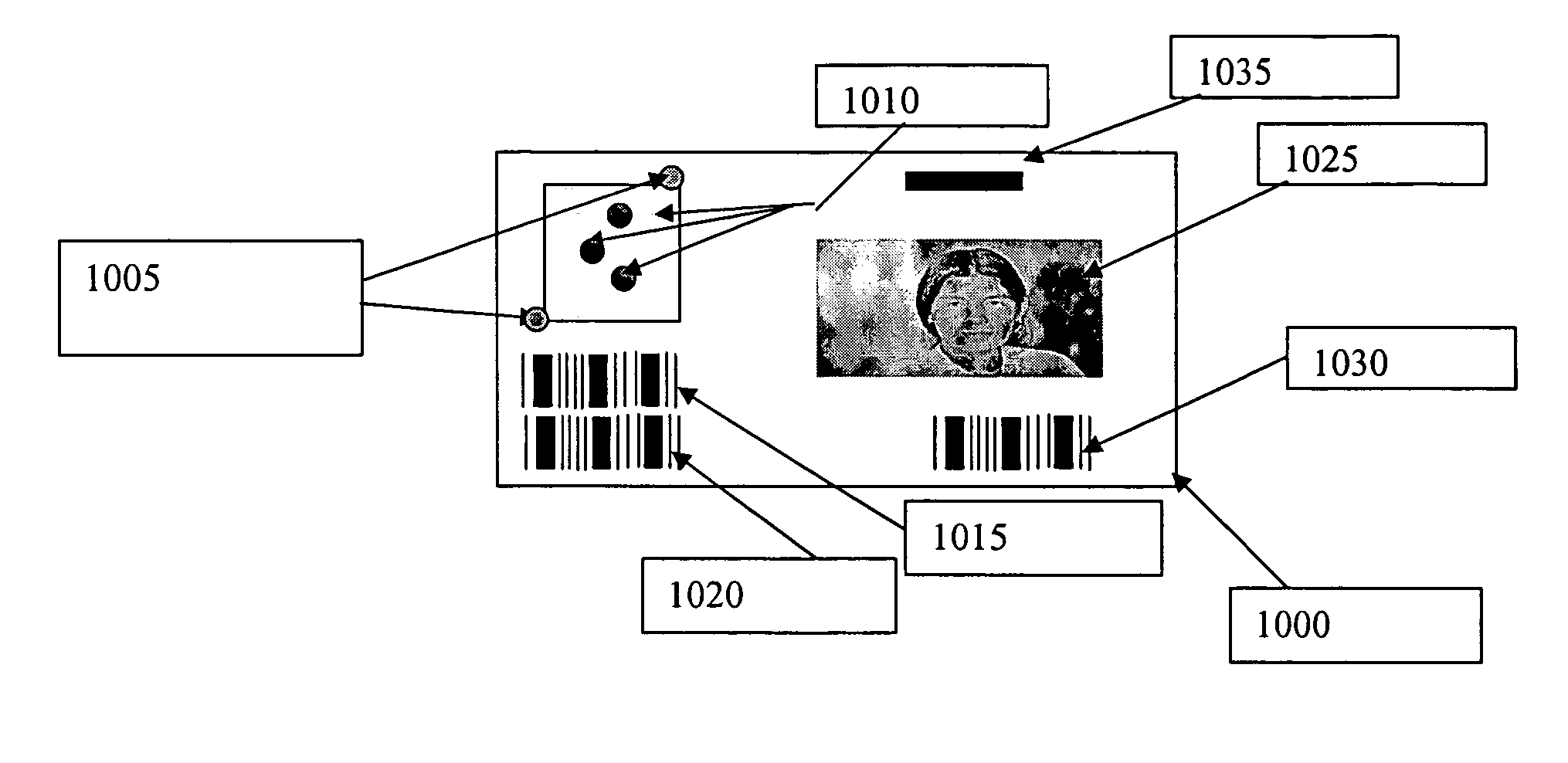

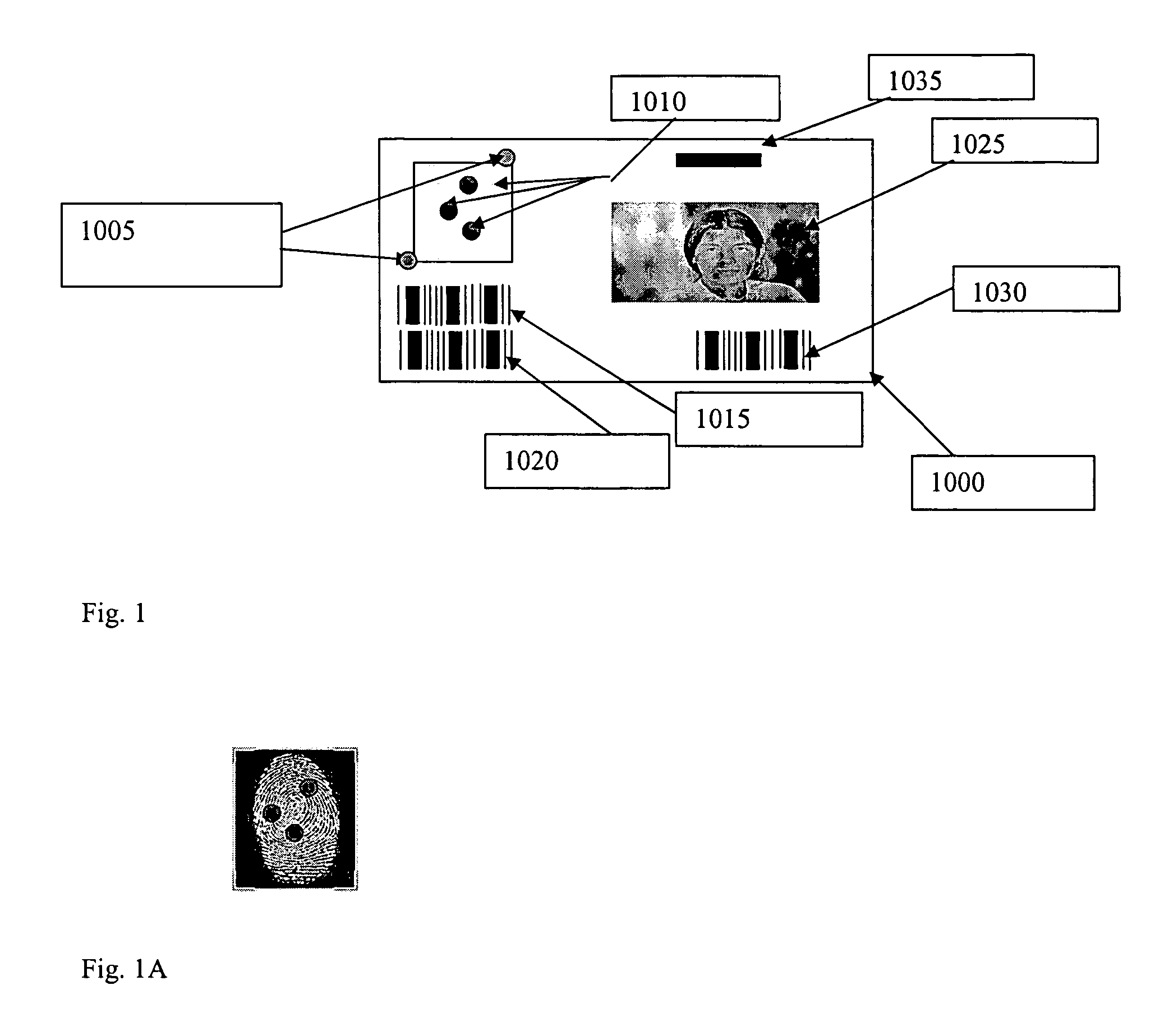

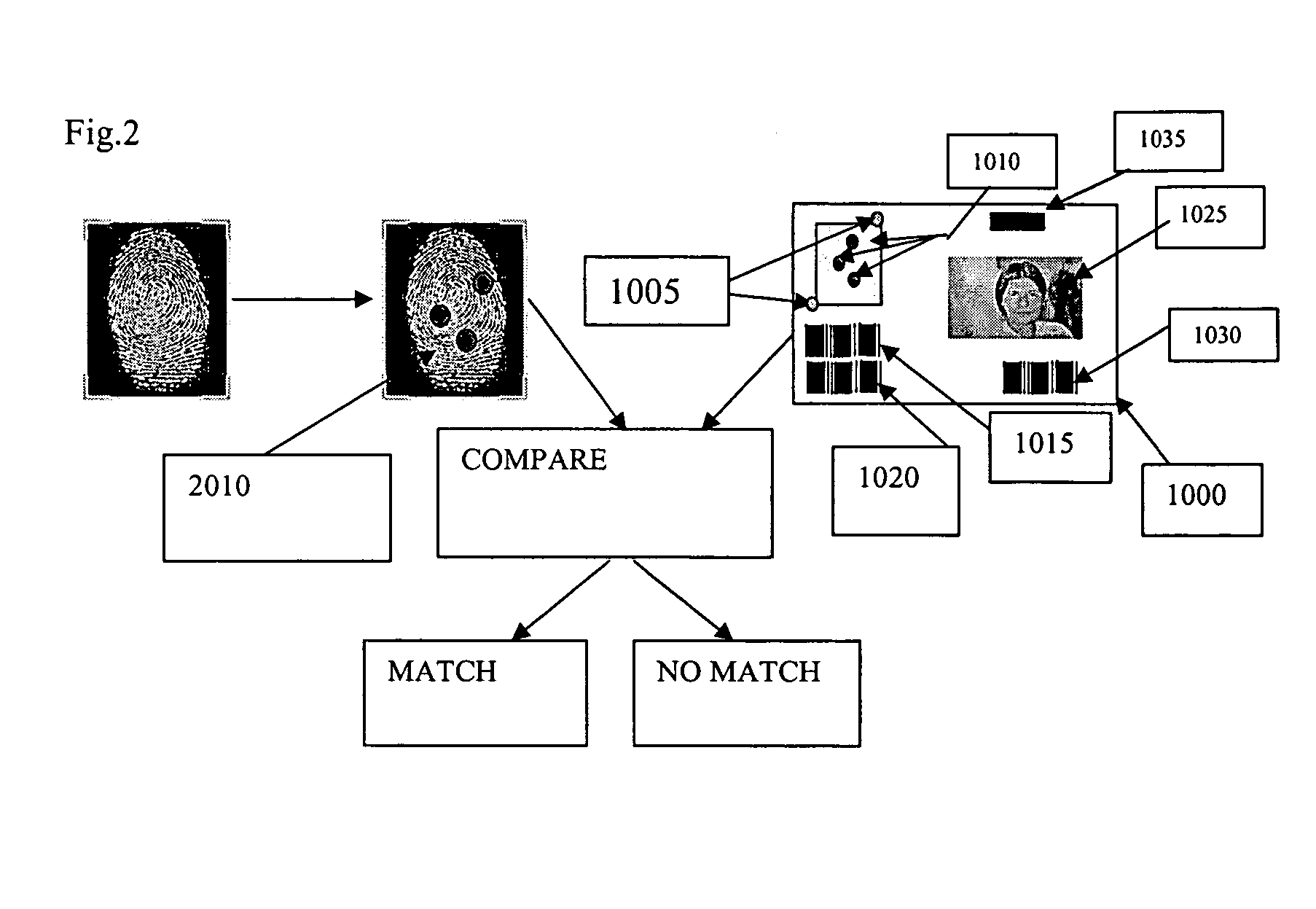

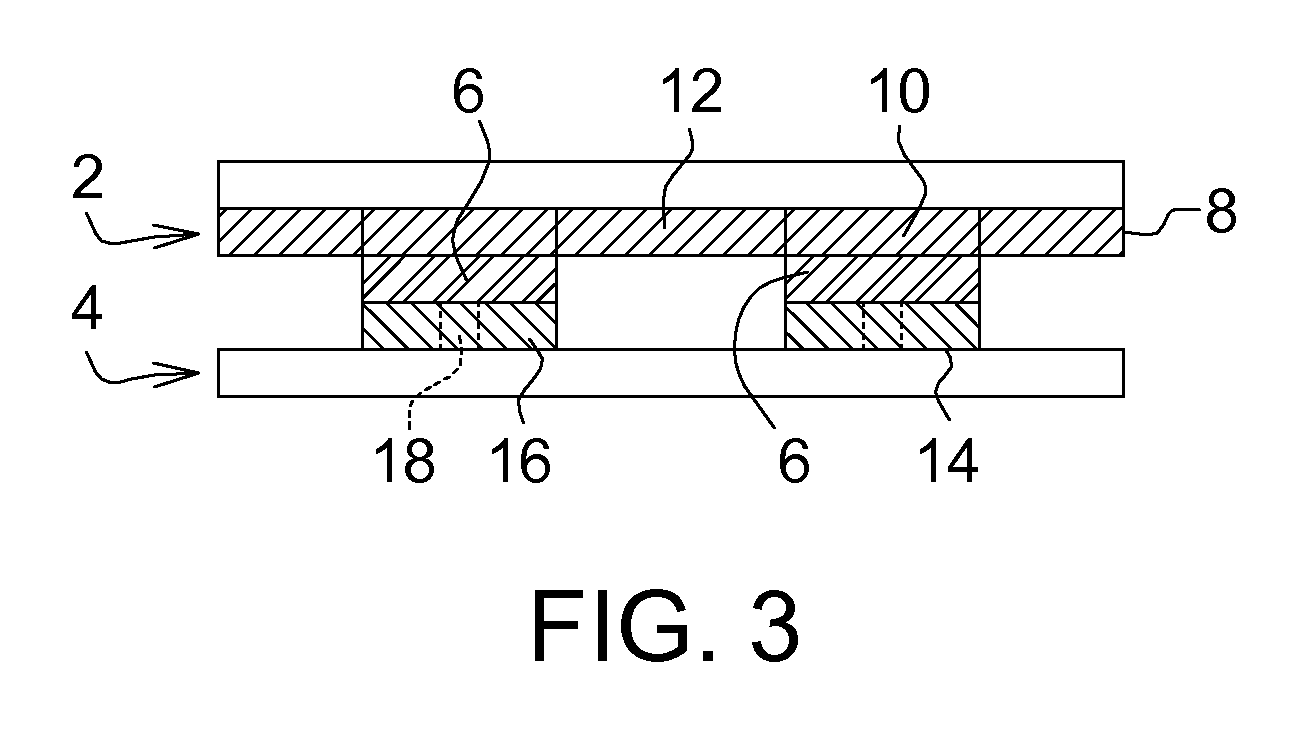

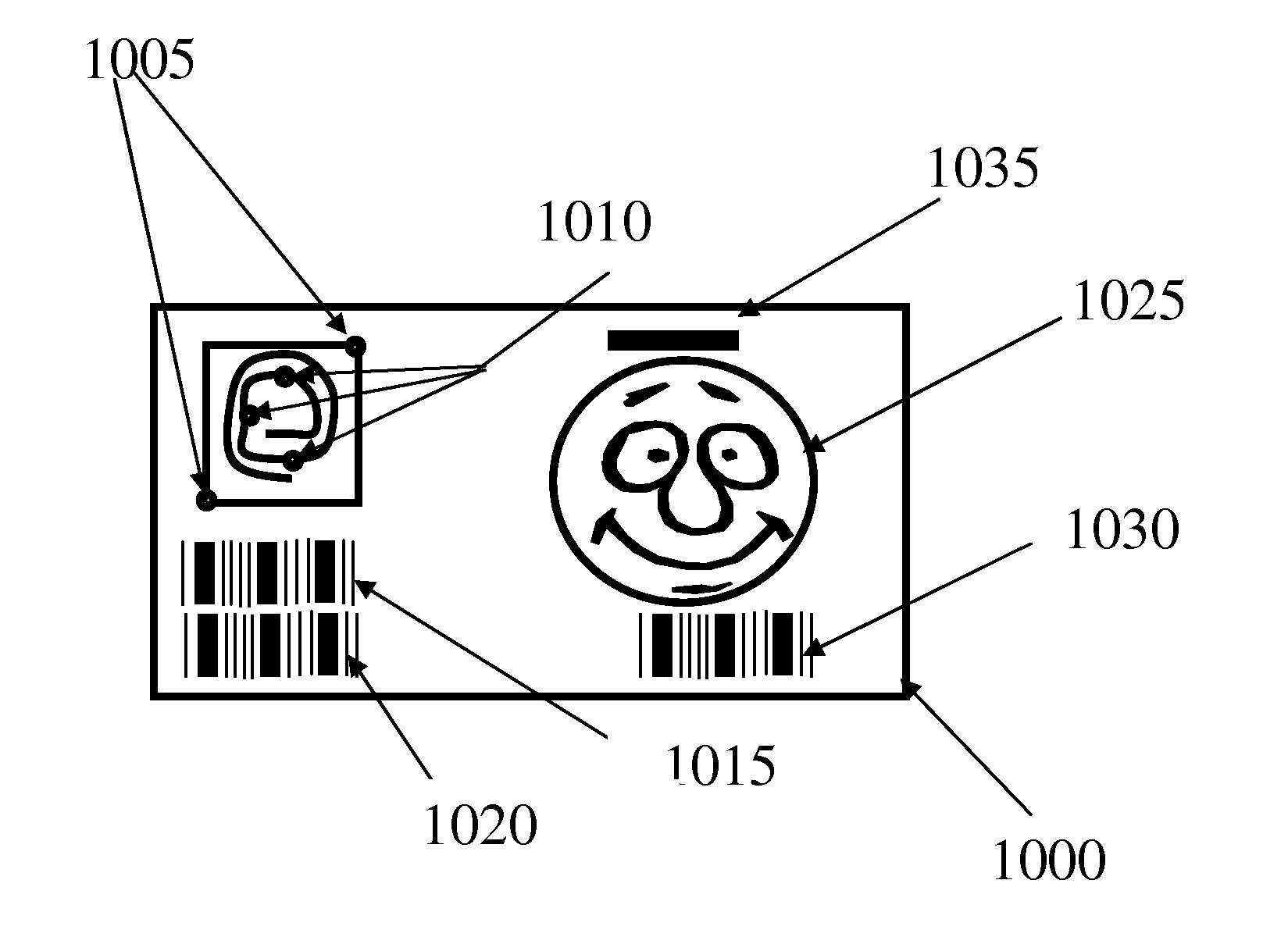

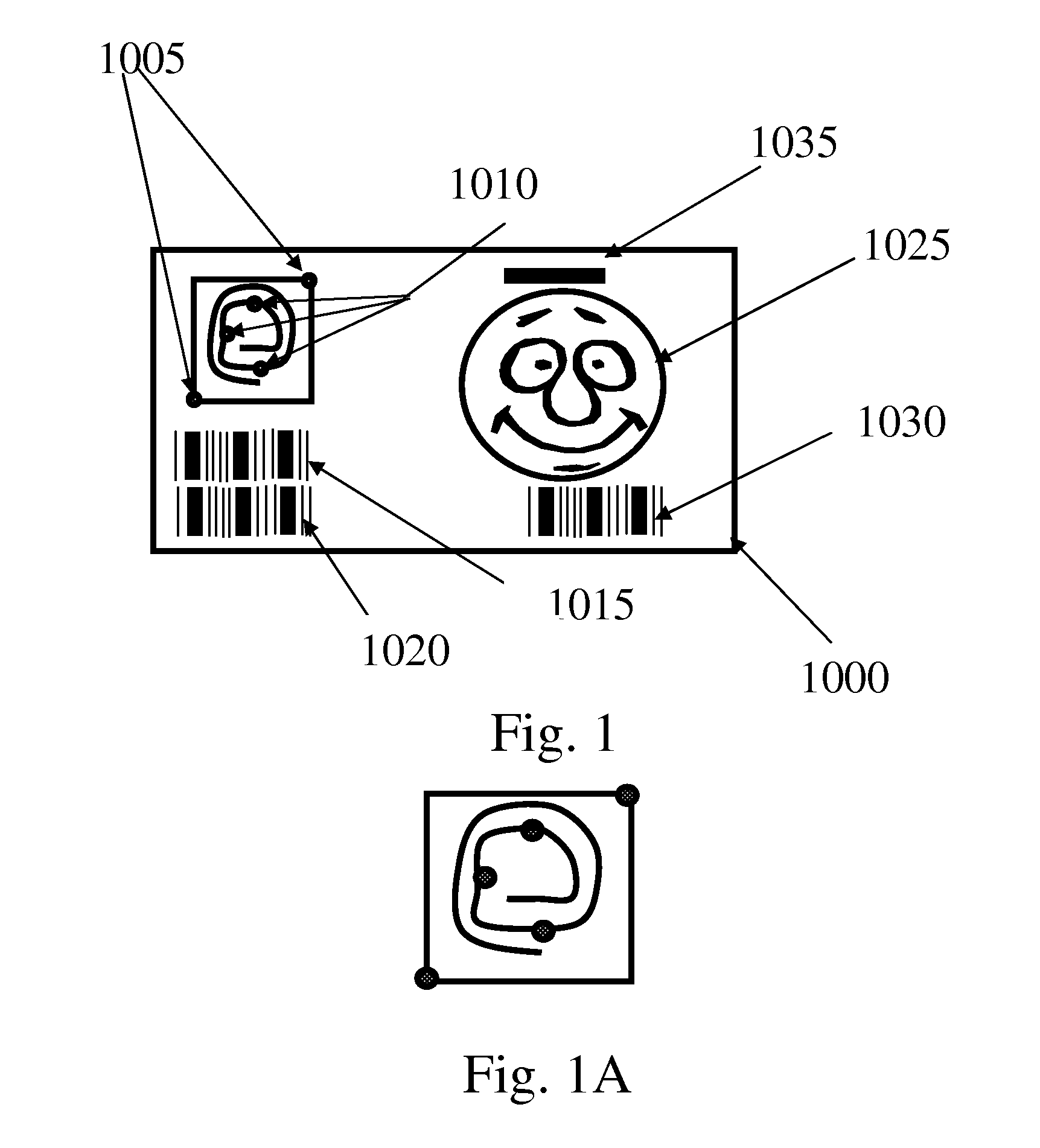

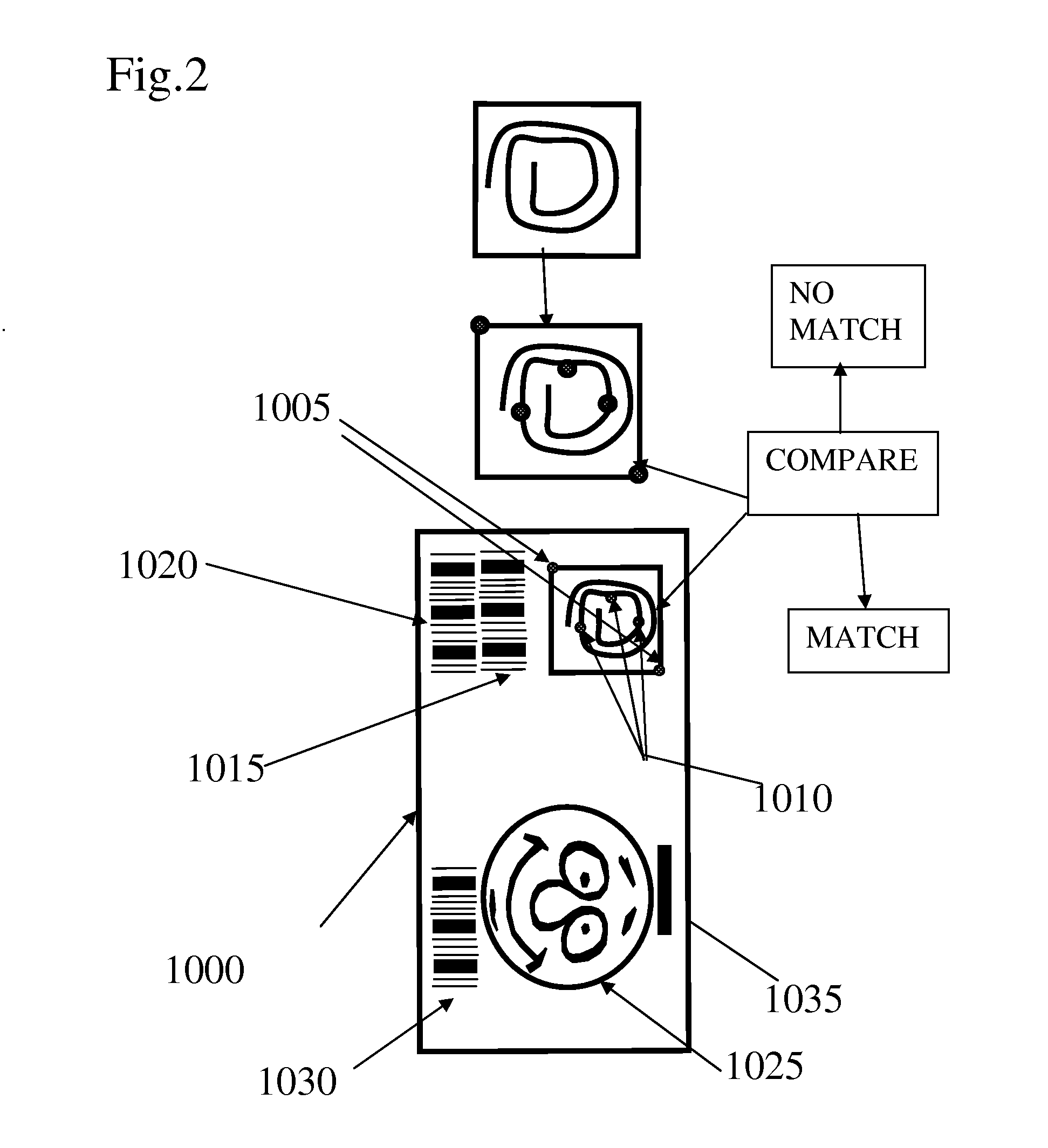

Security marking and security mark

InactiveUS20050156318A1Semiconductor/solid-state device detailsNanoinformaticsPlatinumProduct Identifier

The application discloses a security mark consisting of a plurality of layers, of which the cover layers are highly conductive films and the layers of the card core are films of varying transparency. One layer carries information, which can be read directly, if desired, above a security print, while the transparent conductive layer has an additional security markings, such as biometric or product identifiers marking which can be read conductively only with the aid of a special reader. All the layers consist of polymers, papers or mixtures which can be fused together to form a laminate which is fused together. The conductive layers form conductive traces which may be formed with single-walled or multi walled nano tubes or they can be formed from multiple layers or dispersions containing, carbon nano tubes, carbon nano tubes / antimony tin oxide, carbon nano tubes / platinum, or carbon nano tubes / silver, carbon, silver or carbon nano tubes / silver-cloride. An alternative layer can be formed from a separate conductive layer or suitable dispersion and the encoding accomplished by overlaying a nonconductive trace.

Owner:DOUGLAS JOEL S

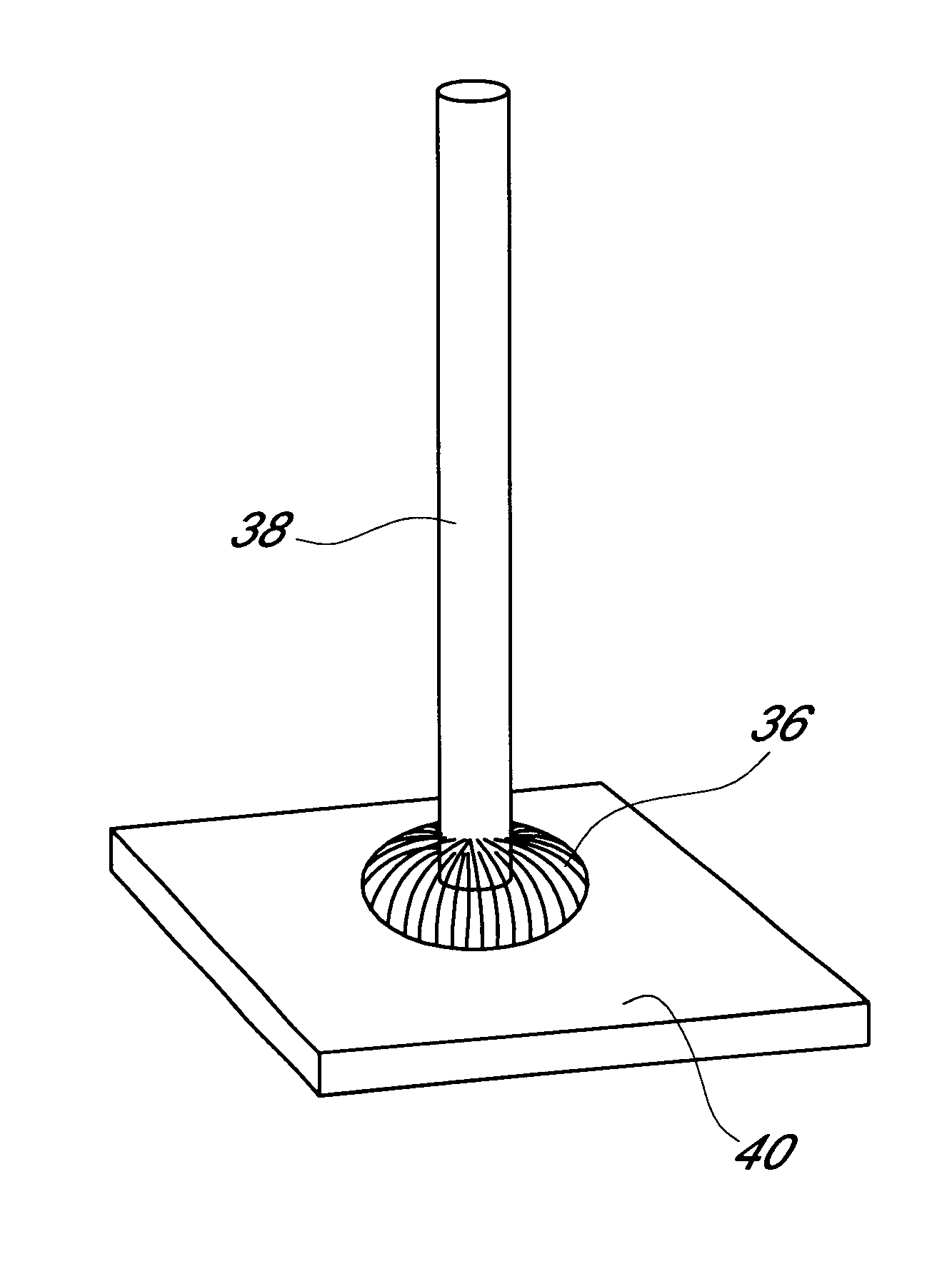

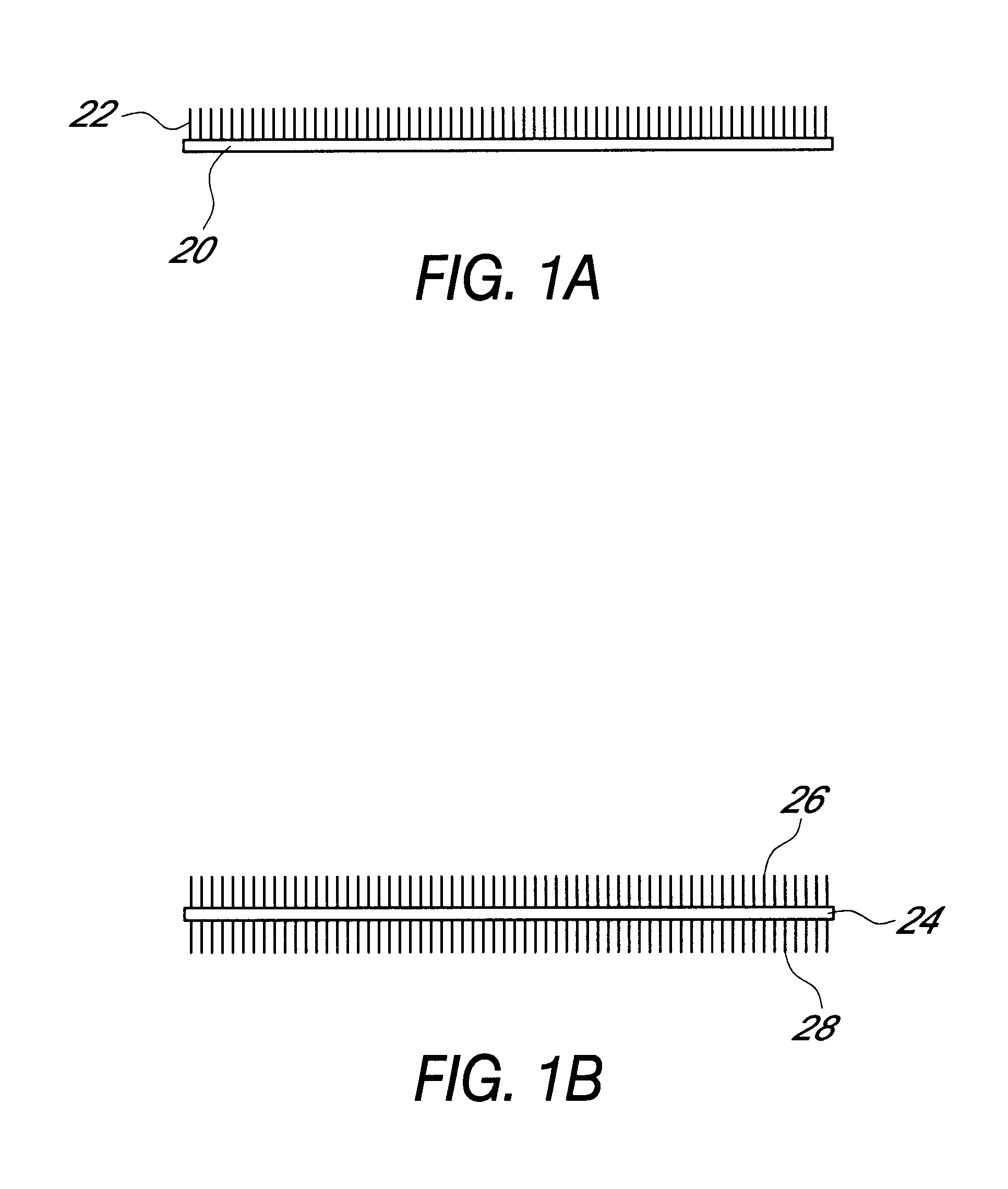

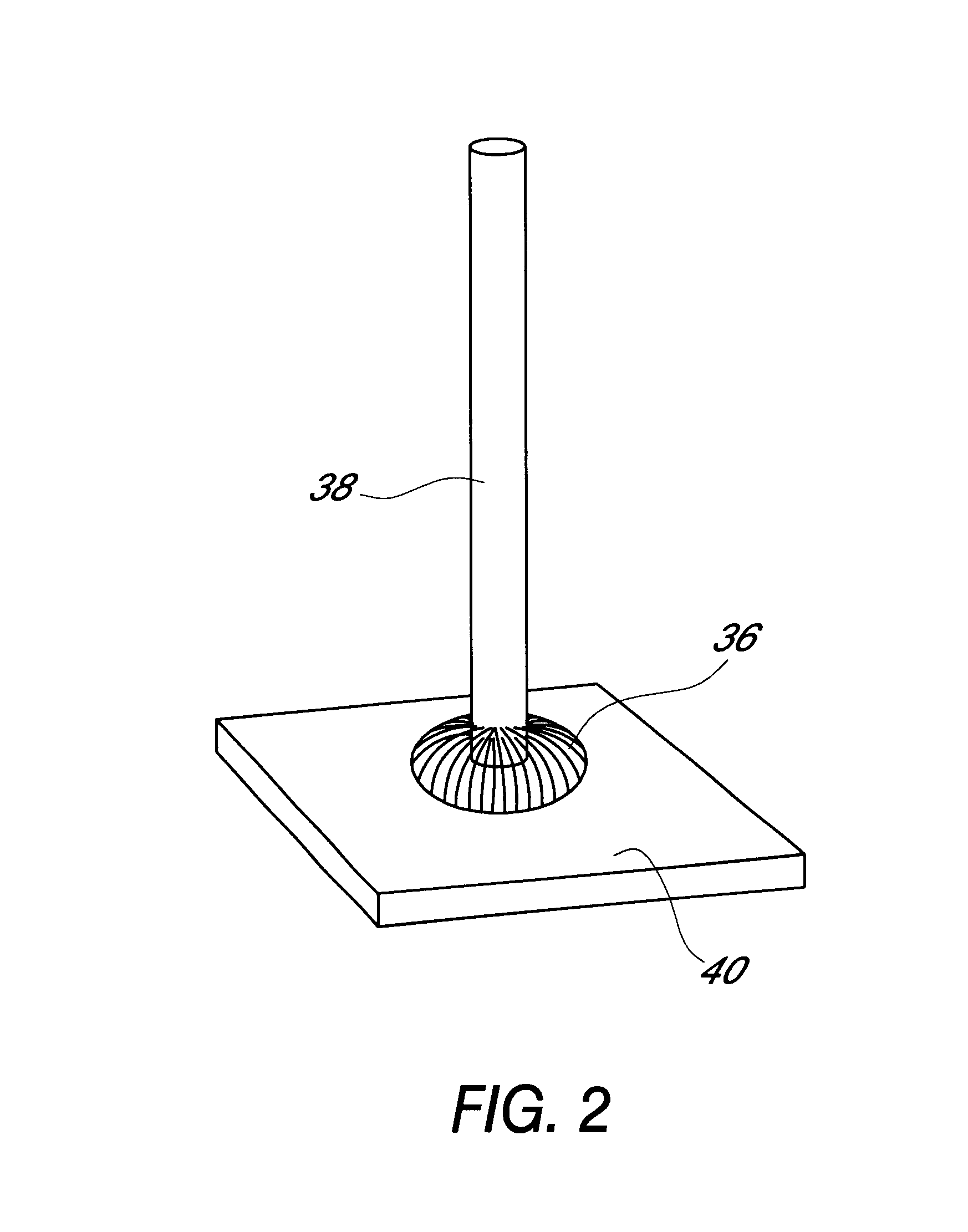

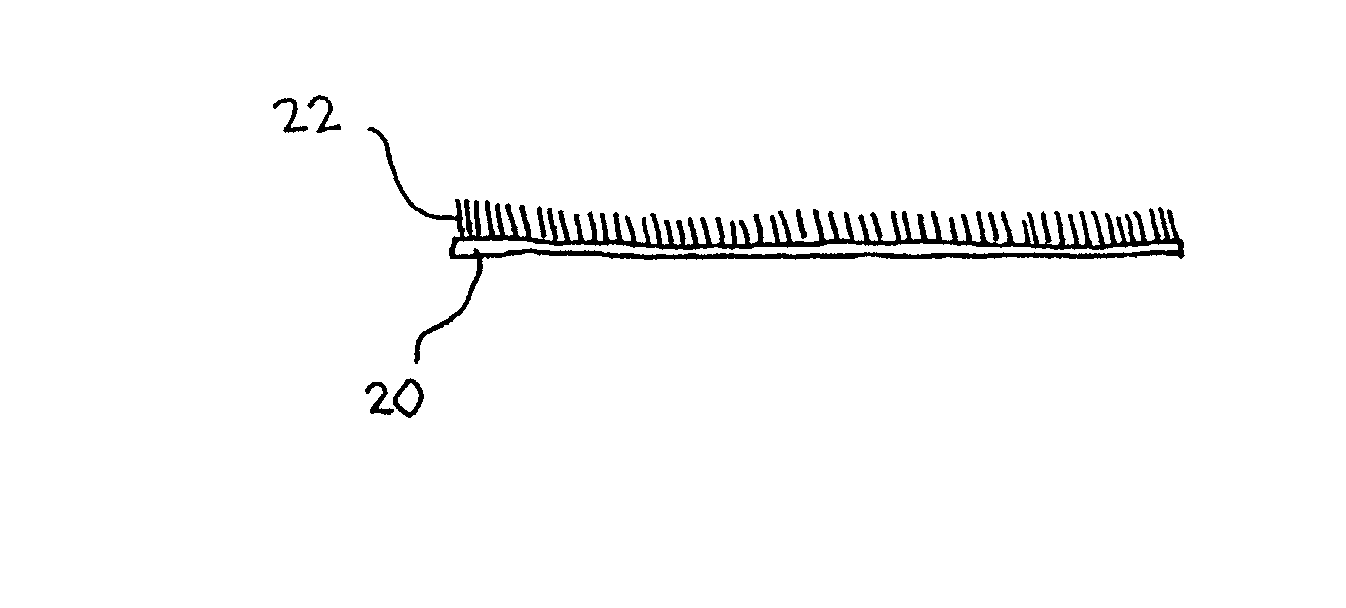

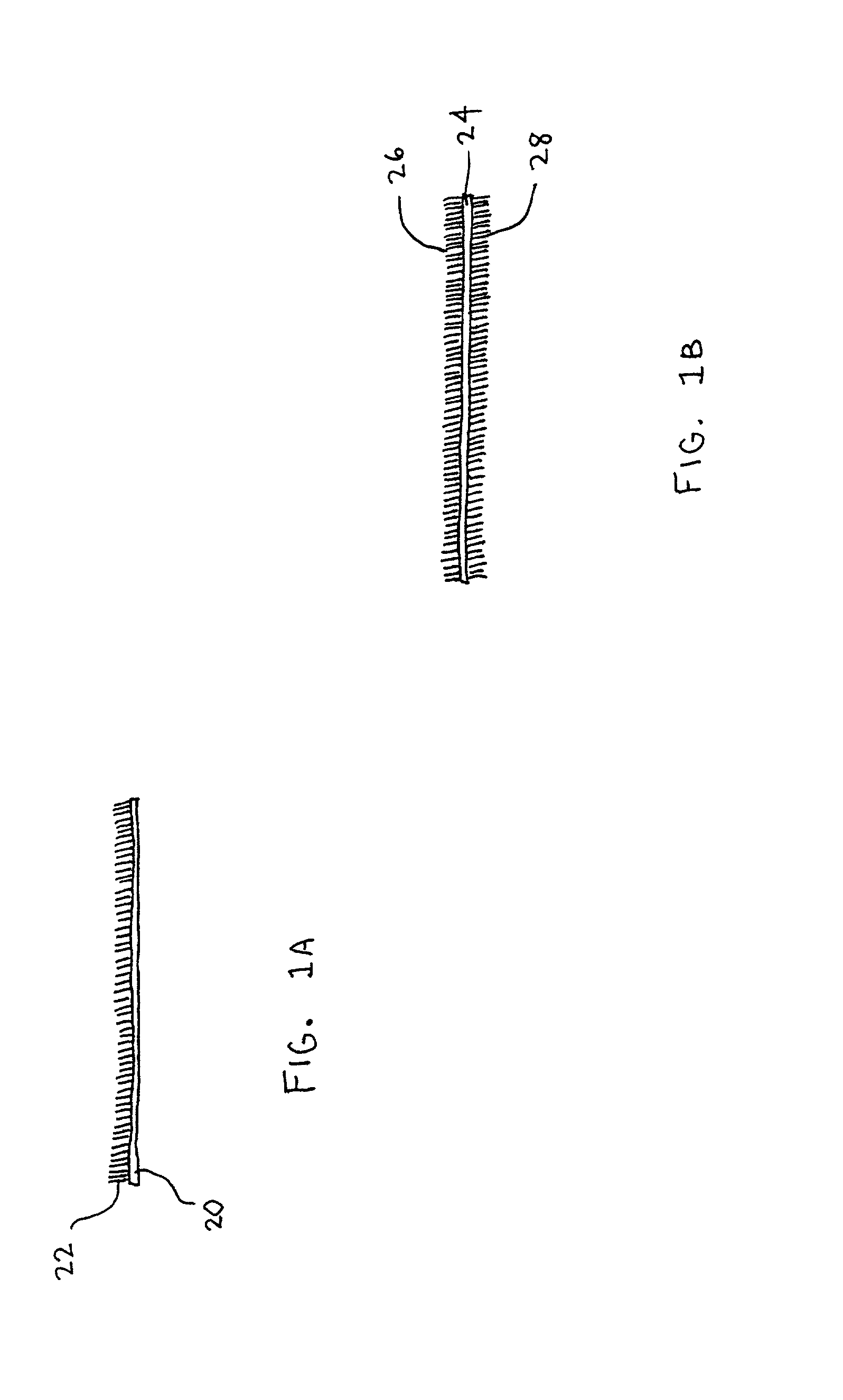

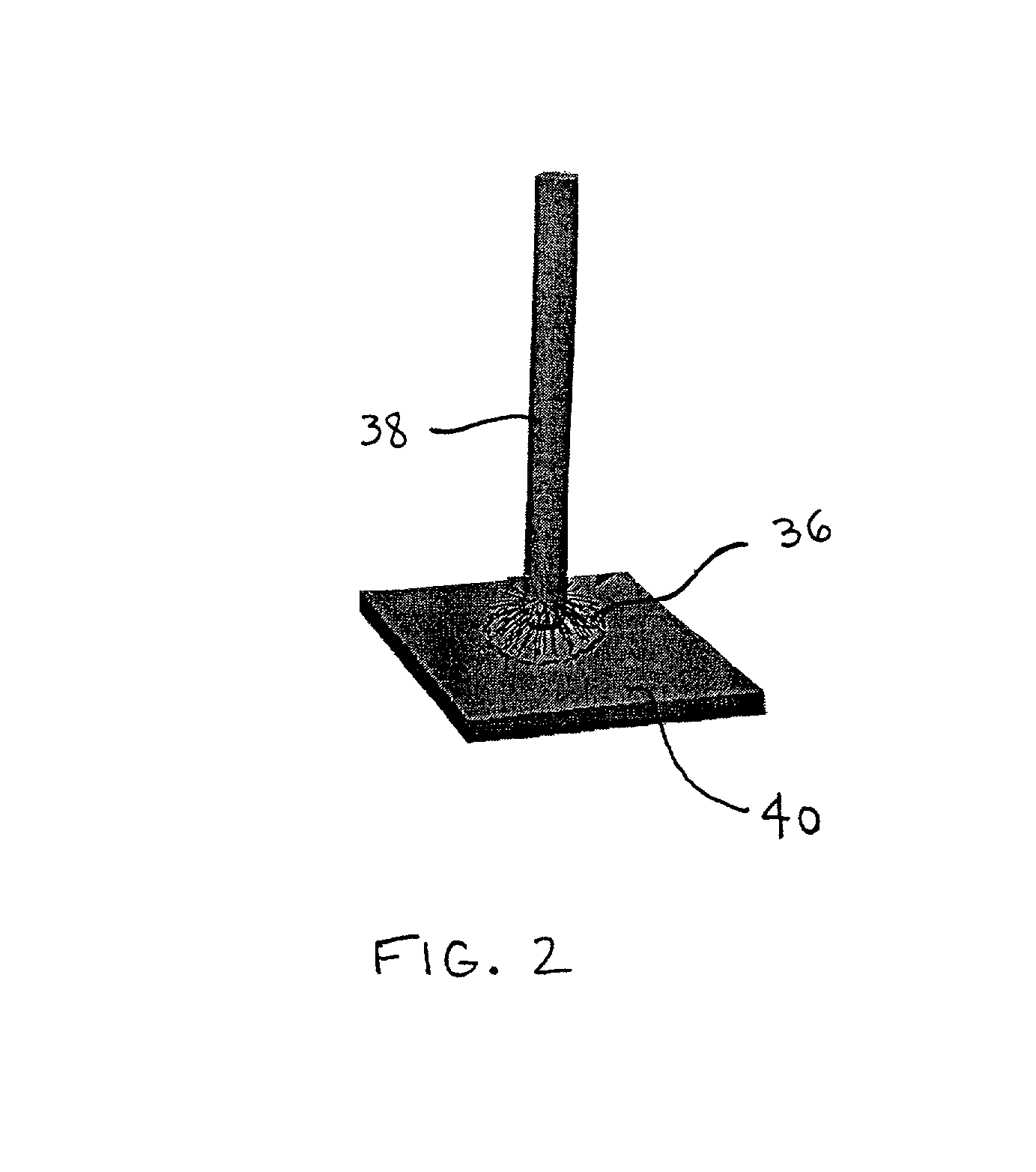

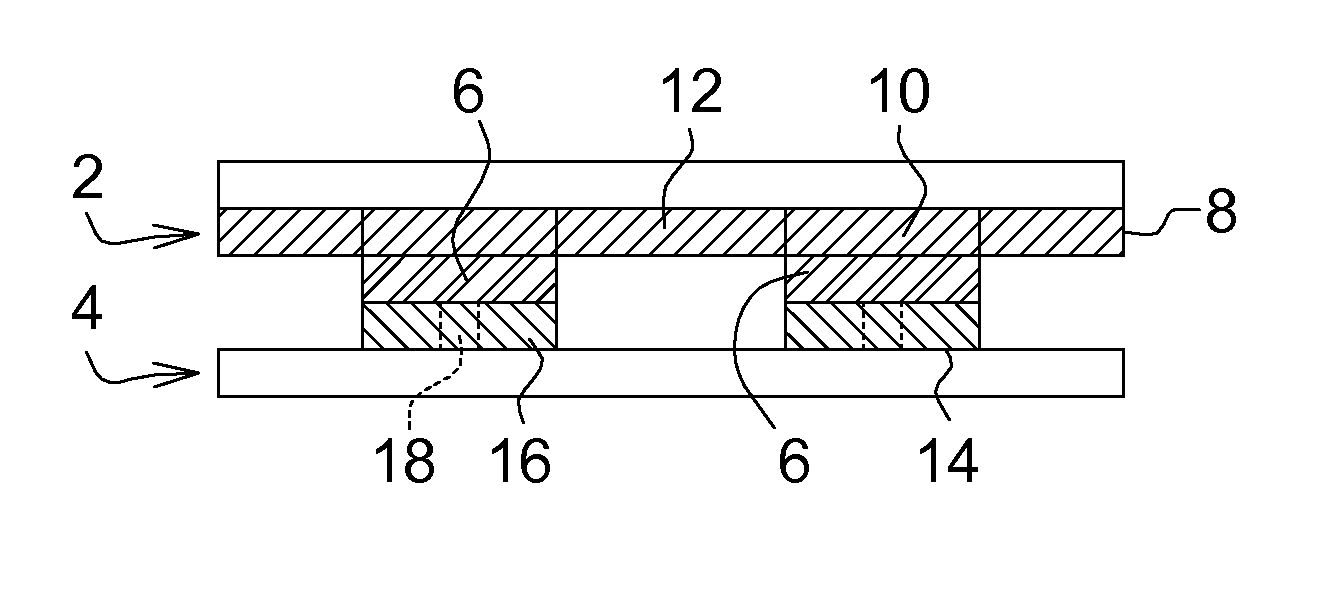

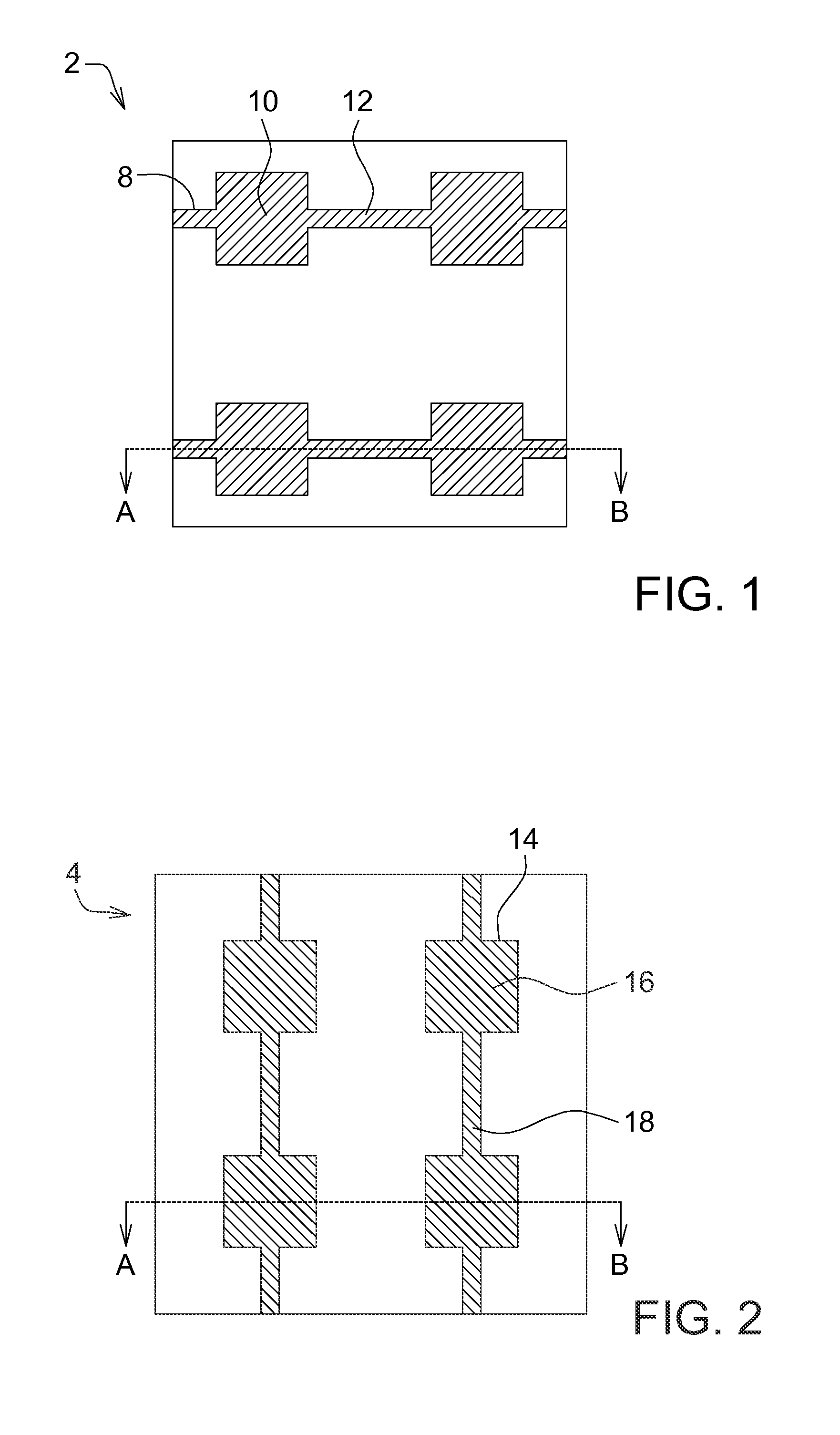

Dendritic fiber material

InactiveUS6913075B1Layered productsSemiconductor/solid-state device detailsFiberMulti-Walled Nanotube

A thermal interface includes nanofibrils. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of larger diameter fibers. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled nanotubes.

Owner:KULR TECH

Catalytic growth of single- and double-wall carbon nanotubes from metal particles

InactiveUS7125534B1Improve productivityImprove scalabilityMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

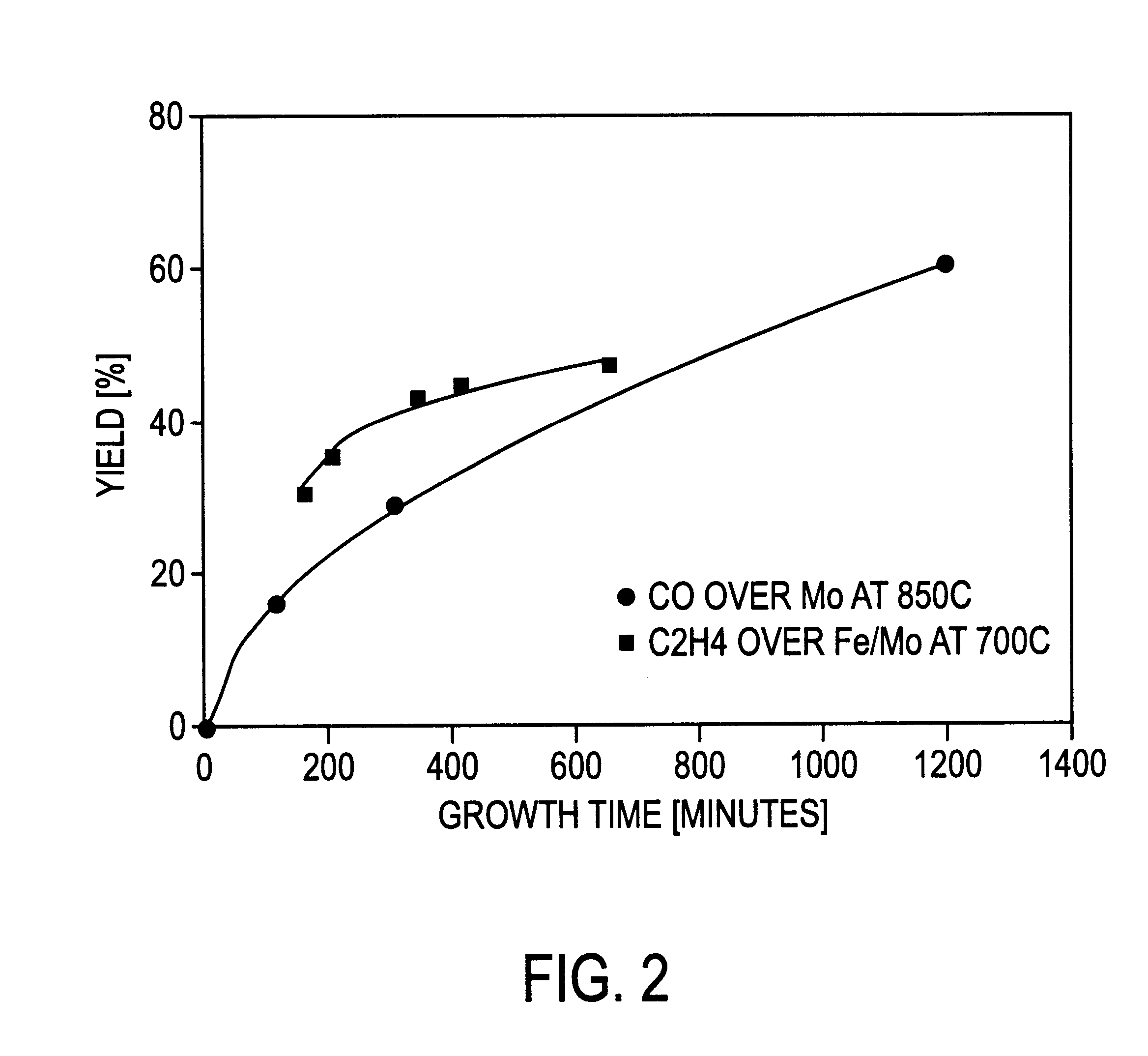

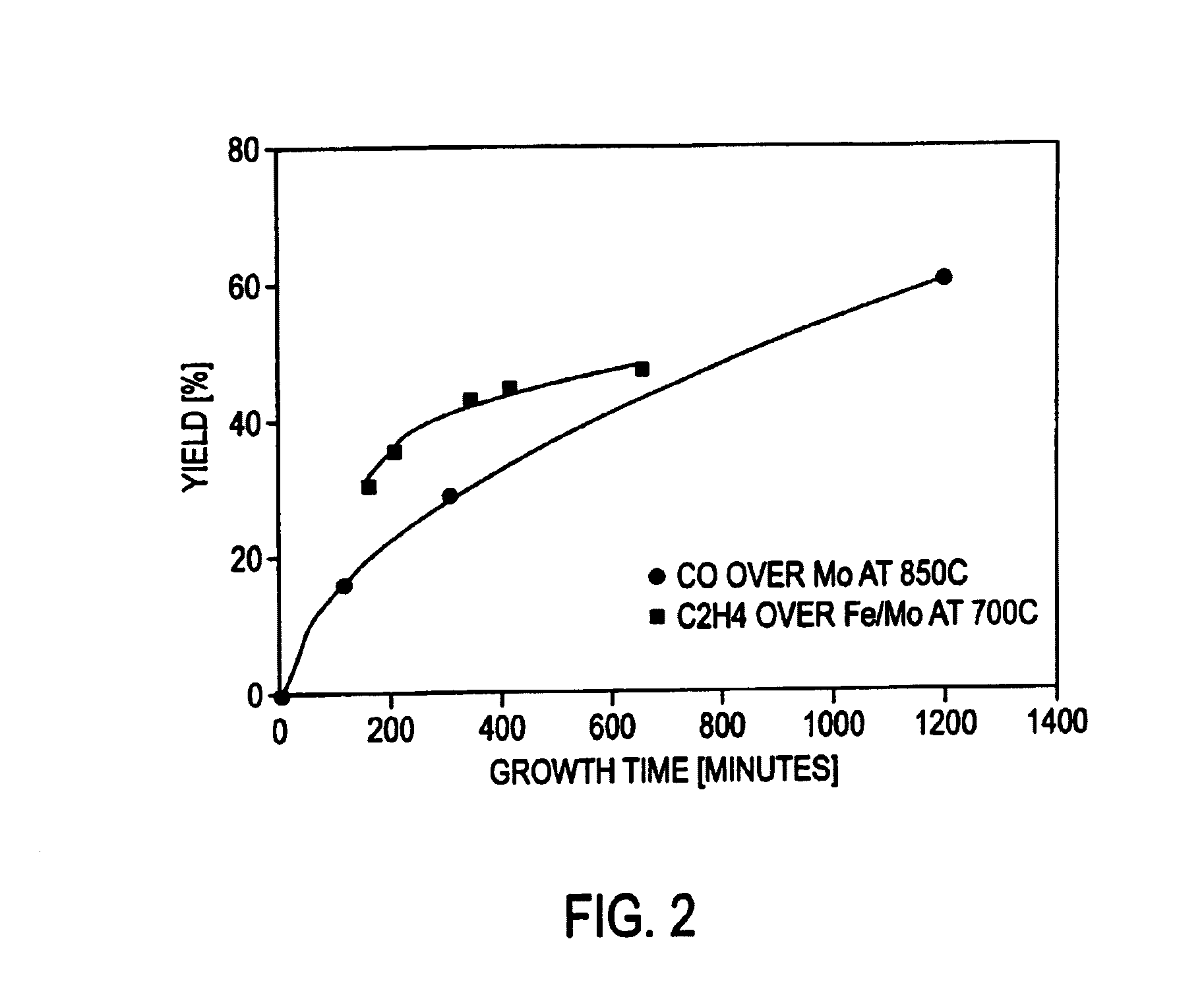

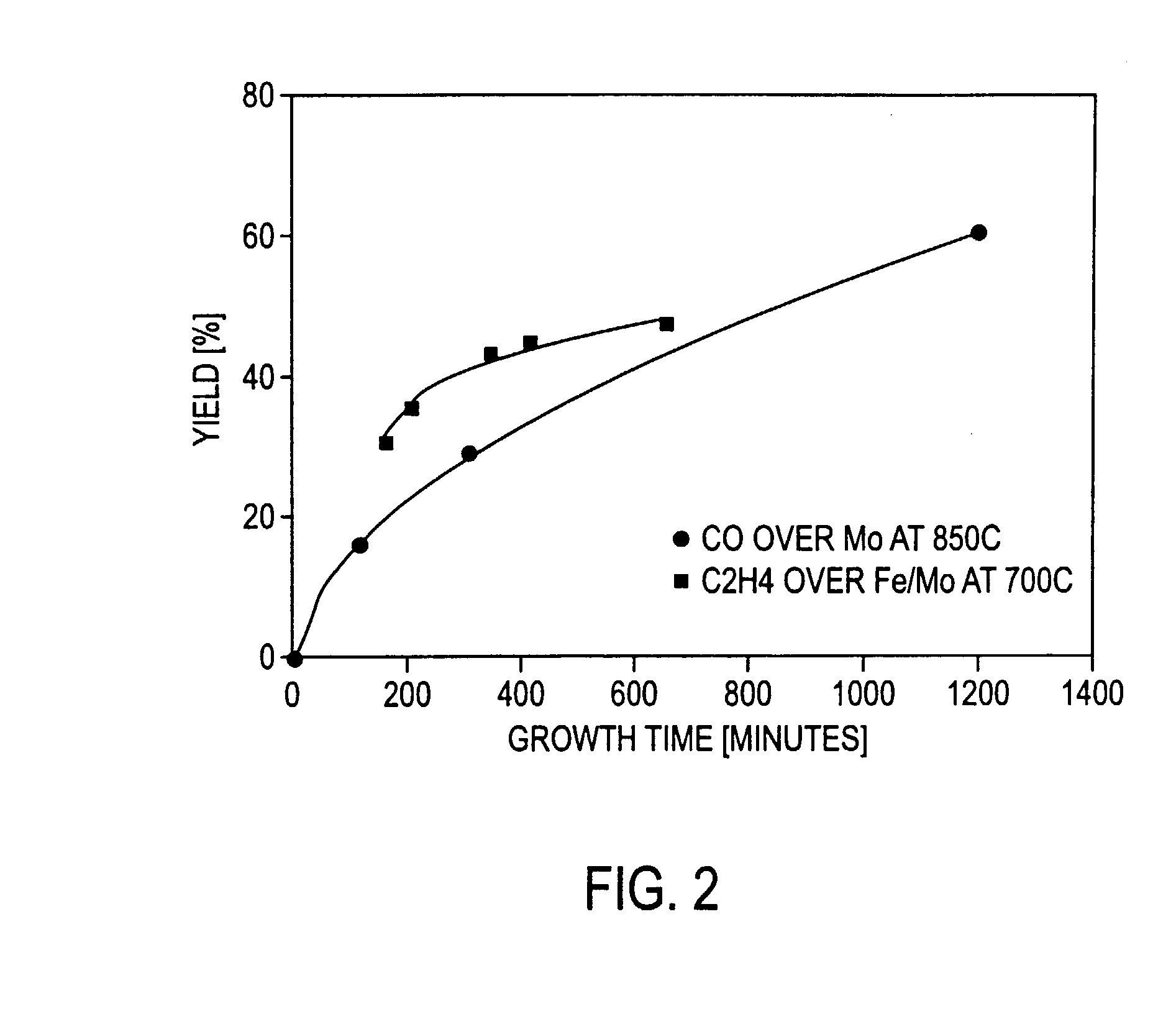

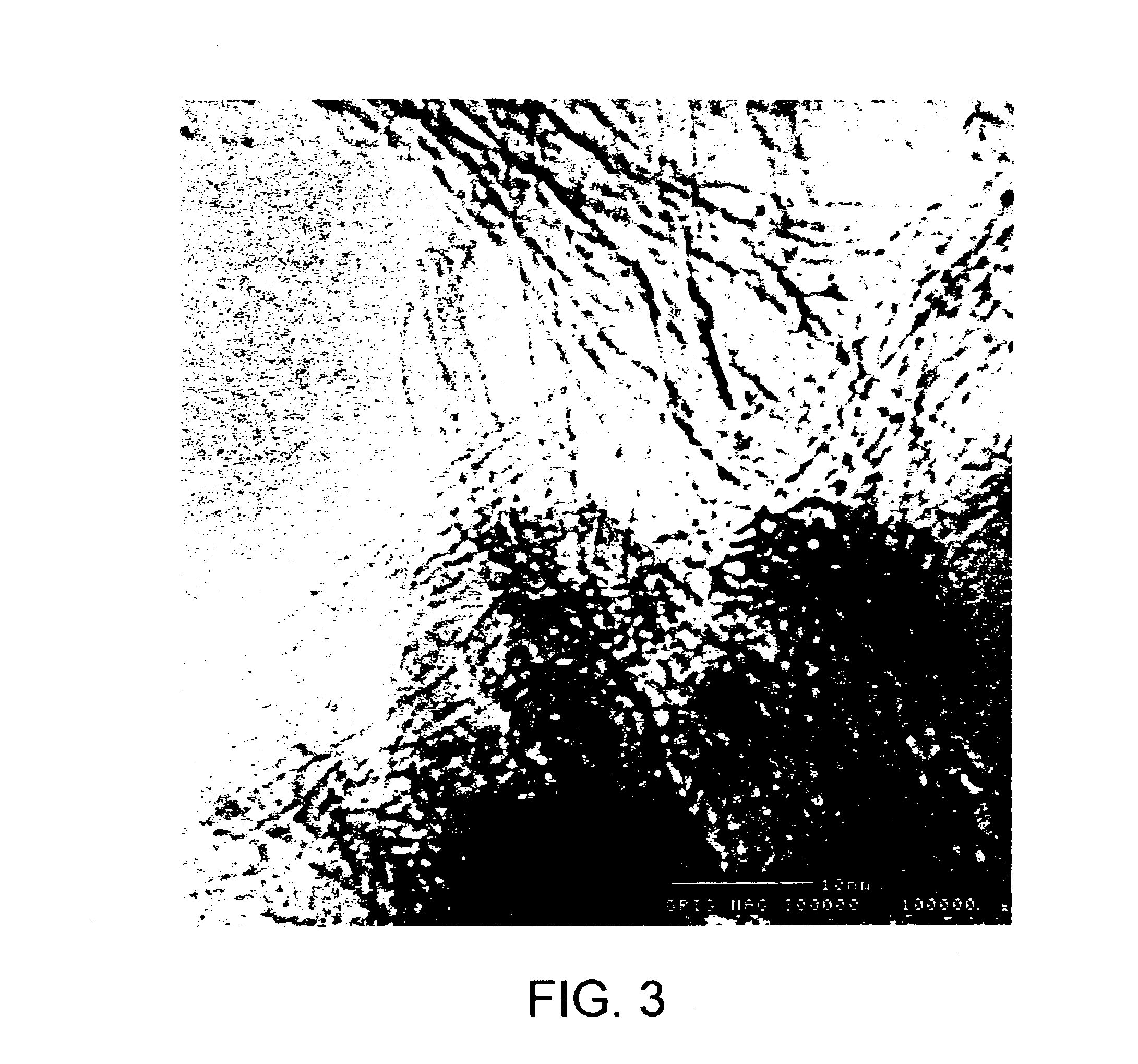

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst. The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

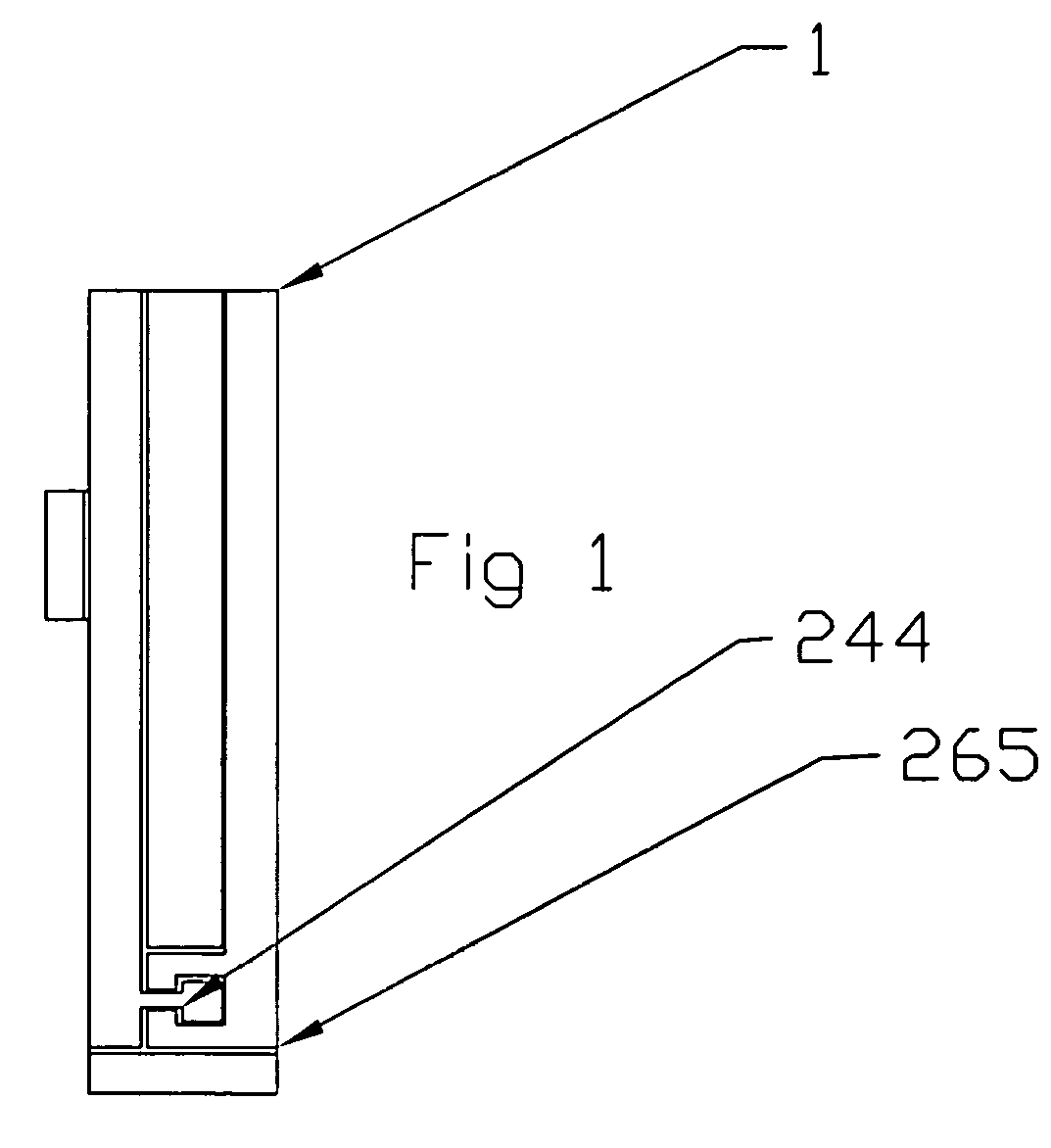

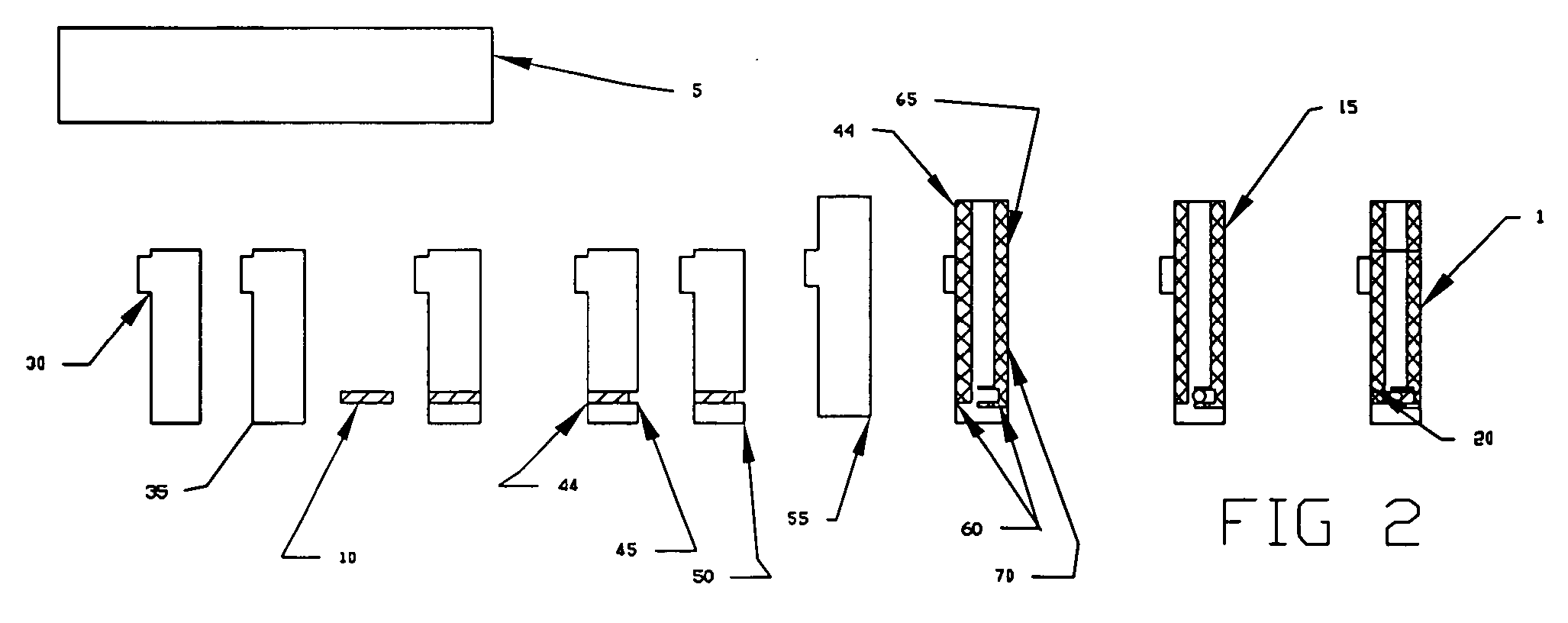

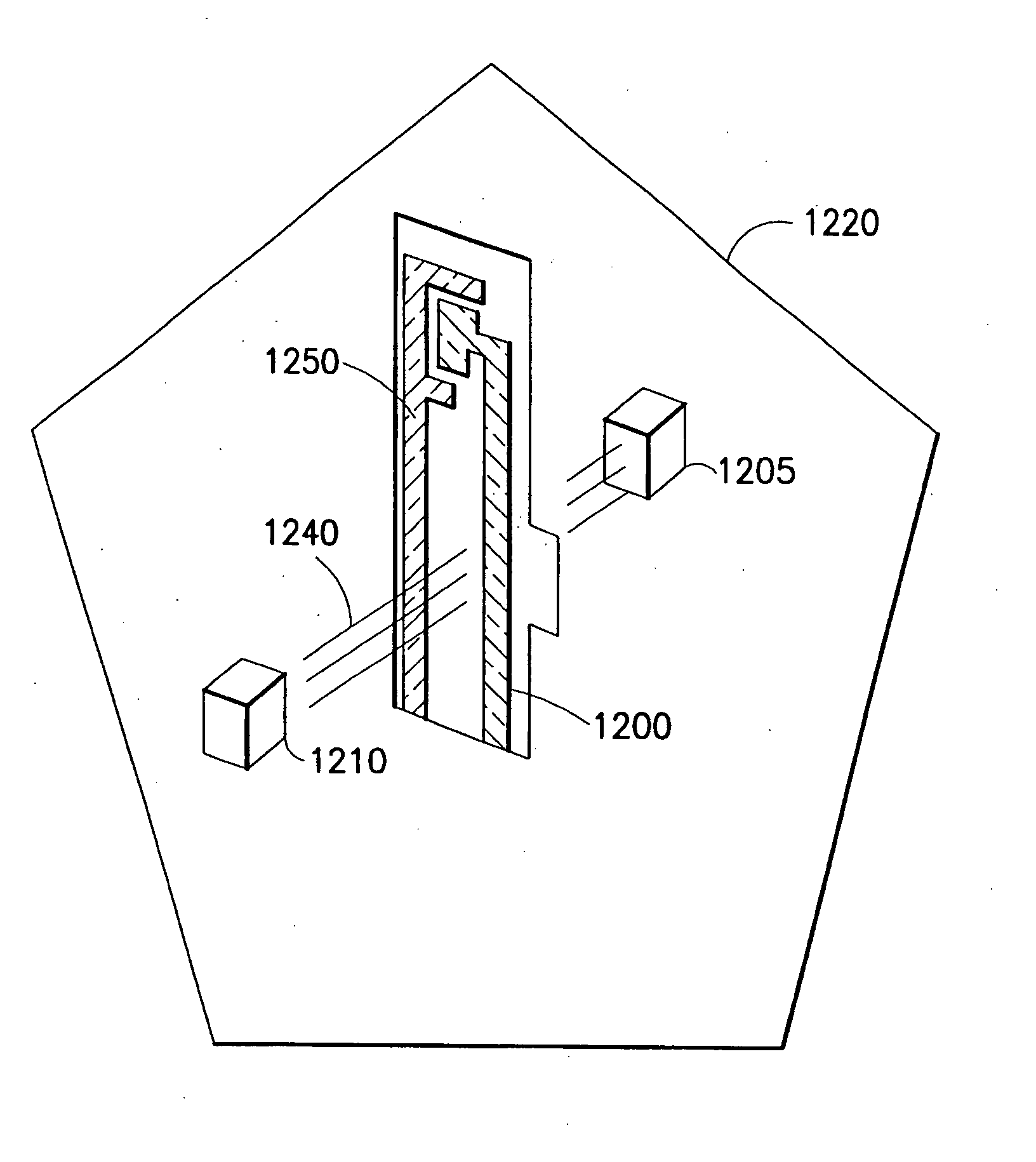

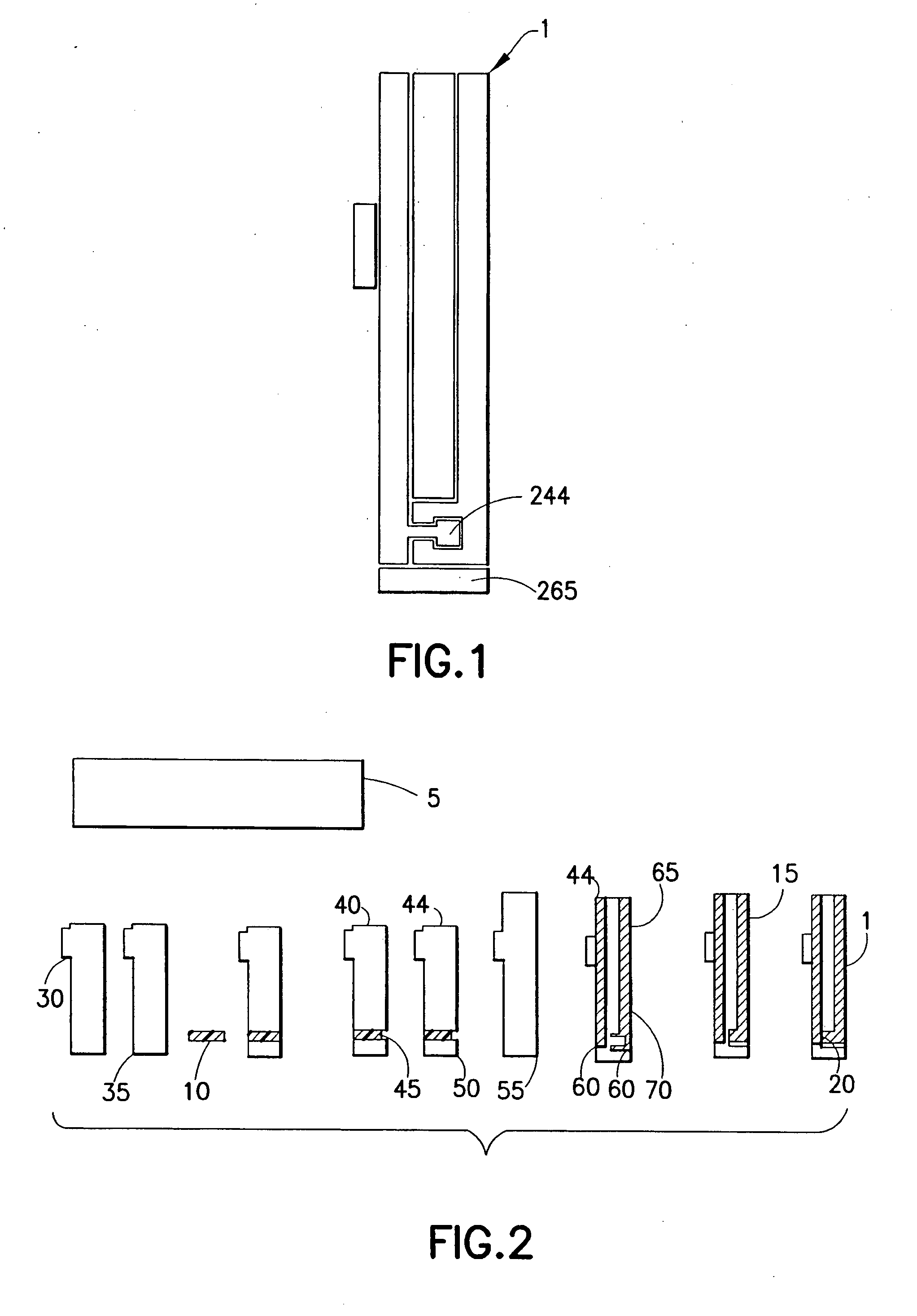

Strip electrode with conductive nano tube printing

InactiveUS20050186333A1Accurate electronic readoutMinimizing strip to strip variationImmobilised enzymesBioreactor/fermenter combinationsSilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-cloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:DOUGLAS JOEL S MR

Thermal interface

InactiveUS20020100581A1Semiconductor/solid-state device detailsNanoinformaticsFiberMulti-Walled Nanotube

A thermal interface includes nanofibrils. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of larger diameter fibers. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled nanotubes.

Owner:KULR TECH

Nanotube coatings for implantable electrodes

ActiveUS7162308B2Reduce polarizationIncrease surface areaSpinal electrodesMaterial nanotechnologyImplantable ElectrodesBoron nitride

Coatings for implantable electrodes consisting of single- or multi-walled nanotubes, nanotube ropes, carbon whiskers, and a combination of these are described. The nanotubes can be carbon or other conductive nanotube-forming materials such as a carbon-doped boron nitride. The nanotube coatings are grown “in situ” on a catalytic substrate surface from thermal decomposition, or they are bonded to the substrate using a metal or conductive metal oxide thin film binder deposited by means of a metal compound precursor in liquid form. In the latter case, the precursor / nanotube coating is then converted to a pure metal or conductive metal oxide, resulting in the desired surface coating with imbedded nanotubes.

Owner:WILSON GREATBATCH LTD

Flame retardant polymer composites and method of fabrication

InactiveUS20050049355A1Quality improvementImprove mechanical propertiesMaterial nanotechnologyFibre treatmentCarbon nanofiberGraphite

A flame retardant composite and a method for its fabrication are disclosed. The flame retardant composite shows both improved mechanical properties and flame retardancy. The composite comprises a matrix material and carbon nanotubes, such as single walled nanotubes, multi-walled nanotubes or fishbone-like graphitic cylinders, exhibiting a hollow core. For example, the outer diameters of the carbon nanofibers may be in the range from 1.2 to 500 nm. For example, a carbon nanotube may be incorporated as a layer in or on the surface of the composite. The method of fabrication of the composite may include a step of de-agglomeration.

Owner:C POLYMERS +1

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS20030175200A1Less pollutionNarrow size distributionMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

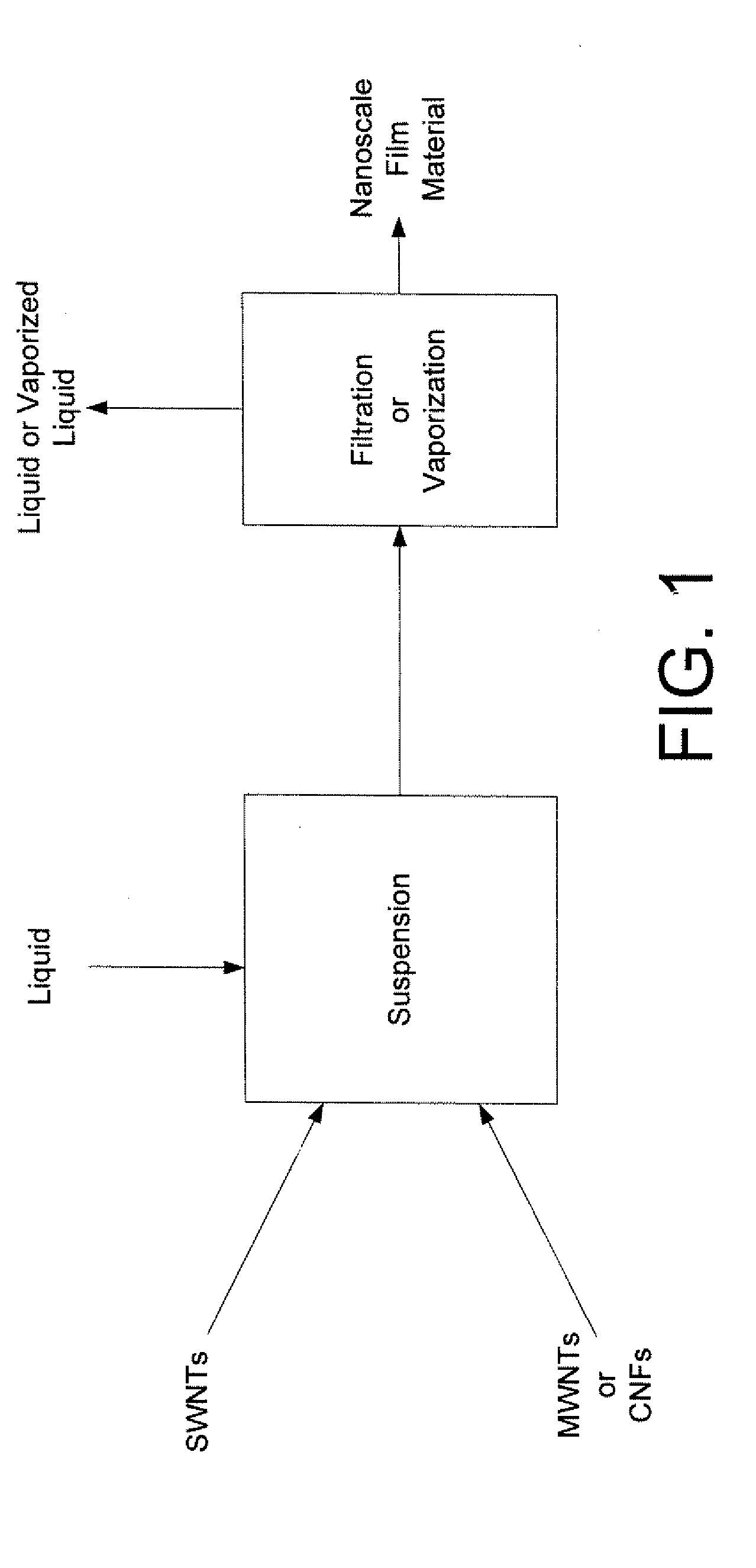

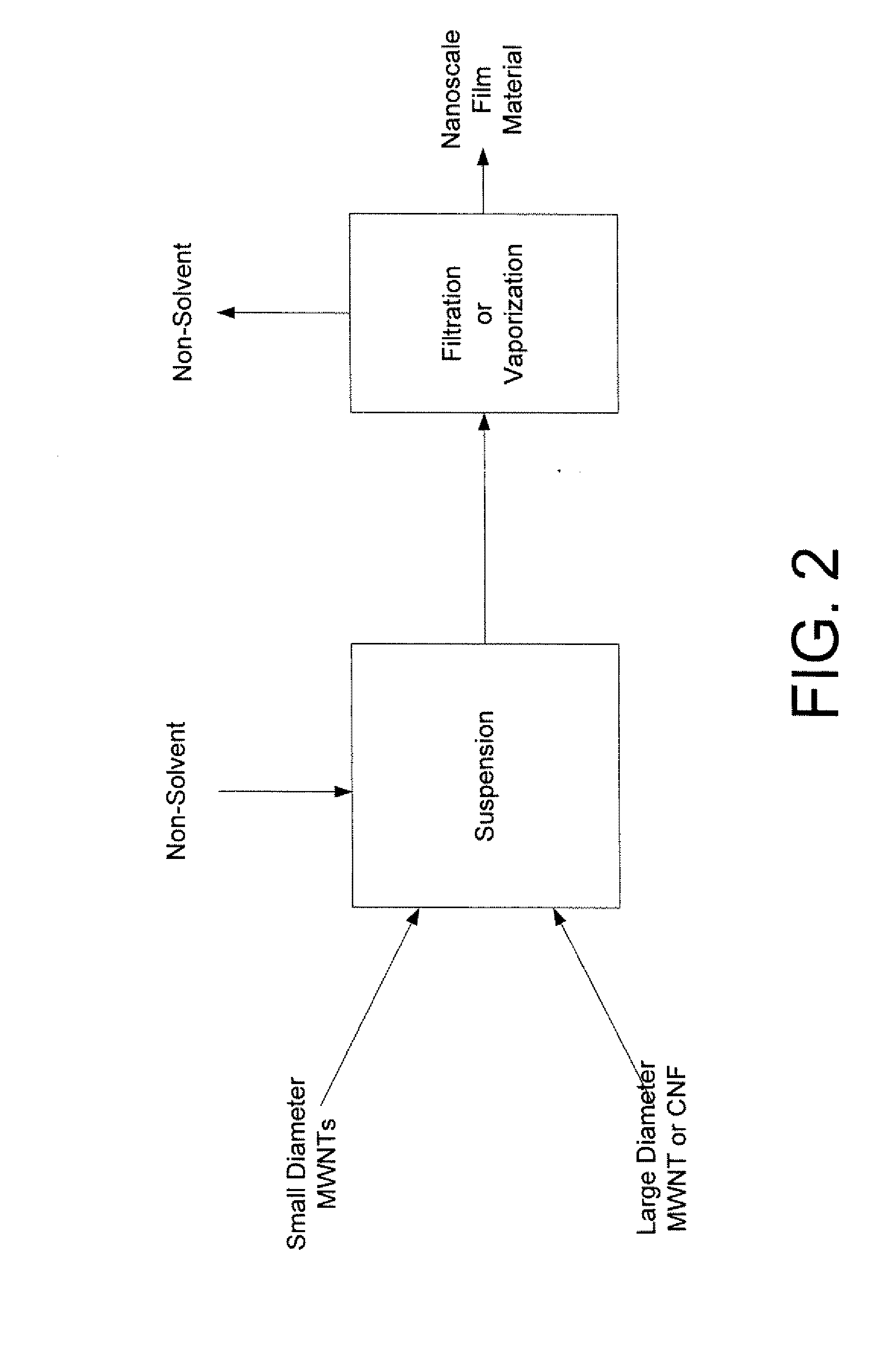

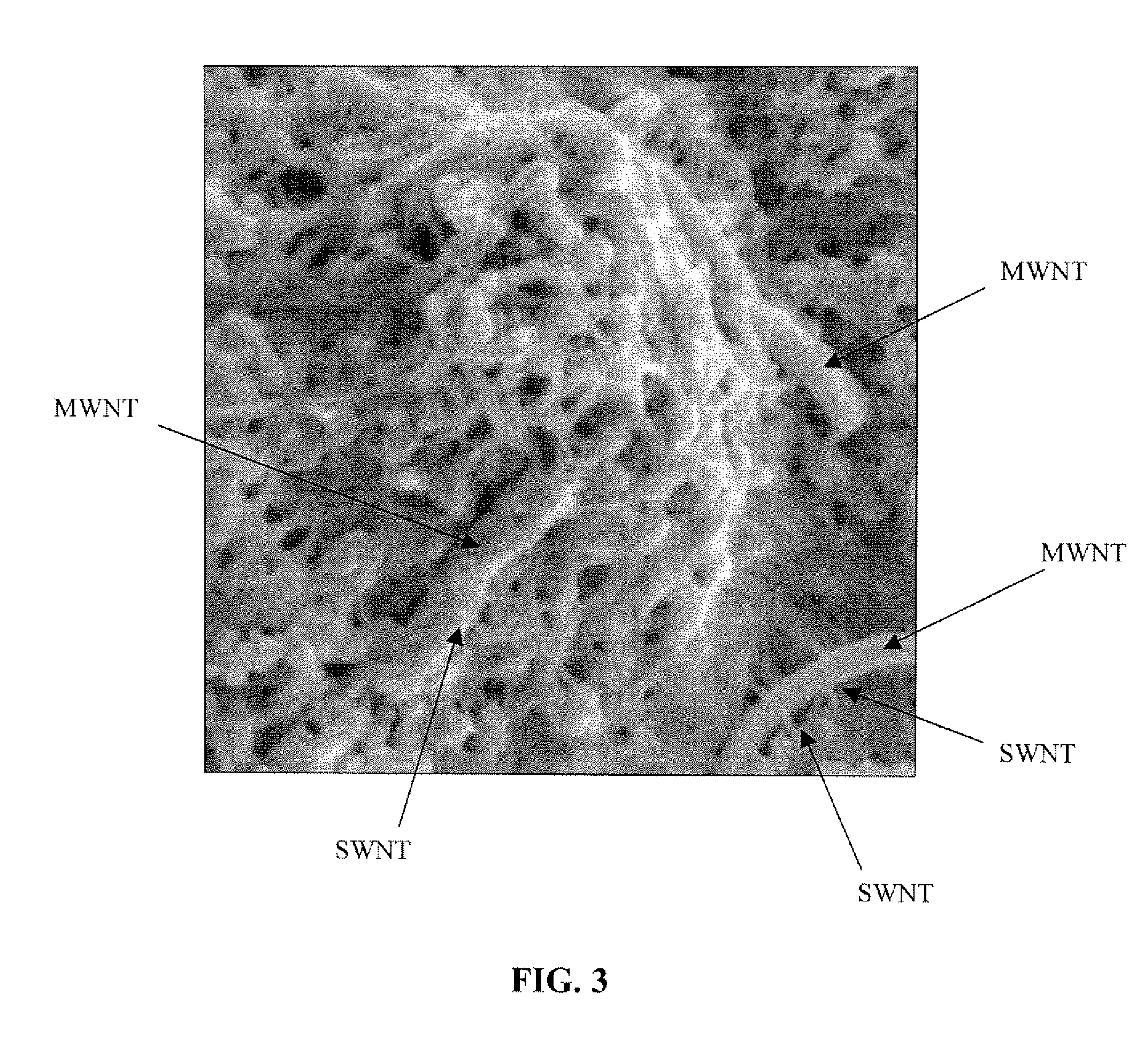

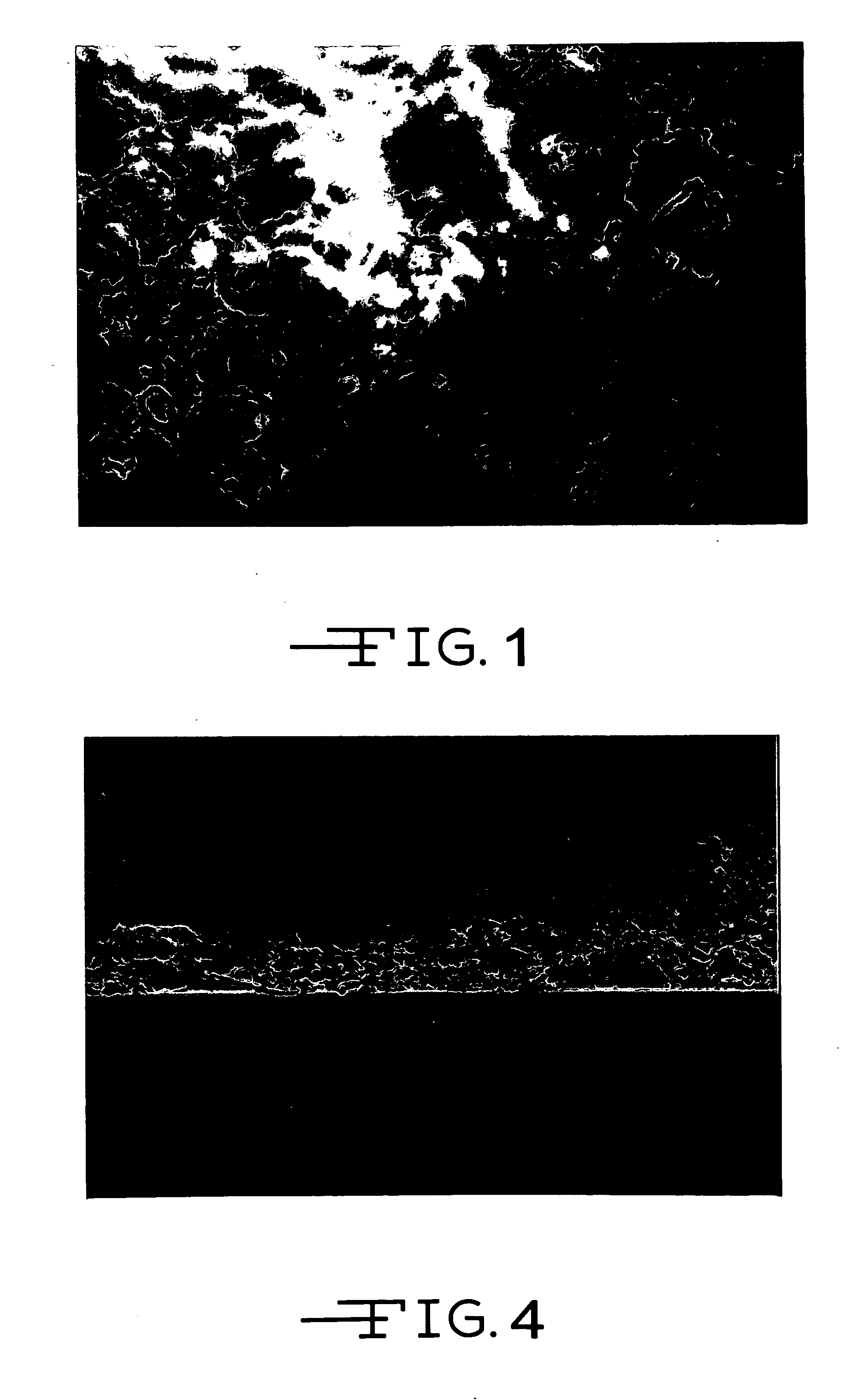

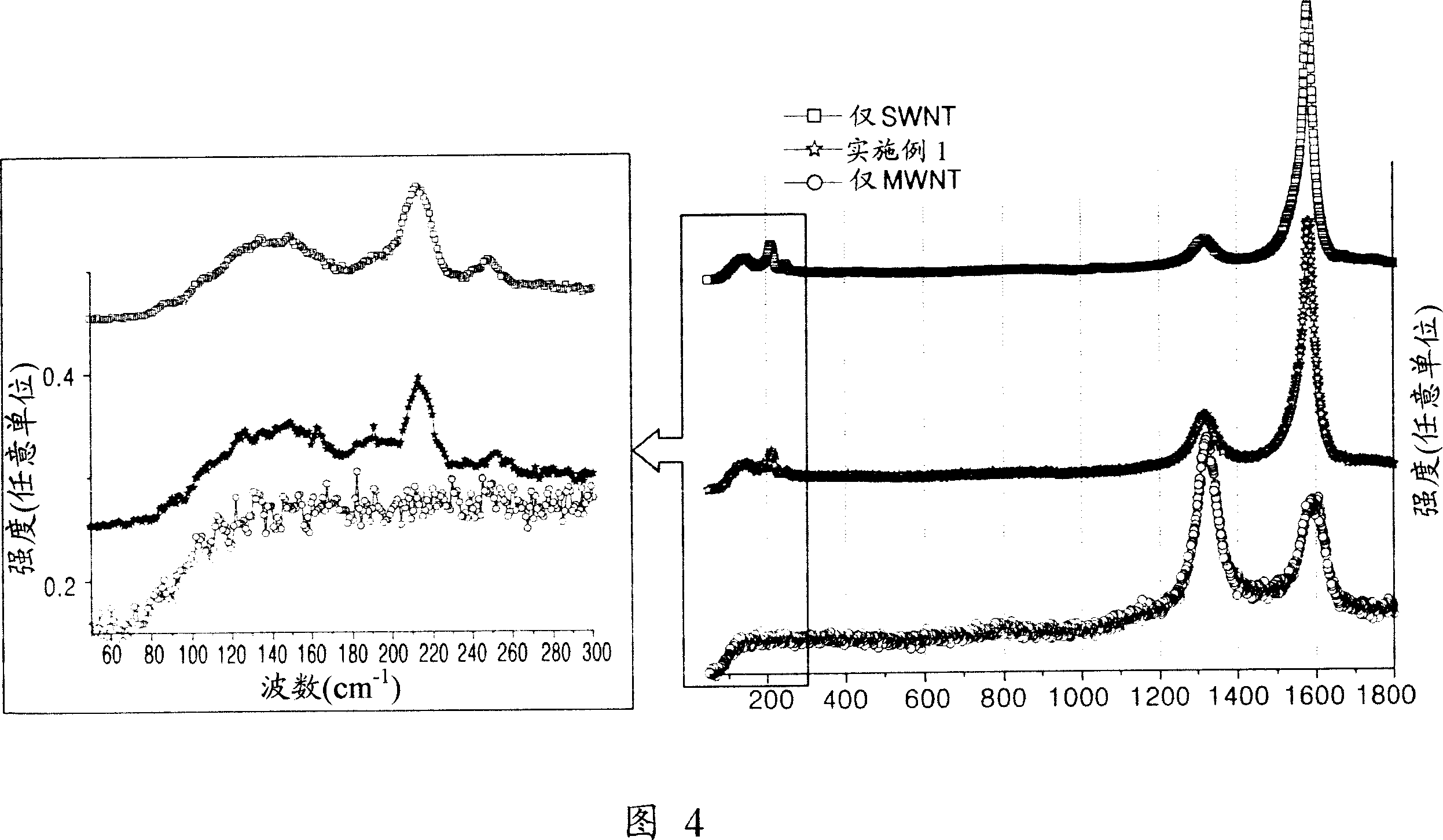

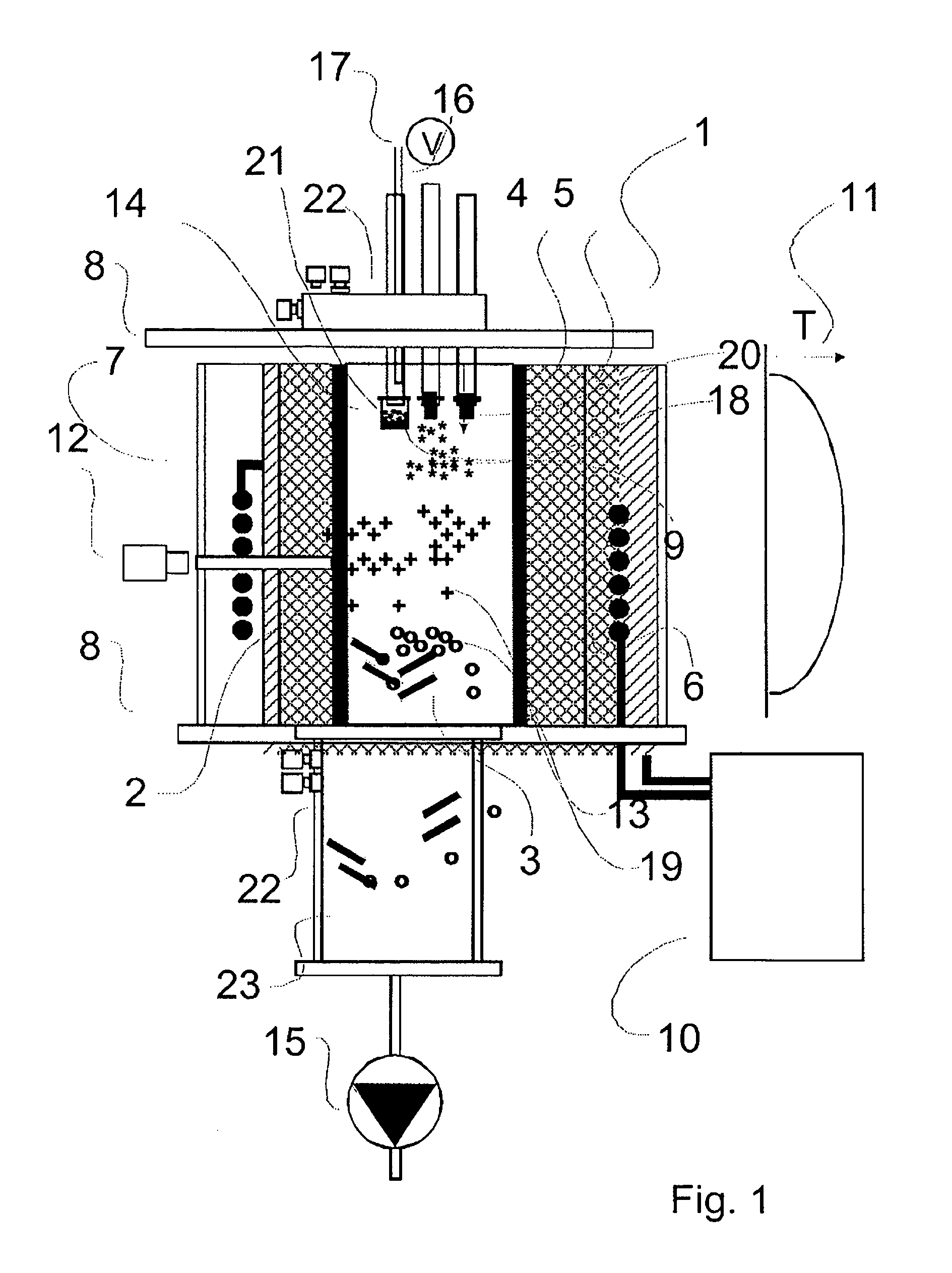

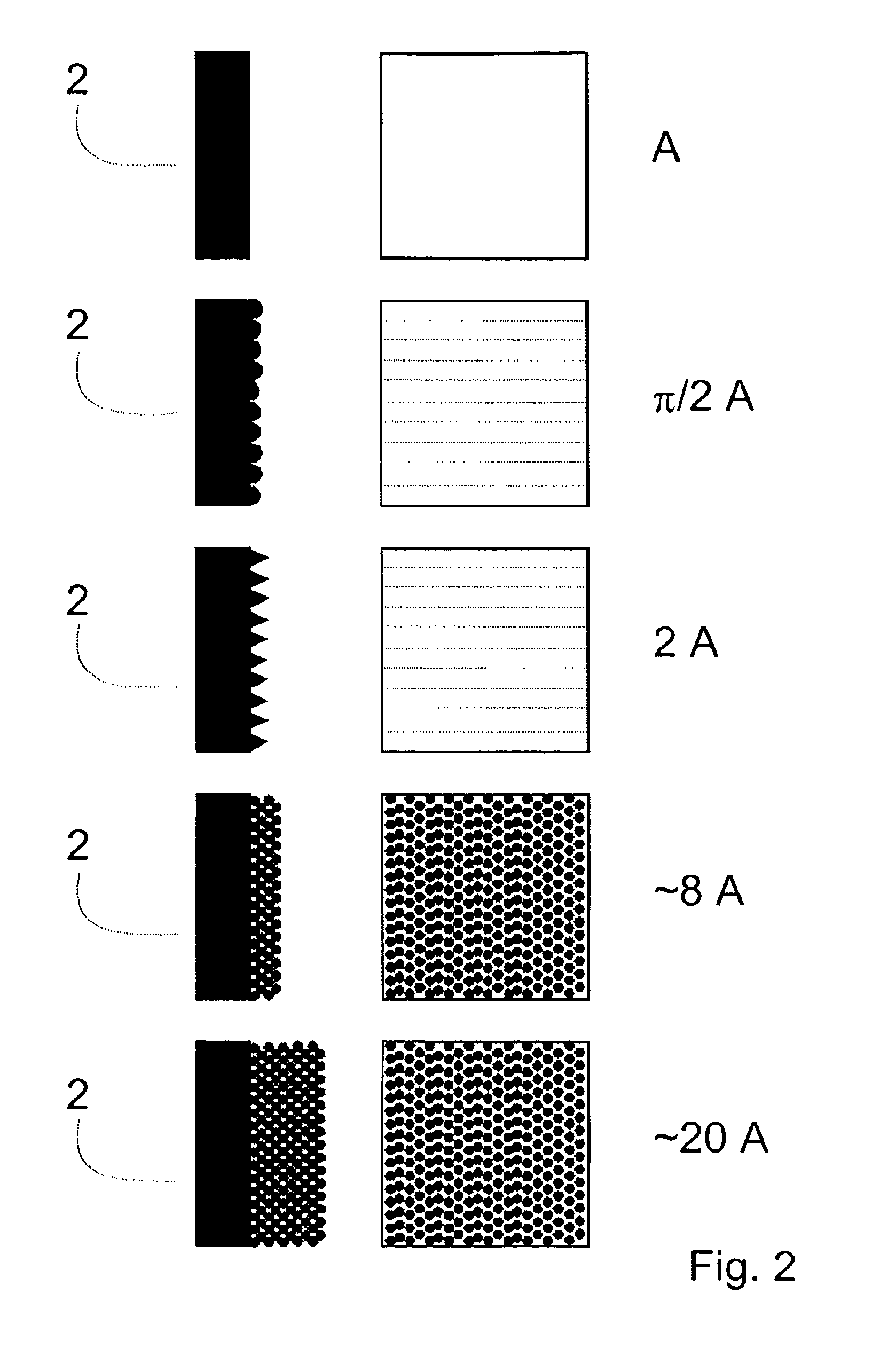

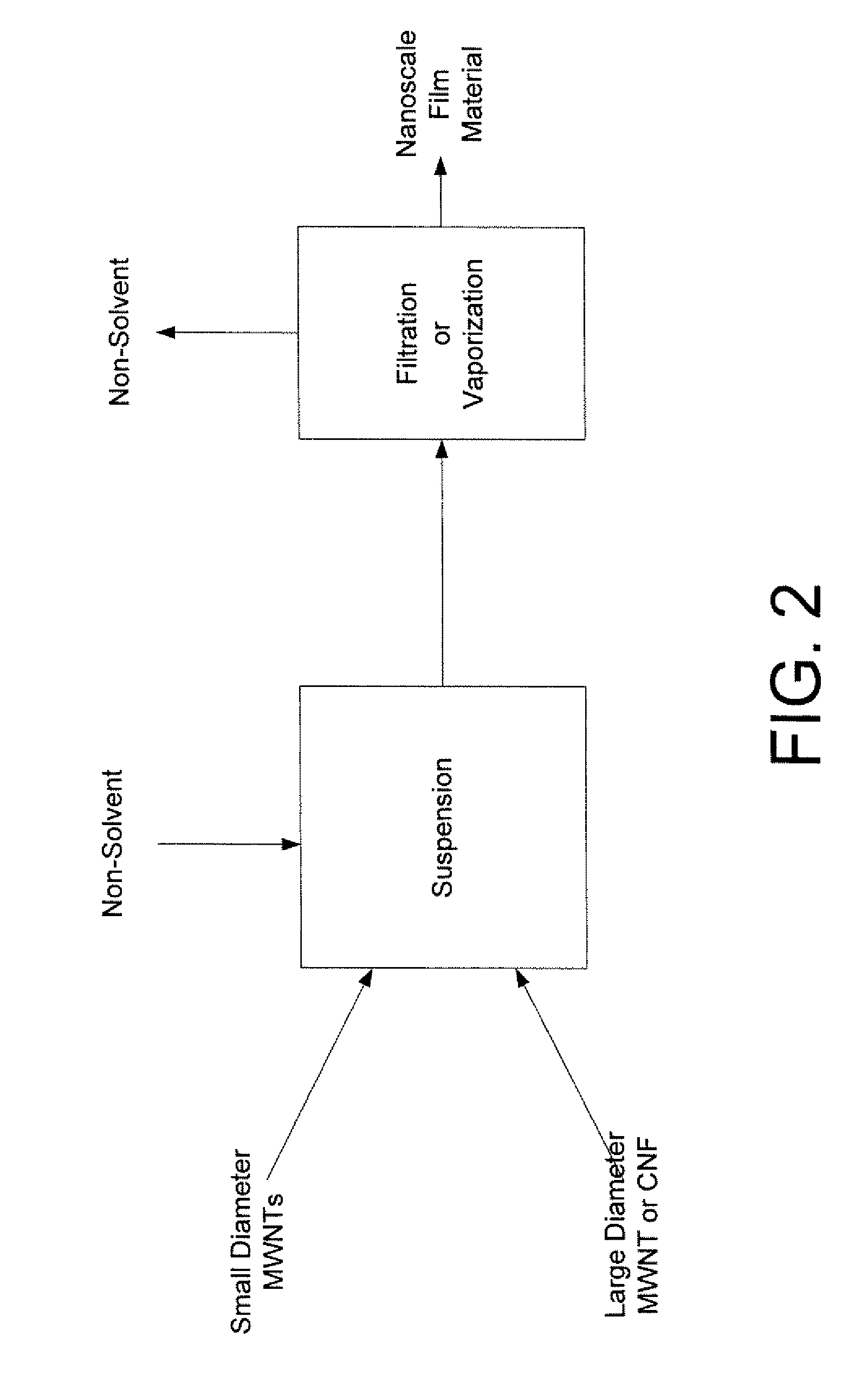

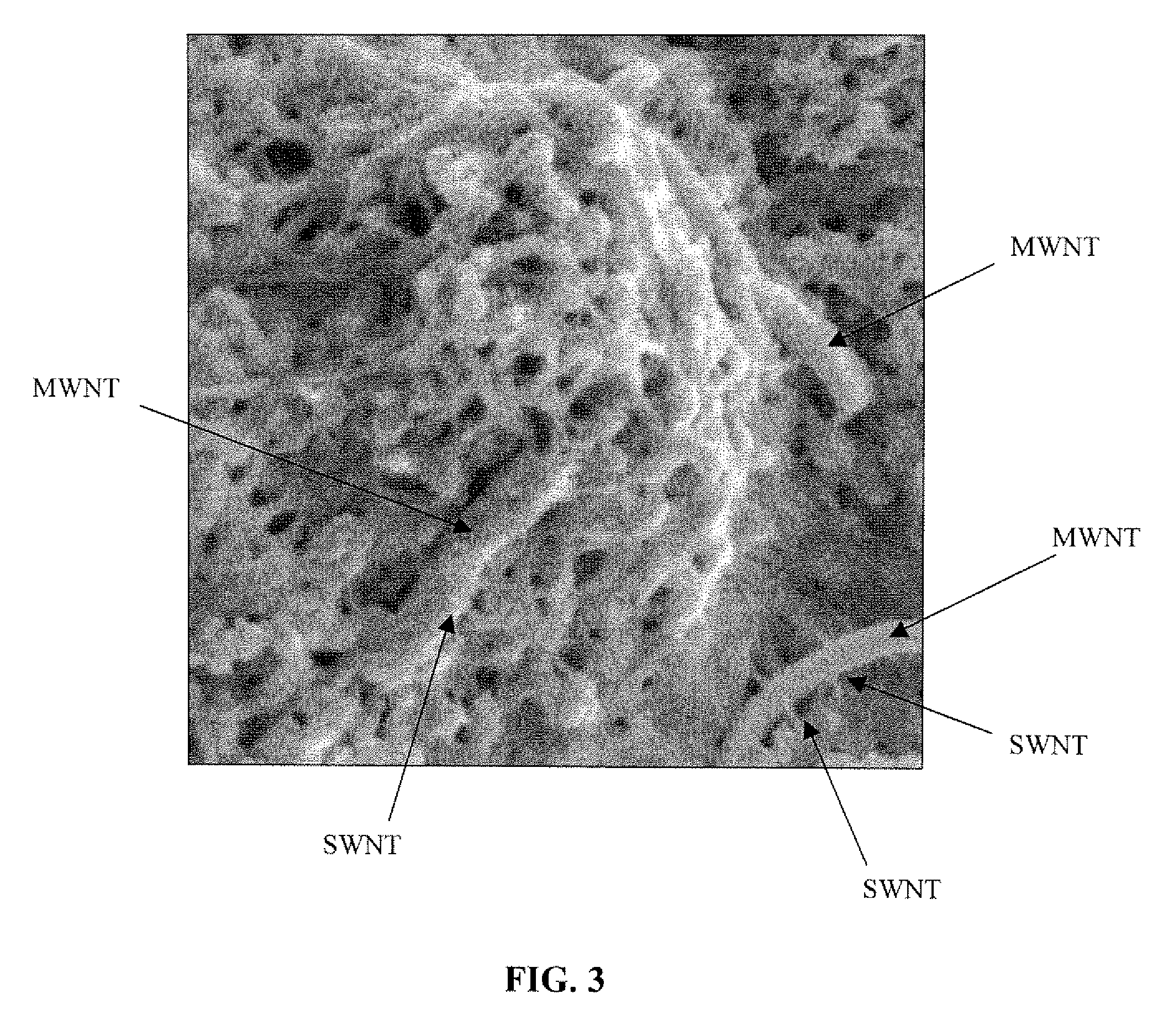

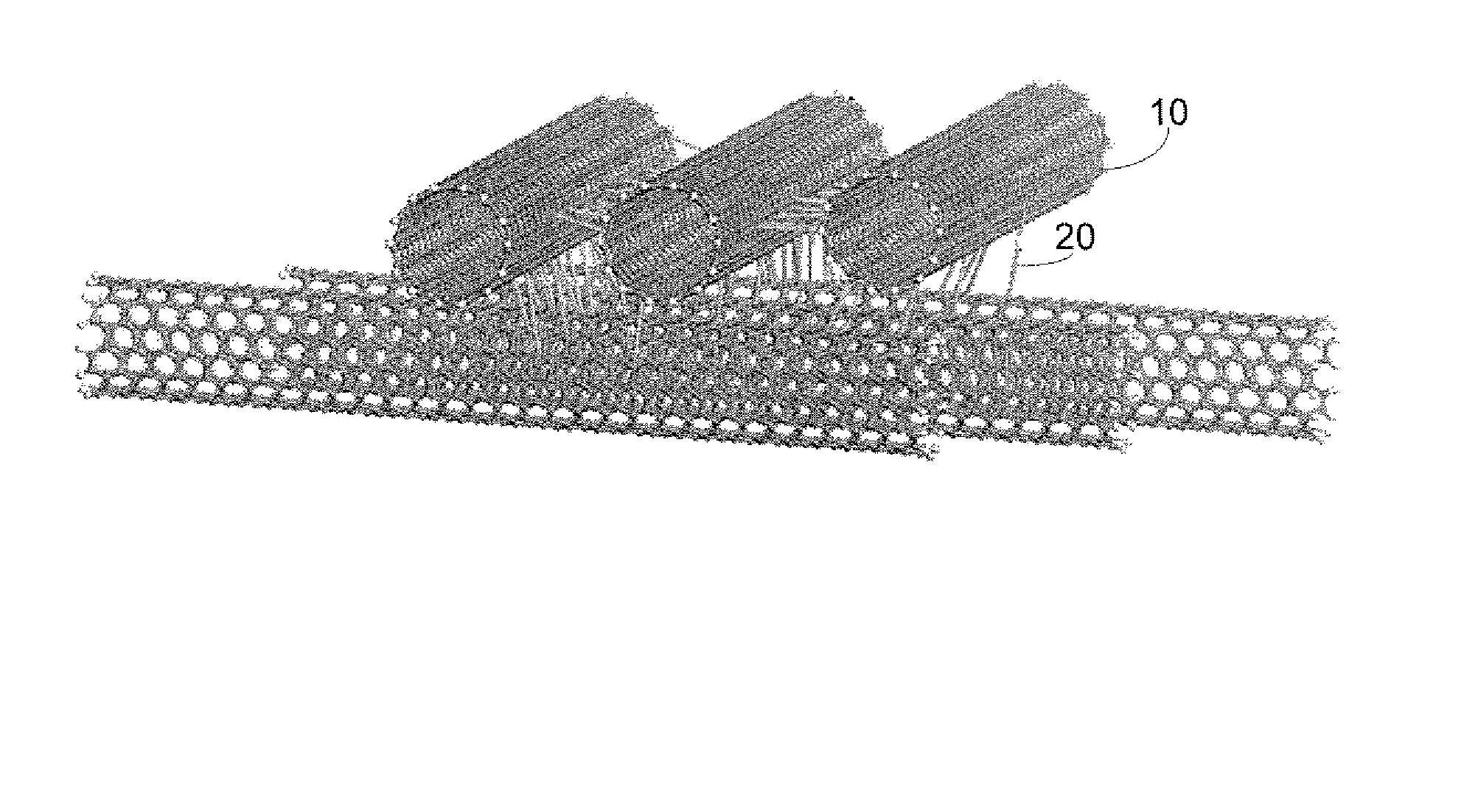

Method for fabricating macroscale films comprising multiple-walled nanotubes

A technique is provided for the fabrication of multi-walled carbon nanotube (MWNT) and carbon nanofiber (CNF) film materials. The method includes mixing a relatively small amount of single-walled nanotubes (SWNTs) with larger amounts of MWNTs and CNFs, which enables one to produce highly flexible SWNT materials—advantageously without the need for bonding agents and at significantly lower costs compared to flexible SWNT materials. The method exploits SWNTs tendency to entangle together to form flexible films, using a small amount of SWNTs to wrap around and entangle the larger diameter MWNTs and CNFs together to form flexible films with highly beneficial mechanical, electrical, and thermal properties at a fraction of the cost of SWNT materials.

Owner:FLORIDA STATE UNIV RES FOUND INC

Nanotube coatings for implantable electrodes

ActiveUS20050075708A1Reduce polarizationIncrease surface areaSpinal electrodesMaterial nanotechnologyImplantable ElectrodesBoron nitride

Coatings for implantable electrodes consisting of single- or multi-walled nanotubes, nanotube ropes, carbon whiskers, and a combination of these are described. The nanotubes can be carbon or other conductive nanotube-forming materials such as a carbon-doped boron nitride. The nanotube coatings are grown “in situ” on a catalytic substrate surface from thermal decomposition, or they are bonded to the substrate using a metal or conductive metal oxide thin film binder deposited by means of a metal compound precursor in liquid form. In the latter case, the precursor / nanotube coating is then converted to a pure metal or conductive metal oxide, resulting in the desired surface coating with imbedded nanotubes.

Owner:WILSON GREATBATCH LTD

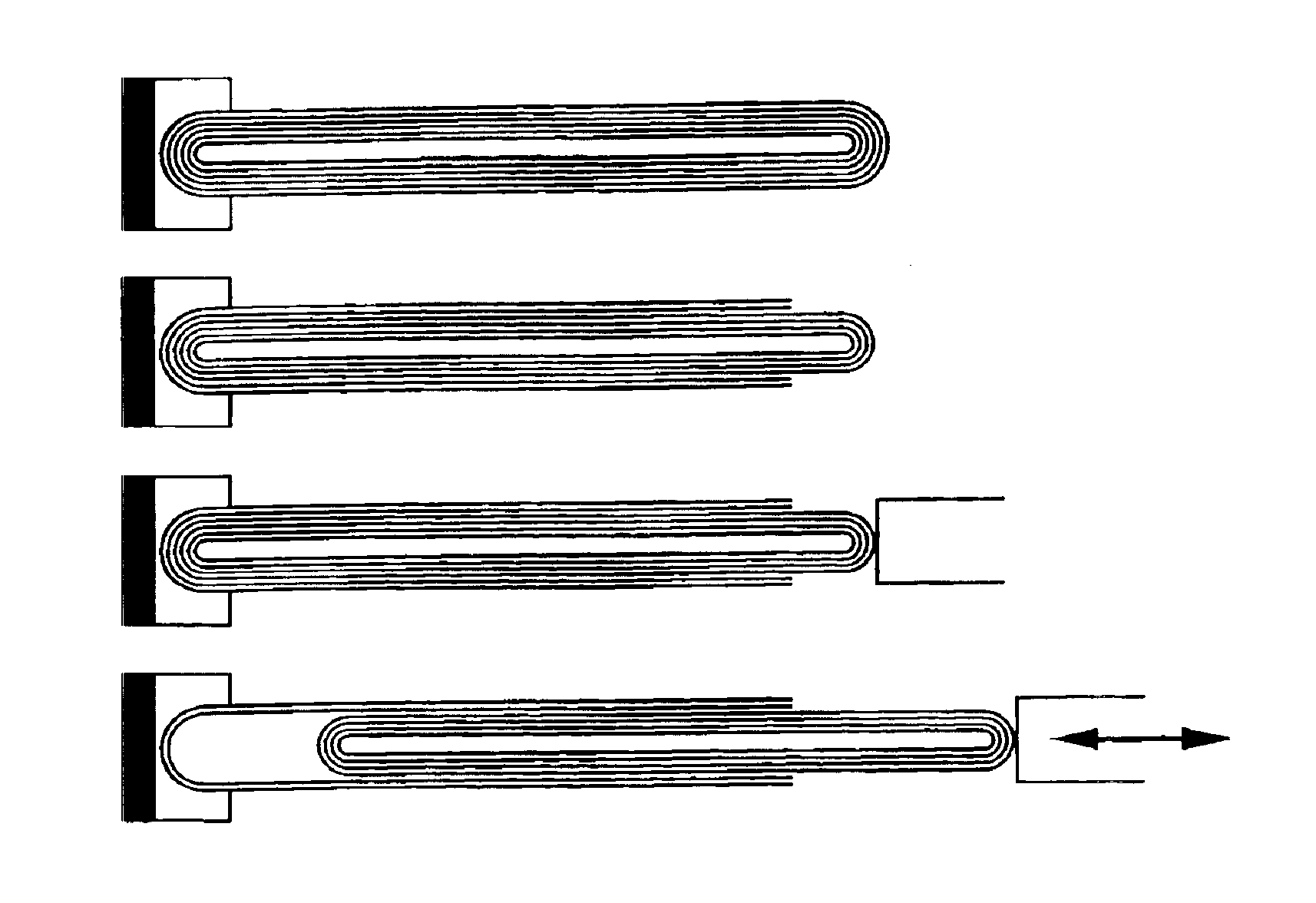

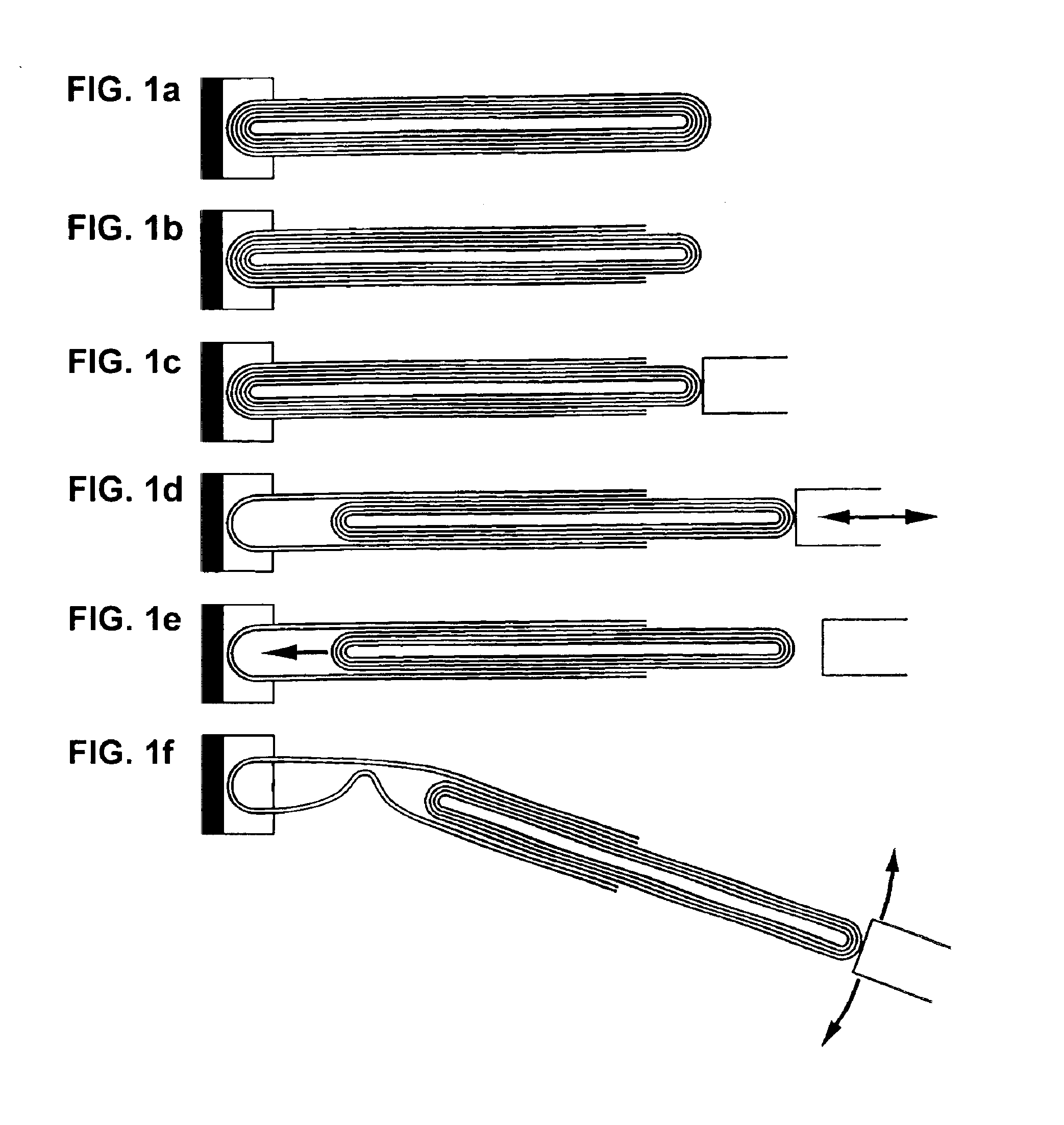

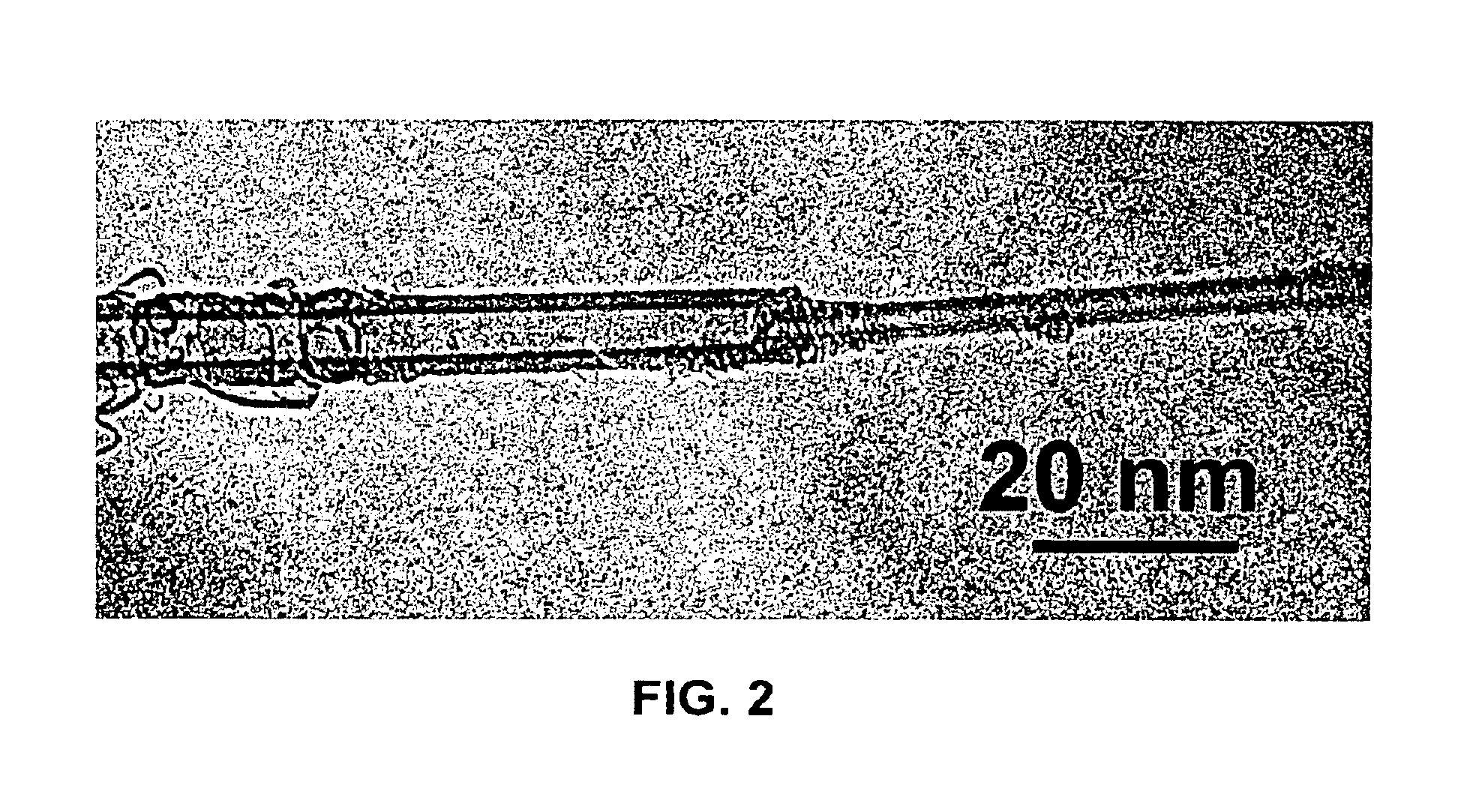

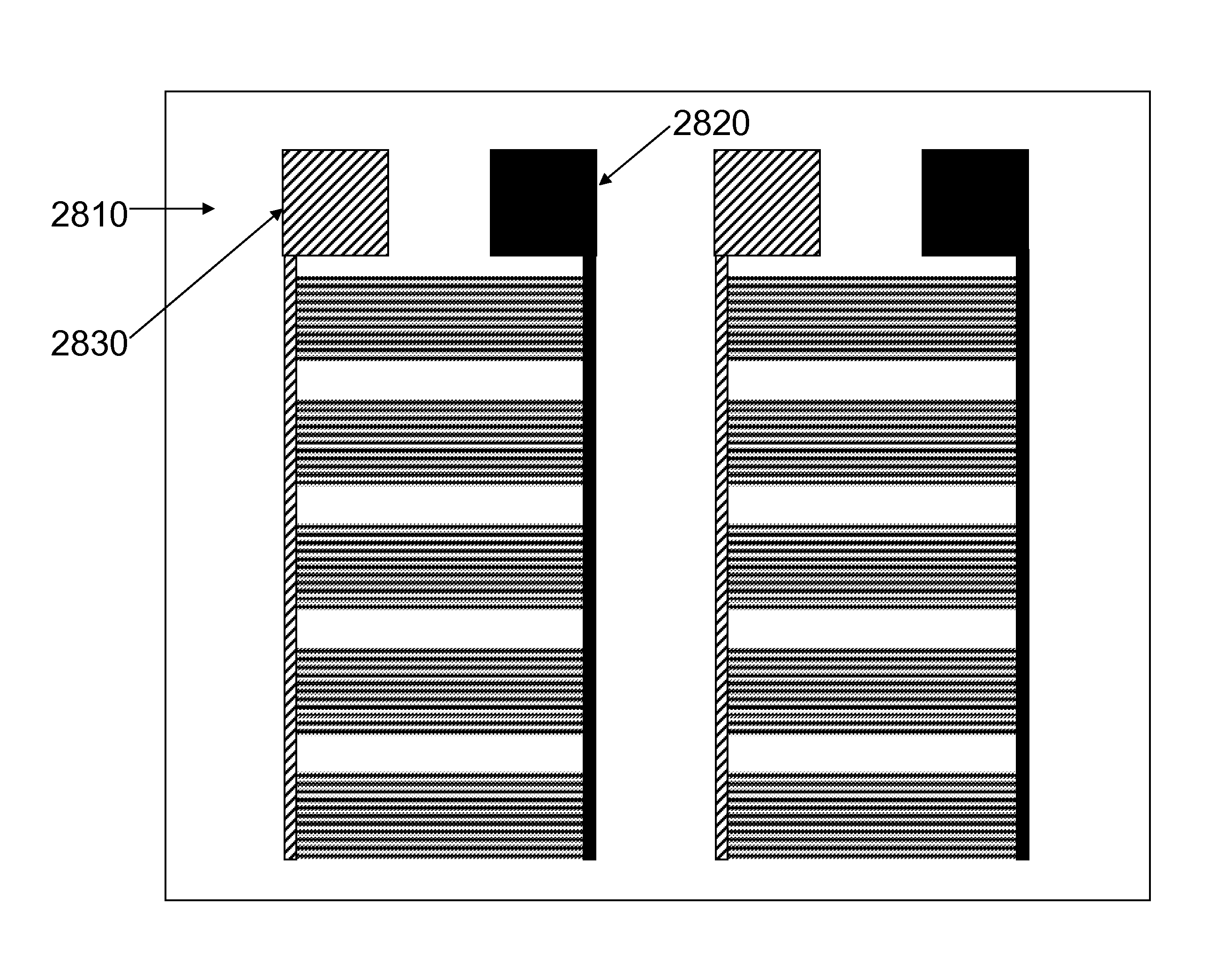

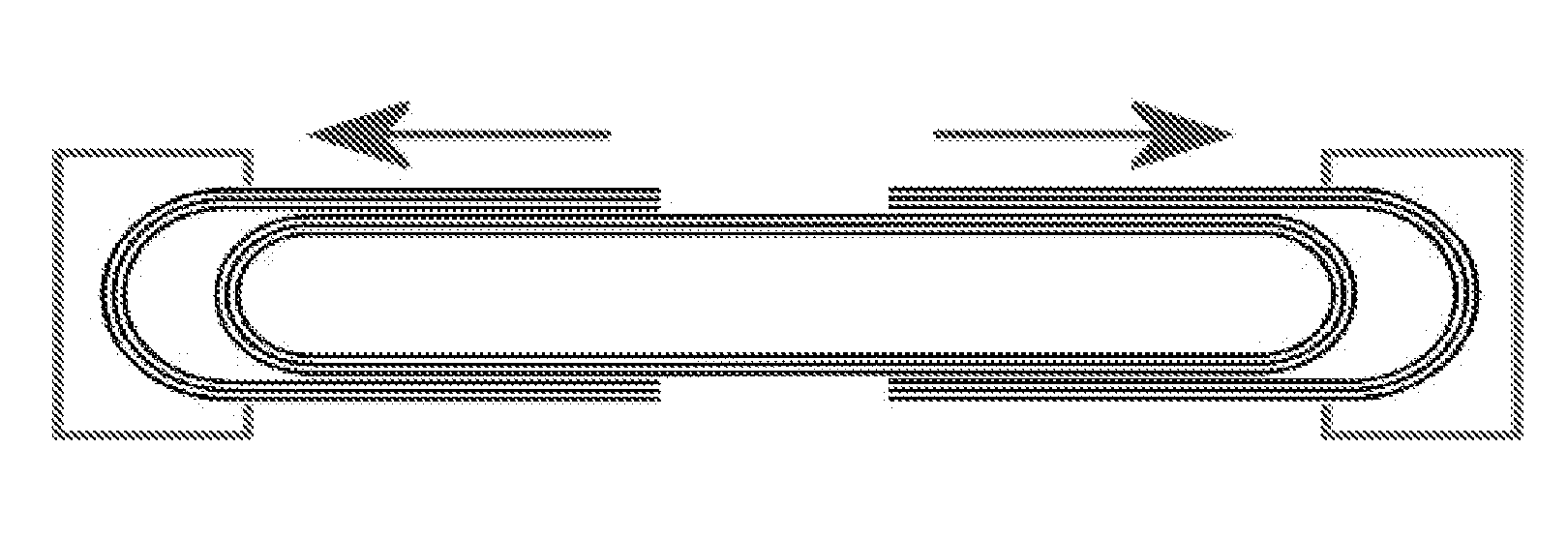

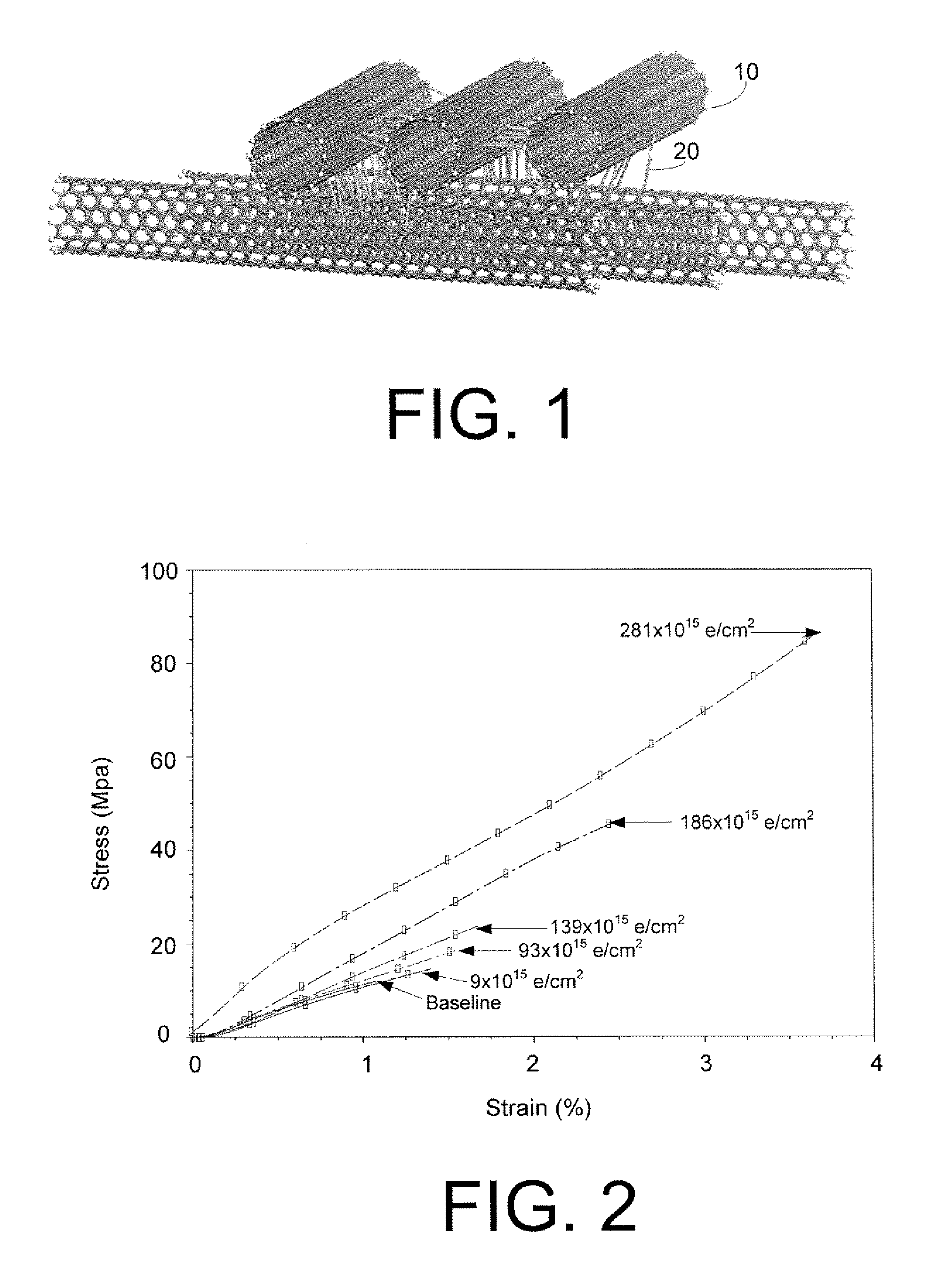

Telescoped multiwall nanotube and manufacture thereof

InactiveUS6874668B2Overcome disadvantagesMaterial nanotechnologyNitrogen compoundsNanomanipulatorConstant force

The invention relates to a method for forming a telescoped multiwall nanotube. Such a telescoped multiwall nanotube may find use as a linear or rotational bearing in microelectromechanical systems or may find use as a constant force nanospring. In the method of the invention, a multiwall nanotube is affixed to a solid, conducting substrate at one end. The tip of the free end of the multiwall nanotube is then removed, revealing the intact end of the inner wall. A nanomanipulator is then attached to the intact end, and the intact, core segments of the multiwall nanotube are partially extracted, thereby telescoping out a segment of nanotube.

Owner:RGT UNIV OF CALIFORNIA

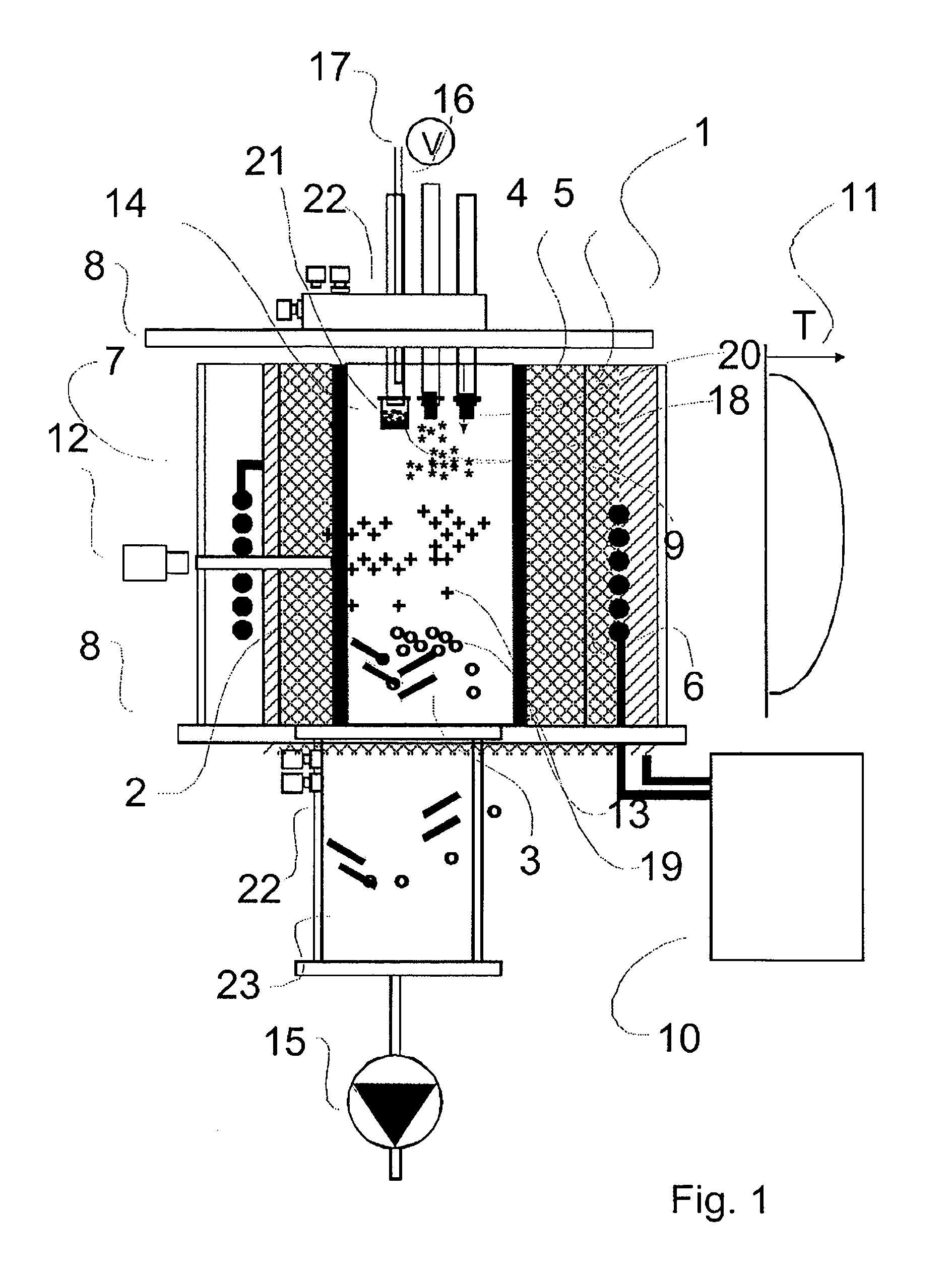

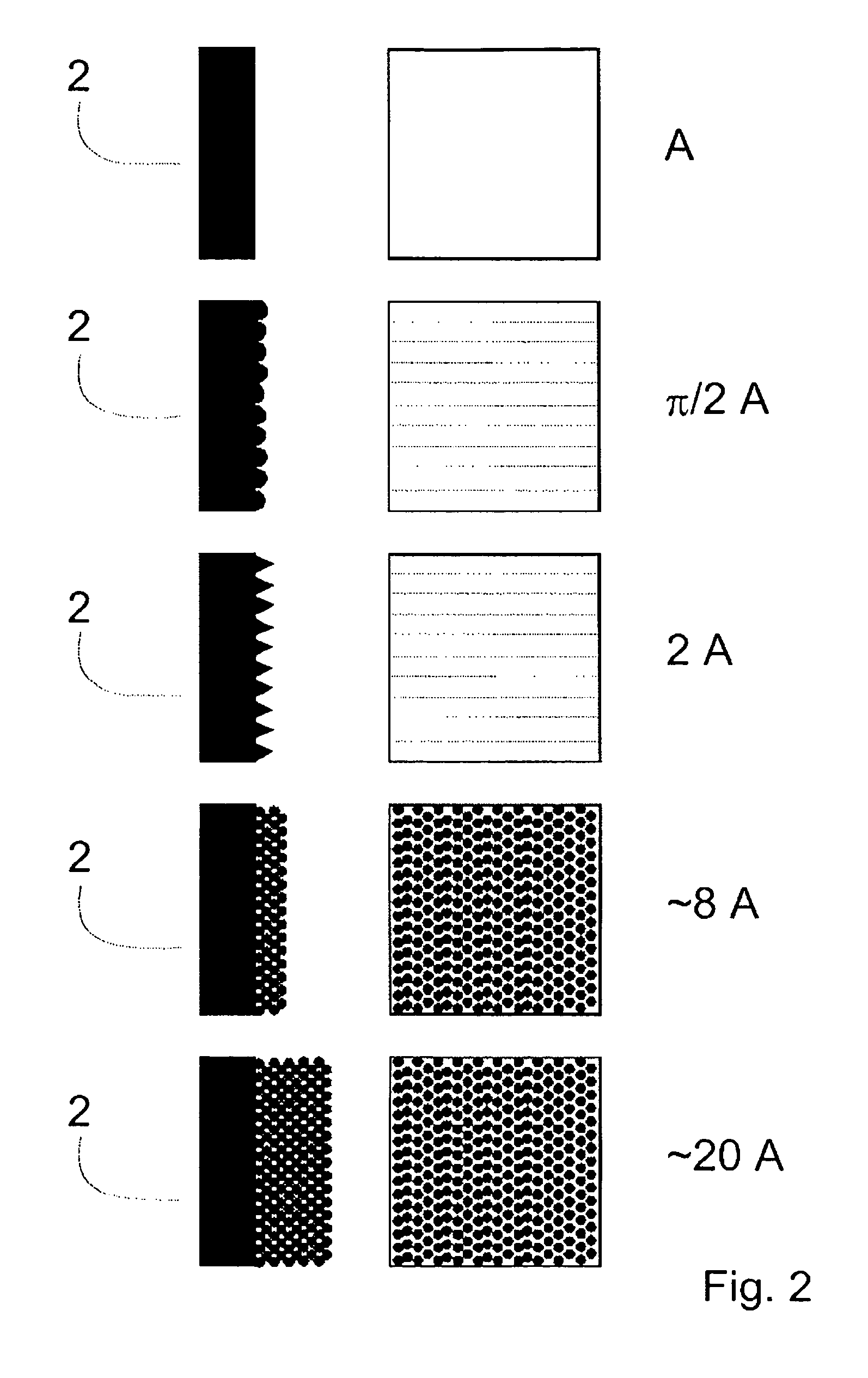

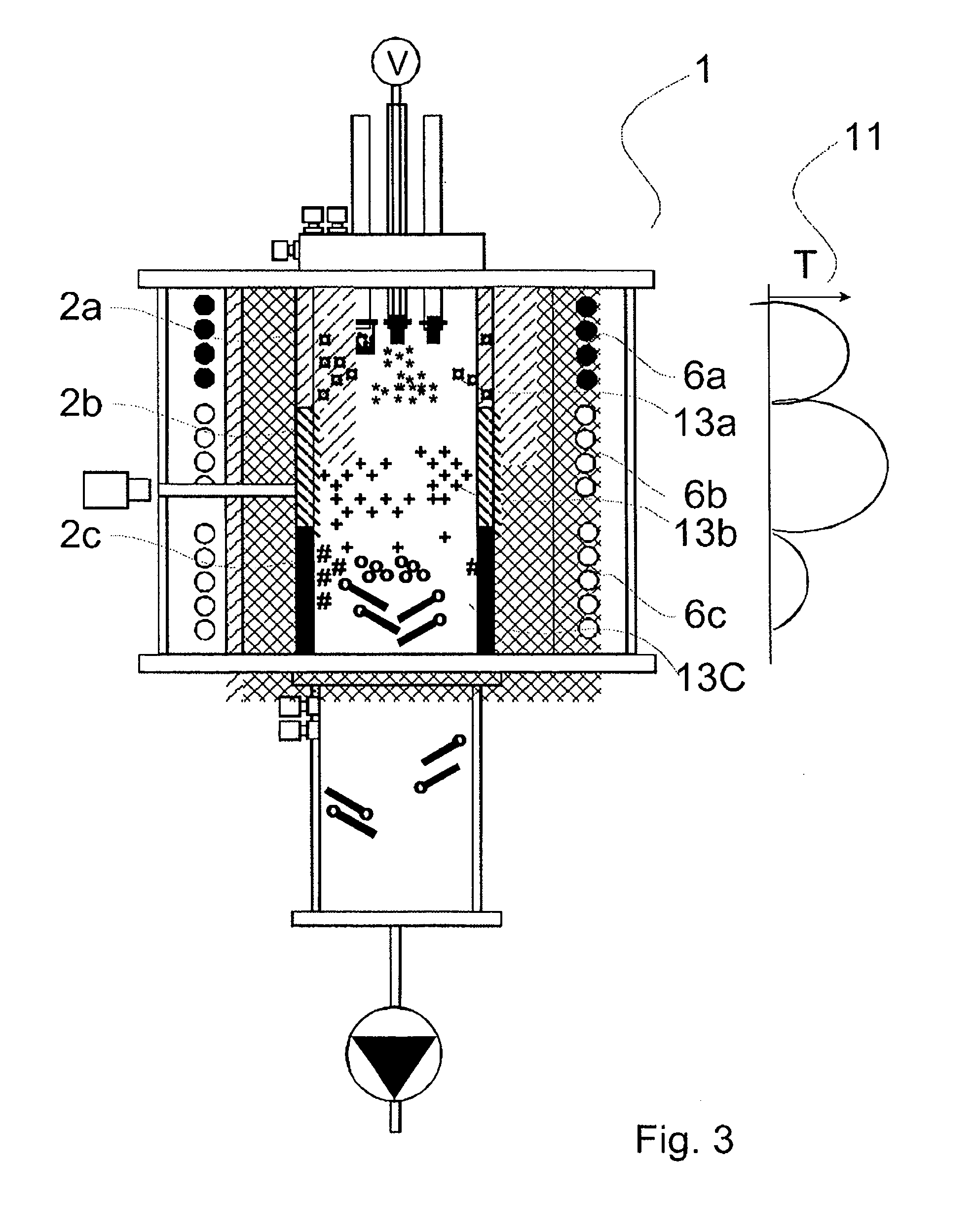

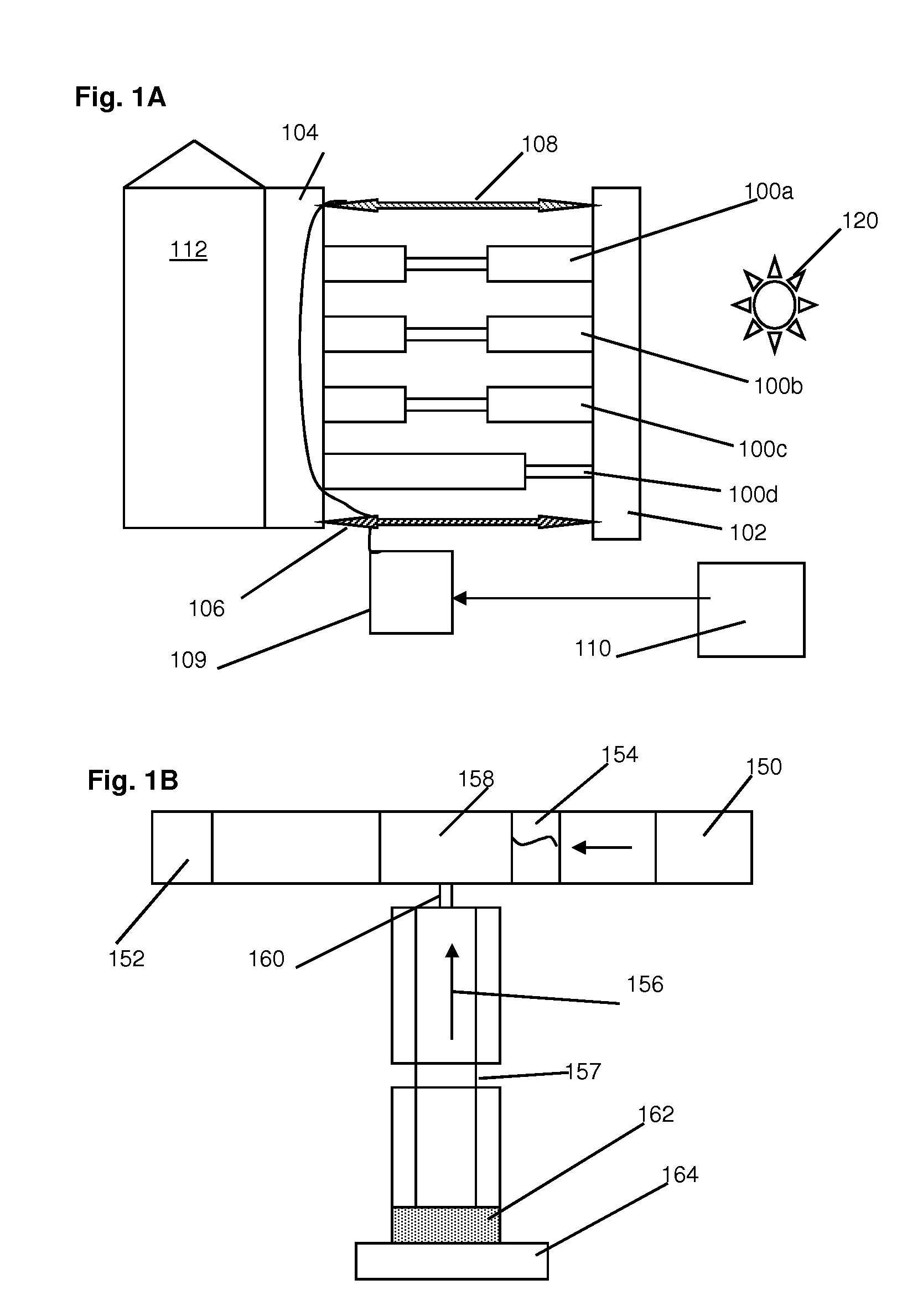

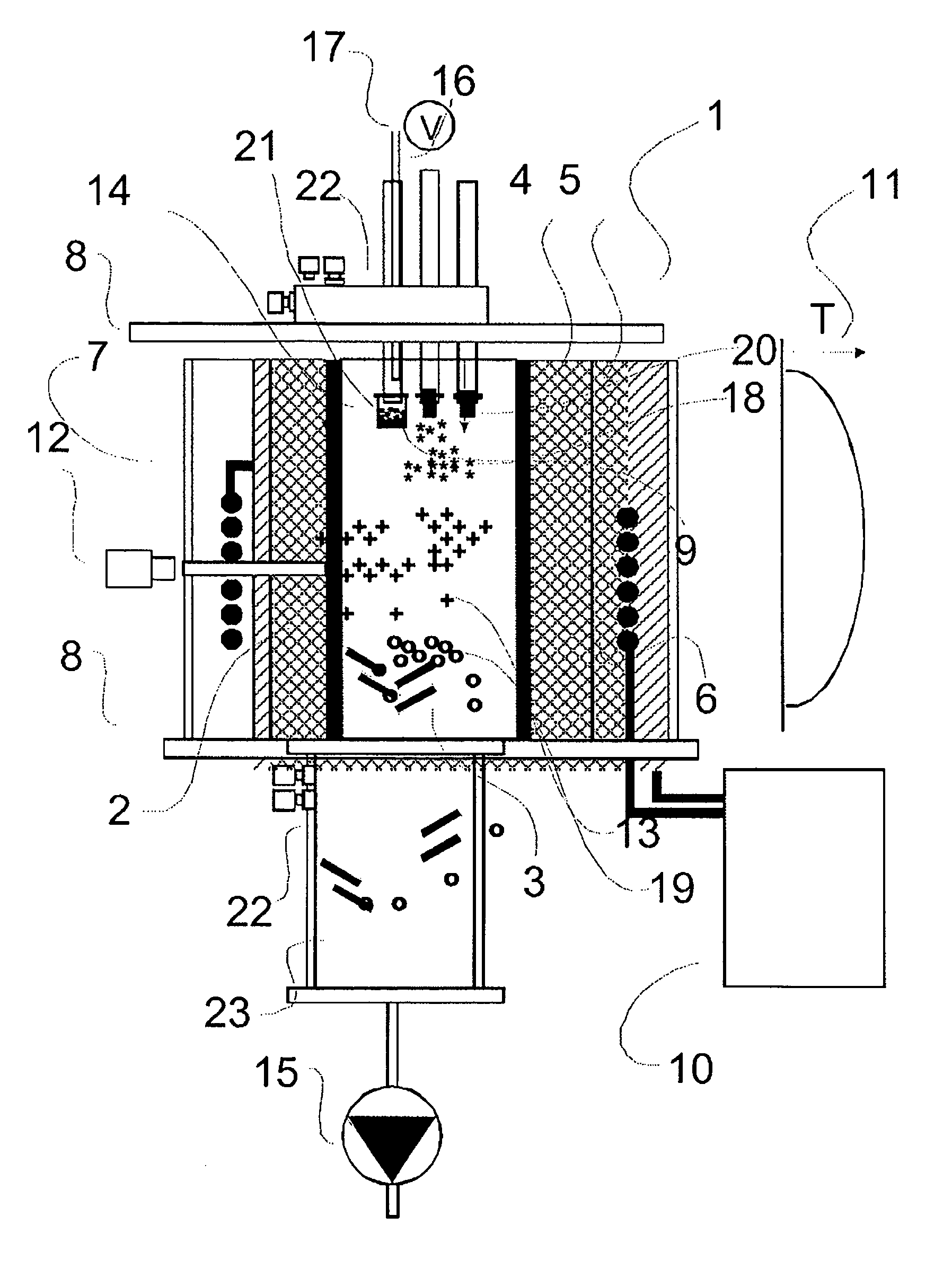

Device and method for producing nanotubes

InactiveUS8475760B2Promote growthGrowth inhibitionMaterial nanotechnologyNanostructure manufactureProcess engineeringMulti-Walled Nanotube

Owner:BENEQ OY

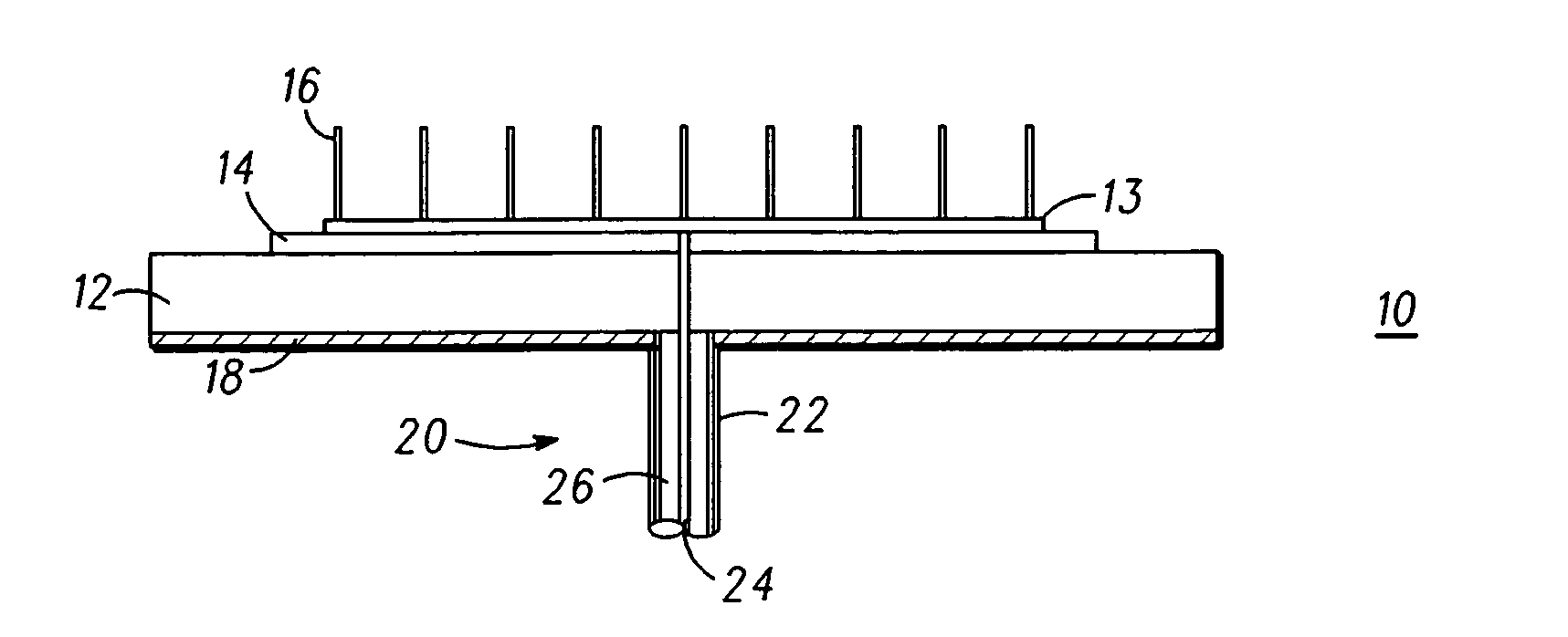

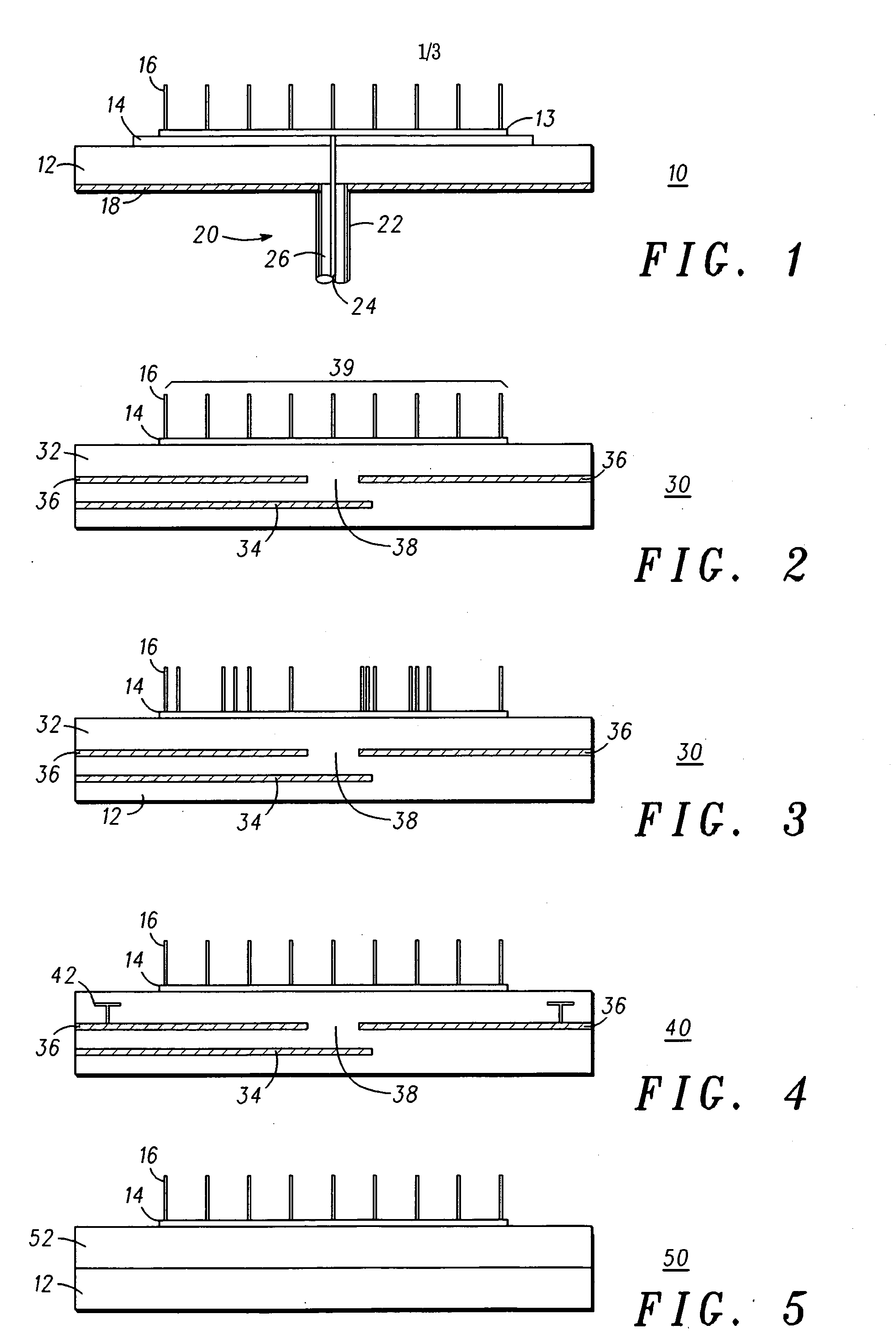

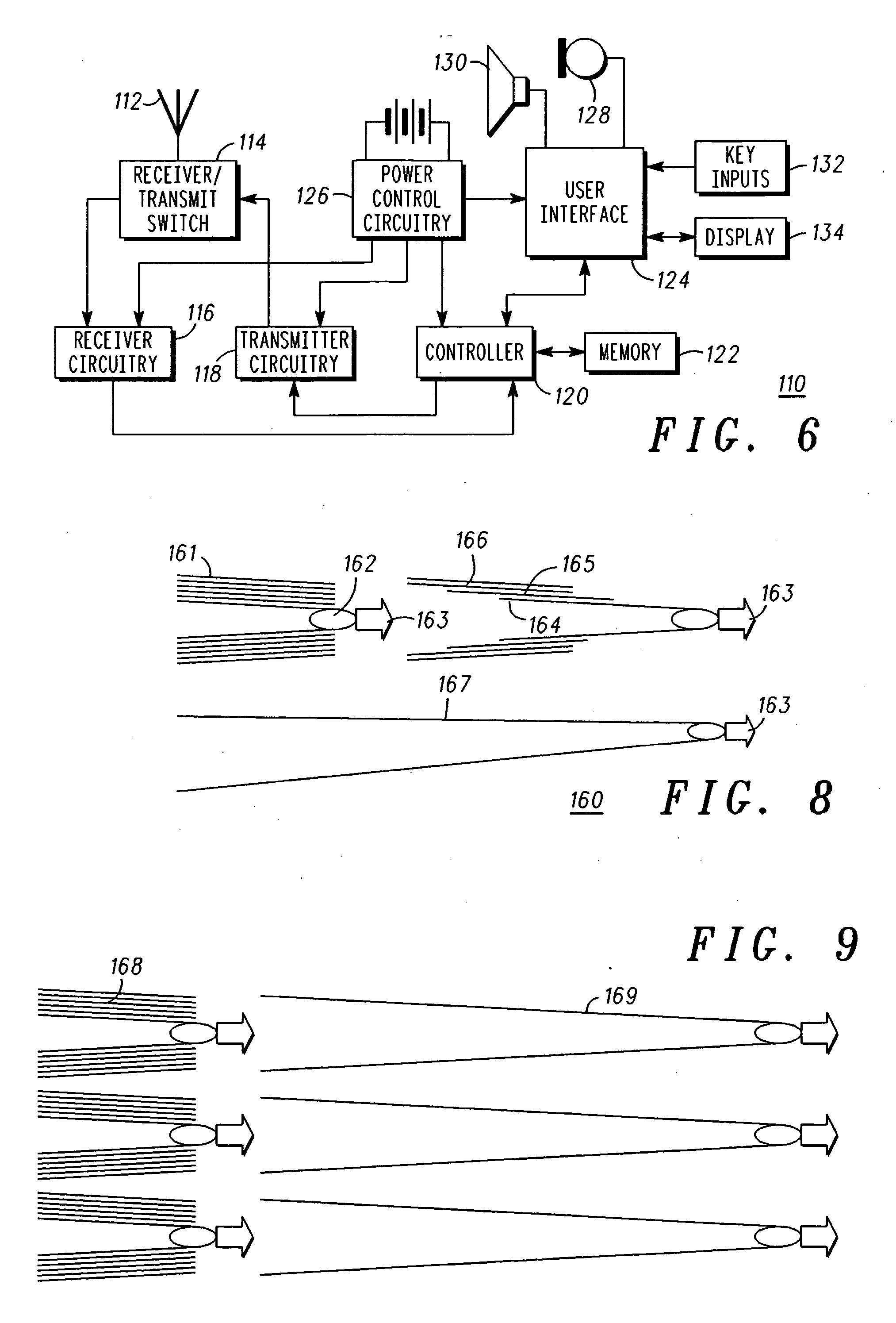

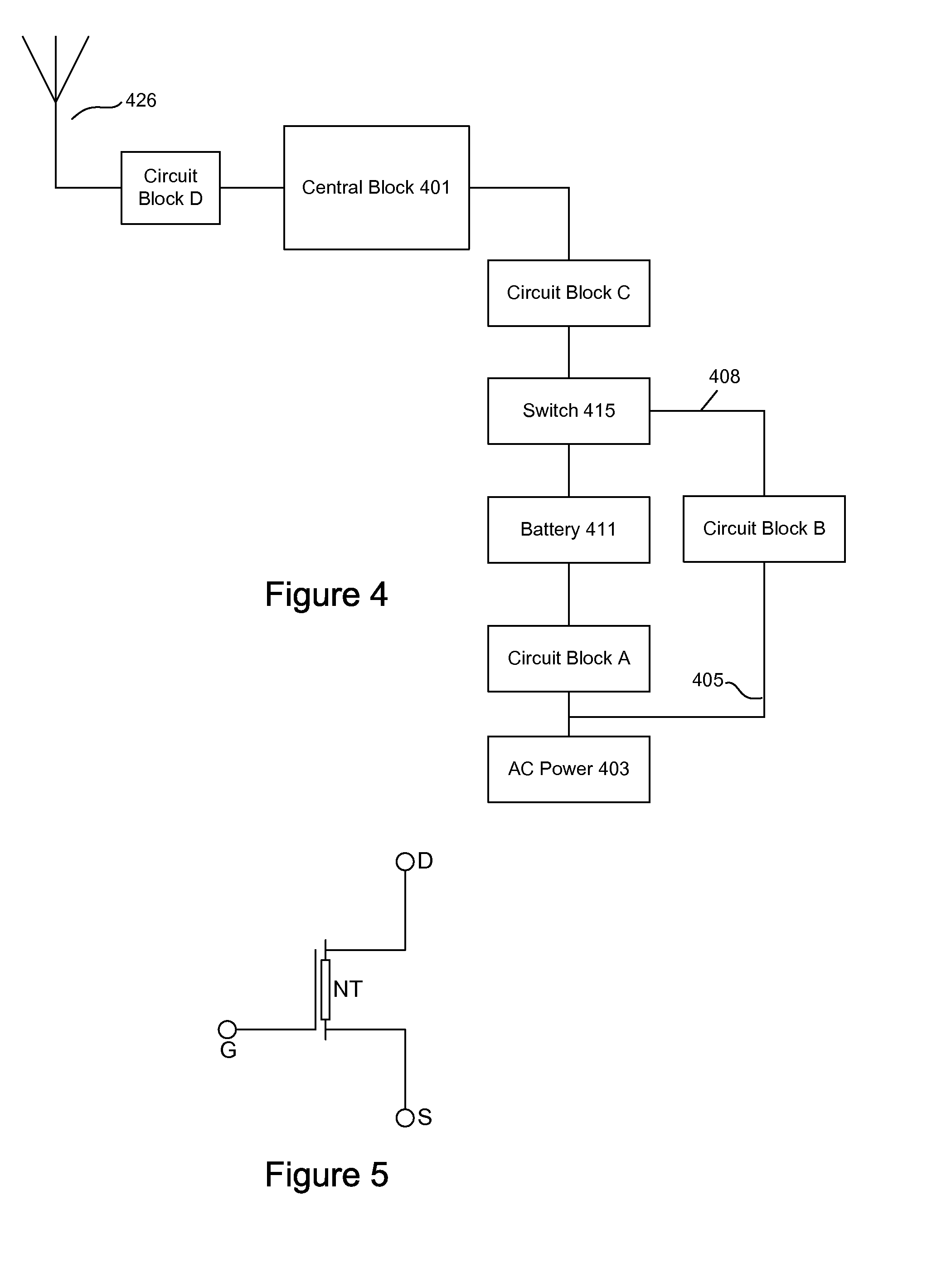

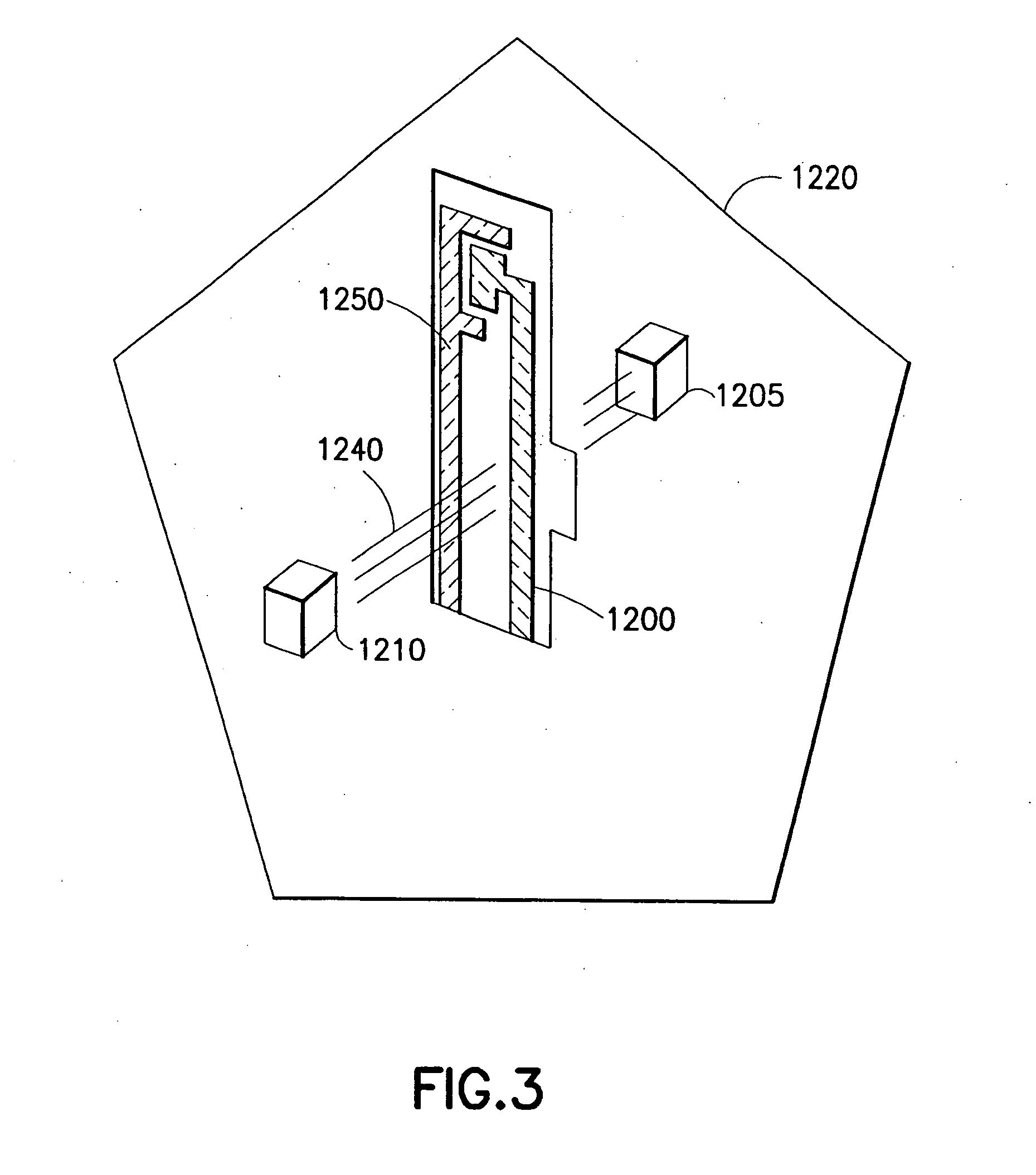

Nanostructured tunable antennas for communication devices

InactiveUS20070176832A1Antenna supports/mountingsAntenna arrays manufactureRadio frequency signalMobile device

An apparatus (10, 30, 40, 50) is provided that relates to nanotubes as radiation elements for antennas and phased arrays, and more particularly to a macro-sized RF antenna for mobile devices. The antenna comprises a plurality of nanostructures (16), e.g., carbon nanotubes, forming an antenna structure on a substrate (12), and a radio frequency signal apparatus formed within the substrate (12) and coupled to the plurality of nanostructures (16). The radiation element length of a nested multiwall nanotube (161) of an exemplary embodiment may be tuned to a desirable frequency by an electromagnetic force (163).

Owner:MOTOROLA SOLUTIONS INC

Method for manufacturing piezoresistive material, piezoresistive composition and pressure sensor device

A method for manufacturing a piezoresistive material, a piezoresistive composition and a pressure sensor device are provided. The piezoresistive composition includes a conductive carbon material, a solvent, a dispersive agent, an unsaturated polyester and a crosslinking agent. The conductive carbon material is selected from a group consisting of multi-wall nanotube, single-wall carbon nanotube, carbon nanocapsule, graphene, graphite nanoflake, carbon black, and a combination thereof. The solvent is selected from a group consisting of ethyl acetate, butyl acetate, hexane, propylene glycol mono-methyl ether acetate and a combination thereof. The dispersive agent includes block polymer solution with functional groups providing the affinity. The unsaturated polyester is selected from a group consisting of an ortho-phthalic type unsaturated polyester, an iso-phthalic type unsaturated polyester, and a combination thereof. The crosslinking agent is selected from a group consisting of ethyl methyl ketone peroxide, cyclohexanone diperoxide, dibenzoyl peroxide, tert-butyl peroxybenzoate and a combination thereof.

Owner:IND TECH RES INST

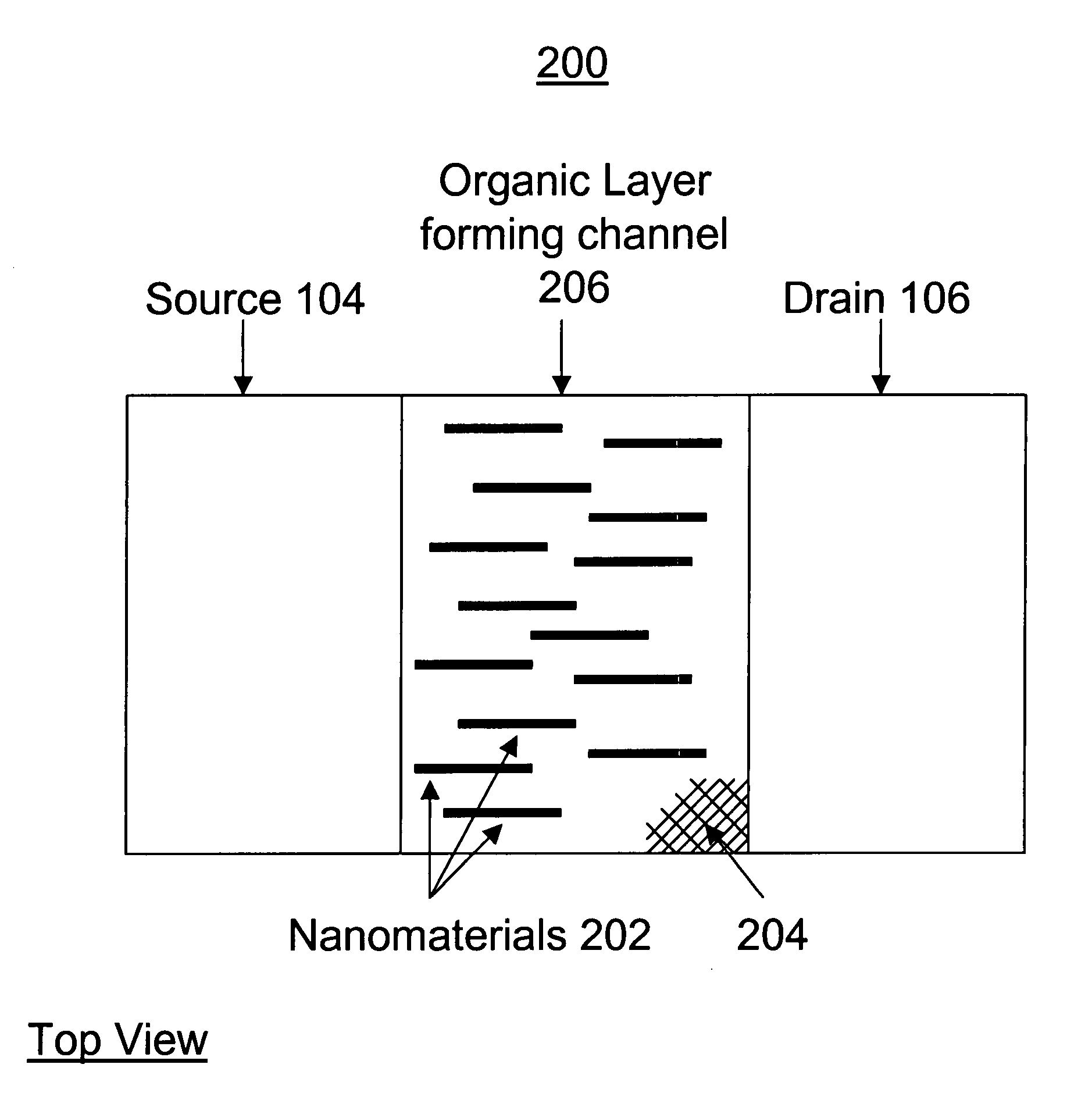

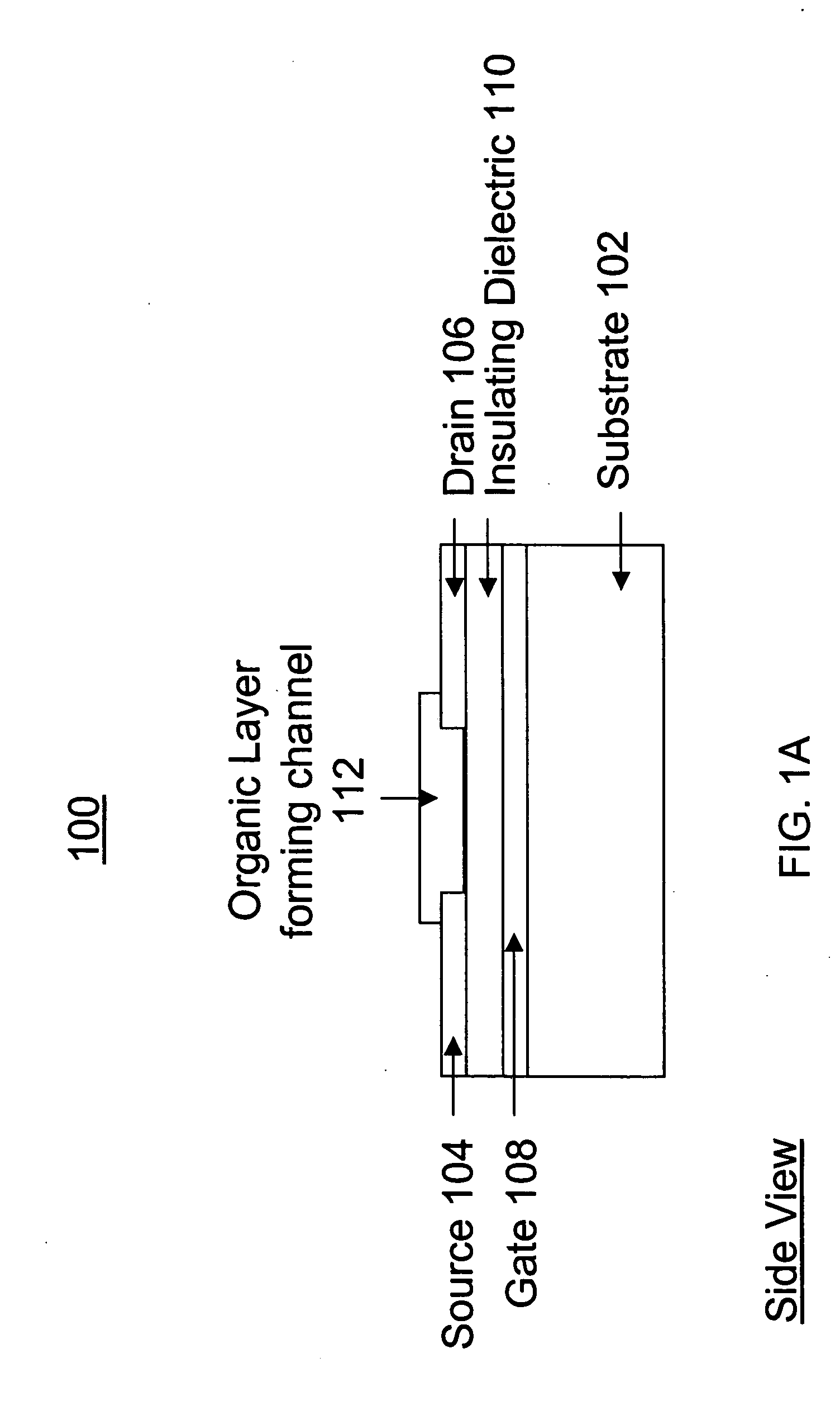

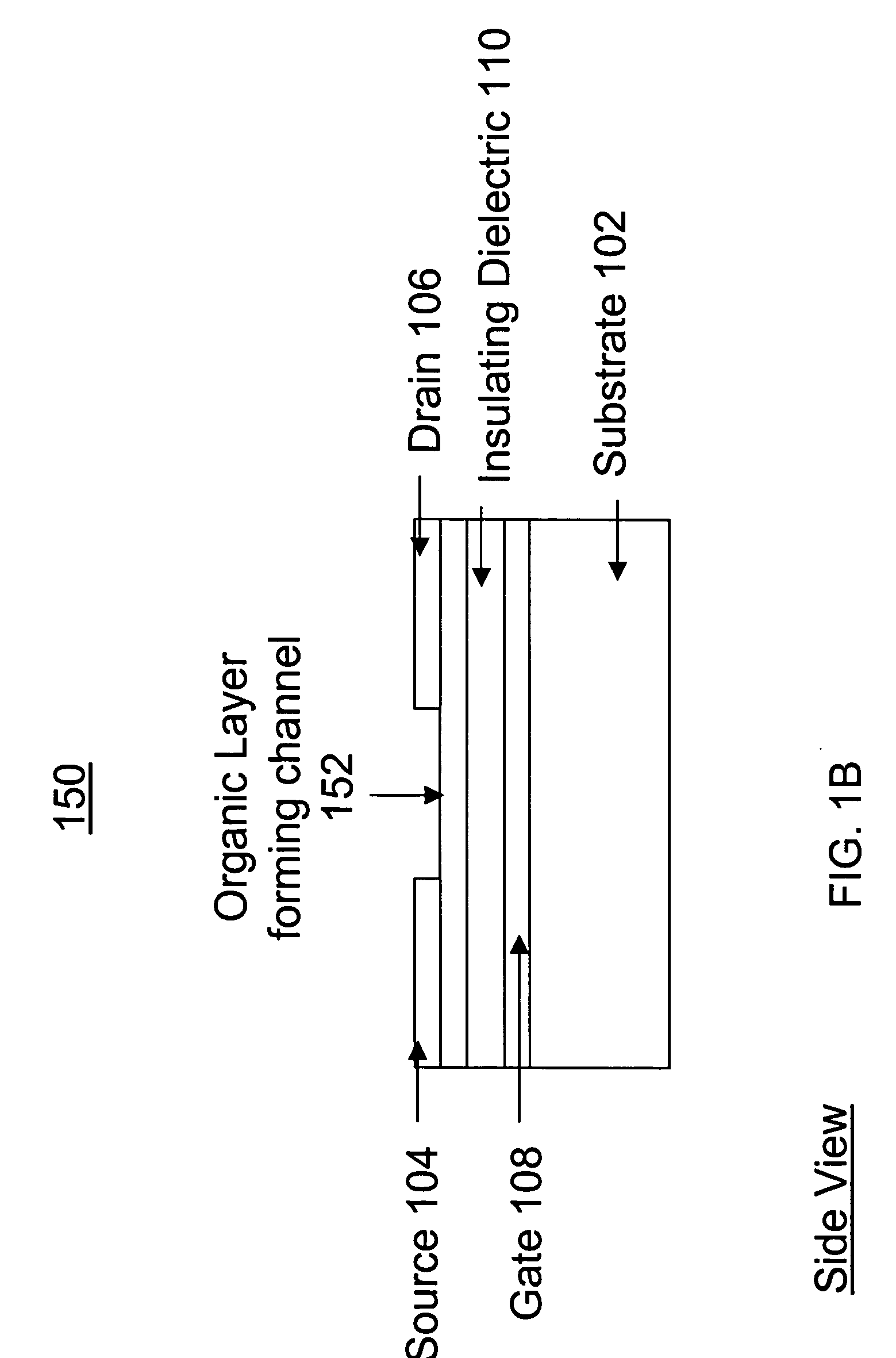

Enhancing performance in ink-jet printed organic semiconductors

InactiveUS20070275498A1Improve performanceMinimize occurrence of cloggingMaterial nanotechnologySolid-state devicesNanodotNanowire

Systems and methods are provided to improve the performance of electronic and optoelectronic devices made using organic semiconductor processing technology. An ink-jet device dispenses an organic composite mixture onto a substrate. The mixture includes a semiconducting polymer and nanomaterials dispersed into an organic solvent. The type of solvent used preferably achieves effective dispersion of the polymer and nanomaterials in the solvent to minimize the occurrence of clogging of the ink-jet nozzles. The range of nanomaterials include, but are not limited to, organic and inorganic, single or multi-walled nanotubes, nanowires, nanodots, quantum dots, nanorods, nanocrystals, nanotetrapods, nanotripods, nanobipods, nanoparticles, nanosaws, nanosprings, nanoribbons, any branched nanostructure, and any mixture of these nanoshaped materials. The nanostructures can be aligned on the substrate to improve the carrier mobility in the organic semiconductors.

Owner:CUTS

Removing undesirable nanotubes during nanotube device fabrication

InactiveUS20110081770A1Total current dropAvoid damageNanoinformaticsSolid-state devicesMulti-Walled NanotubeElectrical current

Fabricating single-walled carbon nanotube transistor devices includes removing undesirable types of nanotubes. These undesirable types of nanotubes may include nonsemiconducting nanotubes, multiwalled nanotubes, and others. The undesirable nanotubes may be removed electrically using voltage or current, or a combination of these. This approach to removing undesirable nanotubes is sometimes referred to as “burn-off.” The undesirable nanotubes may be removed chemically or using radiation. The undesirable nanotubes of an integrated circuit may be removed in sections or one transistor (or a group of transistors) at a time in order to reduce the electrical current used or prevent damage to the integrated circuit during burn-off.

Owner:ETAMOTA CORP

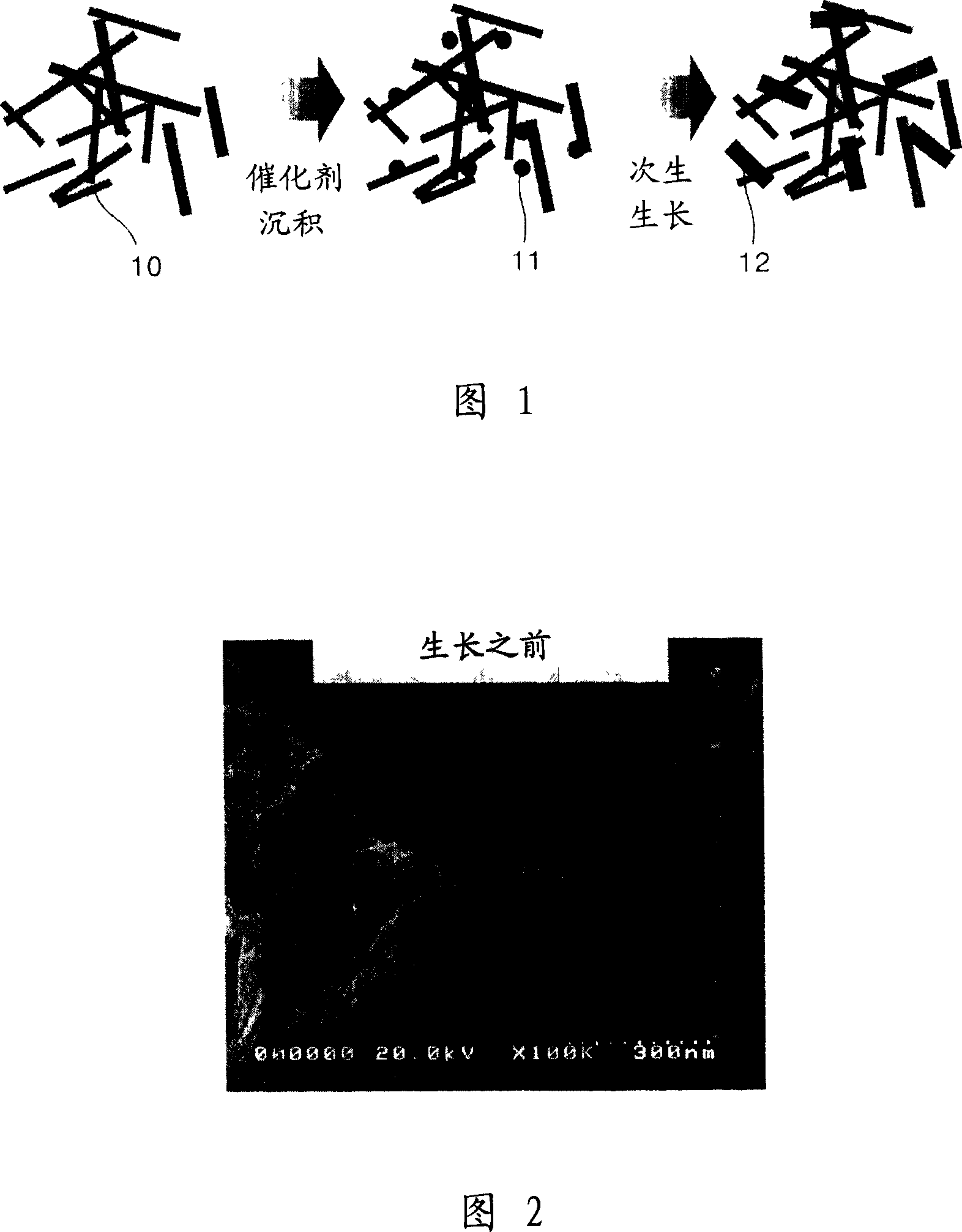

Carbon nanotube, a supported catalyst comprising the same, and fuel cell using the same

InactiveCN101024495AMaterial nanotechnologyCatalyst carriersElectrical resistance and conductanceFuel cells

A carbon nanotube, a method of preparing the same, a supported catalyst including the same, and a fuel cell using the supported catalyst are provided. The method of preparing the carbon nanotube includes: depositing a metal catalyst in single wall nanotubes and growing multi wall nanotubes over the single wall nanotubes using the metal catalyst. The carbon nanotubes of the present invention have satisfactory specific surface area and low surface resistance. Thus, the carbon nanotubes perform remarkably better than a conventional catalyst carrier. Accordingly, the carbon nanotubes, when used as a catalyst carrier of an electrode for a fuel cell, can improve the electrical conductivity of the fuel cell. In addition, a fuel cell employing the electrode has excellent efficiency and overall performance.

Owner:SAMSUNG SDI CO LTD

Security marking and security mark

InactiveUS20080135629A1Semiconductor/solid-state device detailsNanoinformaticsPlatinumConductive polymer

Owner:DOUGLAS JOEL S

Tunable Thermal Link

ActiveUS20090277609A1Large effect on thermal conductivityEasy to separateNanoinformaticsMetal-working apparatusMultiwalled carbonHeat flow

Disclosed is a device whereby the thermal conductance of a multiwalled nanostructure such as a multiwalled carbon nanotube (MWCNT) can be controllably and reversibly tuned by sliding one or more outer shells with respect to the inner core. As one example, the thermal conductance of an MWCNT dropped to 15% of the original value after extending the length of the MWCNT by 190 nm. The thermal conductivity returned when the tube was contracted. The device may comprise numbers of multiwalled nanotubes or other graphitic layers connected to a heat source and a heat drain and various means for tuning the overall thermal conductance for applications in structure heat management, heat flow in nanoscale or microscale devices and thermal logic devices.

Owner:RGT UNIV OF CALIFORNIA

Device and method for producing nanotubes

InactiveUS20100072429A1Increase sublimation areaEfficiently conveyedMaterial nanotechnologyNanostructure manufactureProcess engineeringMulti-Walled Nanotube

Owner:BENEQ OY

Method for fabricating macroscale films comprising multiple-walled nanotubes

A technique is provided for the fabrication of multi-walled carbon nanotube (MWNT) and carbon nanofiber (CNF) film materials. The method includes mixing a relatively small amount of single-walled nanotubes (SWNTs) with larger amounts of MWNTs and CNFs, which enables one to produce highly flexible SWNT materials—advantageously without the need for bonding agents and at significantly lower costs compared to flexible SWNT materials. The method exploits SWNTs tendency to entangle together to form flexible films, using a small amount of SWNTs to wrap around and entangle the larger diameter MWNTs and CNFs together to form flexible films with highly beneficial mechanical, electrical, and thermal properties at a fraction of the cost of SWNT materials.

Owner:FLORIDA STATE UNIV RES FOUND INC

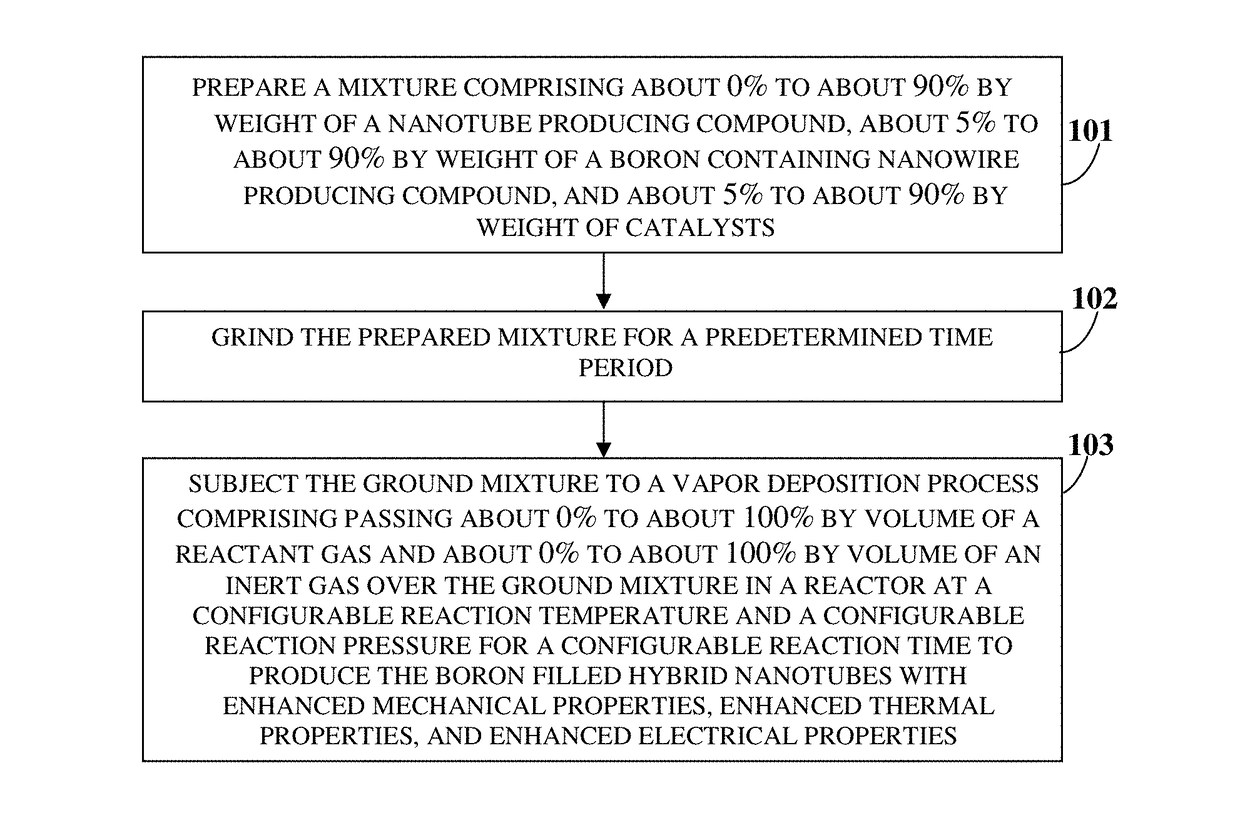

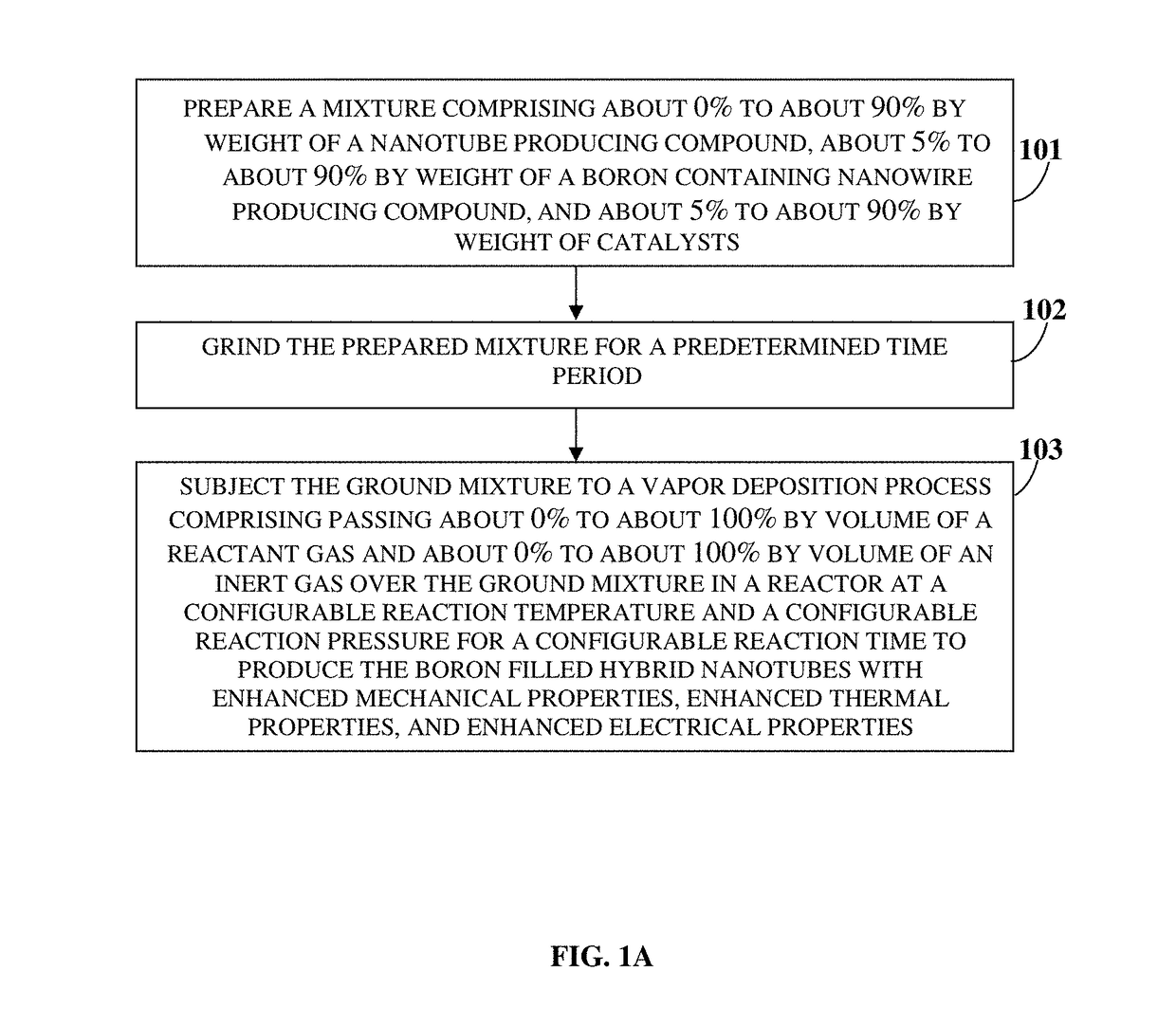

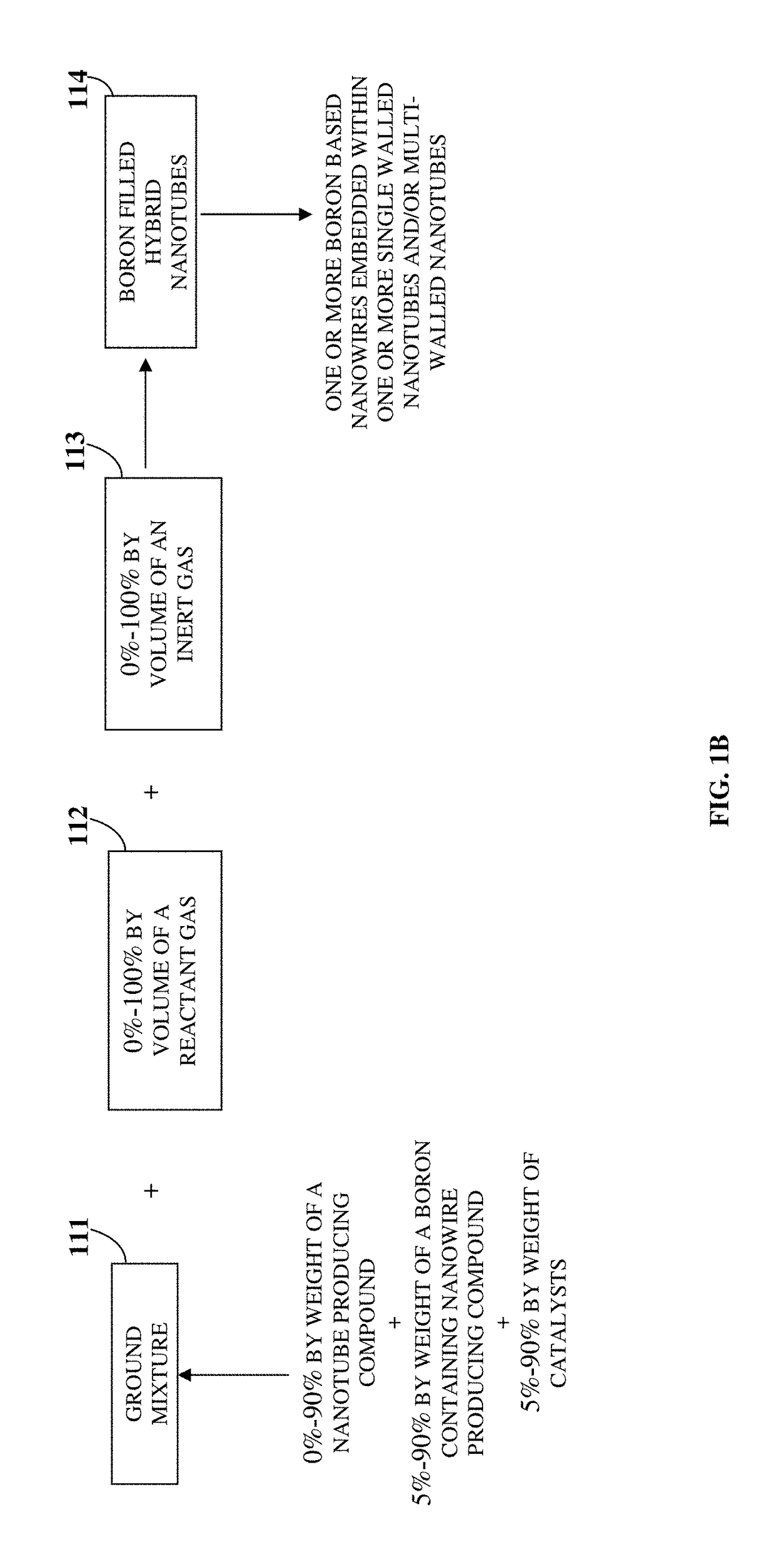

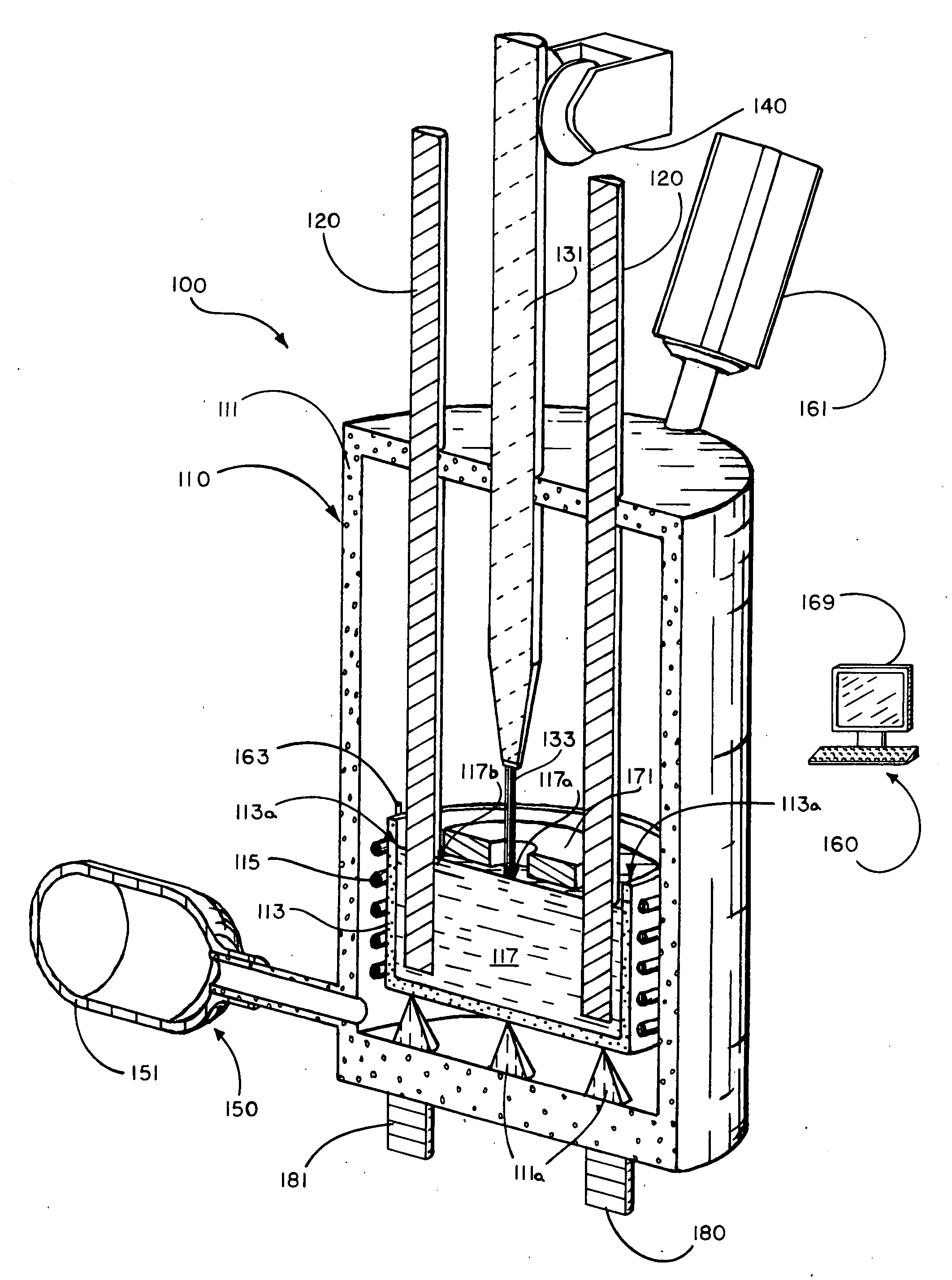

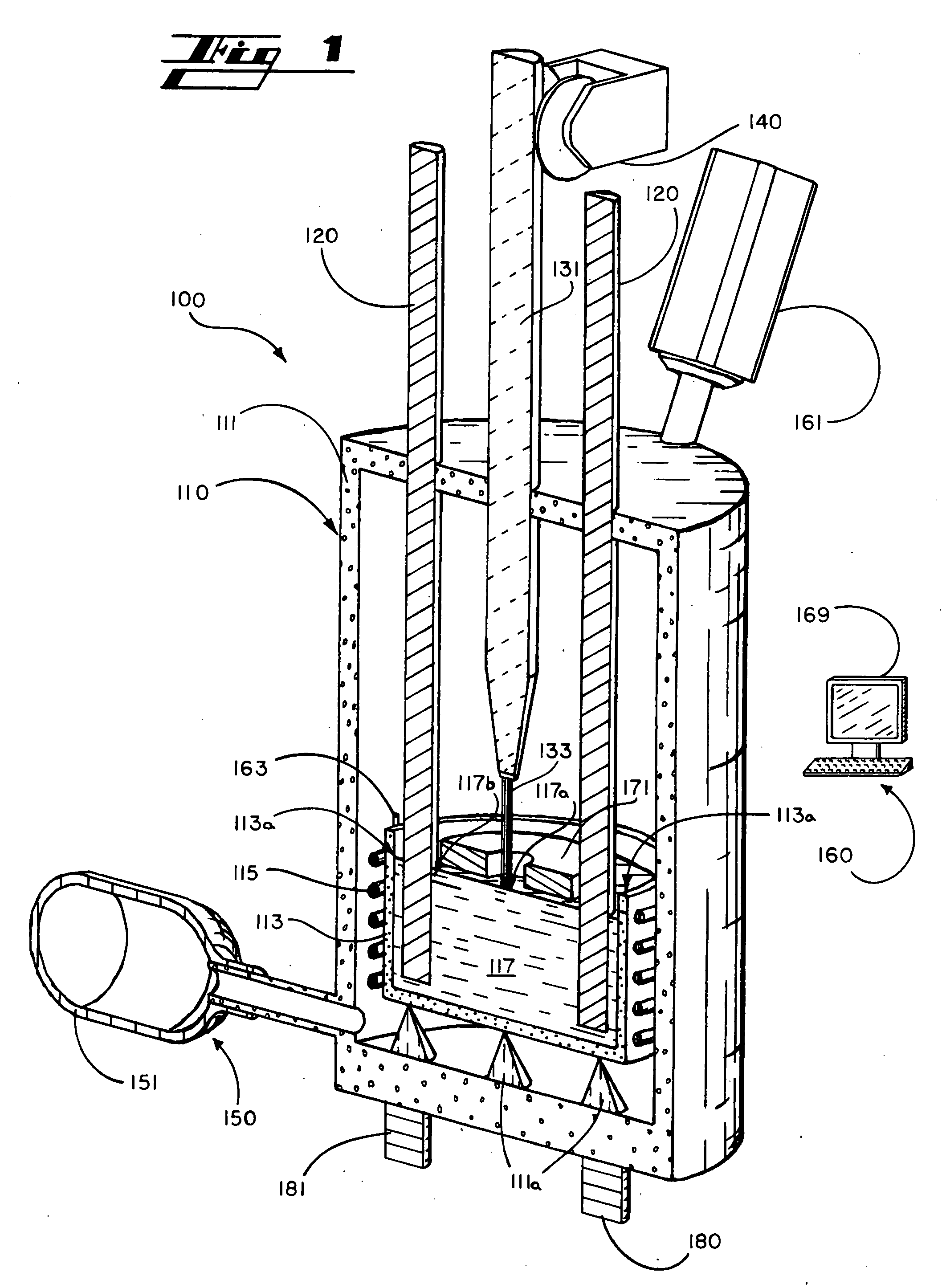

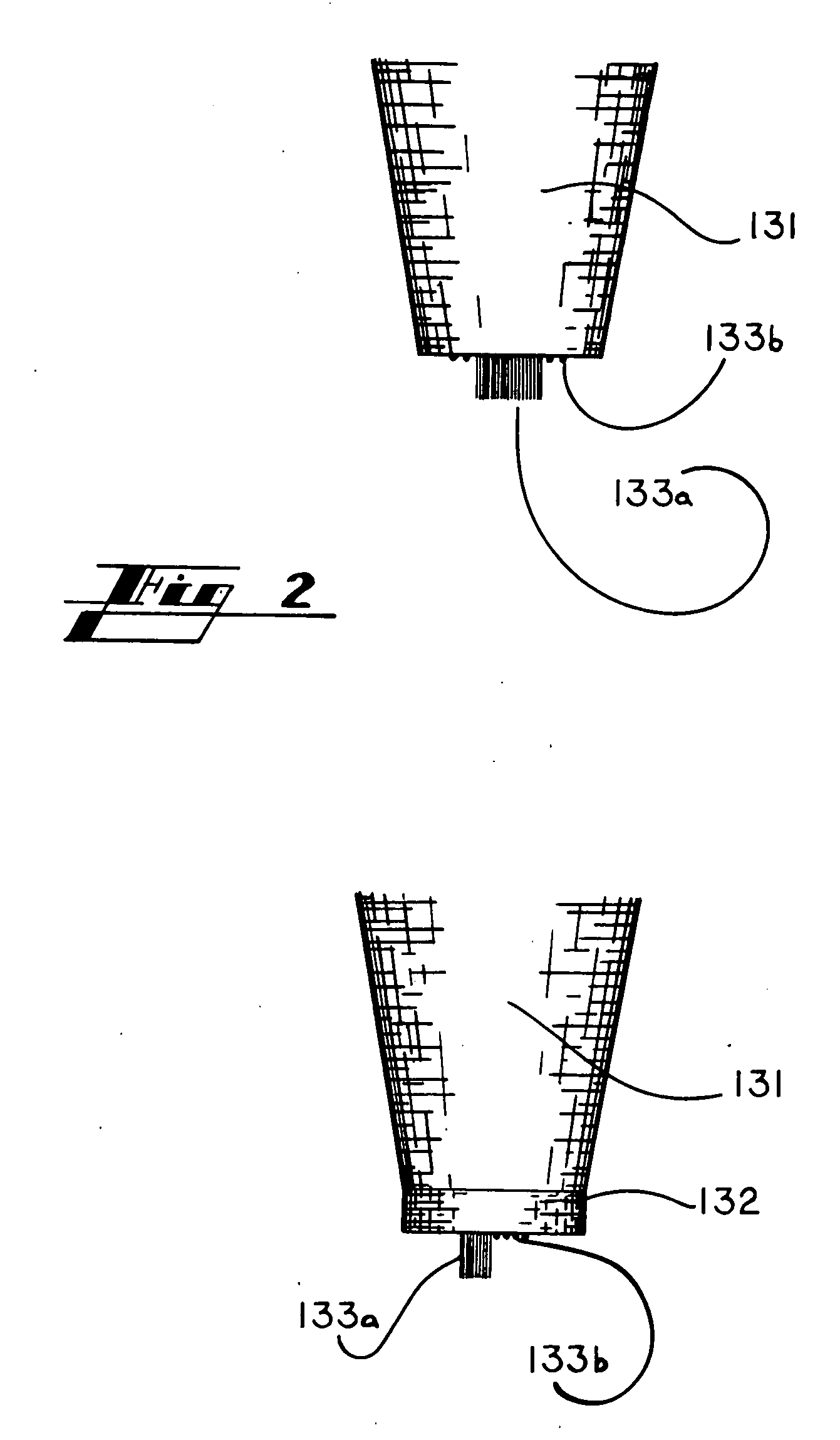

Boron Filled Hybrid Nanotubes

ActiveUS20180057359A1Improve adhesionImprove propertiesVacuum evaporation coatingSputtering coatingNanowireReaction temperature

A boron filled hybrid nanotube and a method for producing and rendering boron filled hybrid nanotubes suitable for applications are provided. A mixture of a boron containing nanowire producing compound and catalysts is prepared and ground for a predetermined time period. The ground mixture is subjected to a vapor deposition process including passing an inert gas over the ground mixture after adding a nanotube producing compound to the ground mixture or after passing a reactant gas on the ground mixture in a reactor at a configurable reaction temperature and a configurable reaction pressure for a configurable reaction time to produce the boron filled hybrid nanotubes with enhanced mechanical, thermal and electrical properties. Each boron filled hybrid nanotube includes one or more boron based nanowires embedded within one or more single walled or multi-walled nanotubes. The boron filled hybrid nanotubes are further purified and functionalized using acids, and / or bases, and / or surfactants.

Owner:PATEL RAJEN BHUPENDRA +1

System and method for manufacturing carbon nanotubes

InactiveUS20090311168A1Allow for manufactureLow costMaterial nanotechnologyNanostructure manufactureMulti-Walled NanotubeBCN nanotube

Owner:DUVALL GIDEON

Strip electrode with conductive nano tube printing

InactiveUS20080023327A1Improve consistencyFlat surfaceImmobilised enzymesMaterial nanotechnologySilver inkCarbon nanotube

A sensor system that detects a current representative of a compound in a liquid mixture features a multi or three electrode strip adapted for releasable attachment to signal readout circuitry. The strip comprises an elongated support which is preferably flat adapted for releasable attachment to the readout circuitry; a first conductor and a second and a third conductor each extend along the support and comprise means for connection to the circuitry. The circuit is formed with single-walled or multi walled nanotubes conductive traces and may be formed from multiple layers or dispersions containing, carbon nanotubes, carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-chloride. An active electrode formed from a separate conductive carbon nanotubes layer or suitable dispersion, positioned to contact the liquid mixture and the first conductor, comprises a deposit of an enzyme capable of catalyzing a reaction involving the compound and preferably an electron mediator, capable of transferring electrons between the enzyme-catalyzed reaction and the first conductor. A reference electrode also formed from a conductive carbon nanotube layer or suitable dispersion is positioned to contact the mixture and the second conductor. The system includes circuitry adapted to provide an electrical signal representative of the current which is formed from printing conductive inks made with nano size particles such as conductive carbon or carbon / platinum or carbon / silver, or carbon nanotubes / antimony tin oxide to form a conductive carbon nanotube layers. The multiple-electrode strip is manufactured, by then applying the enzyme and preferably the mediator onto the electrode. Alternatively the electrode can have a carbon nanotubes / antimony tin oxide, carbon nanotubes / platinum, or carbon nanotubes / silver or carbon nanotubes / silver-chloride surface and or a conductive carbon or silver ink surface connecting leg. The carbon nanotube solution is first coated and patterned into electro shapes and the conductive carbon nanotubes, carbon or silver ink can be attached by printing the ink to interface with the carbon nanotube electro surface. A platinum electrode test strip is also disclosed that is formed from either nano platinum distributed in the carbon nanotube layer or by application or incorporation of platinum to the carbon nanotube conductive ink.

Owner:MYSTICMD

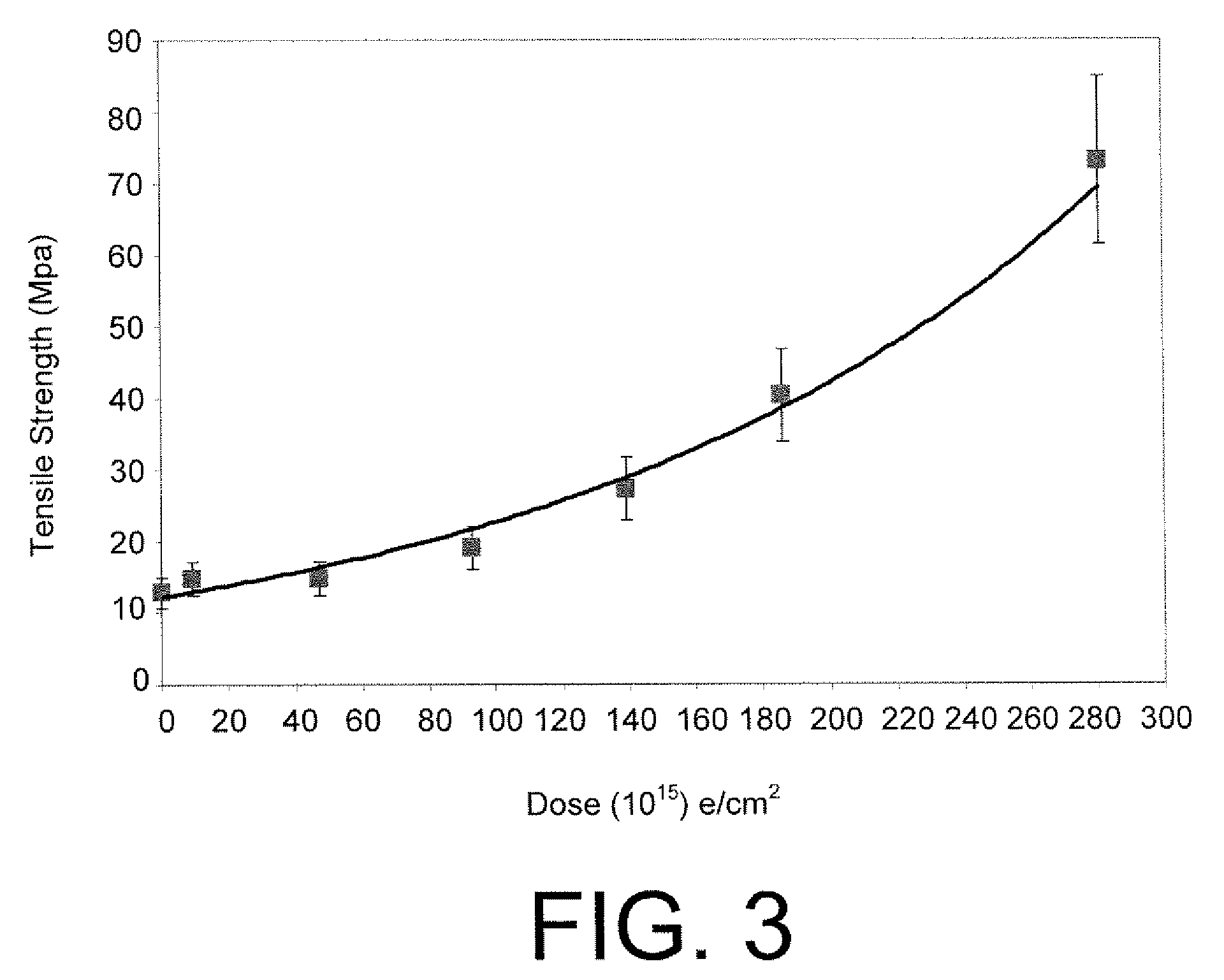

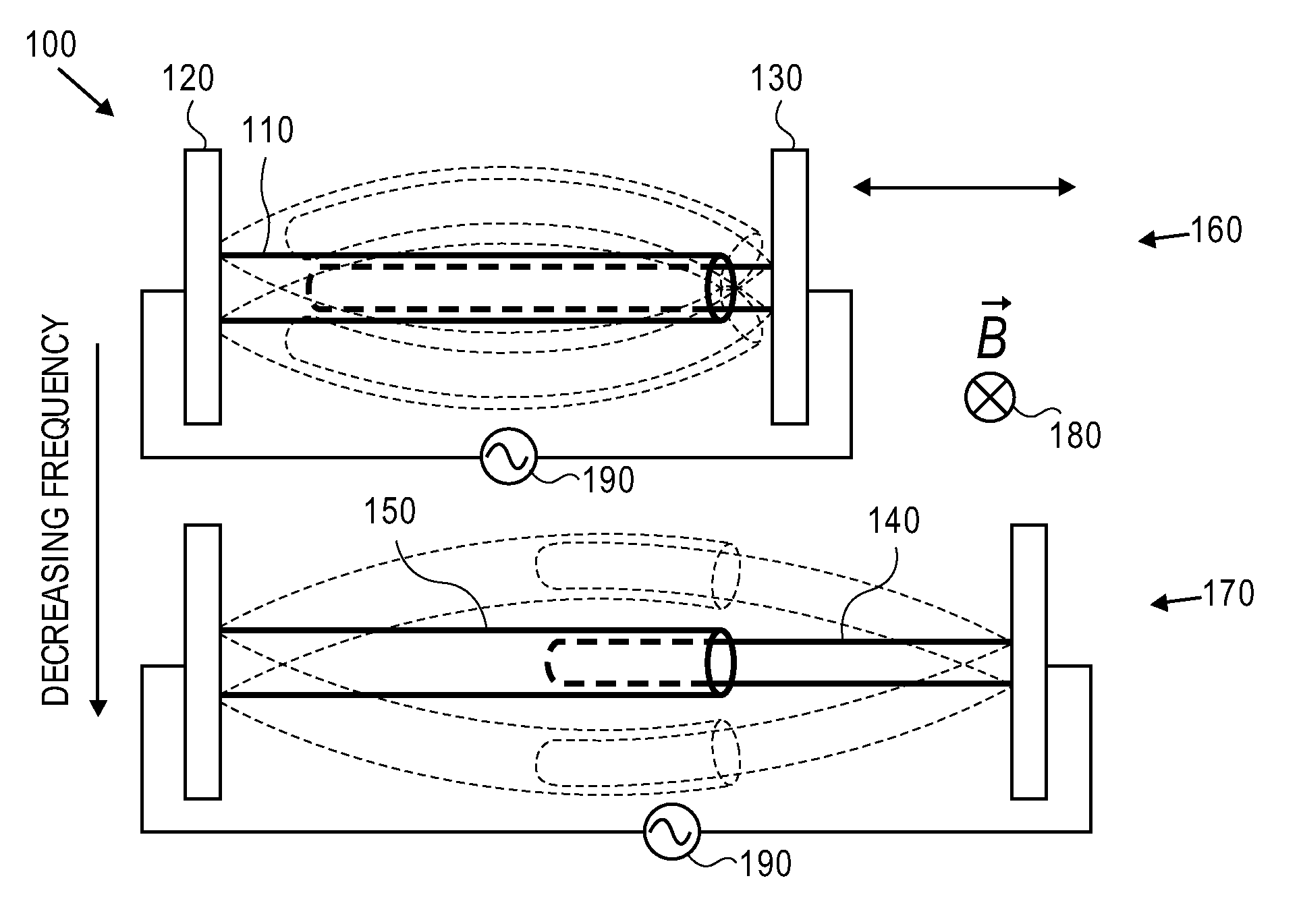

Method for functionalization of nanoscale fiber films

InactiveUS7862766B2Increase modulusHigh strengthMaterial nanotechnologyCarbon compoundsFiberNanofiber

Methods are provided for functionalizing a macroscopic film comprised of nanoscale fibers by controlled irradiation. The methods may include the steps of (a) providing a nanoscale fiber film material comprising a plurality of nanoscale fibers (which may include single wall nanotubes, multi-wall nanotubes, carbon nanofibers, or a combination thereof); and (b) irradiating the nanoscale fiber film material with a controlled amount of radiation in the open air or in a controlled atmosphere. The step of irradiating the nanoscale fiber film material is effective to functionalize the plurality of nanoscale fibers. Irradiated nanoscale fiber films are also provided having improved mechanical and electrical conducting properties.

Owner:FLORIDA STATE UNIV RES FOUND INC

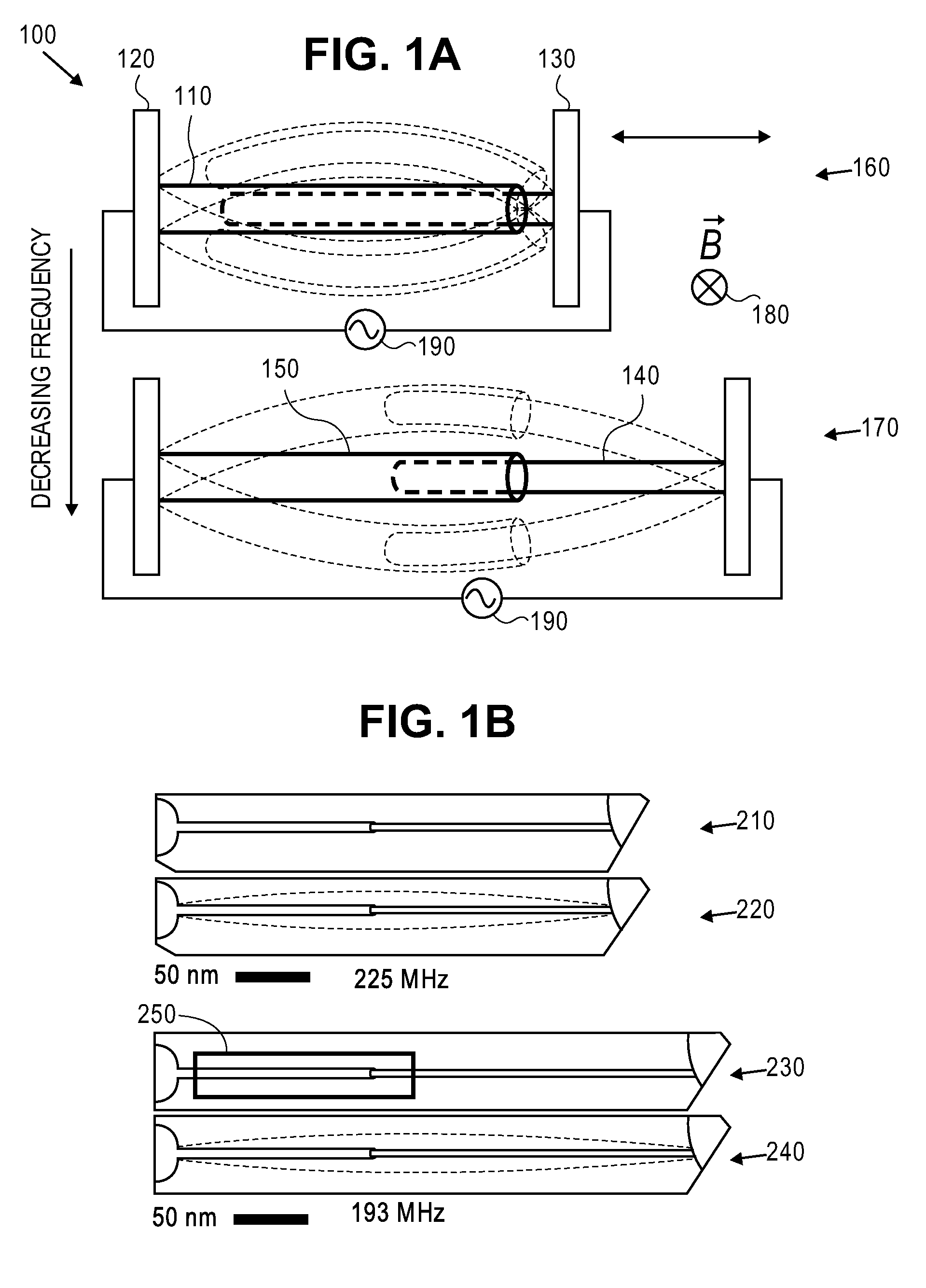

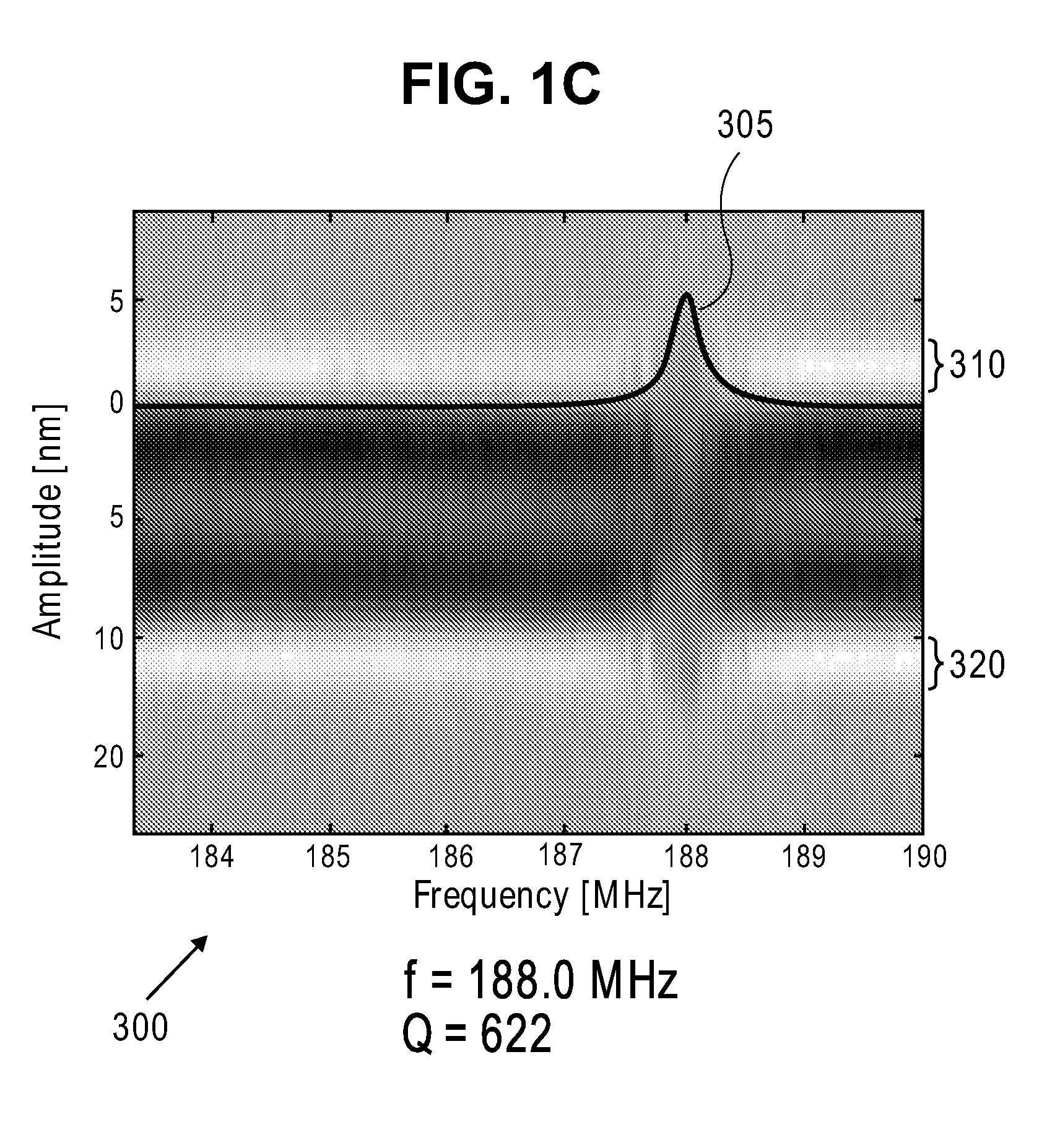

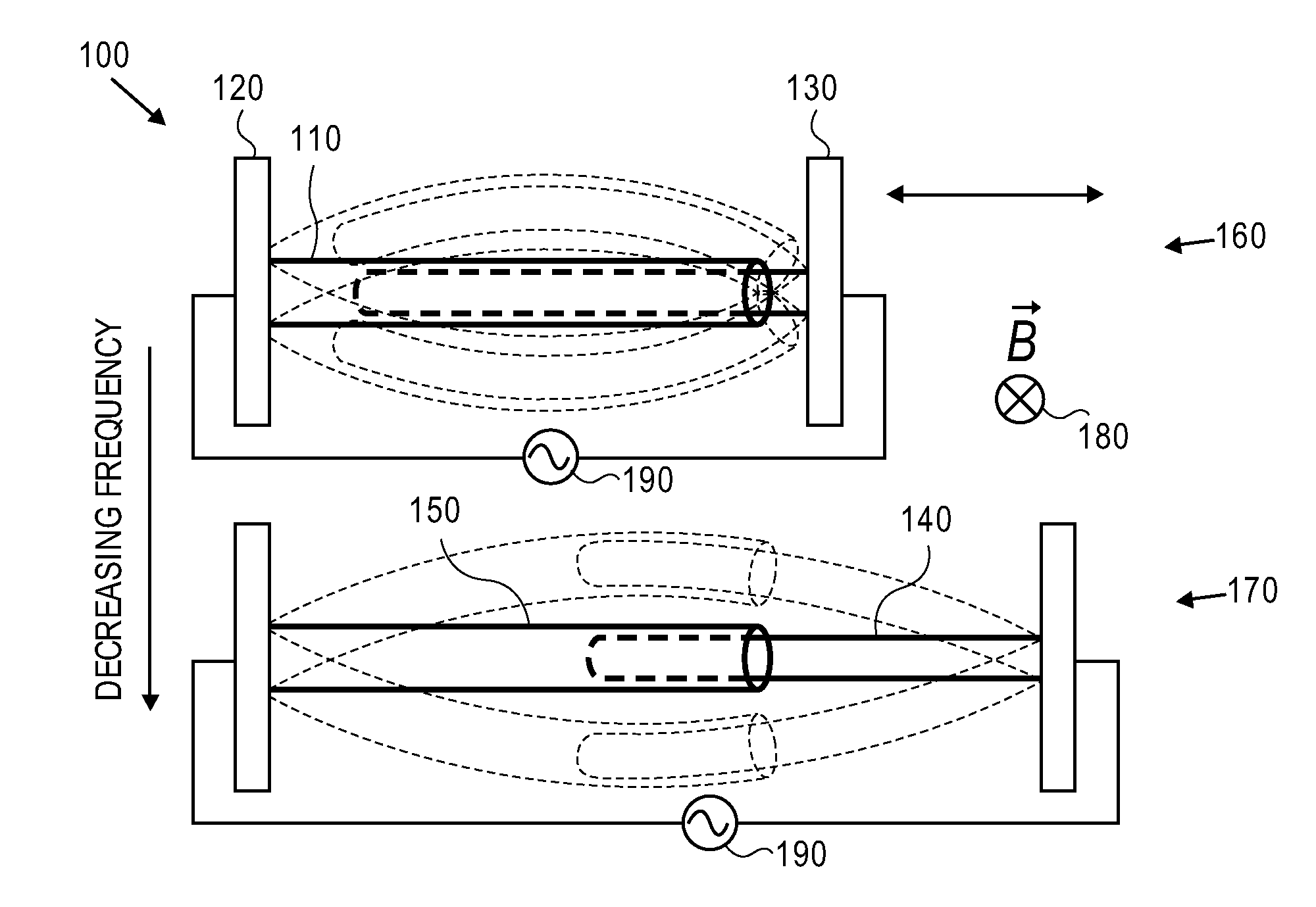

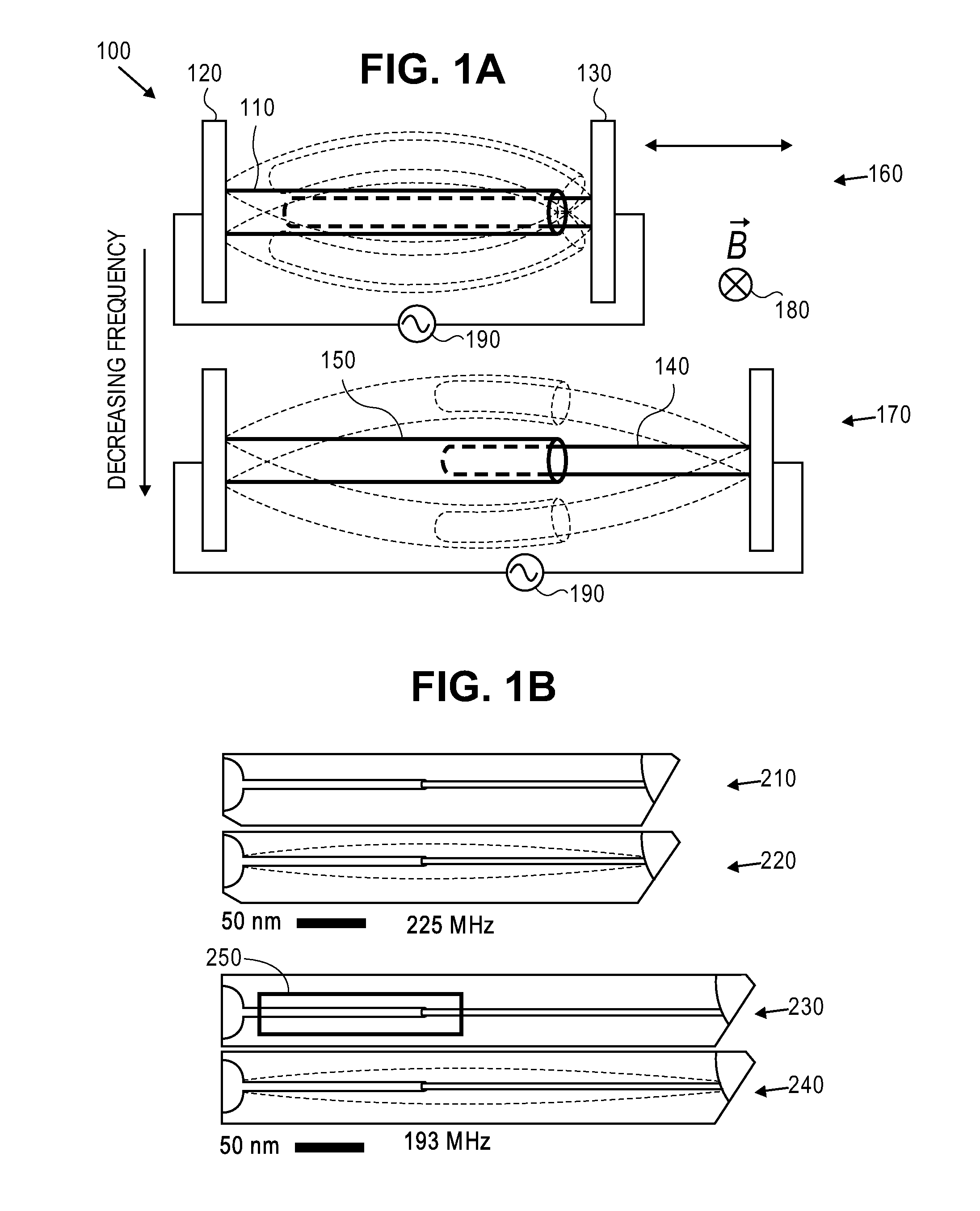

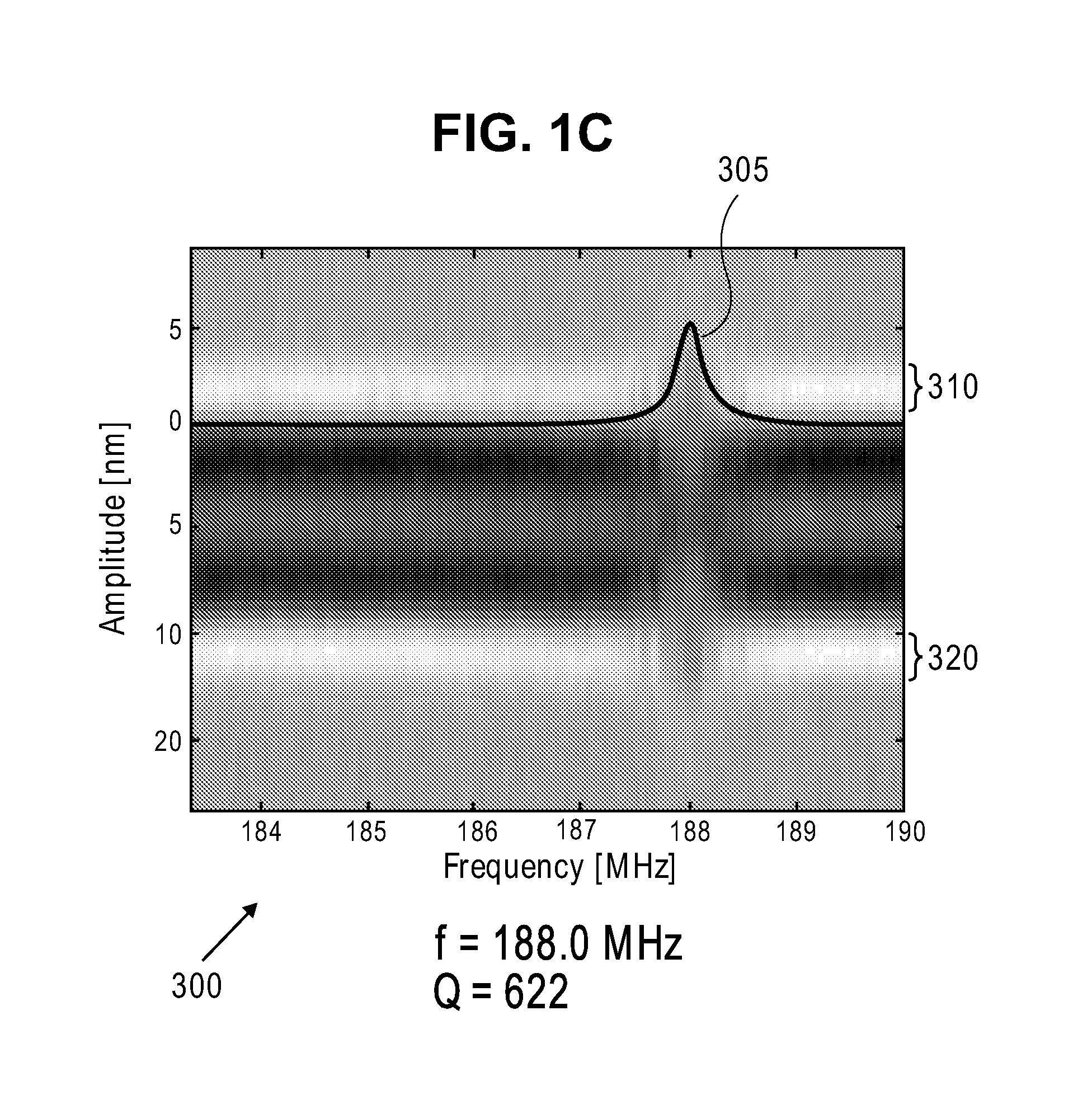

Tunable multiwalled nanotube resonator

ActiveUS7915973B2Material nanotechnologyMaterial analysis using sonic/ultrasonic/infrasonic wavesResonant energyChemical species

A tunable nanoscale resonator has potential applications in precise mass, force, position, and frequency measurement. One embodiment of this device consists of a specially prepared multiwalled carbon nanotube (MWNT) suspended between a metal electrode and a mobile, piezoelectrically controlled contact. By harnessing a unique telescoping ability of MWNTs, one may controllably slide an inner nanotube core from its outer nanotube casing, effectively changing its length and thereby changing the tuning of its resonance frequency. Resonant energy transfer may be used with a nanoresonator to detect molecules at a specific target oscillation frequency, without the use of a chemical label, to provide label-free chemical species detection.

Owner:RGT UNIV OF CALIFORNIA

Tunable Multiwalled Nanotube Resonator

ActiveUS20090309676A1Material nanotechnologyMaterial analysis using sonic/ultrasonic/infrasonic wavesResonant energyChemical species

A tunable nanoscale resonator has potential applications in precise mass, force, position, and frequency measurement. One embodiment of this device consists of a specially prepared multiwalled carbon nanotube (MWNT) suspended between a metal electrode and a mobile, piezoelectrically controlled contact. By harnessing a unique telescoping ability of MWNTs, one may controllably slide an inner nanotube core from its outer nanotube casing, effectively changing its length and thereby changing the tuning of its resonance frequency. Resonant energy transfer may be used with a nanoresonator to detect molecules at a specific target oscillation frequency, without the use of a chemical label, to provide label-free chemical species detection.

Owner:RGT UNIV OF CALIFORNIA

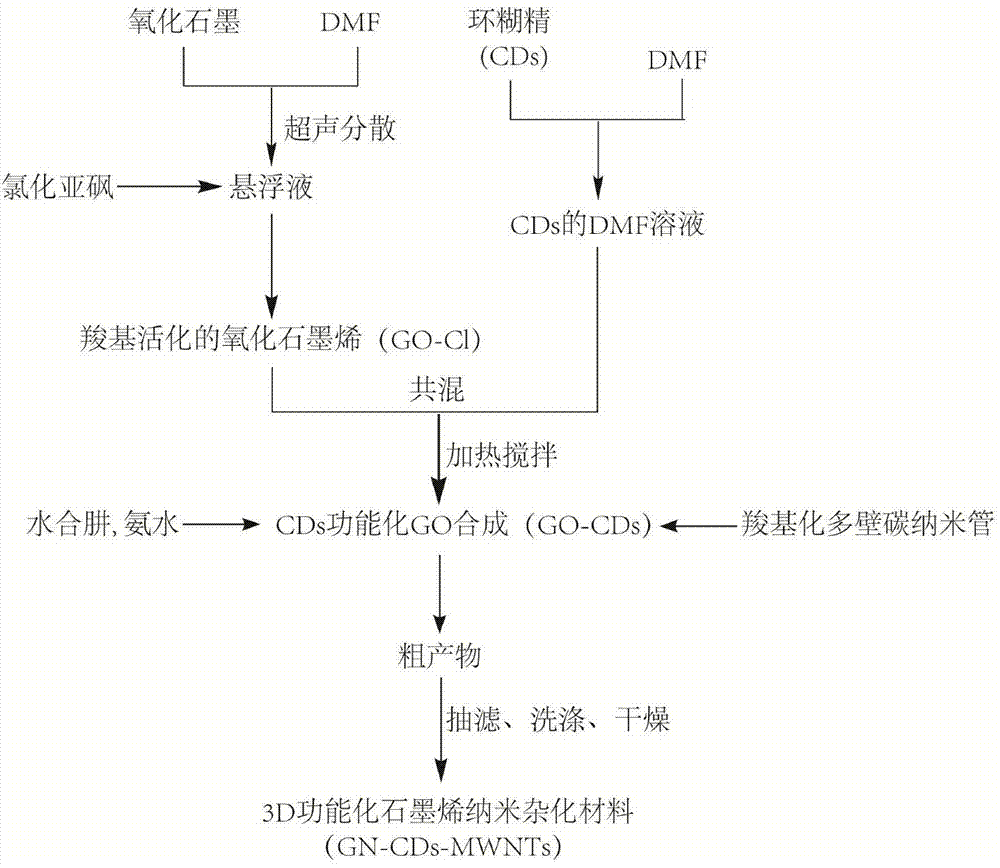

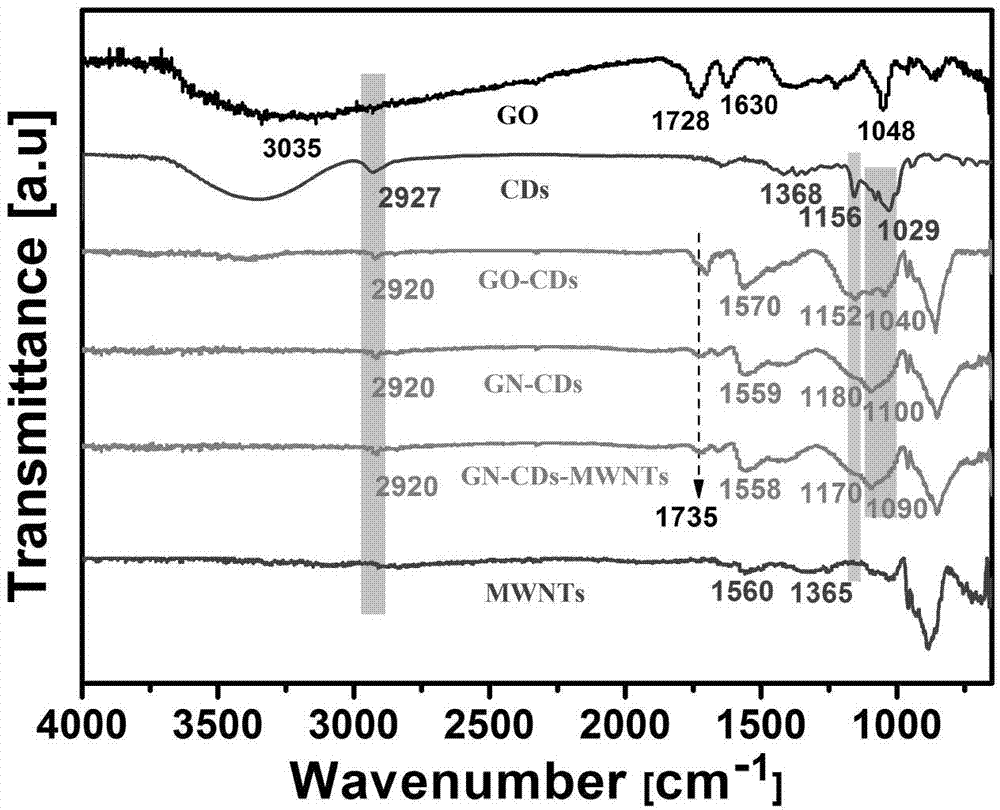

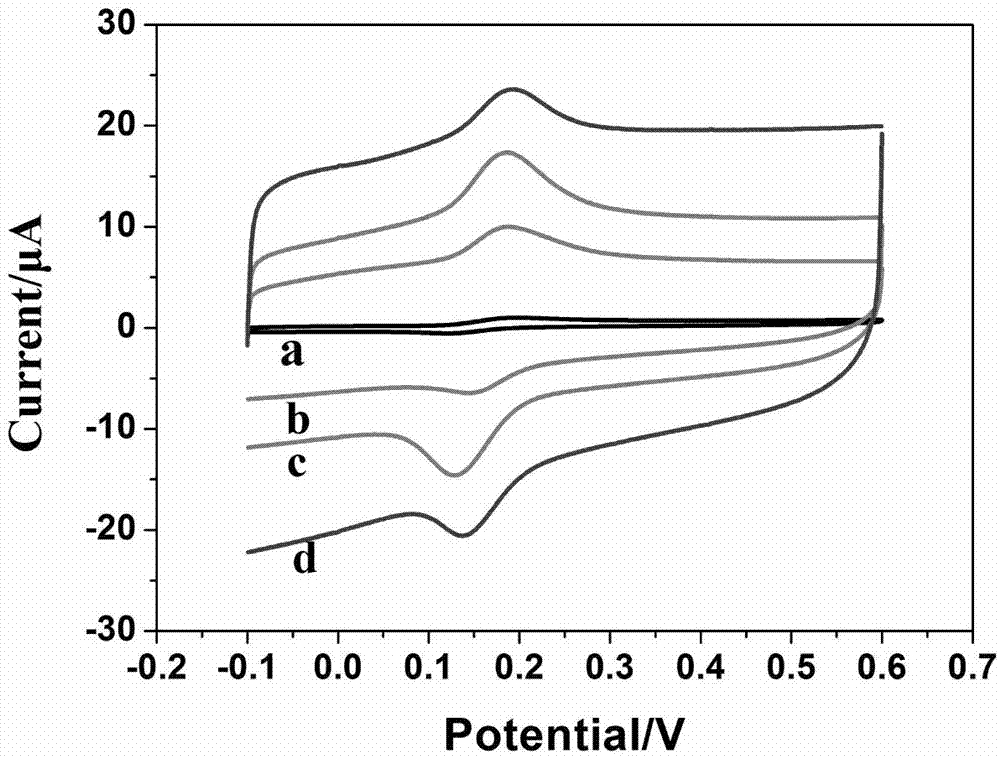

Multi-wall carbon nano-tube bridged 3D graphene conductive network and preparation method thereof

InactiveCN104730121AImprove conductivityEffective collisionMaterial nanotechnologyNanomedicineAfter treatmentCyclodextrin

The invention discloses a carboxylation multi-wall carbon nano-tube bridged 3D graphene conductive network and a preparation method thereof. The method comprises the steps of preparing graphite oxide, preparing cyclodextrin functionalized graphene and preparing the carboxylated multi-wall carbon nano-tube bridged 3D graphene conductive network. The covalence organic decoration technology and the non-covalence organic decoration technology are scientifically combined, a nano hybridized material responding to electrochemical promotion of dopamine, ascorbic acid, purine trione and tryptophan is established, and the electrochemical performance of a nano material is adjusted by changing the type of cyclodextrin and the content of the carboxylated multi-wall nano-tube; the 3D functionalized nano material is simple in synthesis step, efficient, simple in after-treatment and easy for mass preparation; moreover, by adopting the 3D functionalized nano material, DA, AA, UA and Trp can be sensitively detected in a complicated environment in the presence of other interference substances; the defect that CDs is likely to drop can be effectively solved, and the conductivity of the system and the CDs selectivity can be remarkably improved by virtue of the non-covalence bridging of the carboxylated carbon nano-tube.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com