Patents

Literature

57results about How to "Allow for manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

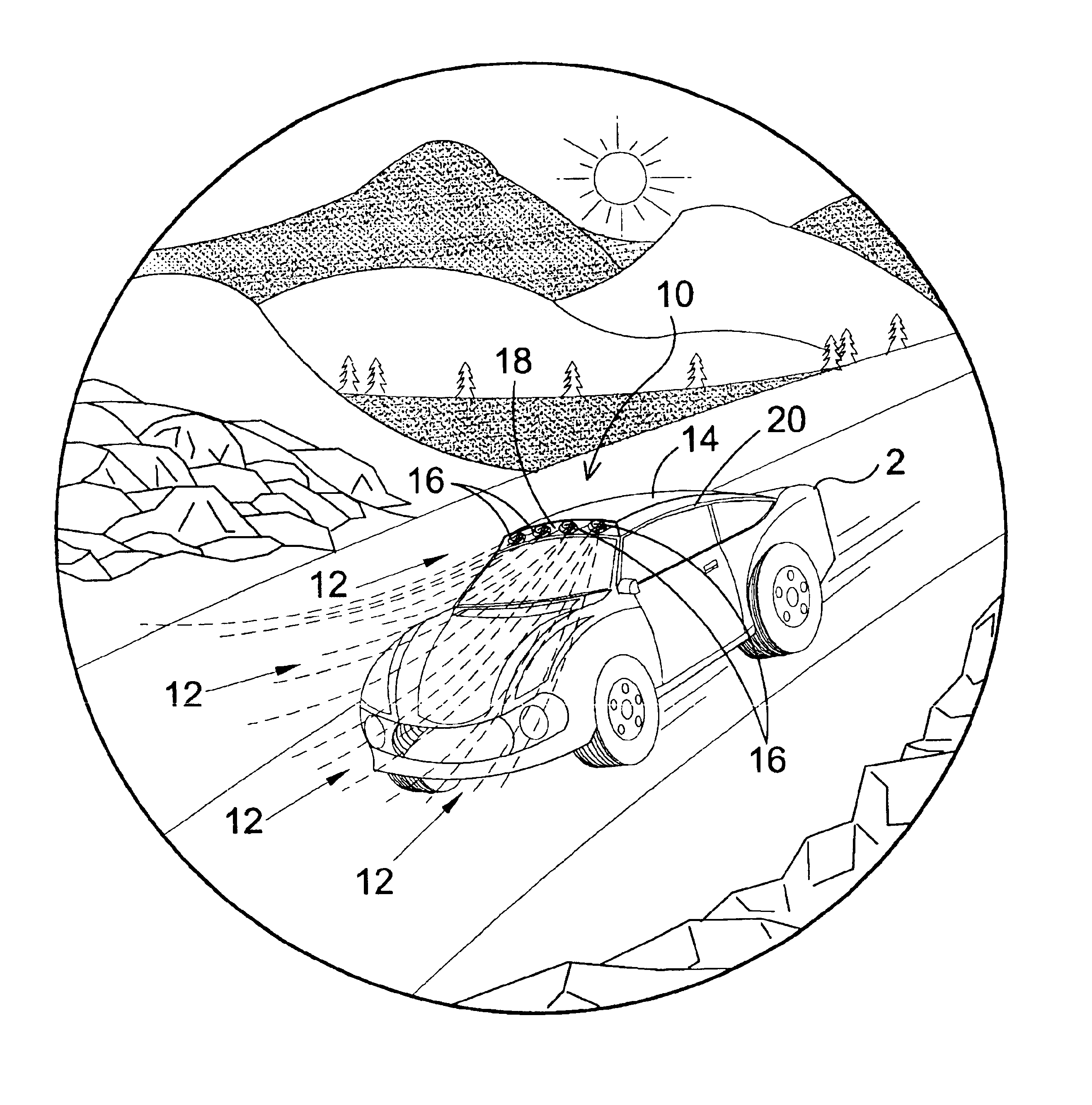

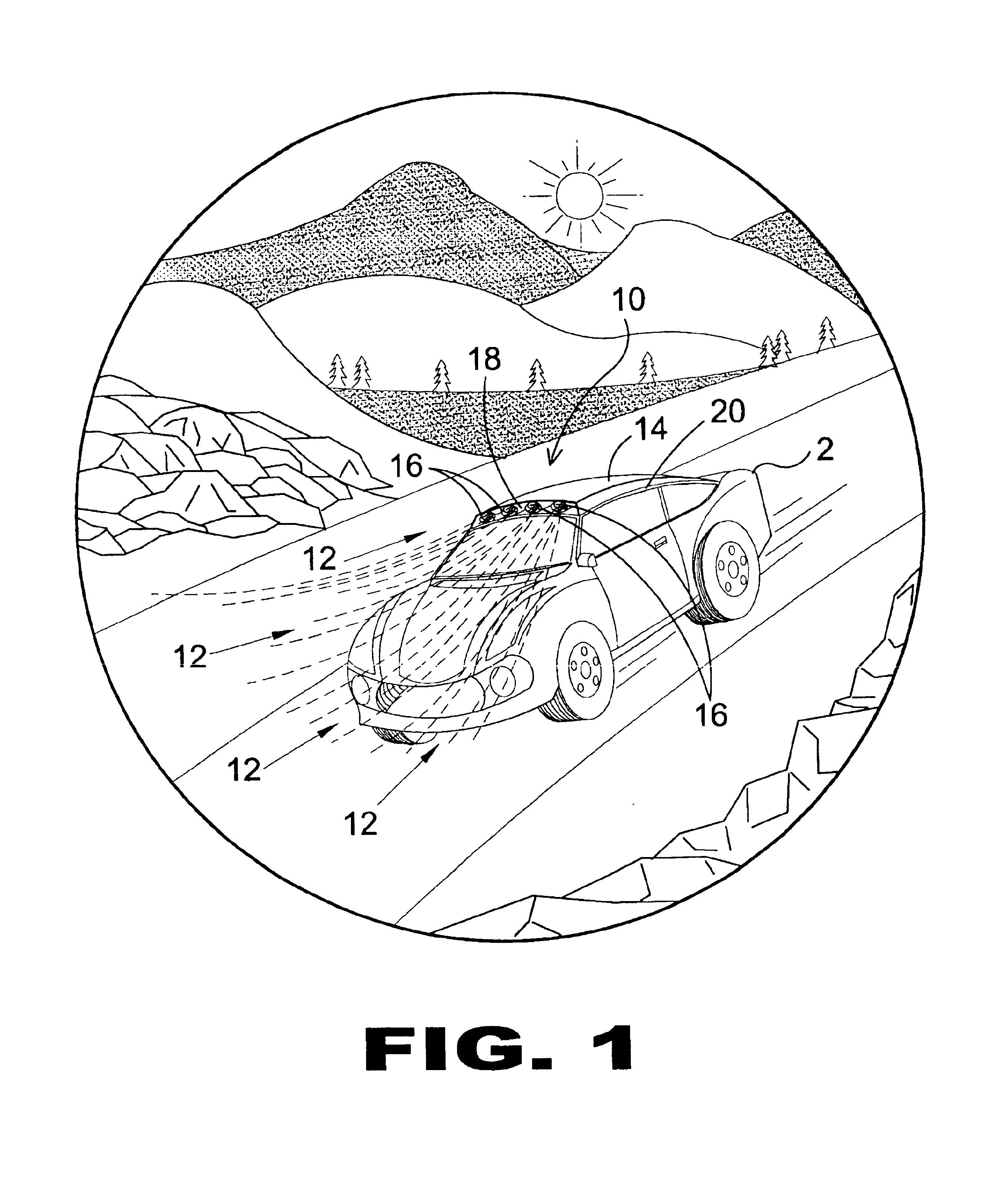

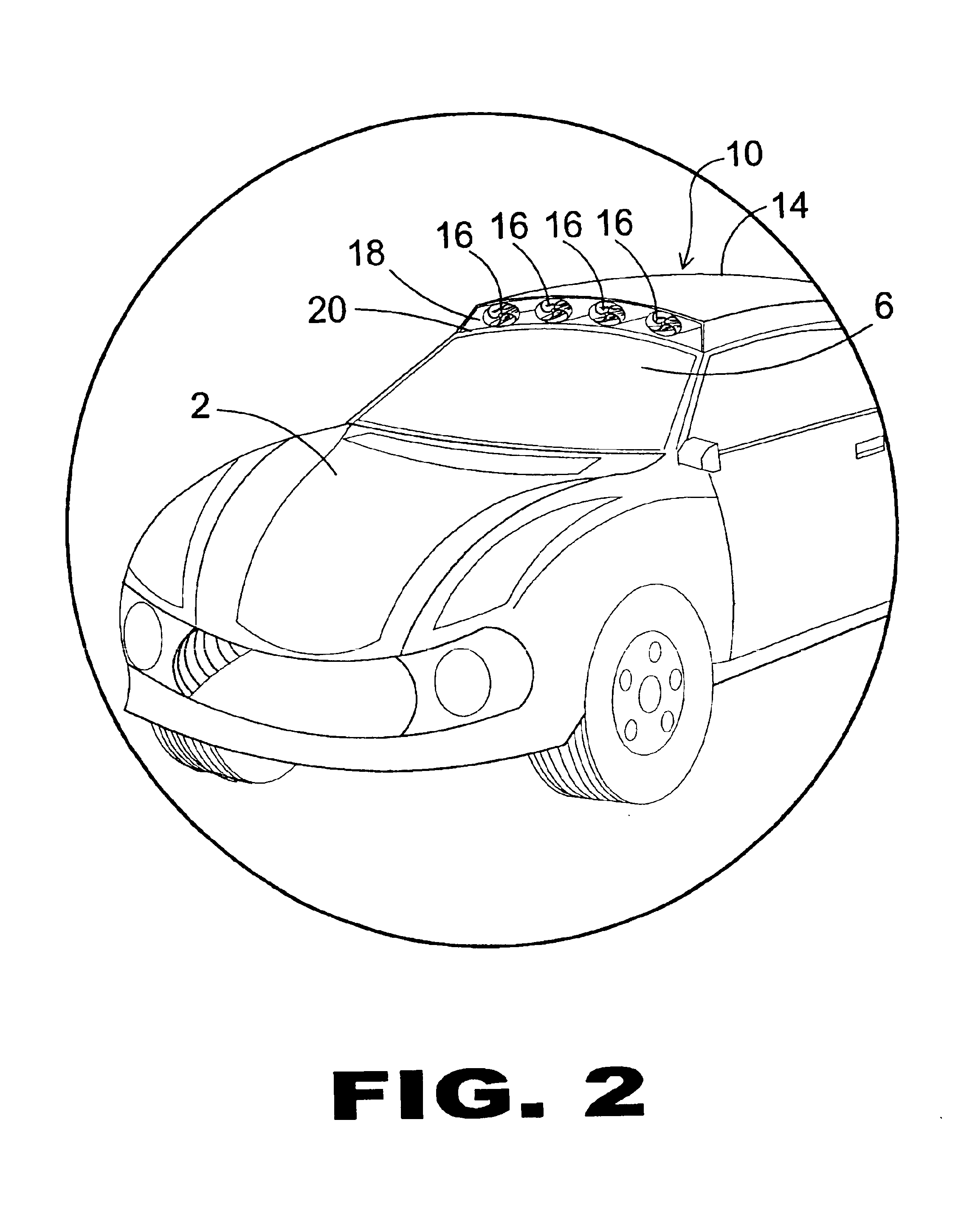

Portable wind power apparatus for electric vehicles

InactiveUS6897575B1Allows flexibilityMake portableHybrid vehiclesAuxillary drivesElectrical batteryAutomotive engineering

A device for converting wind energy into electrical energy for powering a vehicle, the device including a wind turbine positioned on the vehicle and a generator positioned within the vehicle and connected between the wind turbine and systems of the vehicle. When the vehicle is in motion, wind impinges on the wind turbine and causes the wind turbine to rotate. The generator converts rotational energy of the wind turbine into electrical energy. The electrical energy is provided to power the systems of the vehicle and the batteries of the vehicle are recharged.

Owner:YU XIAOYING

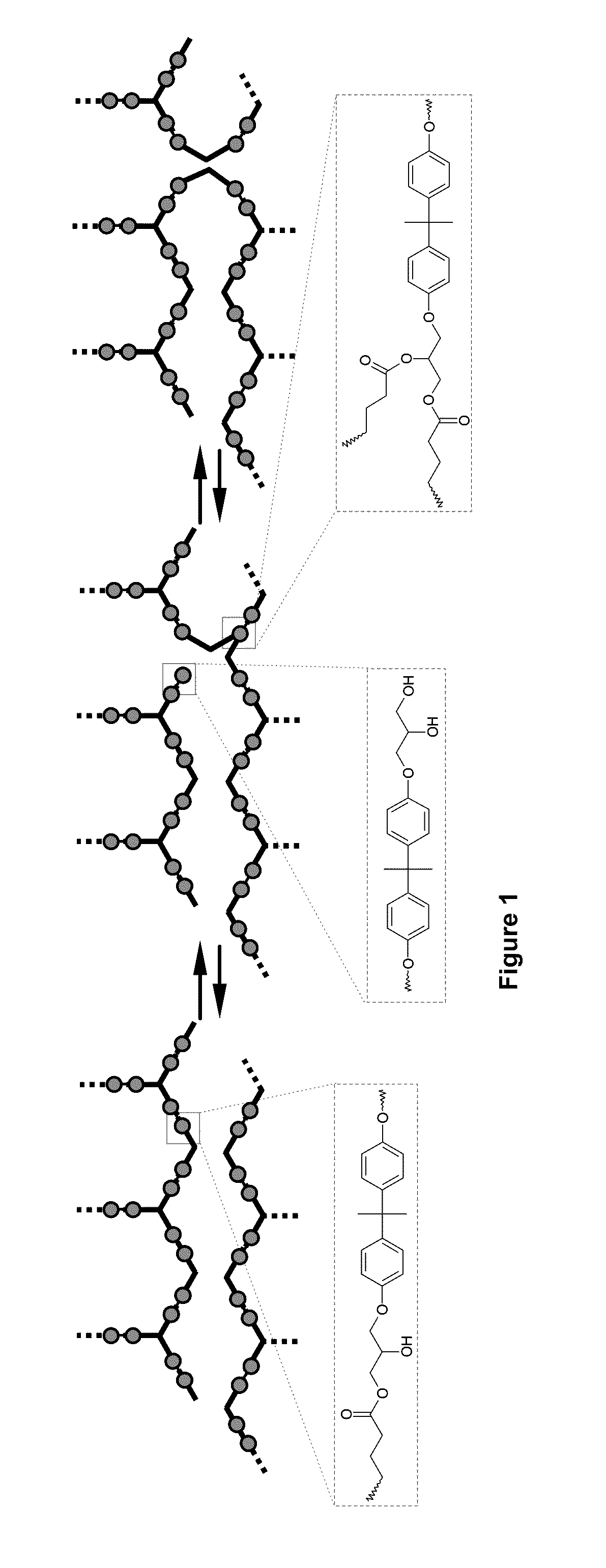

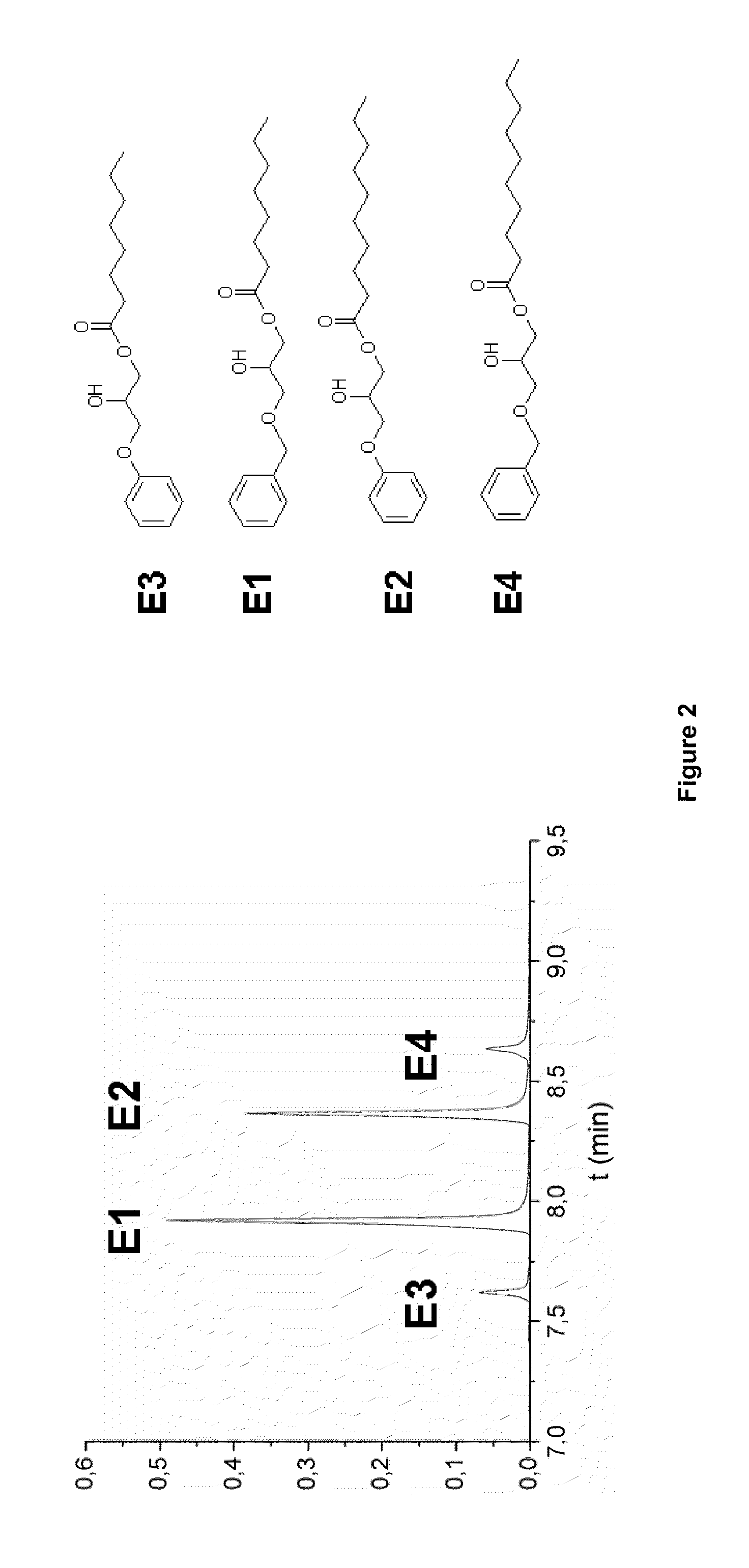

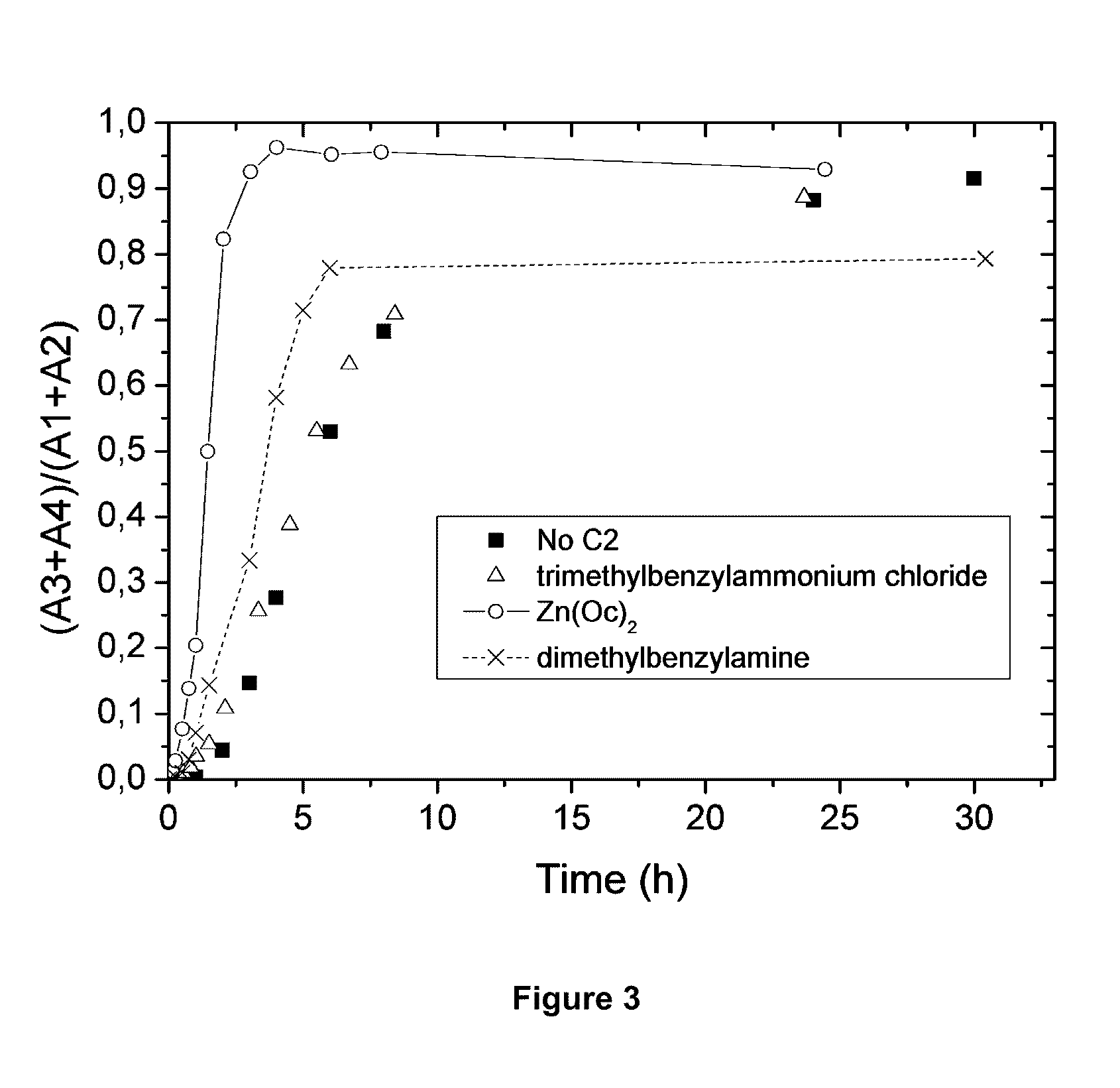

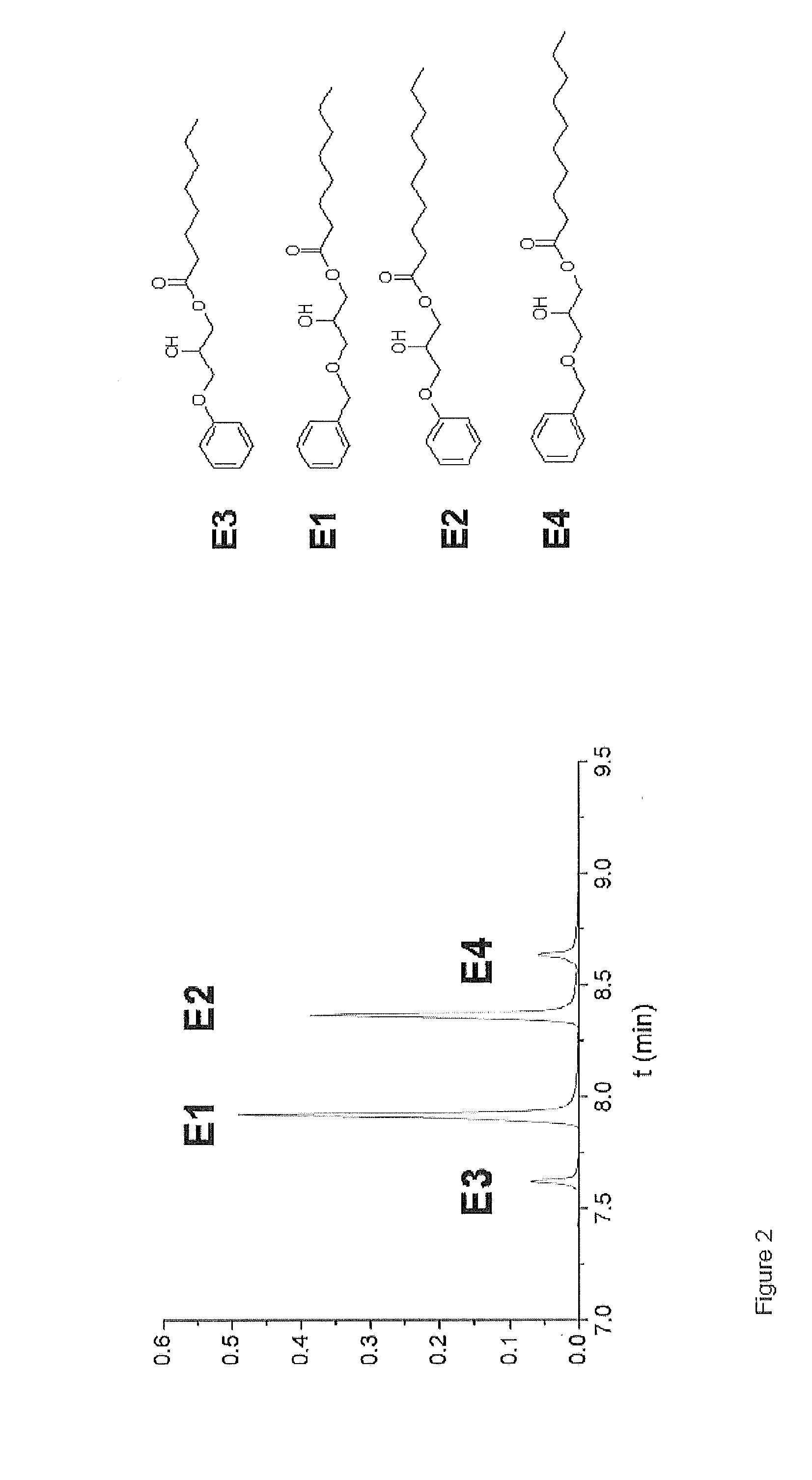

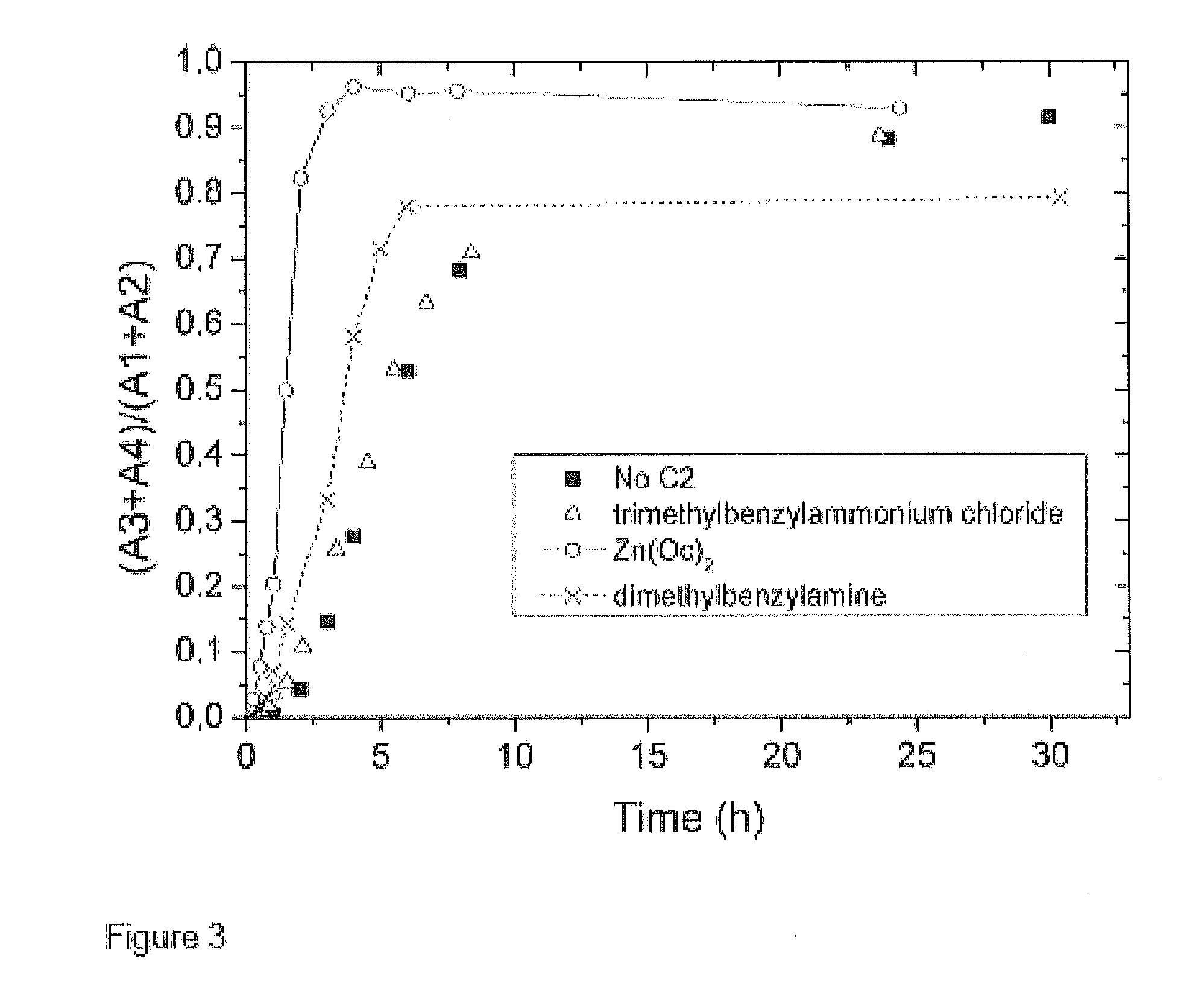

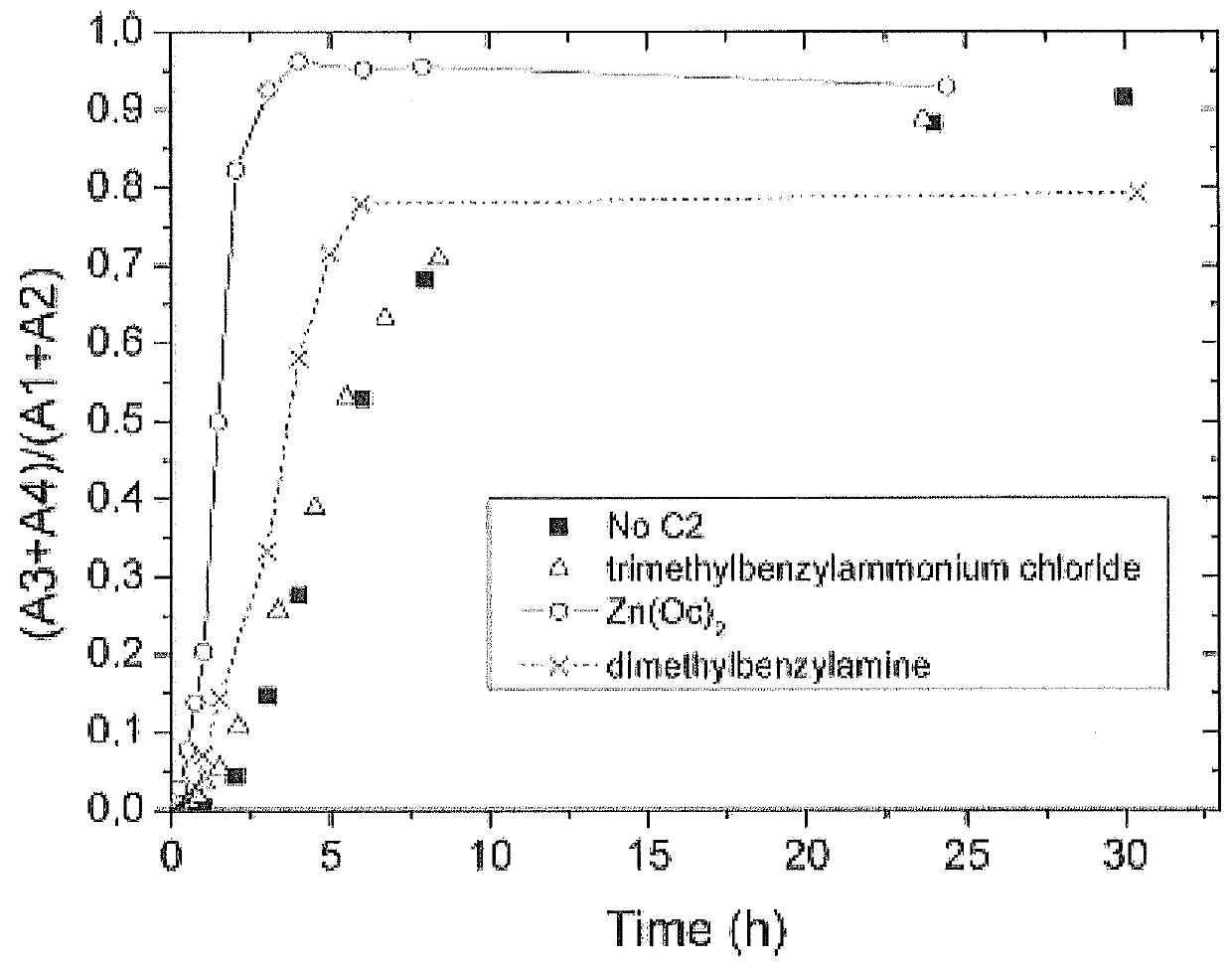

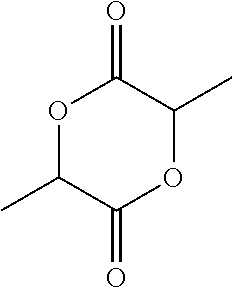

Epoxy Acid Thermoset Resins and Composites that Can Be Hot-Fashioned and Recycled

Resins and thermoset composites comprising them, these materials being able to be hot-fashioned. These compositions resulting from placing at least one thermosetting resin precursor, this thermosetting resin precursor comprising hydroxyl functions and / or epoxy groups, and optionally ester functions, in contact with at least one hardener chosen from carboxylic acids, in the presence of at least one transesterification catalyst whose total molar amount is between 5% and 25% of the total molar amount of hydroxyl and epoxy contained in the thermosetting resin precursor. Process for manufacturing these materials, process for transforming and process for recycling these materials. New solid forms of resins and of thermoset composites that may be used in the implementation of these processes.

Owner:CENT NAT DE LA RECHERCHE SCI +1

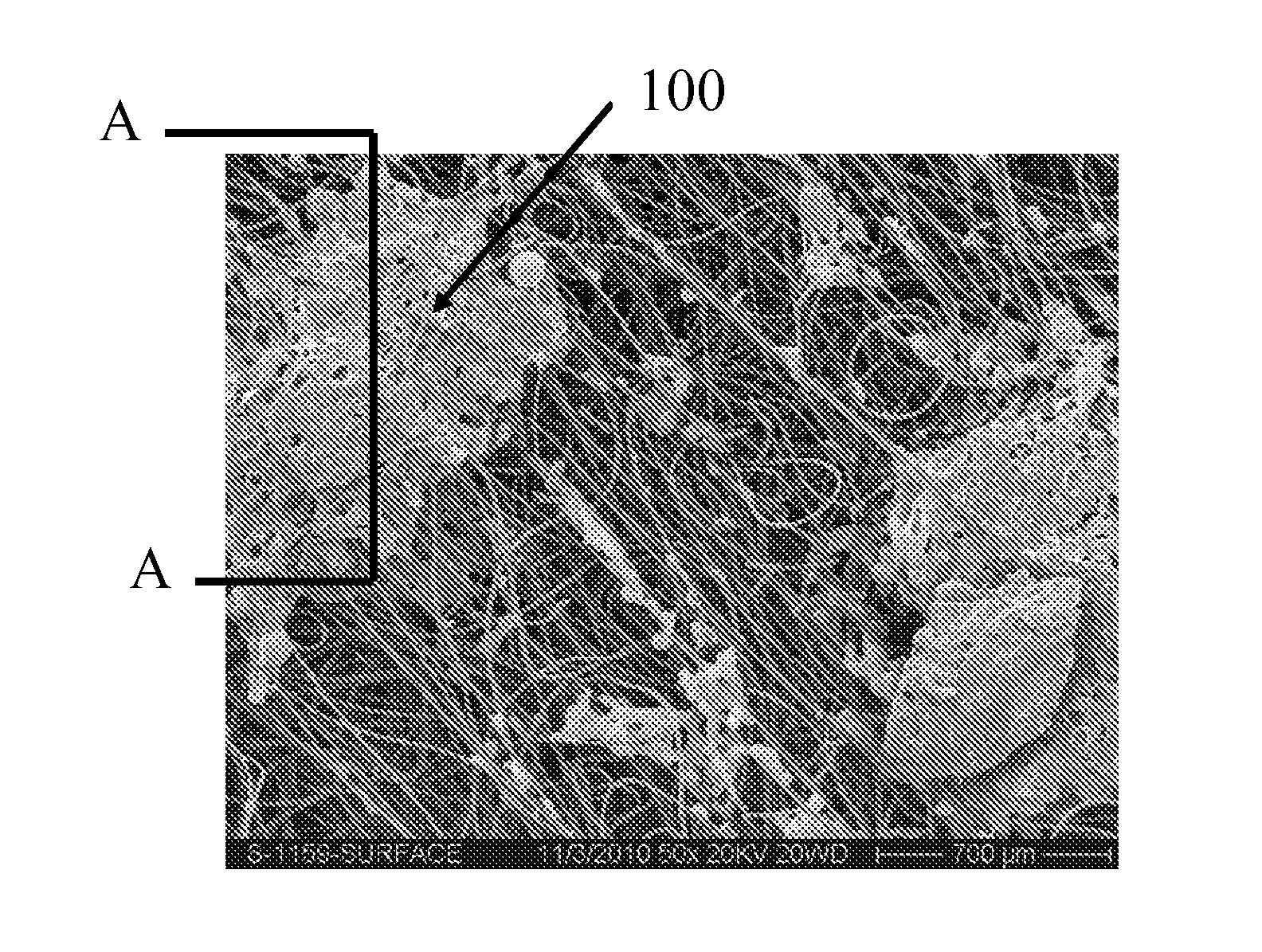

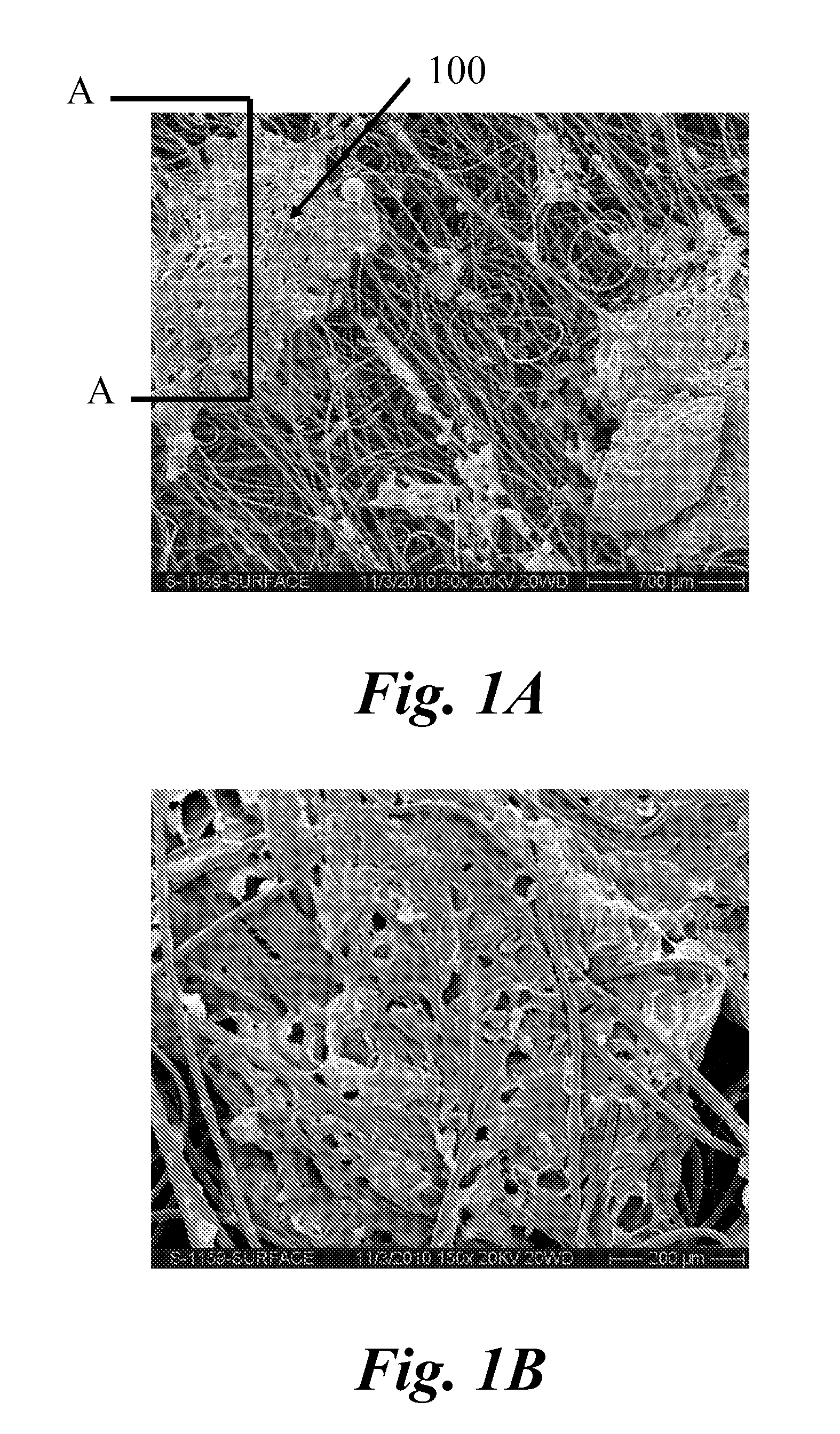

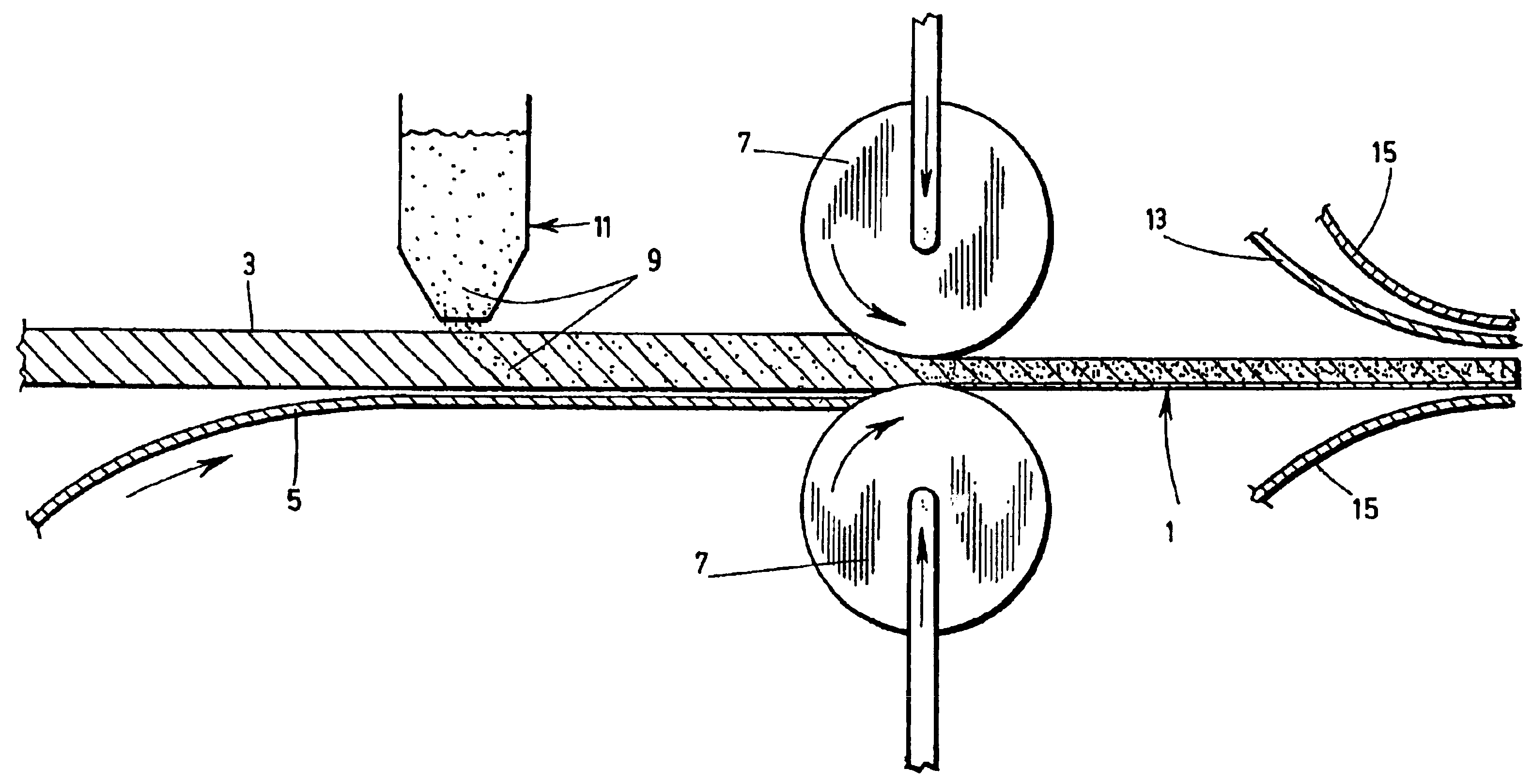

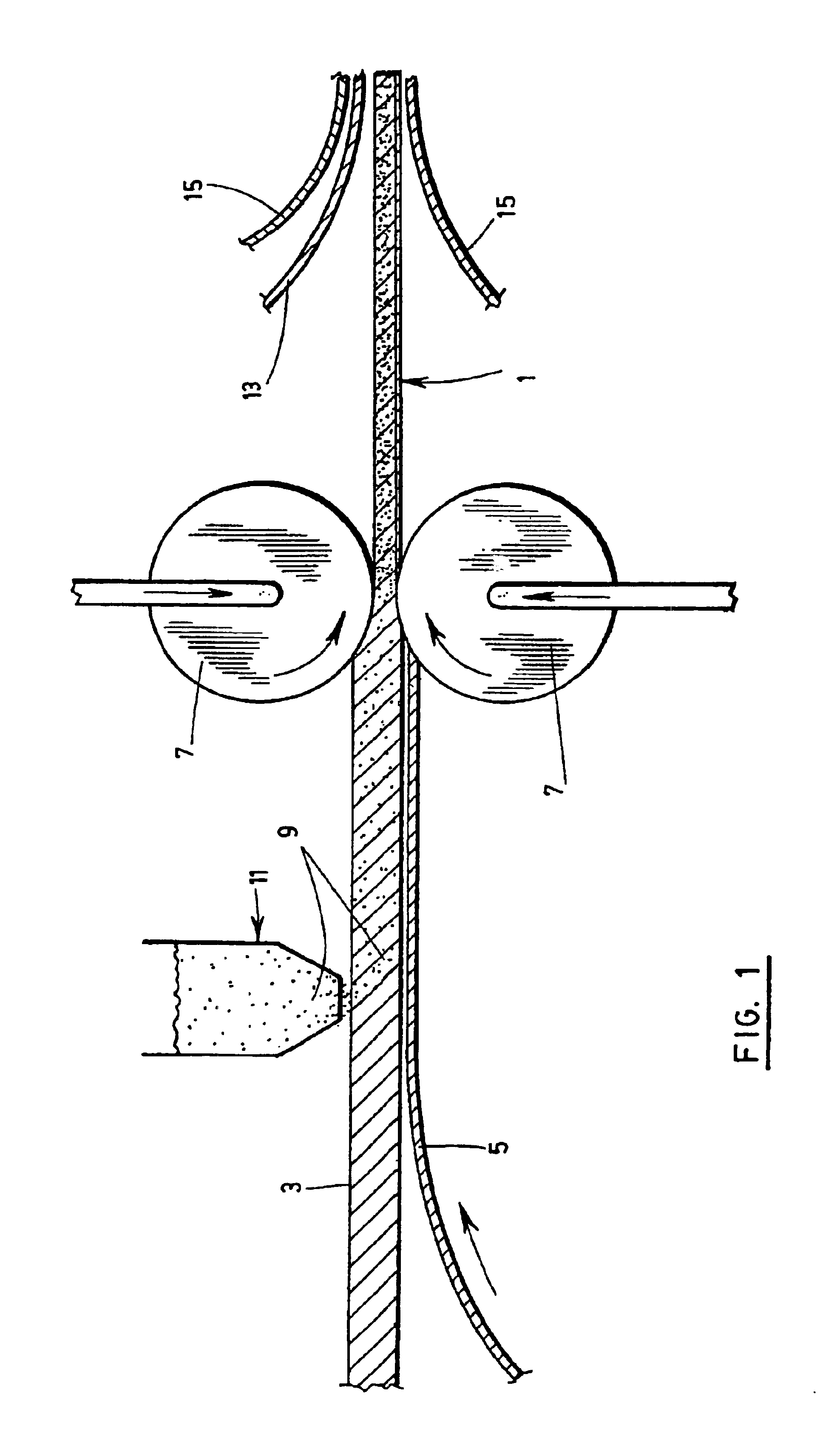

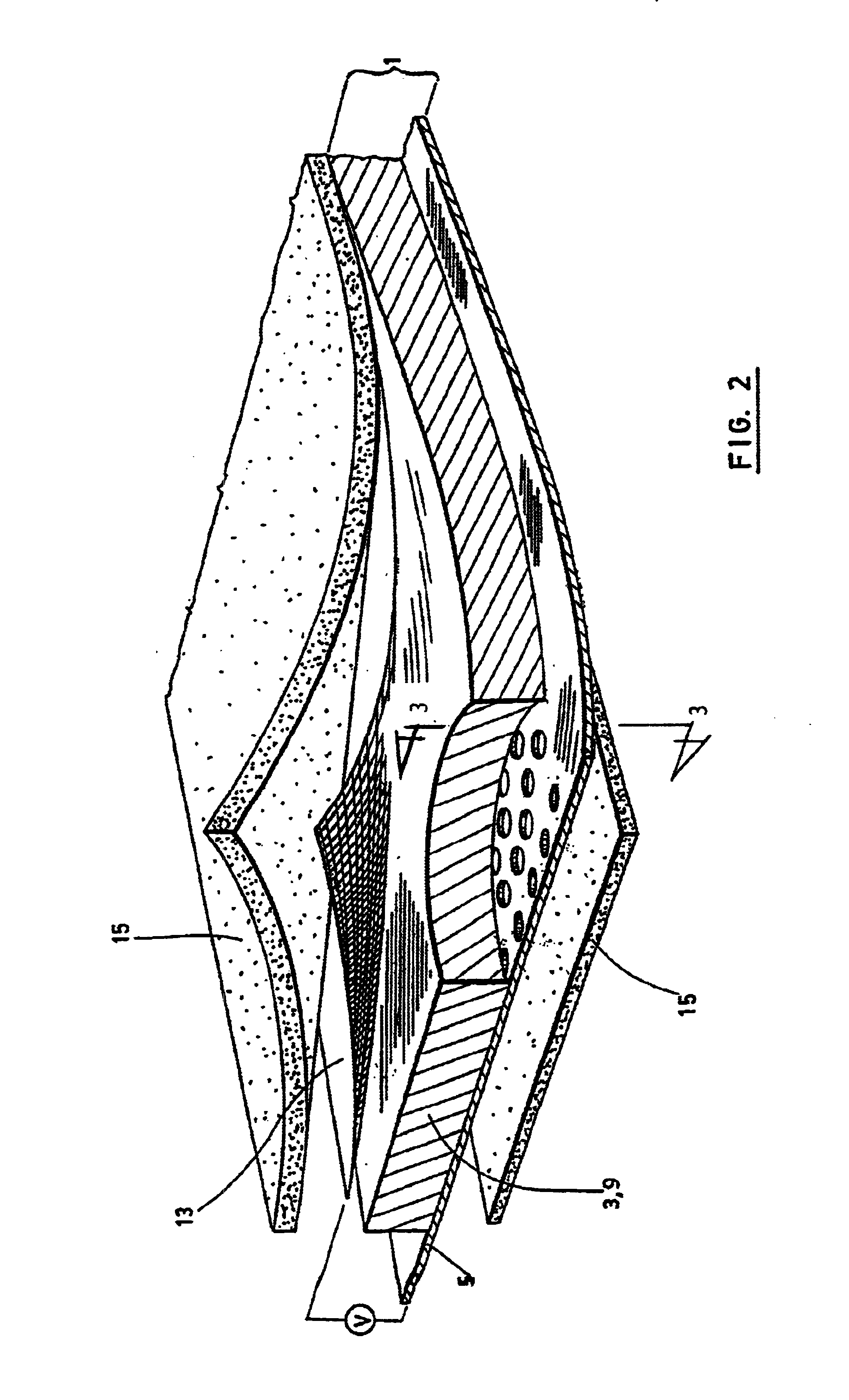

In-line printing process on wet non-woven fabric and products thereof

ActiveUS20120094091A1Allow for manufactureIncrease in sizeCarpet cleanersFibre treatmentScreen printingNonwoven fabric

A process for manufacturing a non-woven fabric having on its surface distributed elements having a physical dimension, comprises screen printing on wet fabric a desired shape using a paste that expands under heating by virtue of a puffing agent contained therein.

Owner:N R SPUNTECH IND

Kinetic batteries

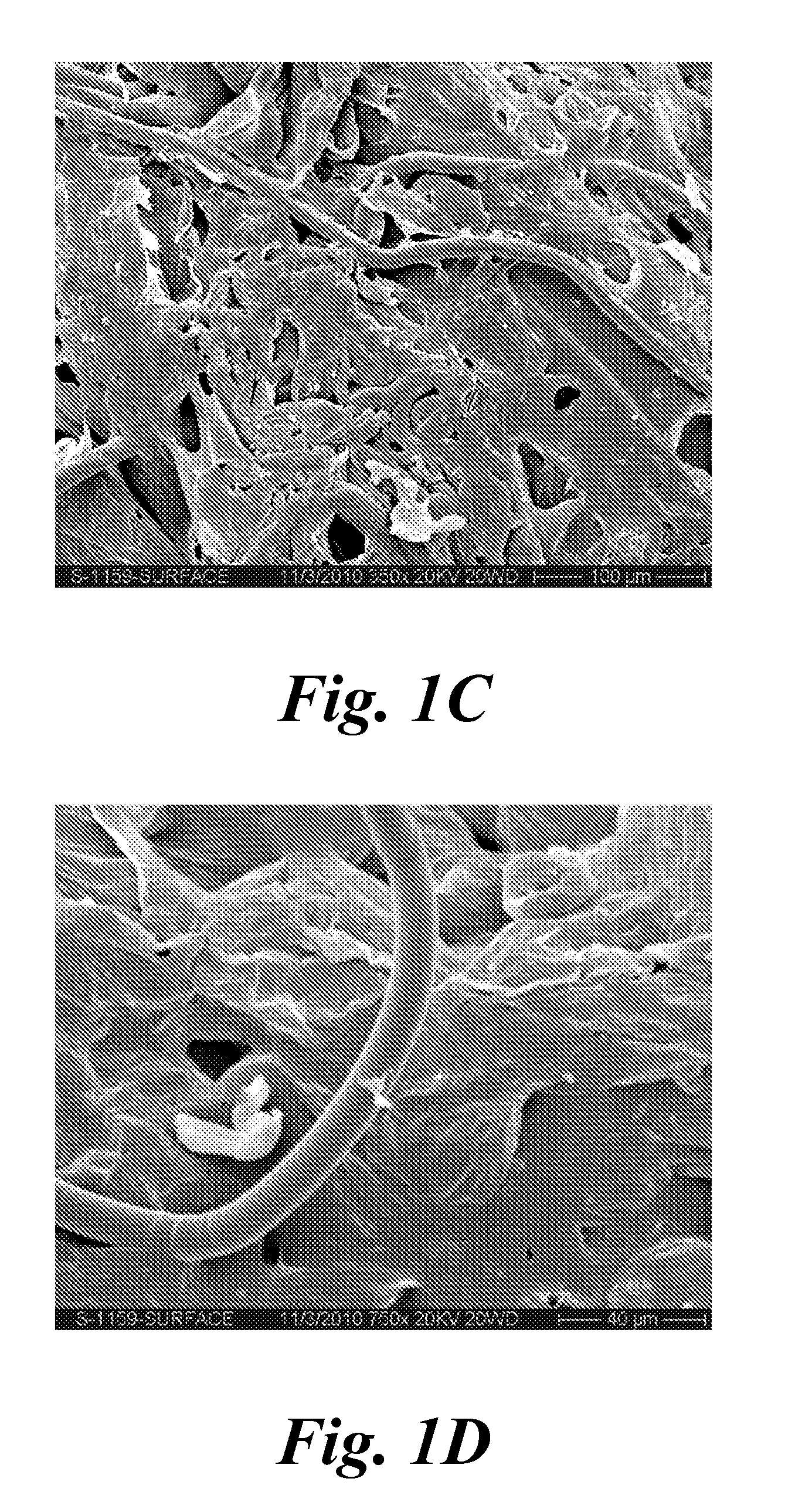

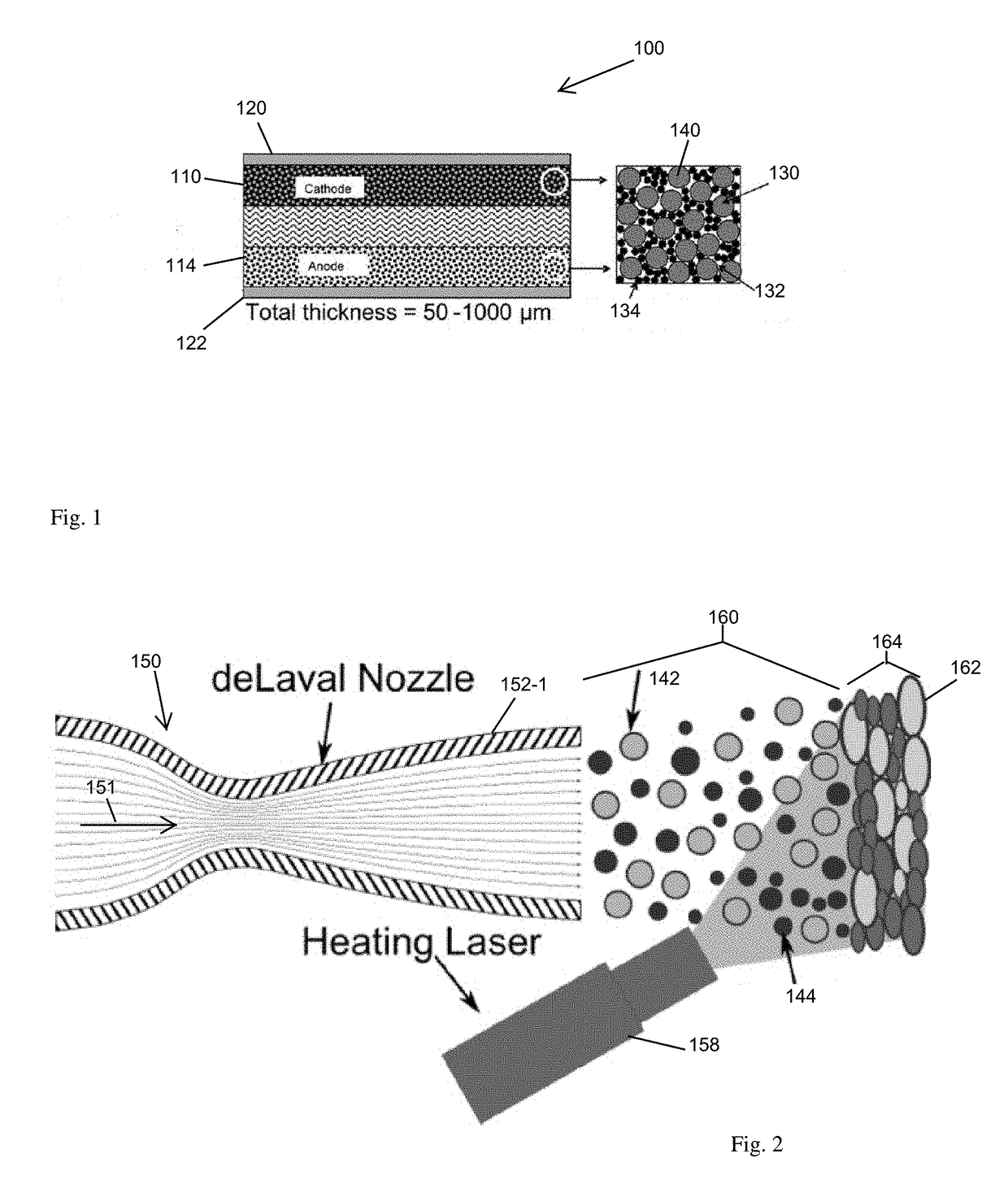

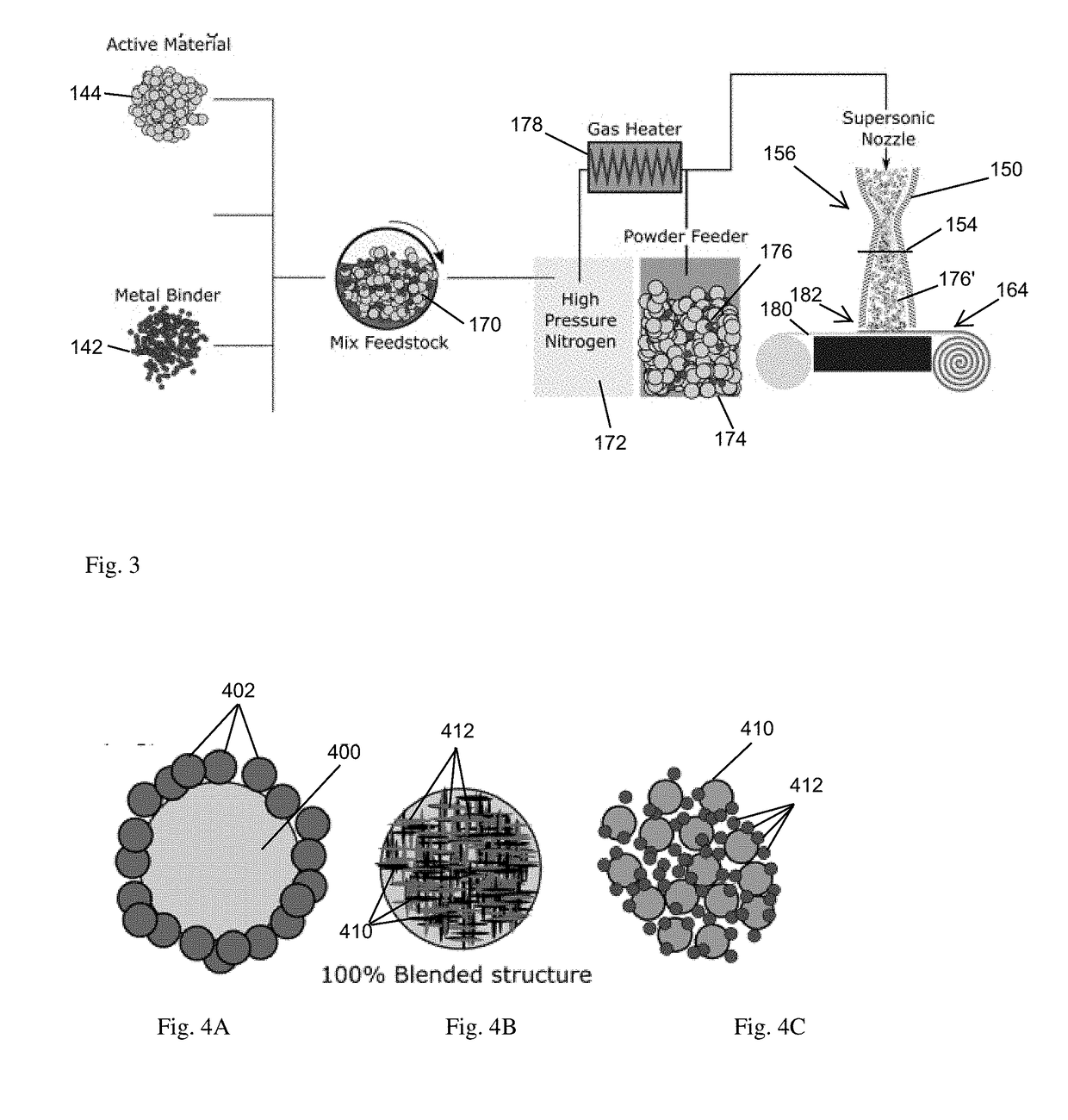

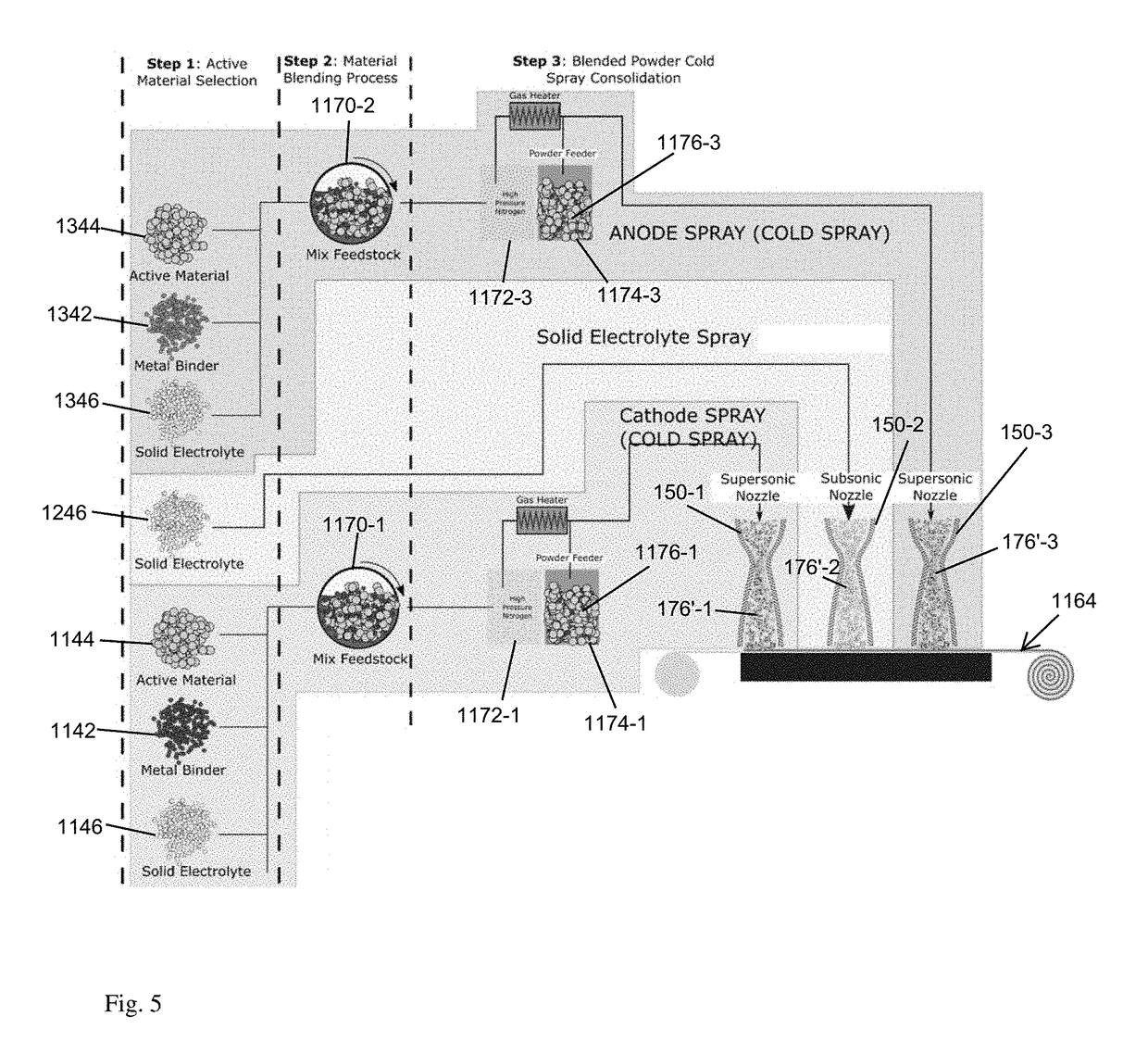

InactiveUS20180138494A1Reduce the temperatureIncrease energy densityManufacture by sprayingPressure inorganic powder coatingLithiumElectrolysis

A rechargeable lithium-ion (Li-ion) battery employs a solvent-less, low temperature approach to battery manufacturing that forms charge material from kinetic energy of high velocity particles impelled into an aggregation such that bombardment of the particles against other particles in the aggregation forms a charge conveying structure. High velocity bombardment from a carrier gas nozzle accumulates an active charge material (active material) and metal binder in a layered arrangement for the finished battery. Preparation of the particles, such as by ball milling or freeze drying, arranges particle agglomerations. The particle agglomerations, when impelled against other agglomerations or a current collector, forms a layer of cathodic, anodic or electrolytic battery material. The metallic binder conveys charge for mitigating or eliminating a need for a planar current collector underlying the sprayed layer. The resulting layers are suitable for battery operation, and are manufactured in an absence of any solvent drying or disposal.

Owner:WORCESTER POLYTECHNIC INSTITUTE

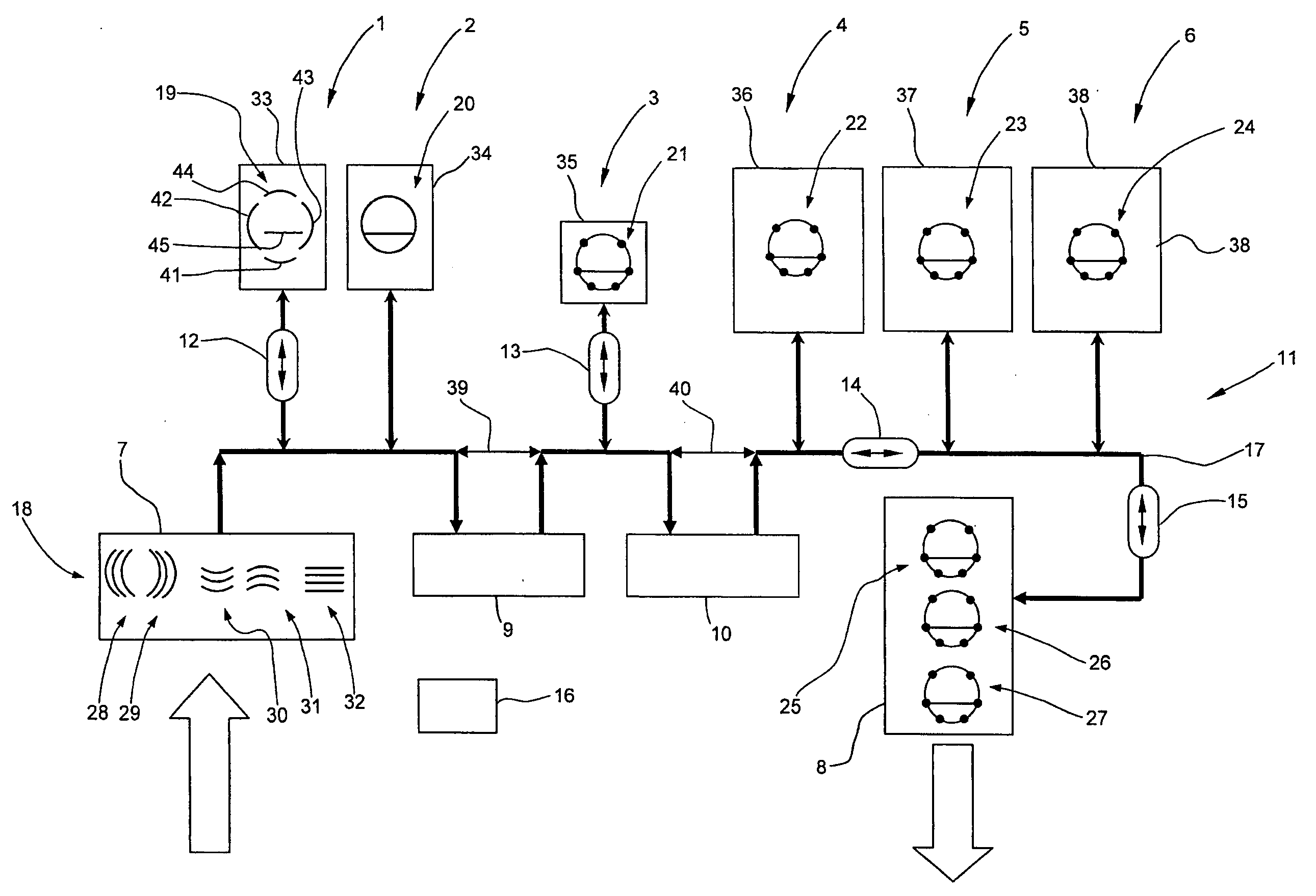

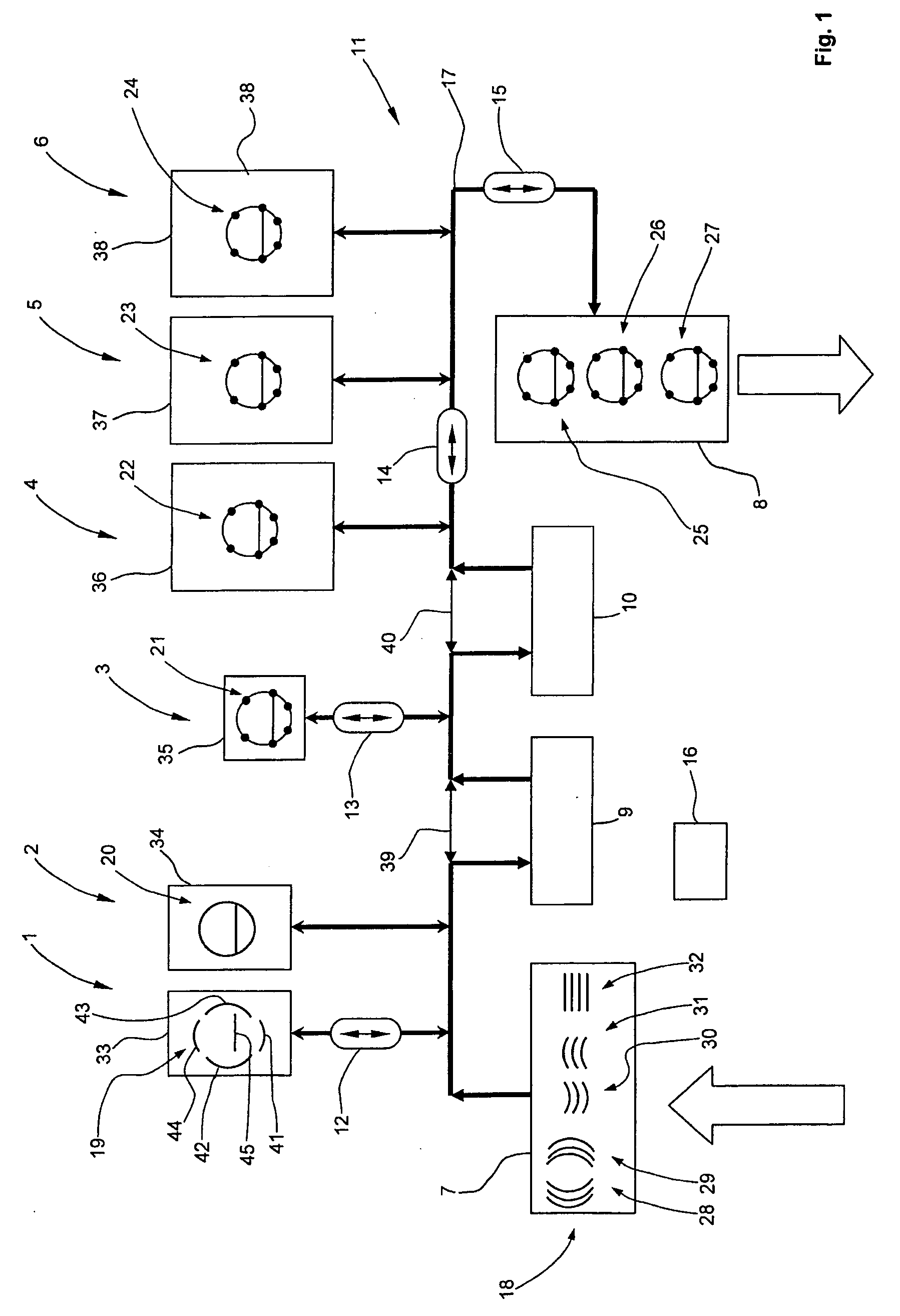

Method and device for manufacturing sections for transportation systems

InactiveUS20060185143A1Prevent unnecessary time delayNo human intervention requiredAssembly machinesAircraft assemblyWorkstationAutomation

A device for manufacturing sections that are composed of several individual components uses a plurality of workstations. According to an embodiment of the invention, each workstation is designed for carrying out at least one of at least three manufacturing steps. Sections may be processed in each workstation regardless of their shape and / or size. A specialized manufacturing step such as assembly and tacking, connecting, finishing or performing follow-up work is carried out in each workstation. This allows a high degree of automation in at least some of the stations and improved capacity utilization, because the sections are transferred to a downstream workstation after the completion of the respective manufacturing. In one example, a method for manufacturing sections for transportation devices, such as aircraft, by assembling several individual components in a plurality of workstations is disclosed. One of at least three manufacturing steps is carried out in each workstation and the respective sections are processed in each workstation regardless of their shape and / or size.

Owner:AIRBUS OPERATIONS GMBH

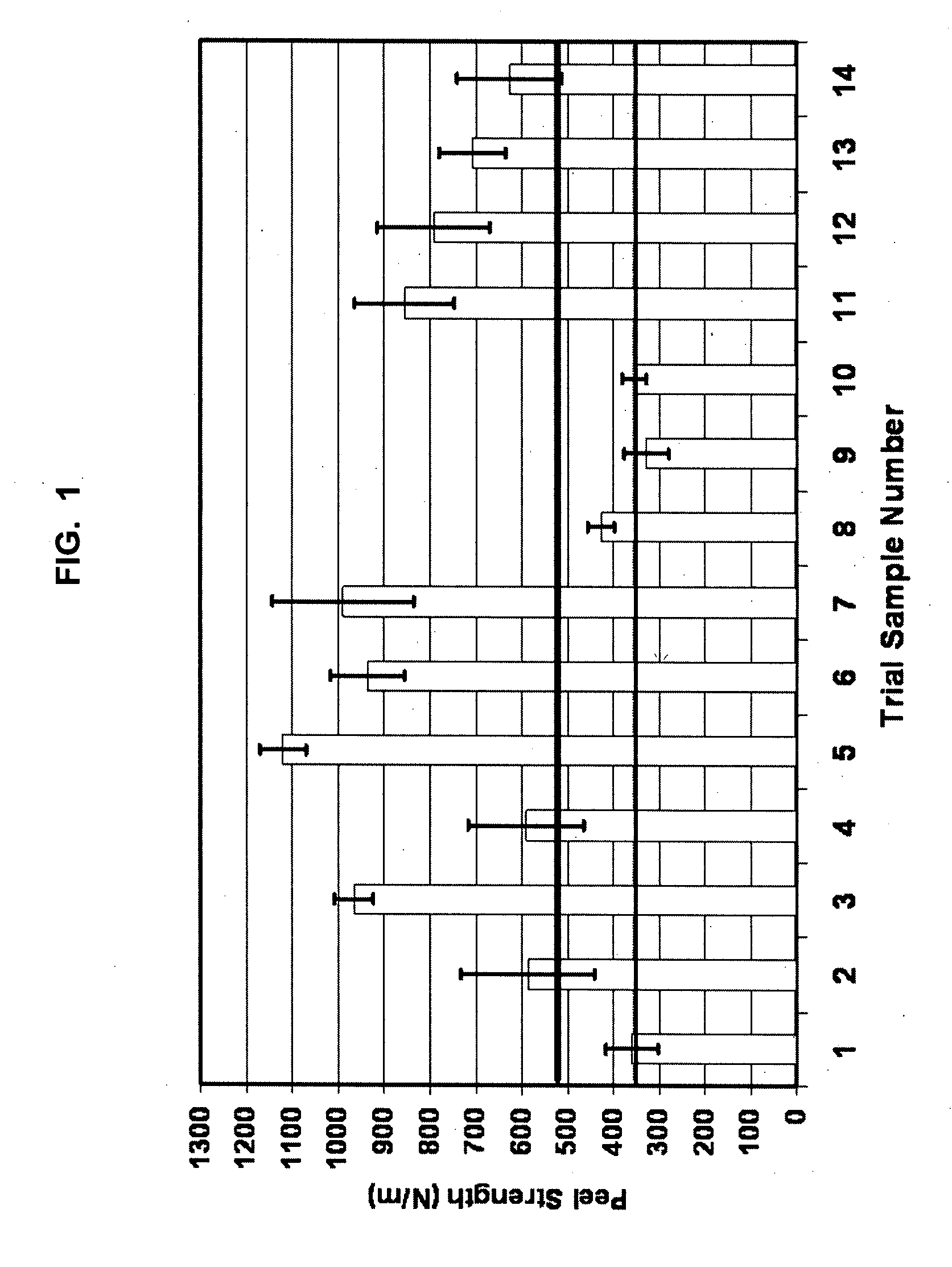

Moldable composite sheet with improved adhesion at elevated service temperatures

InactiveUS20080032094A1Improved thermal adhesive characteristicImprove adhesionThin material handlingMetal layered productsThermoplasticMetal forming

A moldable composite sheet having improved adhesion characteristics, particularly at elevated service temperatures, as well as improved sound absorption and attenuation of transmitted sound intensities. In one aspect, the composite sheet may be a porous fiber-reinforced thermoplastic comprising discontinuous reinforcing fibers and having an adhesive skin layer covering. Generally, the-composite sheet may have a void content or porosity from about 5% to about 95% by volume of the sheet, an areal weight between about 400 g / m2 to about 4000 g / m2 and a fiber content from about 20% to about 98% by weight. The composite sheet can be molded via low pressure processes, such as thermoforming, match metal molding on stops, vacuum forming and pressure forming, to produce durable automotive interior trim parts capable of withstanding service temperatures exceeding 100° C. for extended periods of time along with improved sound absorption capabilities exceeding a noise reduction coefficient (NRC) rating of 0.5.

Owner:AZDEL INC

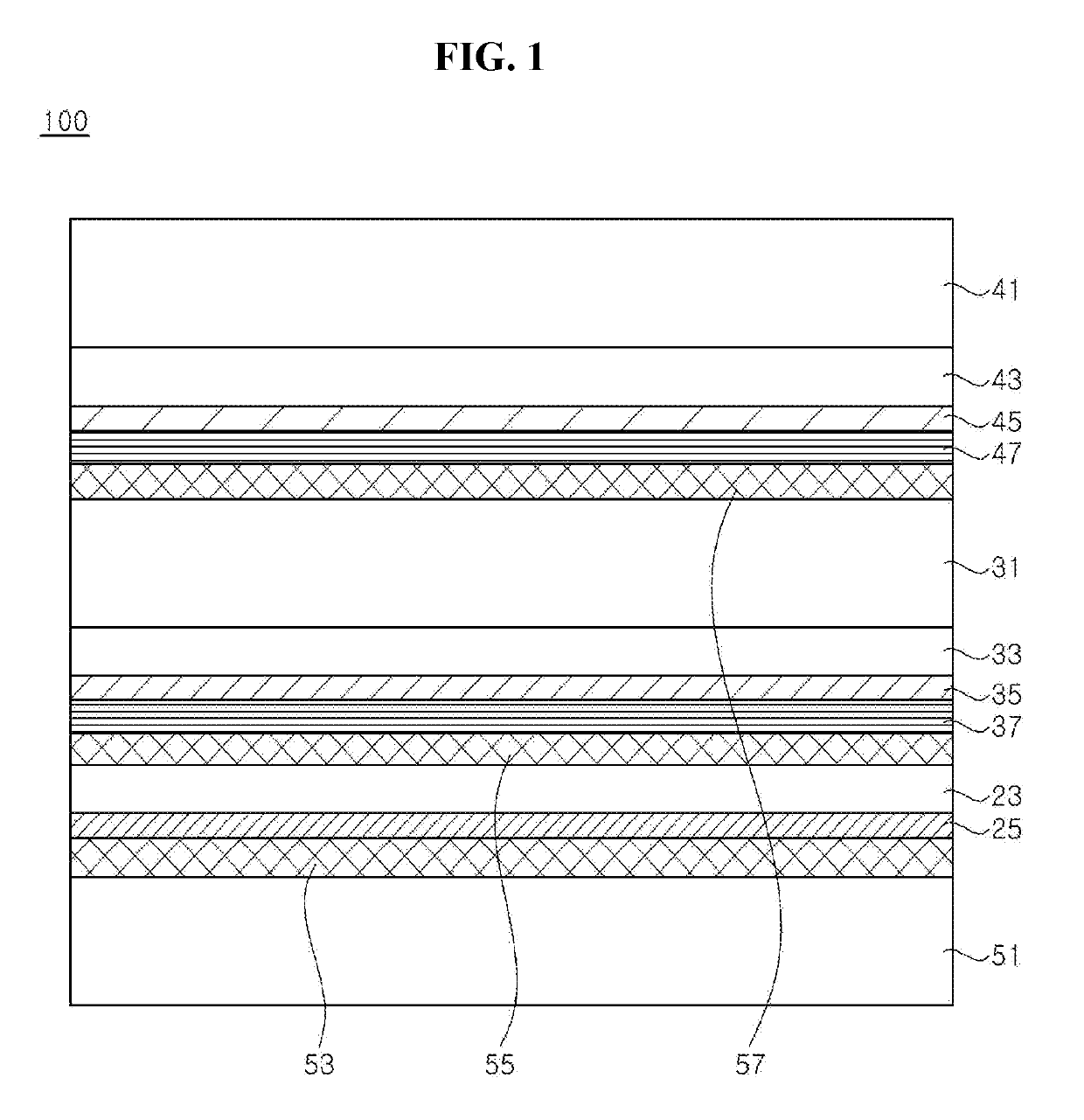

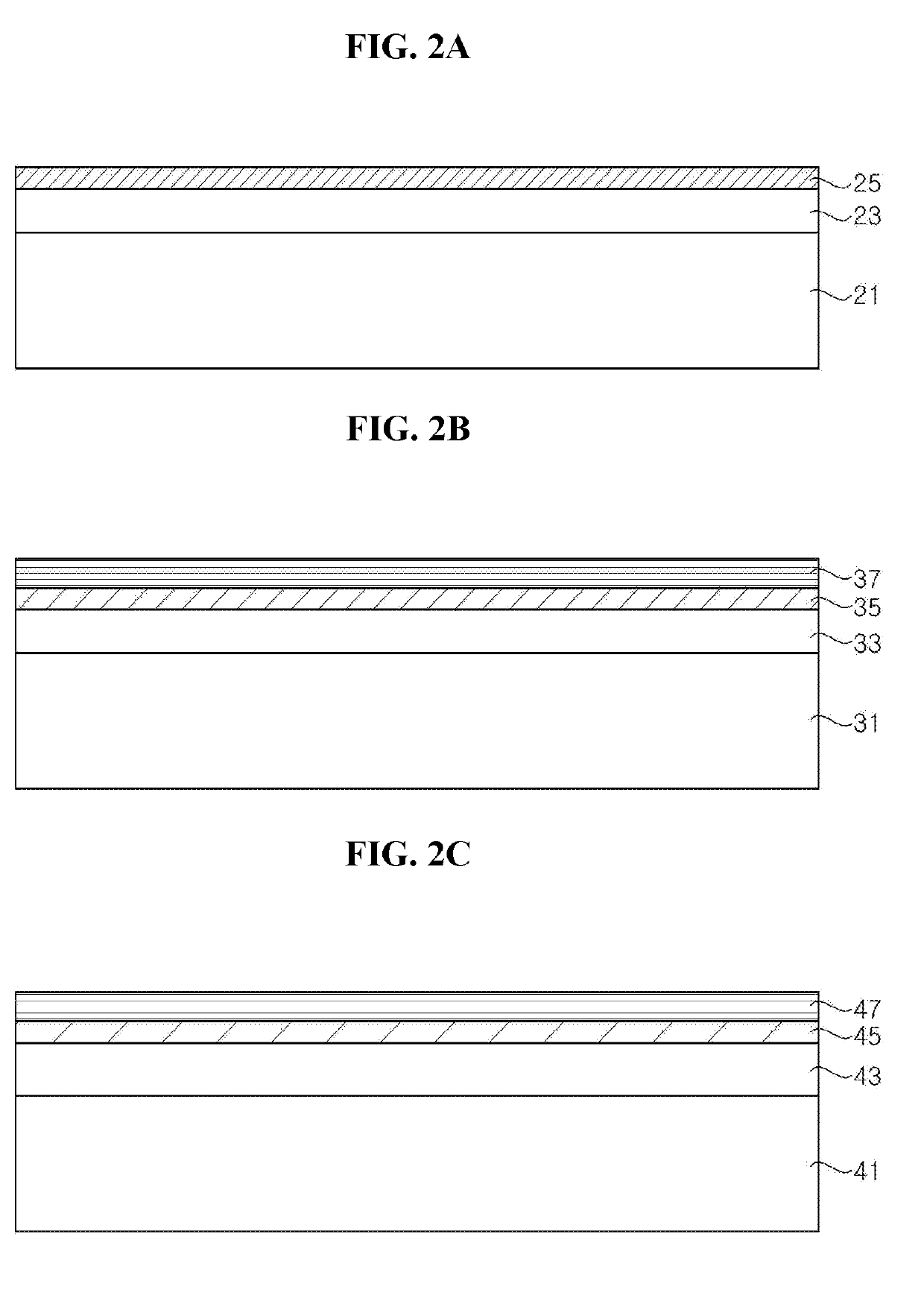

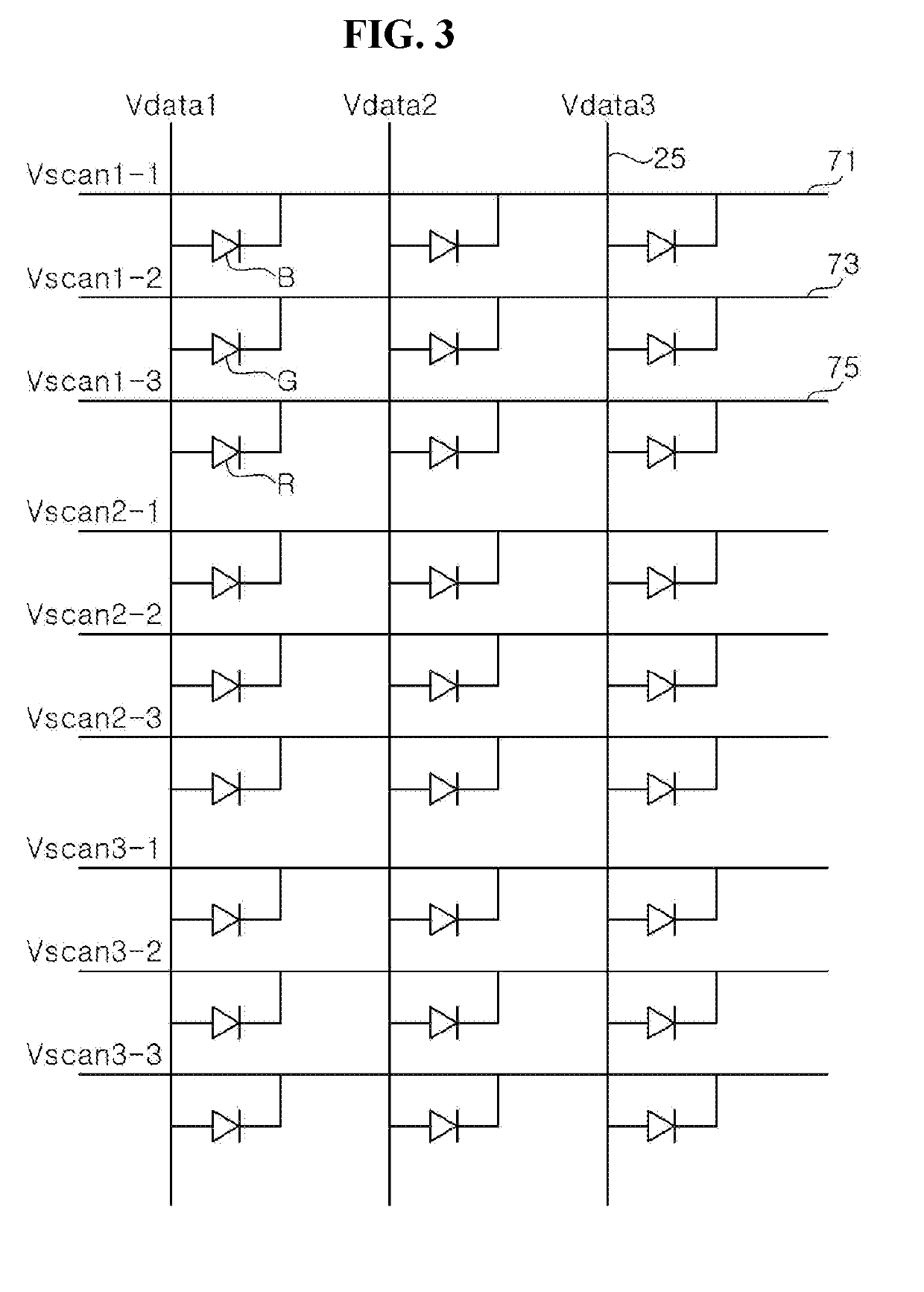

Light emitting diode for display and display apparatus having the same

PendingUS20190164945A1Increase light emitting areaReduce areaSolid-state devicesSemiconductor devicesDisplay deviceLight-emitting diode

A light emitting diode stack for a display includes a support substrate, a first LED stack, a second LED stack, and a third LED stack, a conductive growth substrate coupled to the second LED stack or the third LED stack, a first color filter interposed between the first and second LED stacks and transmitting light generated from the first LED stack while reflecting light generated from the second LED stack, and a second color filter interposed between the second and third LED stacks and transmitting light generated from the first and second LED stacks while reflecting light generated from the third LED stack, in which light generated from the first LED stack is emitted outside through the second LED stack, the third LED stack, and the conductive growth substrate, and light generated from the second LED stack is emitted outside through the third LED stack and the conductive growth substrate.

Owner:SEOUL VIOSYS CO LTD

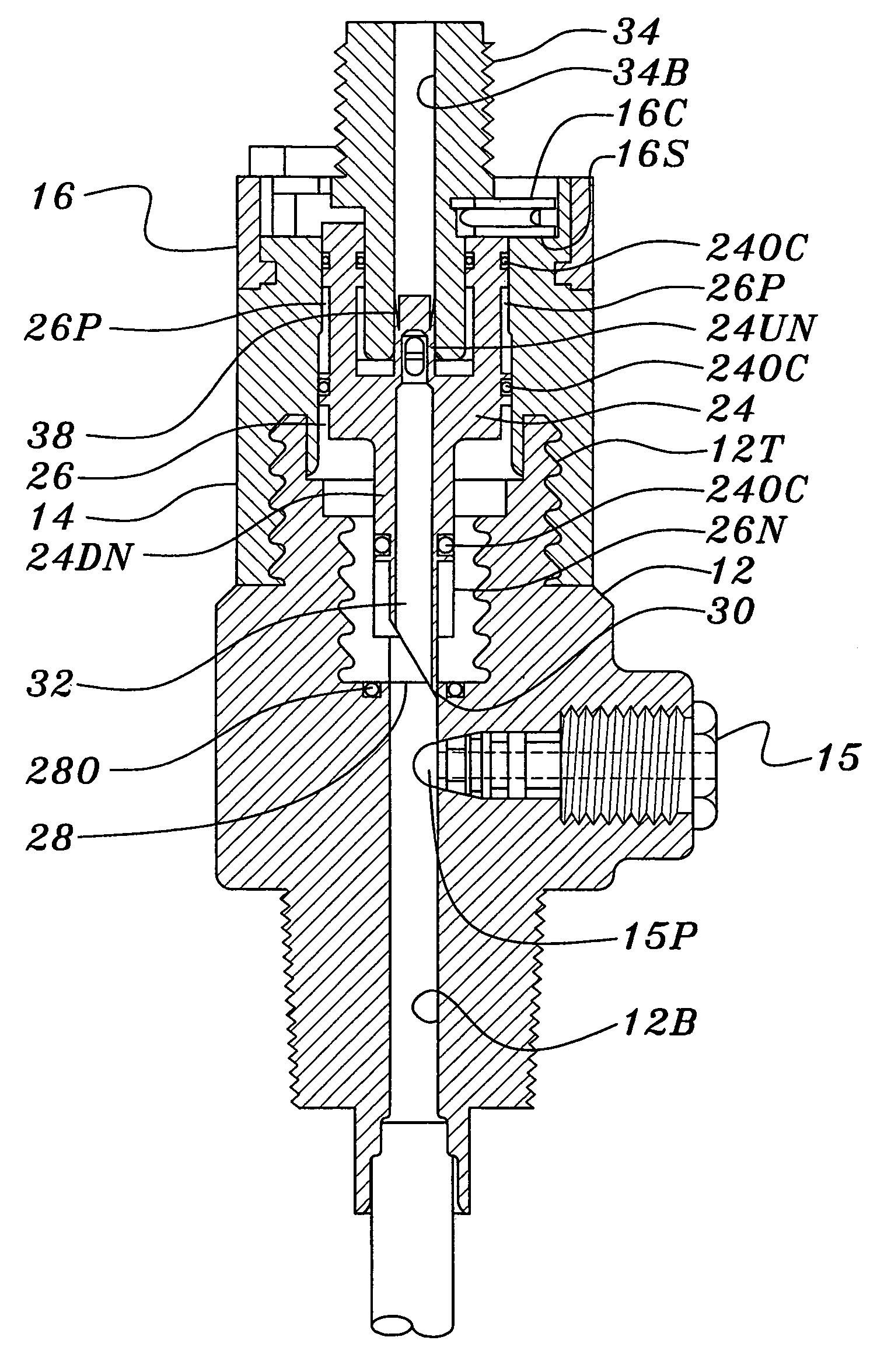

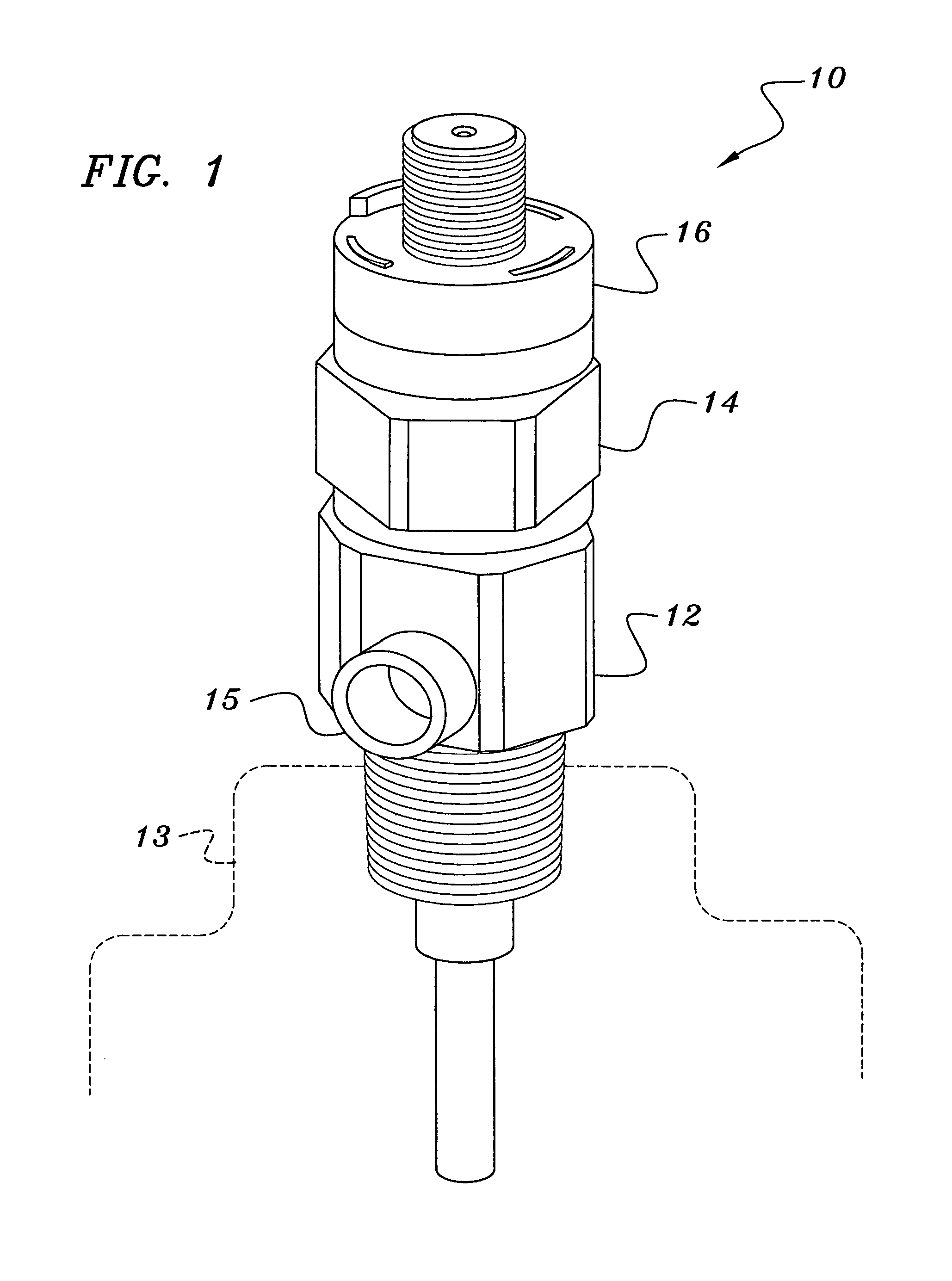

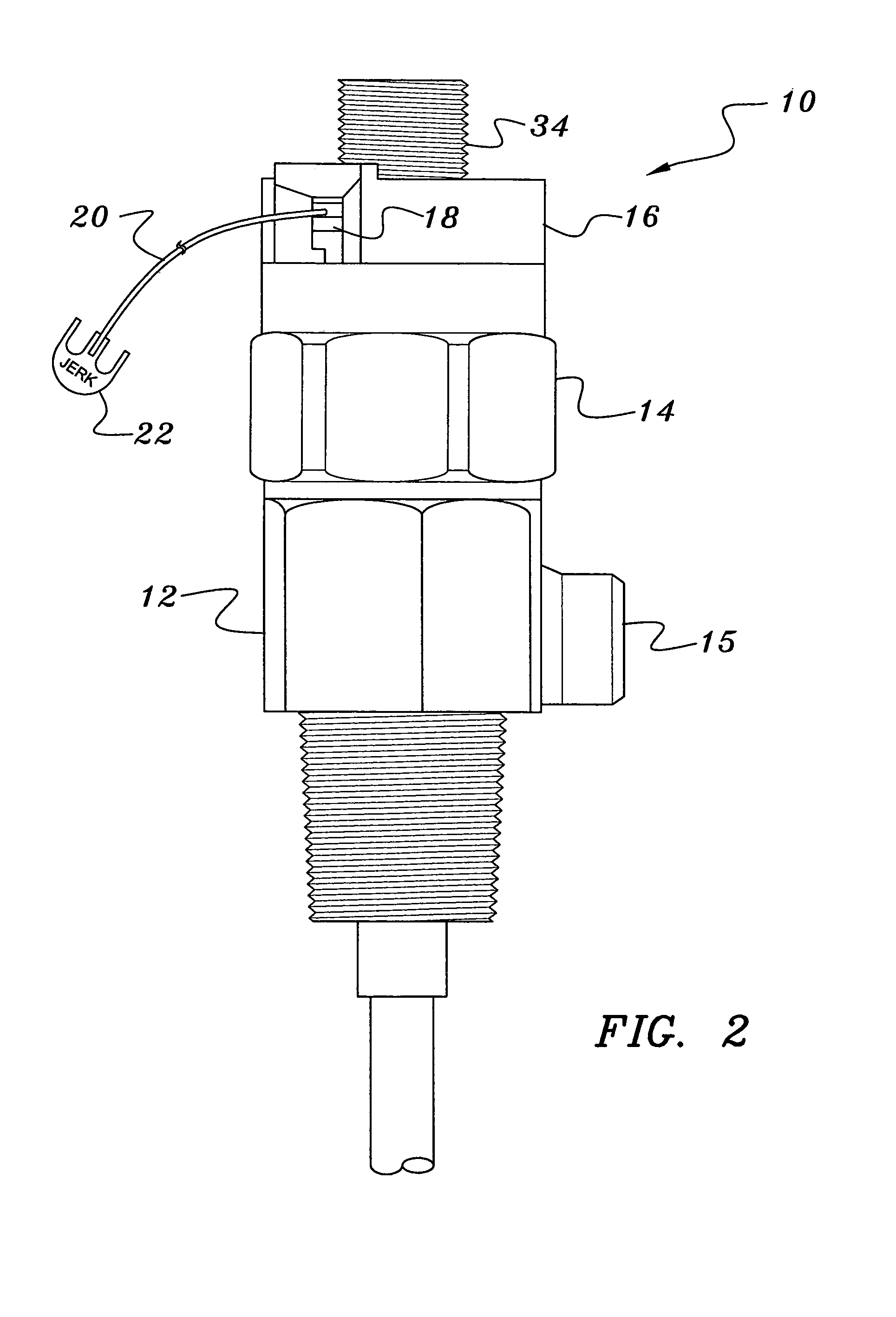

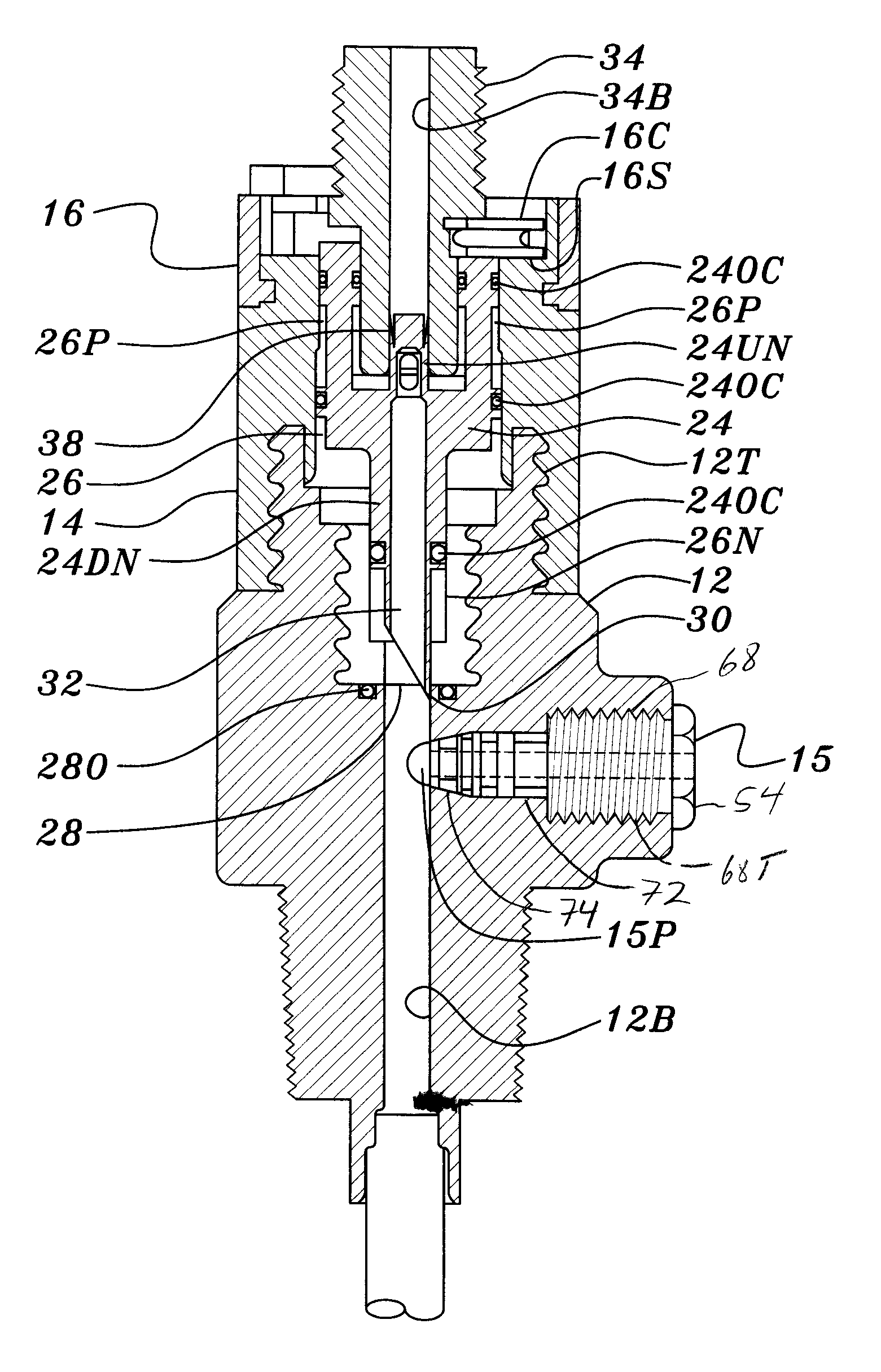

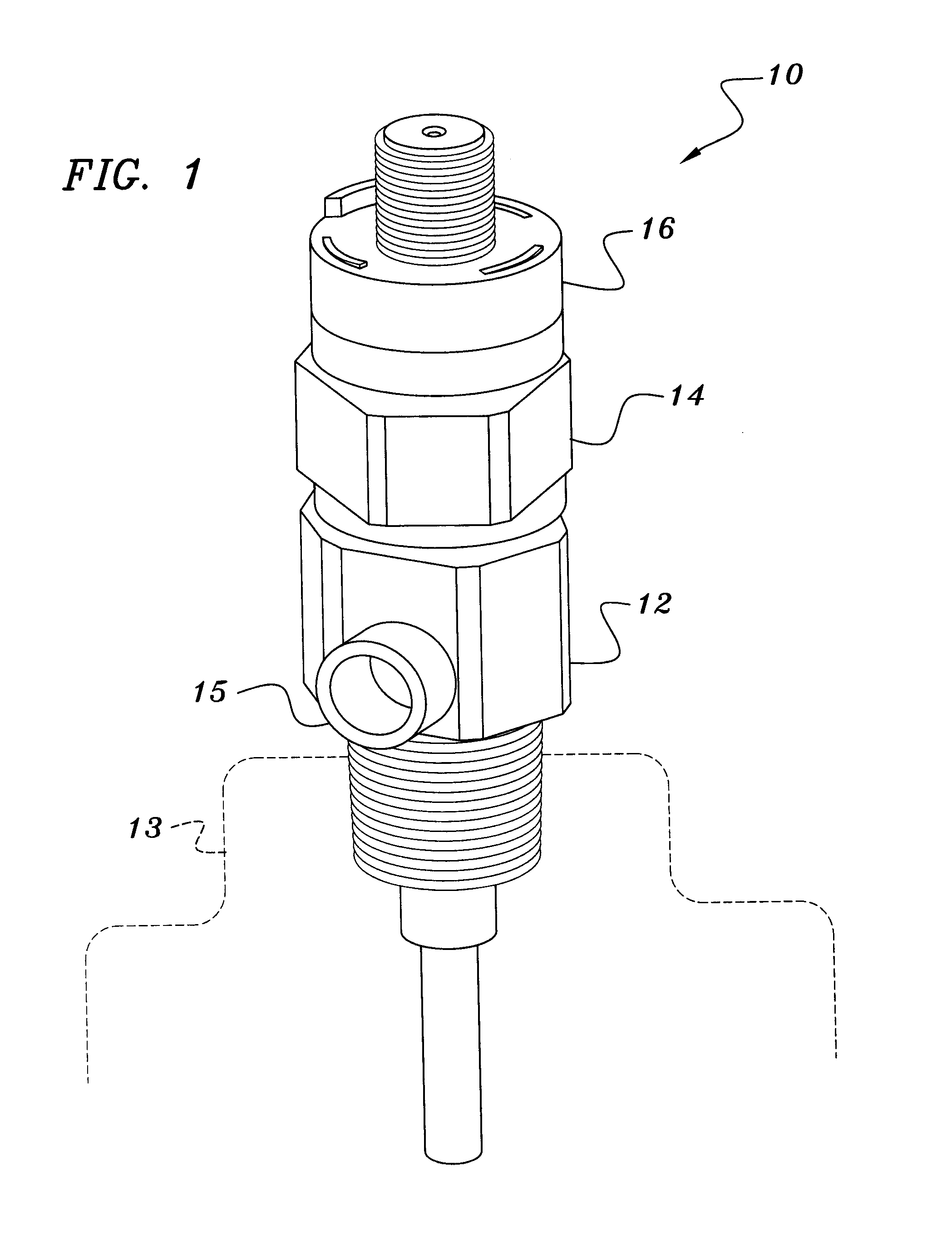

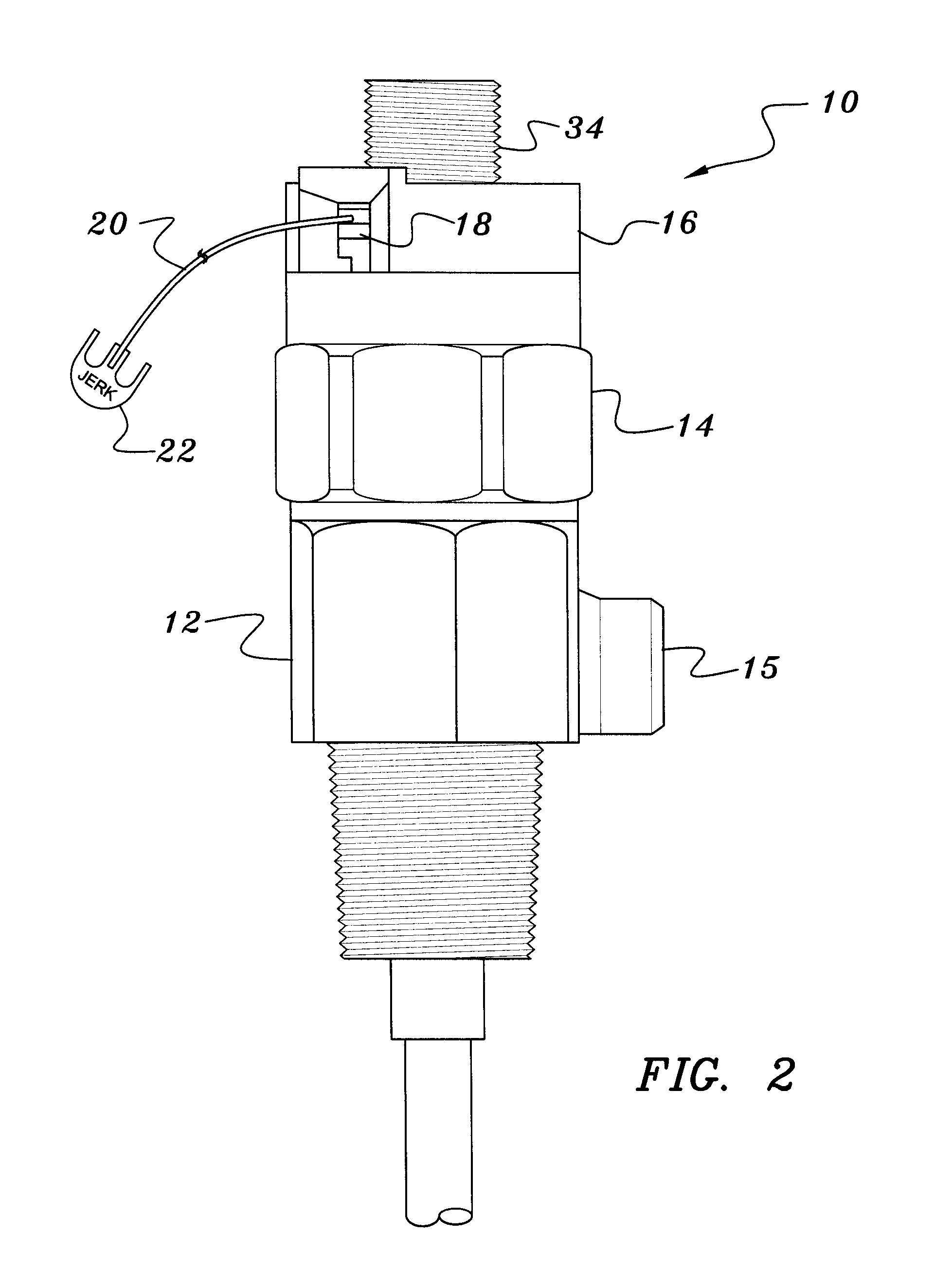

Inflation valve with pneumatic assist

ActiveUS7178547B2Allow for manufactureEliminate needOpening closed containersBottle/container closureGas cylinderEngineering

A pneumatically assisted inflator for gas cylinders comprises an inline configuration such that gas contained within the gas cylinder flows axially through the inflator to be exhausted therefrom and inflate an inflatable article. The inline configuration of the inflator reduces the stress otherwise imparted to the component parts thereof and thereby allows most of the component parts to be manufactured from an injection molded high-strength plastic or the like. The inflator comprises an inflator piston positioned within a piston cylinder that moves against a rotatable cam surface, such as a rotatable collar connected to a pull lanyard, to force a pierce pin to make at least a small pin hole in a frangible seal and allow high pressure gas from the gas cylinder to flow into the piston cylinder, whereupon the high pressure gas in the piston cylinder further moves the inflator piston to more fully force the pierce pin into the frangible seal to fully open the frangible seal.

Owner:HALKEY ROBERTS CORP

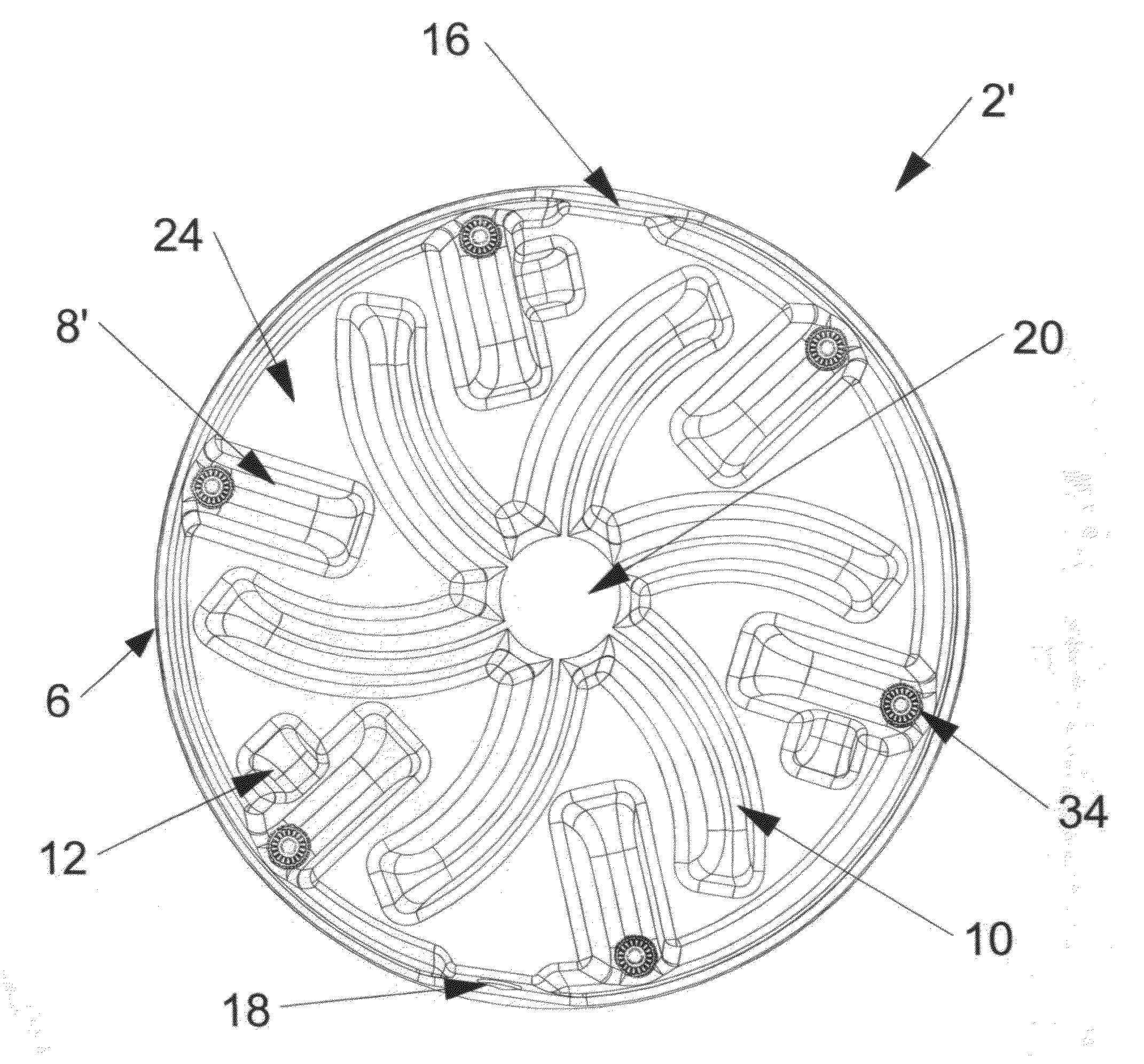

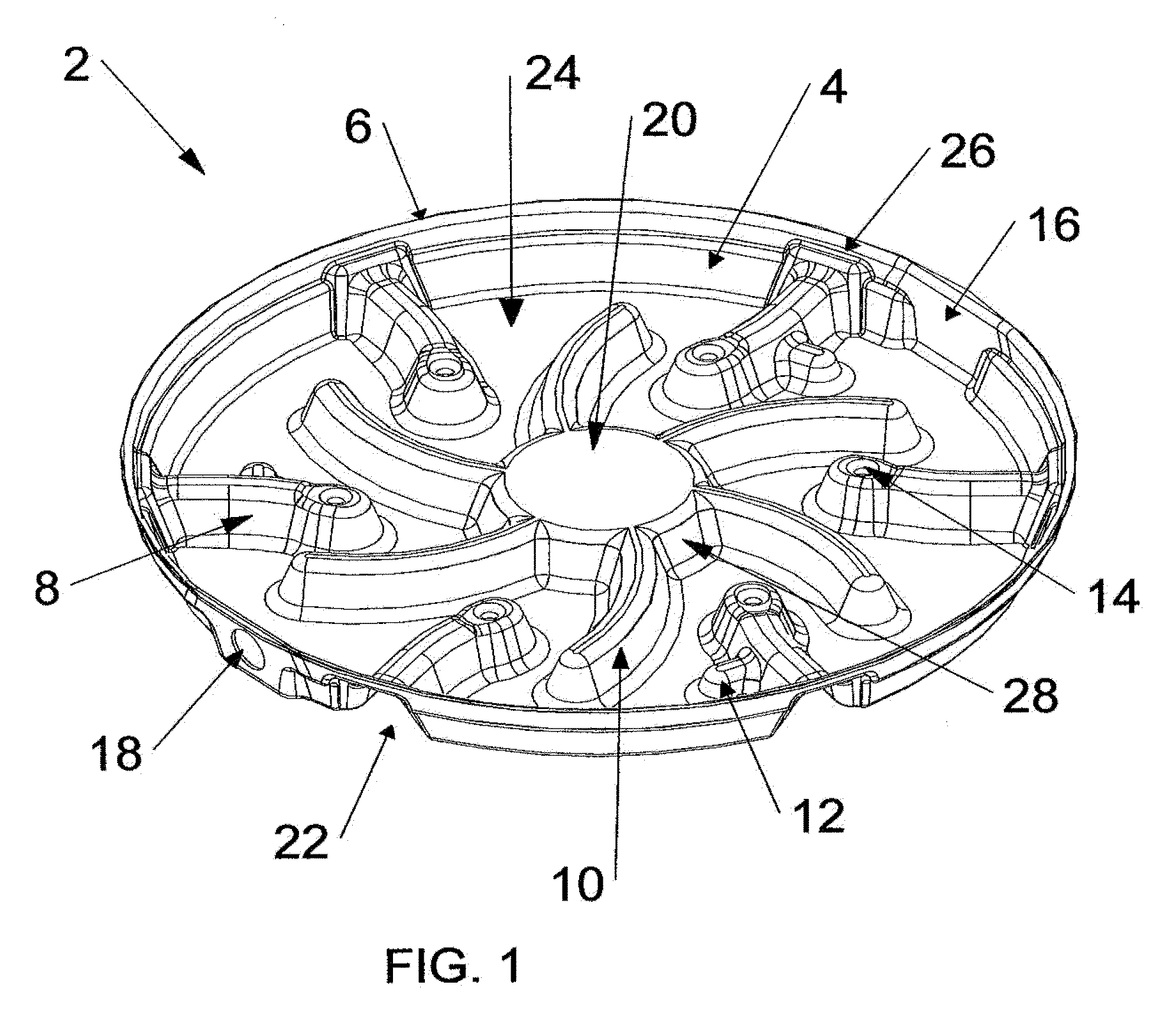

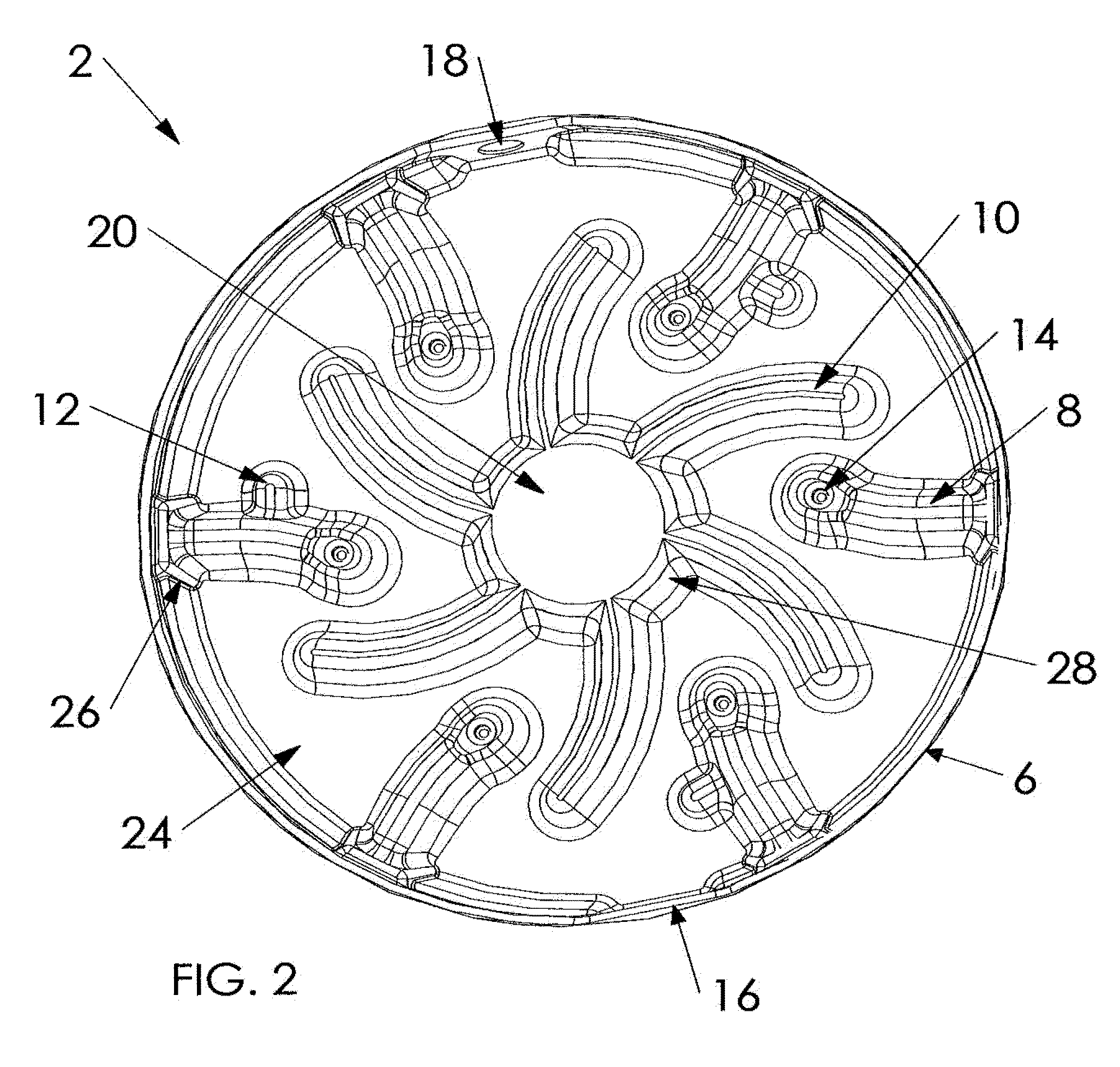

Strength-enhanced water-collecting pan for use under storage hot water heaters

ActiveUS8100140B1Easy to manufactureEasy to installFluid heatersOther washing machinesEngineeringThermal water

A multi-level fluid-collecting pan configured for placement under an upright cylindrical hot water heater tank and support thereof. It has a circular bottom surface integral with a raised central hub, multiple raised arcuate spokes extending outwardly from the hub, and multiple elevated risers extending from the perimeter wall toward the hub. A perimeter wall around the bottom surface defines a non-raised fluid-collecting area. Vibration isolators that support a hot water heater tank upon the risers maintain the tank above any accumulated water in the non-raised areas of the bottom surface. Low elevation risers in perpendicular orientation to some risers, a nesting configuration with mismatched indents, sturdy and impact-resistant materials, a drain opening in the perimeter wall, and an upturned lip extending upwardly from the perimeter wall, are also preferred. The hub, spokes, and risers cover much of the pan's bottom surface and force accumulated water toward the perimeter wall.

Owner:WATERTITE PRODS

Metal hydride bands and use thereof for storing hydrogen

InactiveUS6936185B1Efficient solutionEasy to carryReversible hydrogen uptakeTransportation and packagingPorosityEngineering

The invention concerns a piece based on one or several metal hydrides capable of reversibly absorbing hydrogen. Said piece is in the form of a thin and dense band, having a thickness preferably not more than 1 mm and porosity preferably less than 20%. The piece is obtained by rolling a powder of selected hydride(s), with or without additional component(s), such as binders or heat-transfer elements. Said piece can easily be produced on an industrial scale. By its very nature, it is particularly adapted for use as a base element in a tank for storing and transporting hydrogen. It can also be used in a Ni-MH typre battery for storing and transporting energy.

Owner:HYDRO QUEBEC CORP

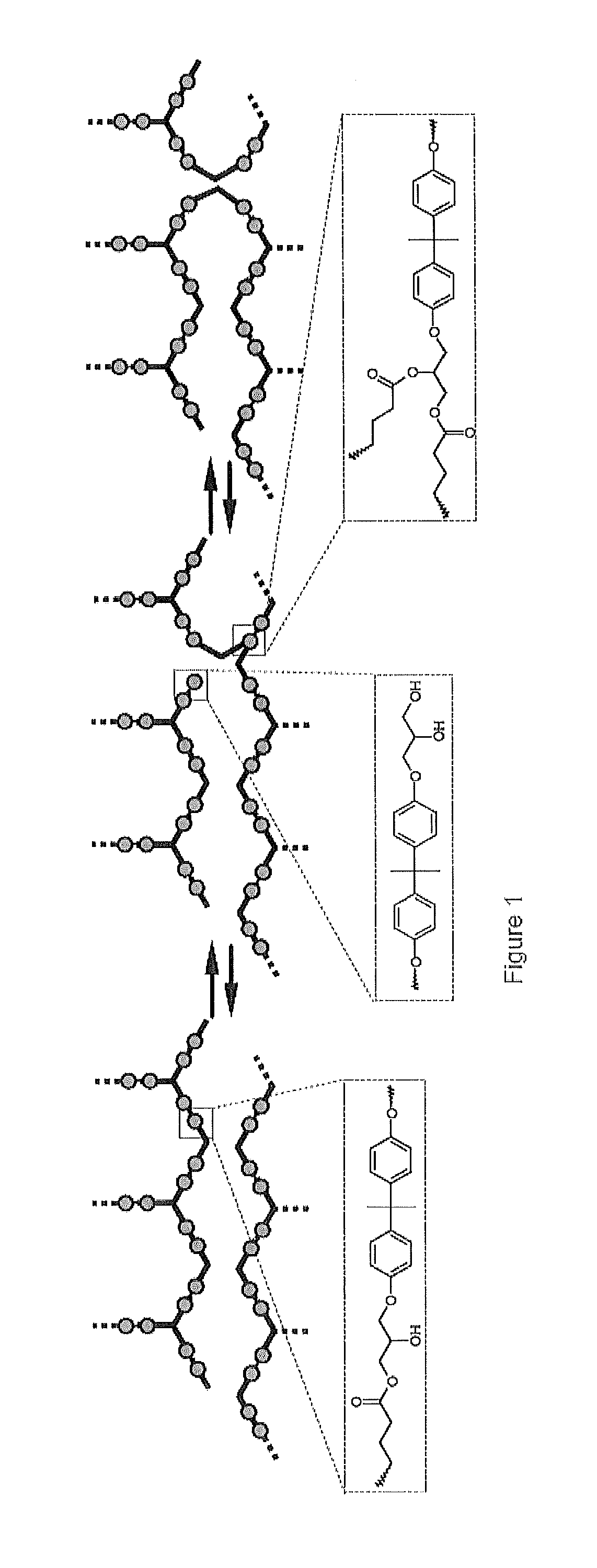

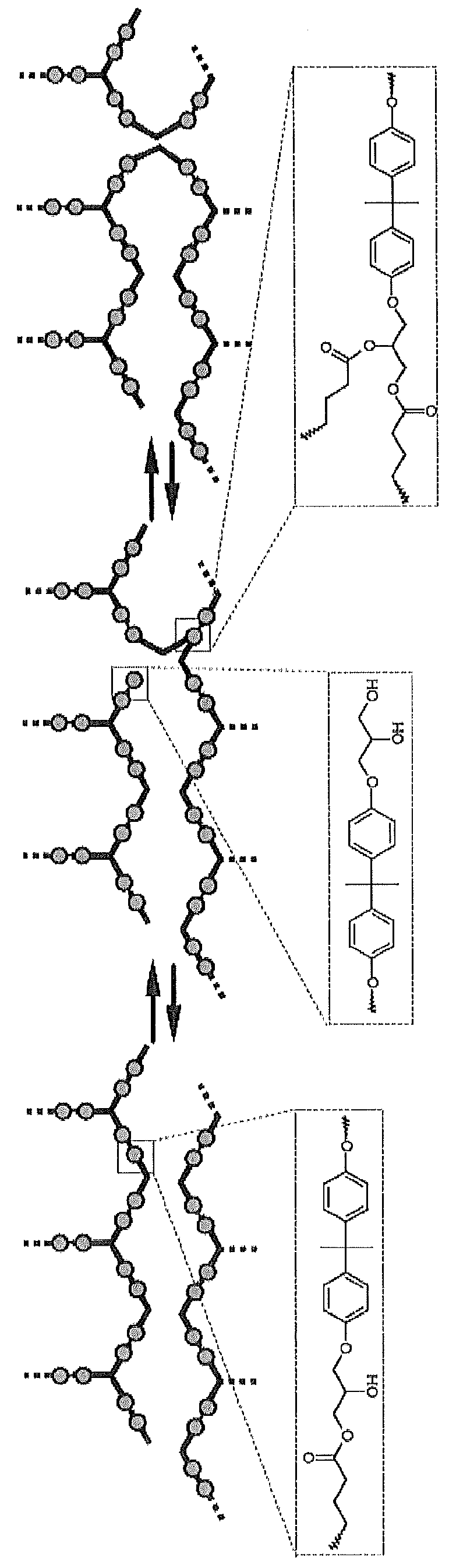

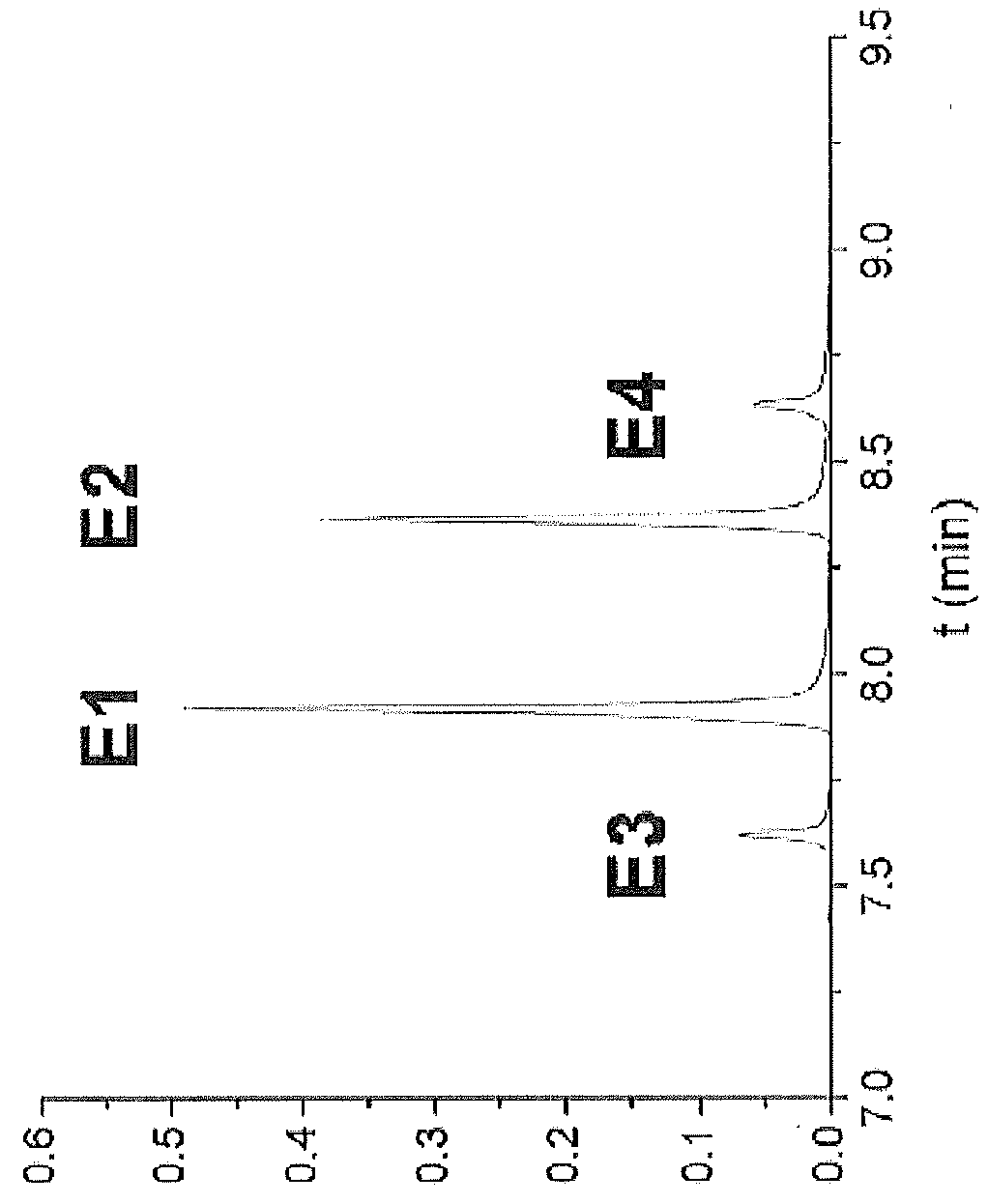

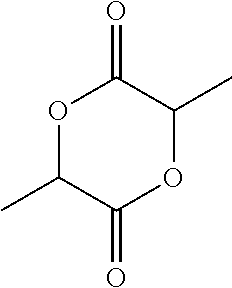

Thermoset/supramolecular hybrid composites and resins that can be hot-formed and recycled

ActiveUS20140088223A1Avoid insufficient temperatureWide rangePlastic recyclingWood working apparatusComposite materialTrans esterification

Thermoset / supramolecular hybrid composites and resins, resulting from bringing at least one thermosetting resin precursor, this thermosetting resin precursor comprising hydroxyl functions and / or epoxy groups, and optionally ester functions, into contact with at least one hardener chosen from carboxylic acids and acid anhydrides, and with at least one compound comprising, on the one hand, at least one associative group, and on the other hand at least one function enabling the grafting thereof to the thermosetting resin precursor, to the hardener or to the product resulting from the reaction of the thermosetting resin precursor and the hardener, in the presence of at least one transesterification catalyst. Process for manufacturing these materials, process for transforming and process for recycling these materials. Novel solid forms of hybrid composites and resins which can be used in the implementation of these processes.

Owner:ARKEMA FRANCE SA +1

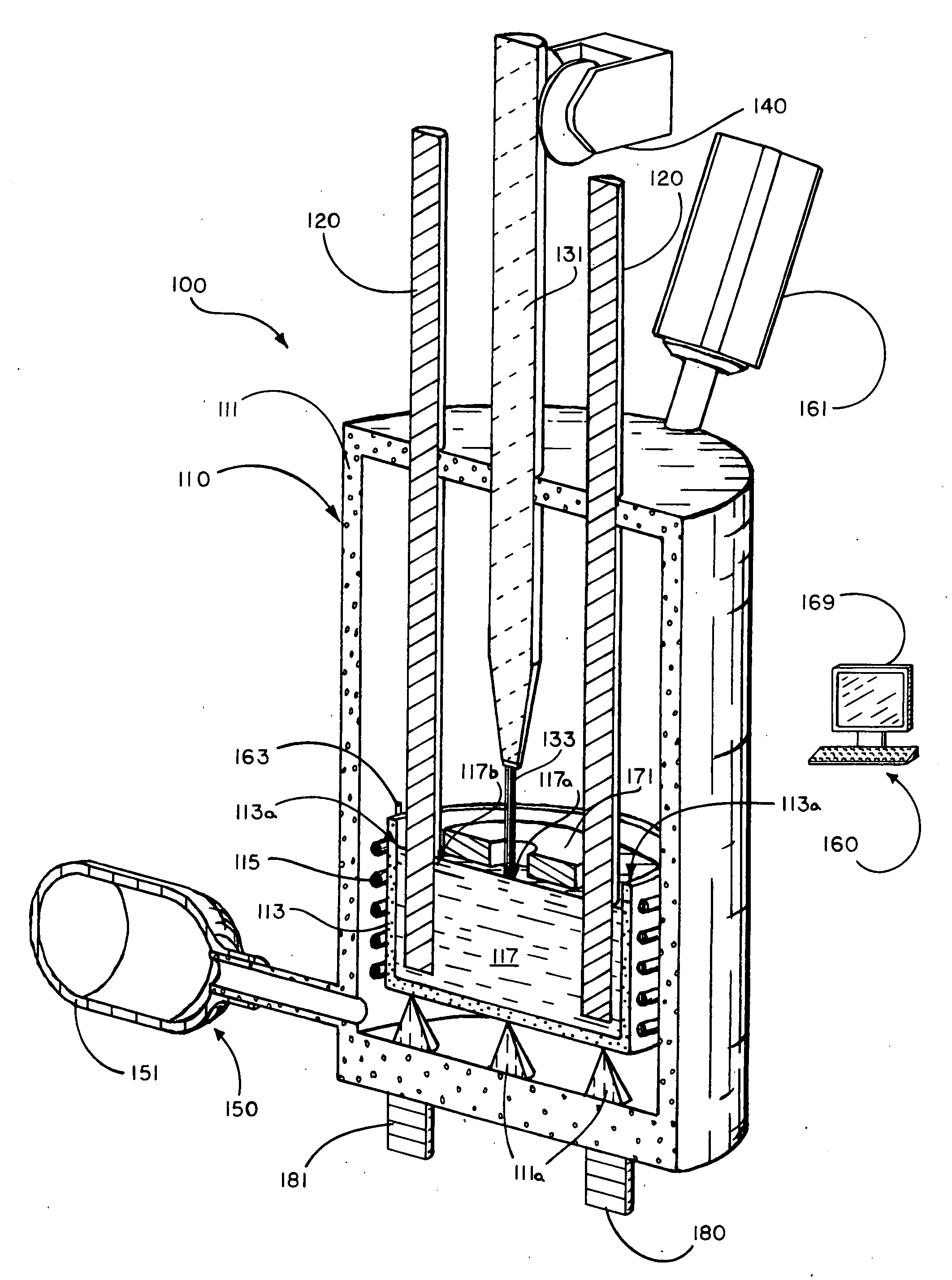

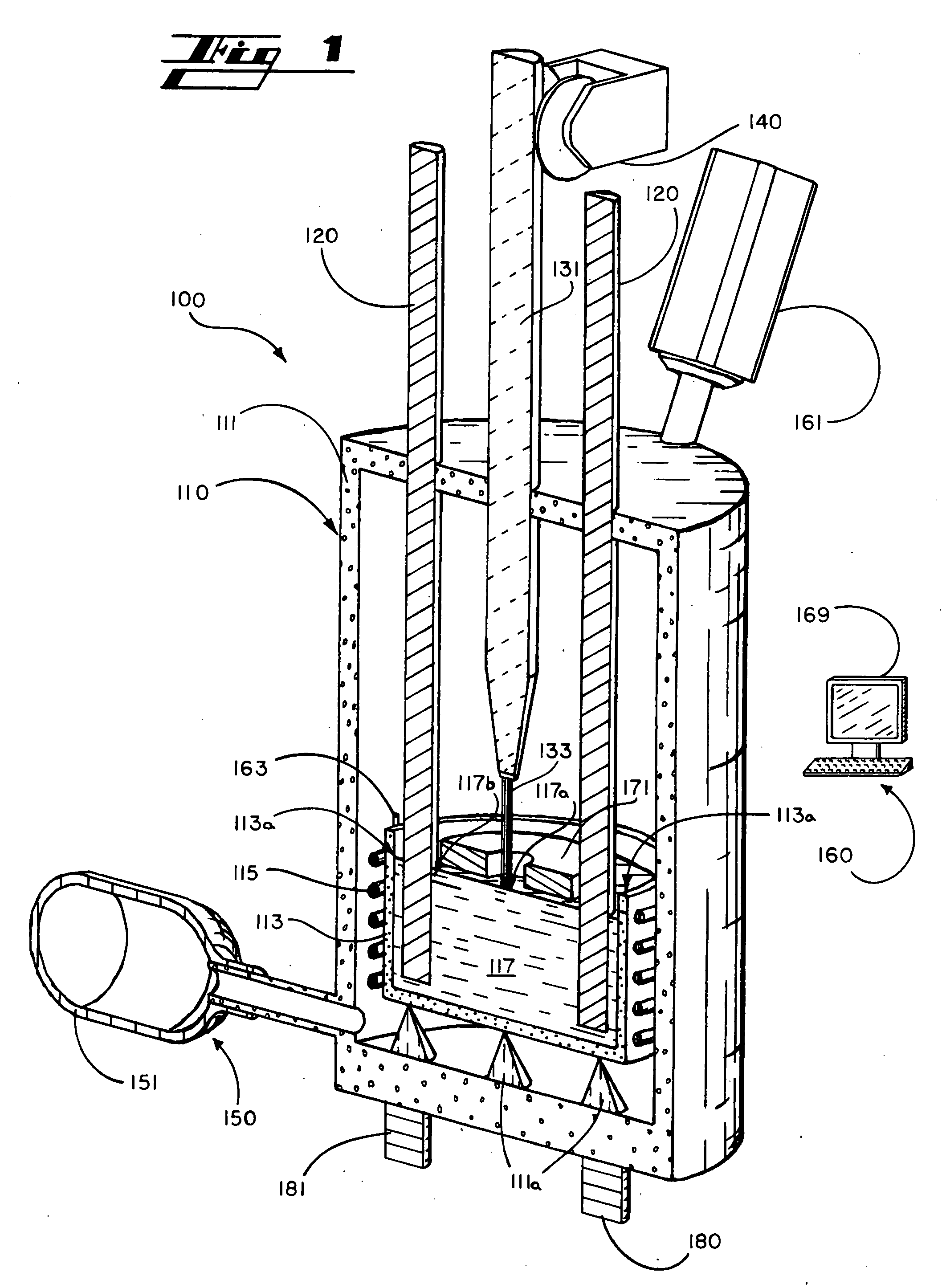

System and method for manufacturing carbon nanotubes

InactiveUS20090311168A1Allow for manufactureLow costMaterial nanotechnologyNanostructure manufactureMulti-Walled NanotubeBCN nanotube

Owner:DUVALL GIDEON

Sintered Material, Sinterable Powder Mixture, Method for Producing Said Material and Use Thereof

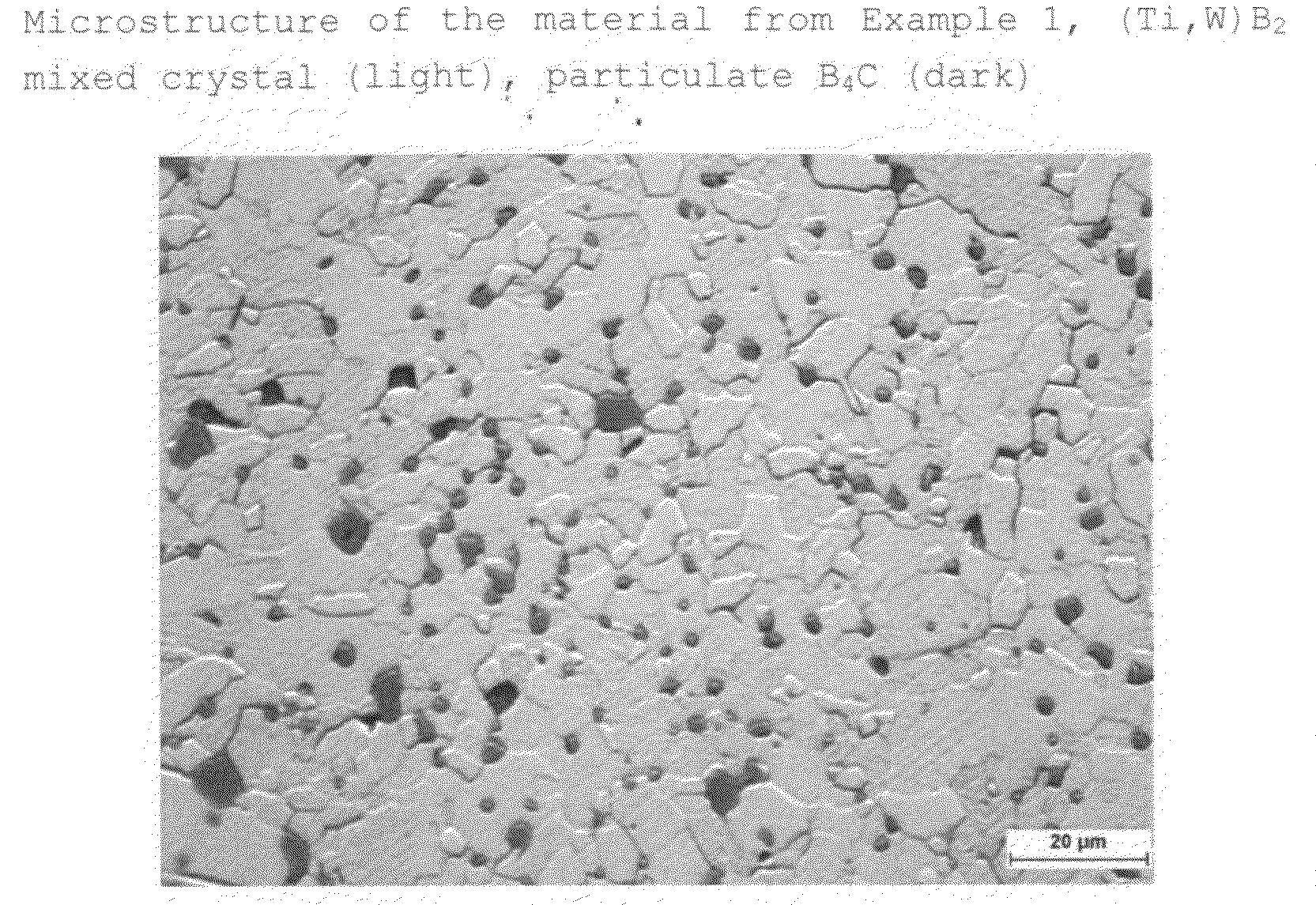

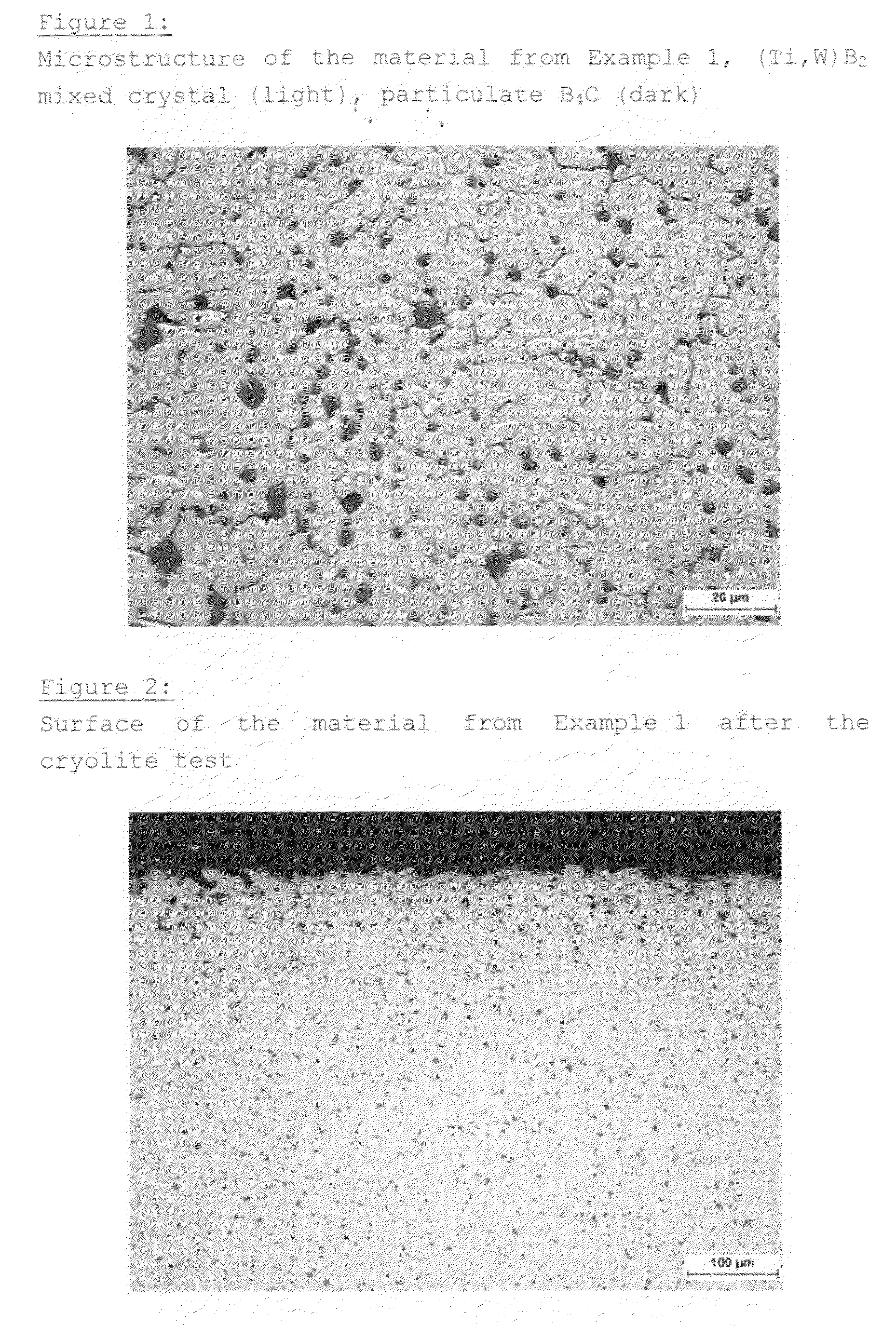

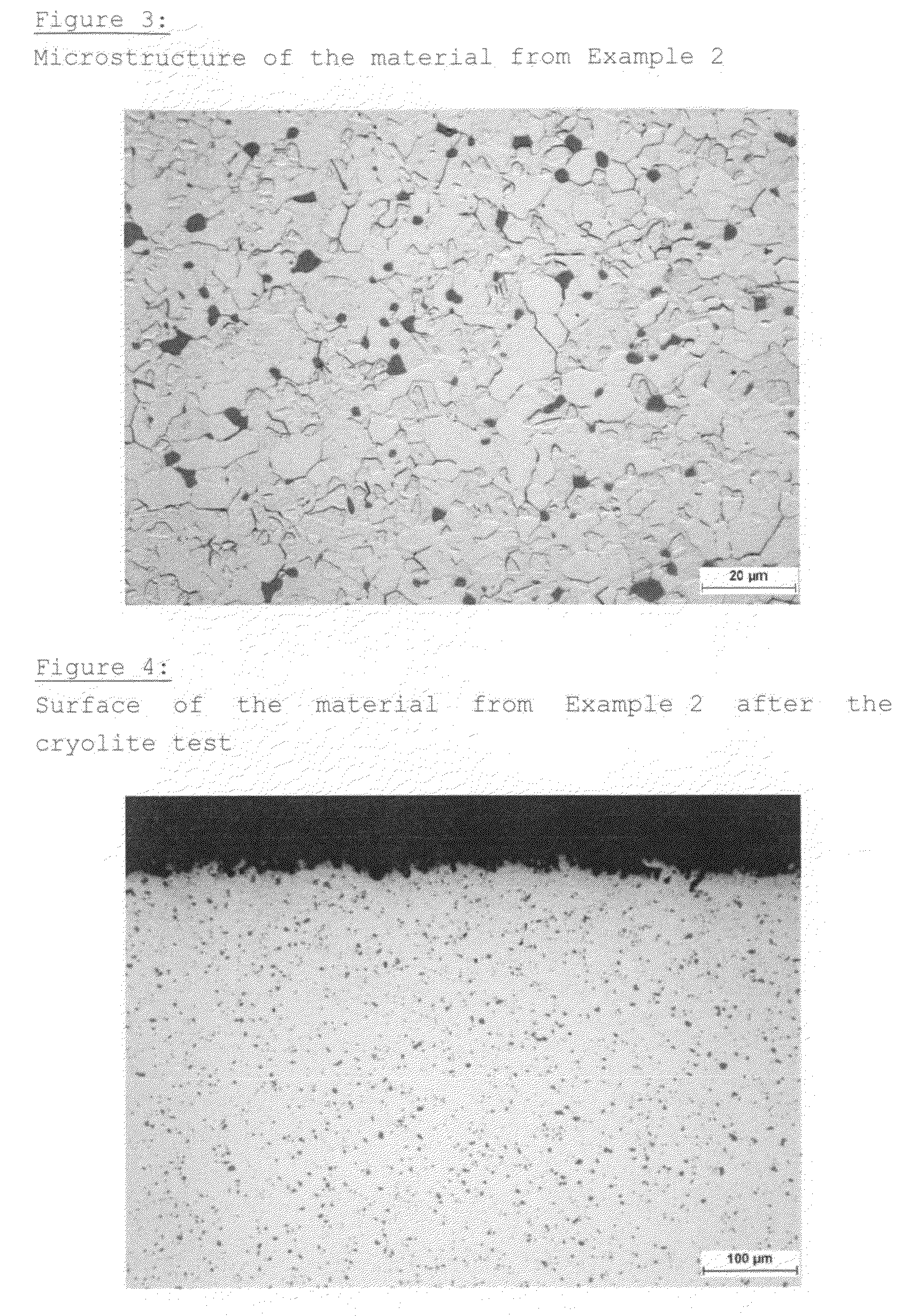

InactiveUS20090121197A1Improve mechanical propertiesSimple and inexpensiveThermometer detailsConductive materialParticulatesBoride

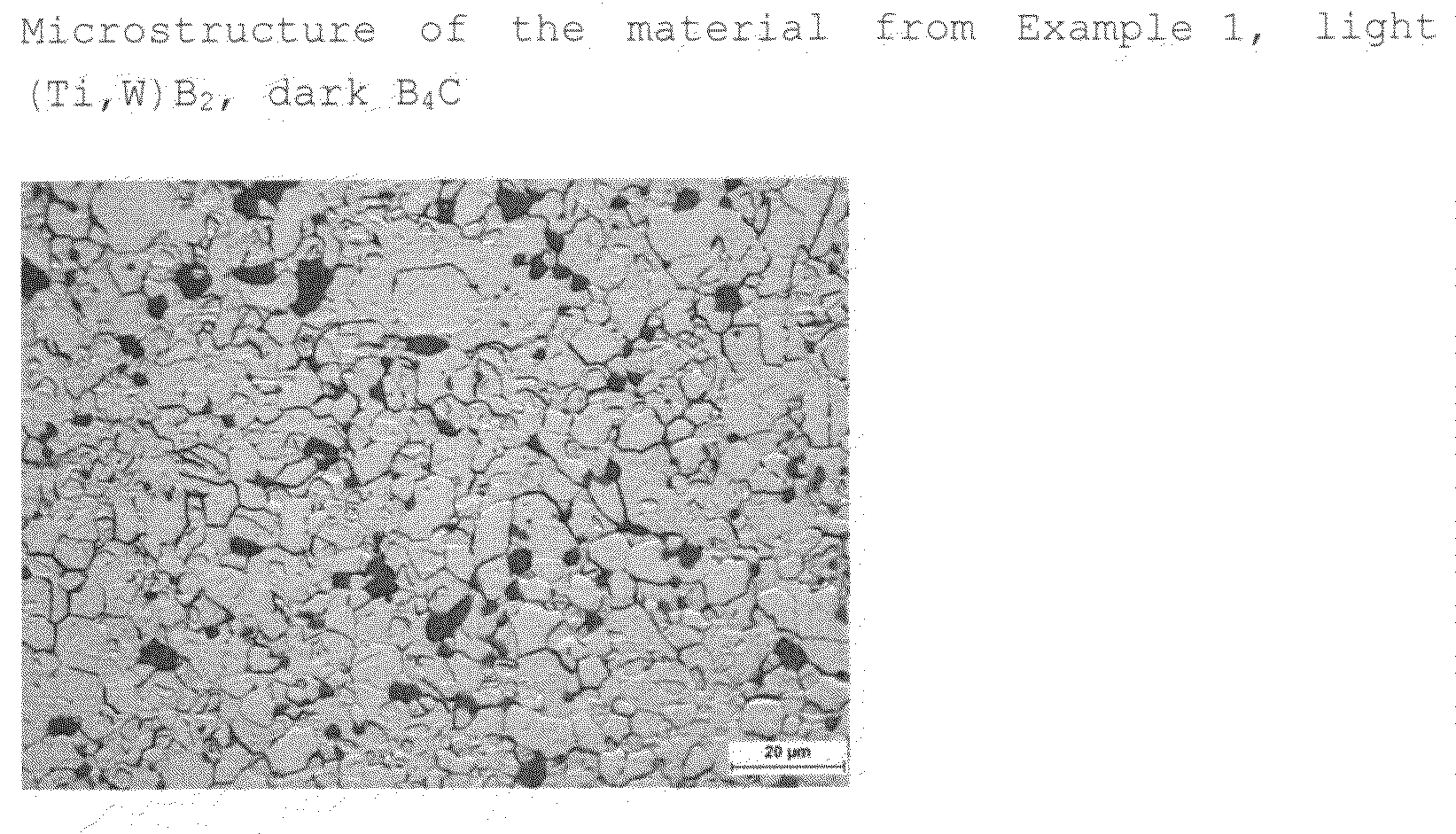

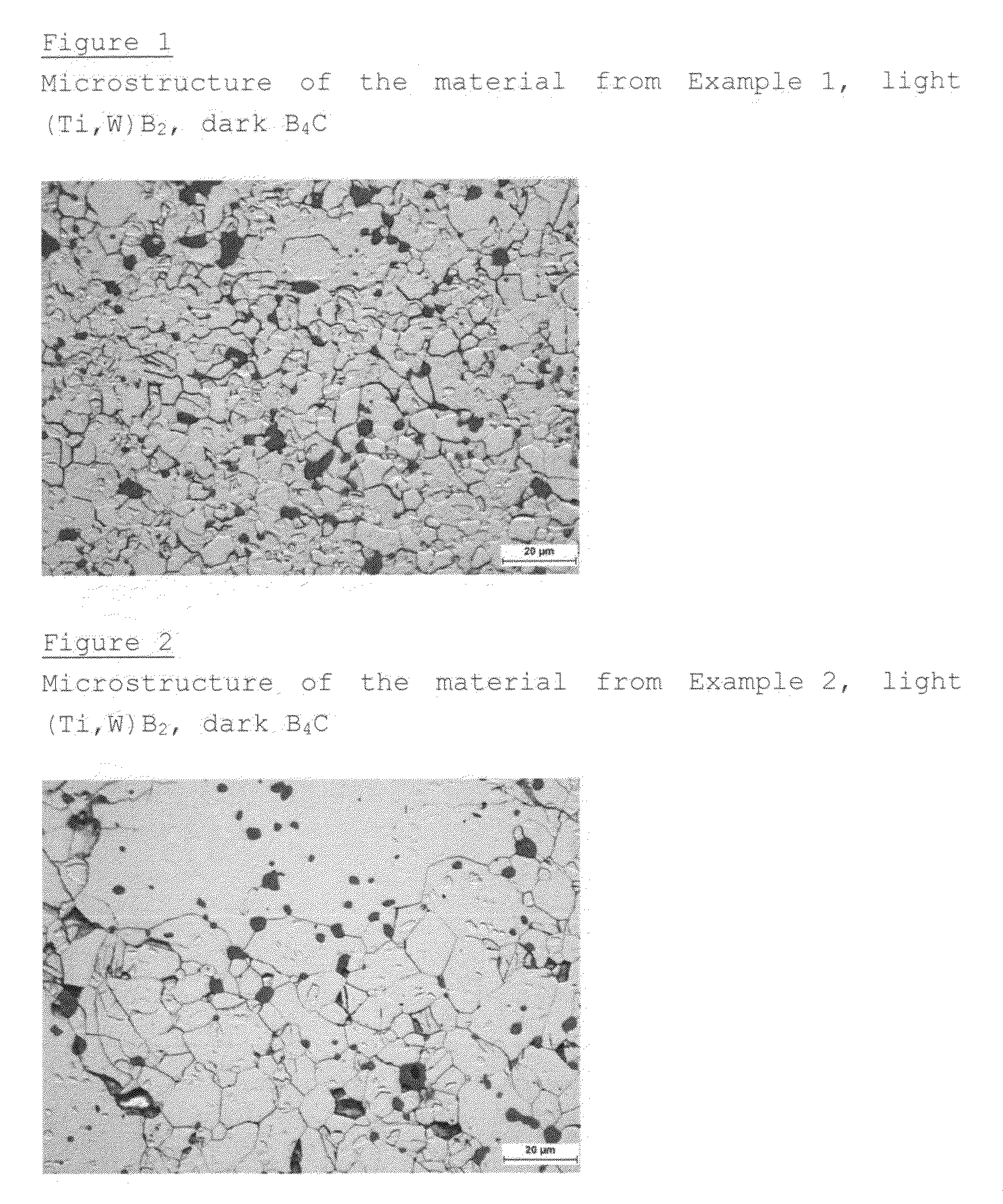

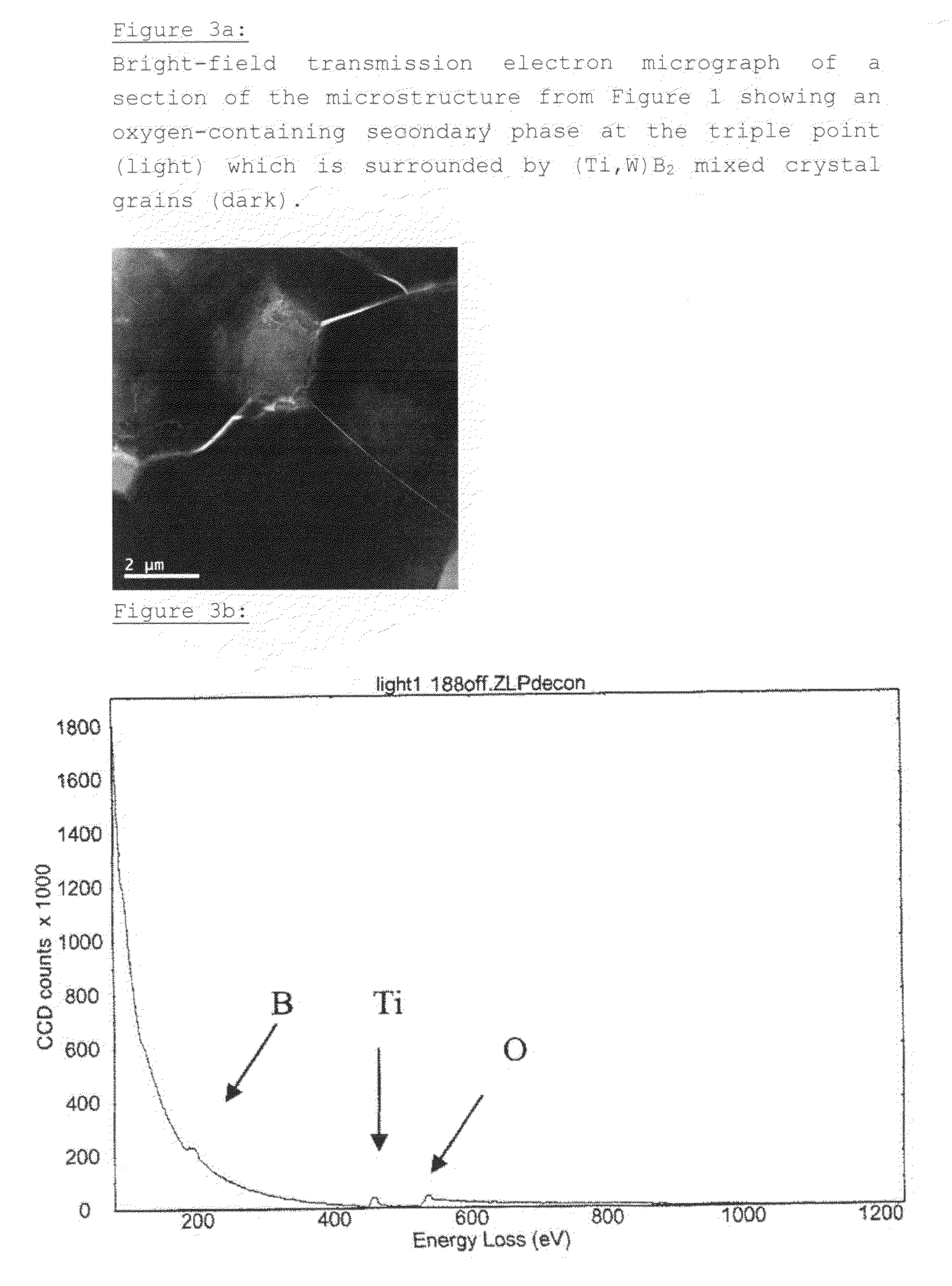

The invention relates to a sintered material which is based on transition metal diborides and comprisesa) as main phase, 90-99% by weight of a fine-grained transition metal diboride or transition metal diboride mixed crystal comprising at least two transition metal diborides or mixtures of such diboride mixed crystals or mixtures of such diboride mixed crystals with one or more transition metal diborides, where the transition metals are selected from sub-groups IV to VI of the Periodic Table,b) as second phase, 1-5% by weight of particulate boron carbide and / or silicon carbide andc) optionally as third phase, up to 5% by weight of a non-continuous, oxygen-containing grain boundary phase.The invention further relates to a pulverulent sinterable mixture for producing such a sintered material, processes for producing the sintered material, preferably by pressureless sintering, and also to the use of the sintered material as corrosion protection material for salt and metal melts, in particular cryolite-containing melts.

Owner:ESK CERAMICS GMBH & CO KG

Sintered Wear-Resistant Boride Material, Sinterable Powder Mixture, for Producing Said Material, Method for Producing the Material and Use Thereof

The invention relates to a sintered wear-resistant material which is based on transition metal diborides and comprisesa) as main phase, 80-98.8% by weight of a fine-grained transition metal diboride or transition metal diboride mixed crystal comprising at least two transition metal diborides or mixtures of such diboride mixed crystals or mixtures of such diboride mixed crystals with one or more transition metal diborides, where the transition metals are selected from sub-groups IV to VI of the Periodic Table,b) as second phase, 0.2 to 5% by weight of a continuous, oxygen-containing grain boundary phase andc) as third phase, 1-15% by weight of particulate boron carbide and / or silicon carbide.The invention further relates to a pulverulent sinterable mixture for producing such a sintered material, process for producing the sintered material, preferably by pressureless sintering, and also the use of the sintered material for producing wear parts in general mechanical engineering, in particular chemical plant construction.

Owner:ESK CERAMICS GMBH & CO KG

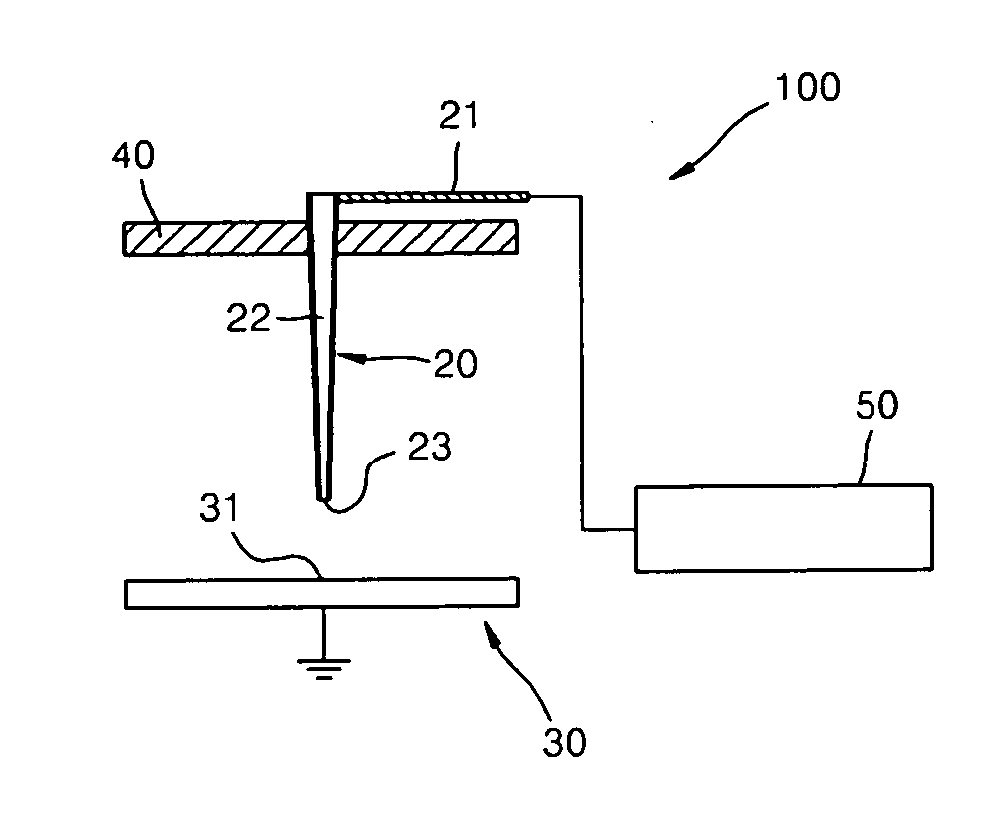

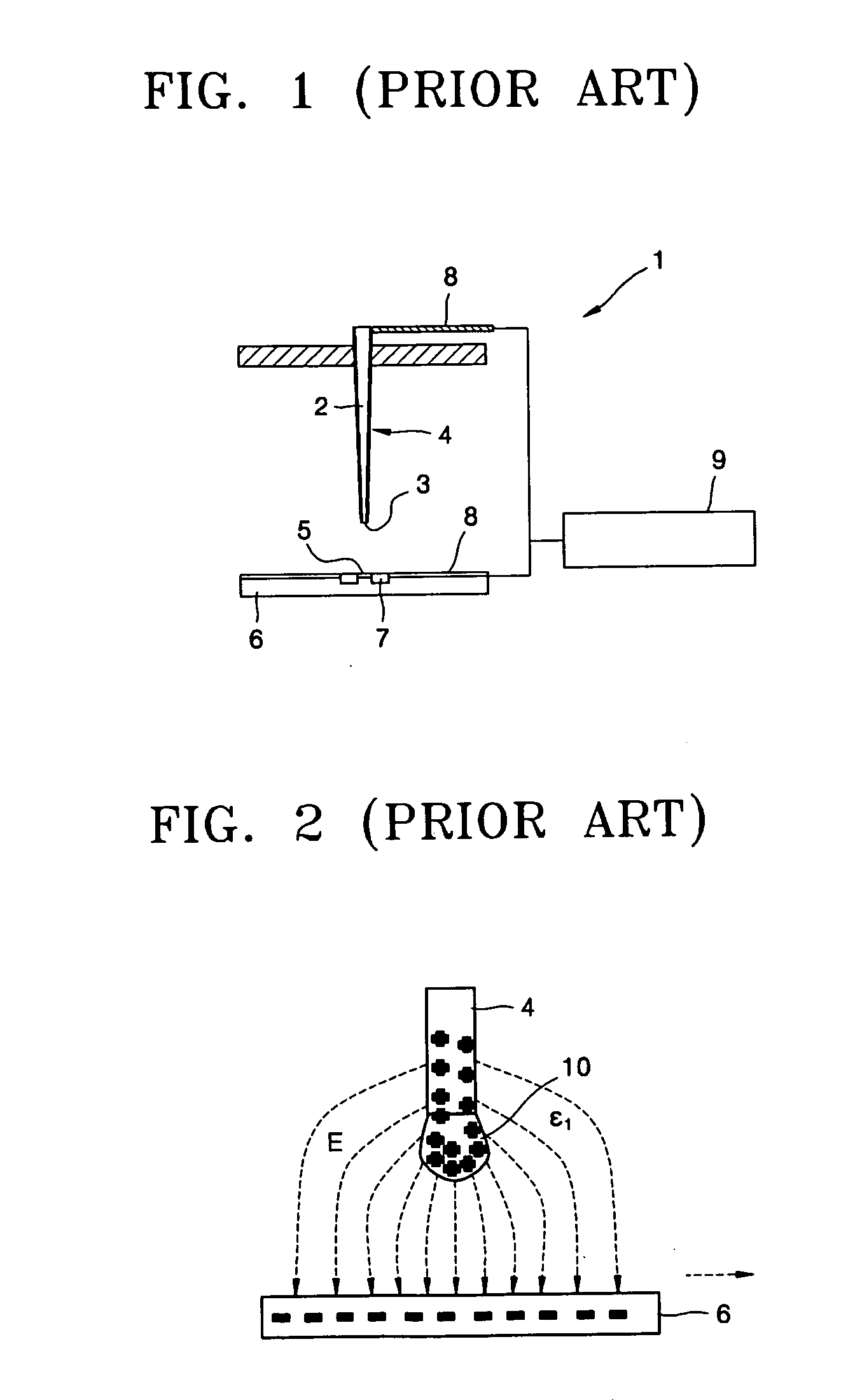

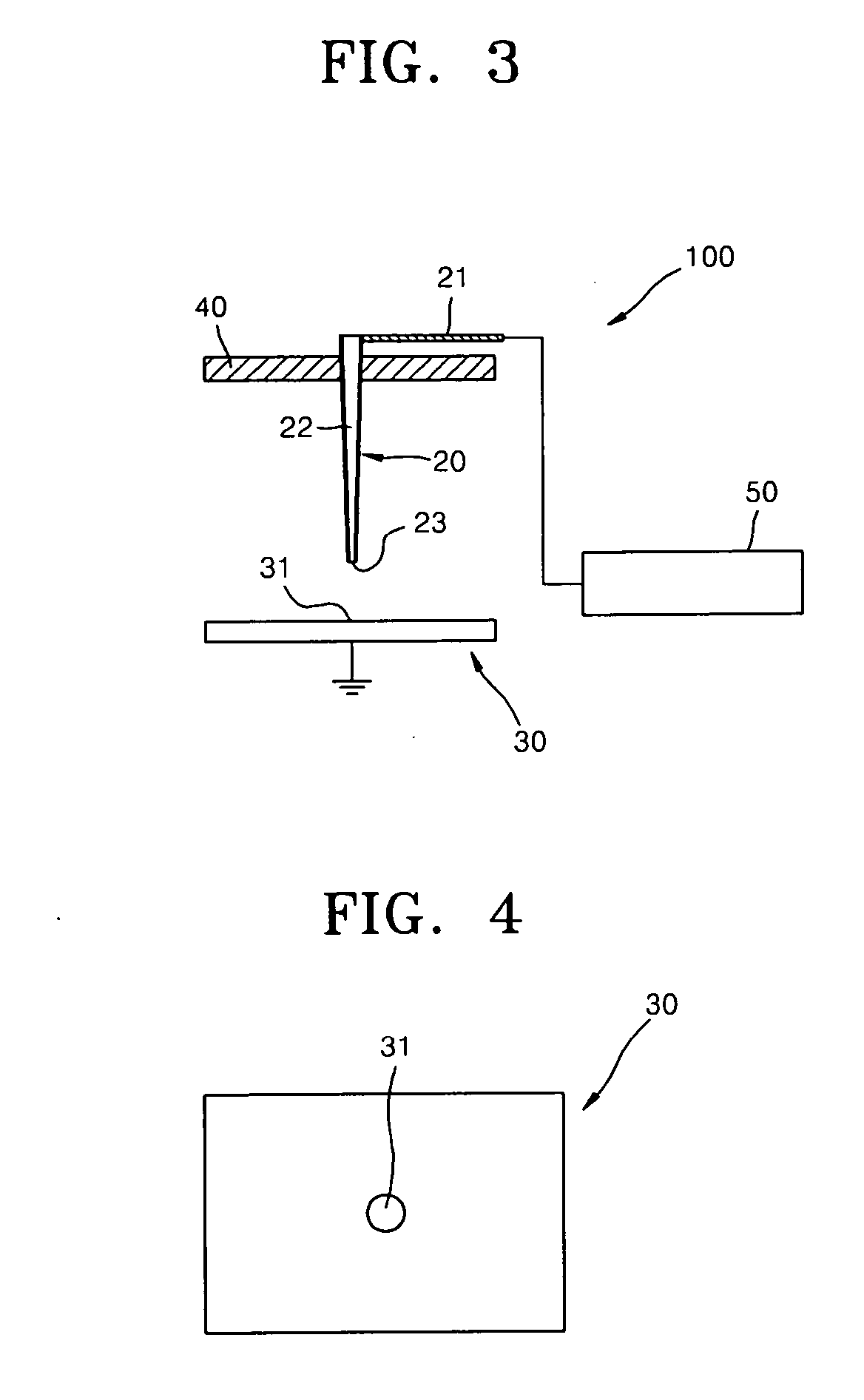

Devices for printing biomolecular droplet on substrate and for printing ink on substrate or print paper using electric charge concentration effect and method of printing biomolecular droplet on substrate

InactiveUS20070035587A1Precise processControl of distanceSequential/parallel process reactionsLaboratory glasswaresElectric dischargeEngineering

A device and method for printing biomolecules on a substrate uses an electric charge concentration effect. The device overcomes limitations of the material and surface characteristics of a substrate, enables accurate dropping of a biomolecular droplet onto a target surface of the substrate, prevents electric discharge, and thus allows the manufacturing of a high density biochip by depositing numerous biomolecular droplets, which are small in size and volume, onto a substrate. The device includes: a needle-shaped electric field forming electrode; a substrate which is grounded and disposed below the electric field forming electrode, the substrate including a target surface; and an open circuit type voltage applying unit which supplies first electric charges to the electric field forming electrode to drop the biomolecular droplet onto the target surface of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

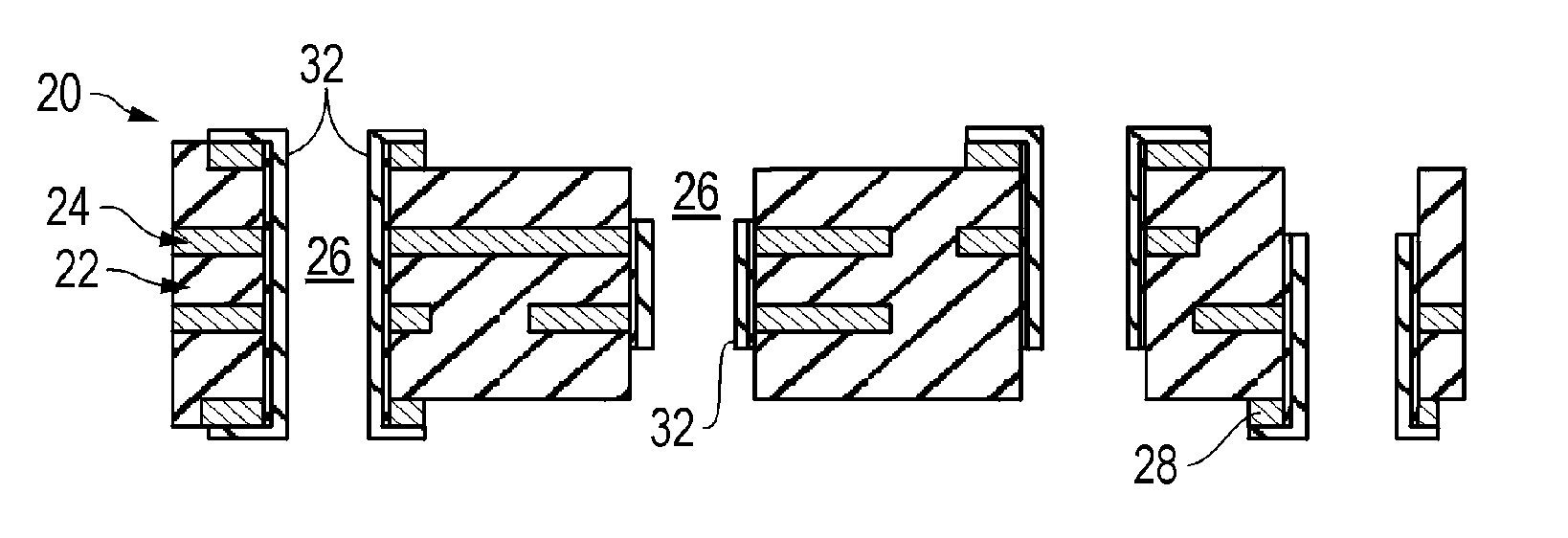

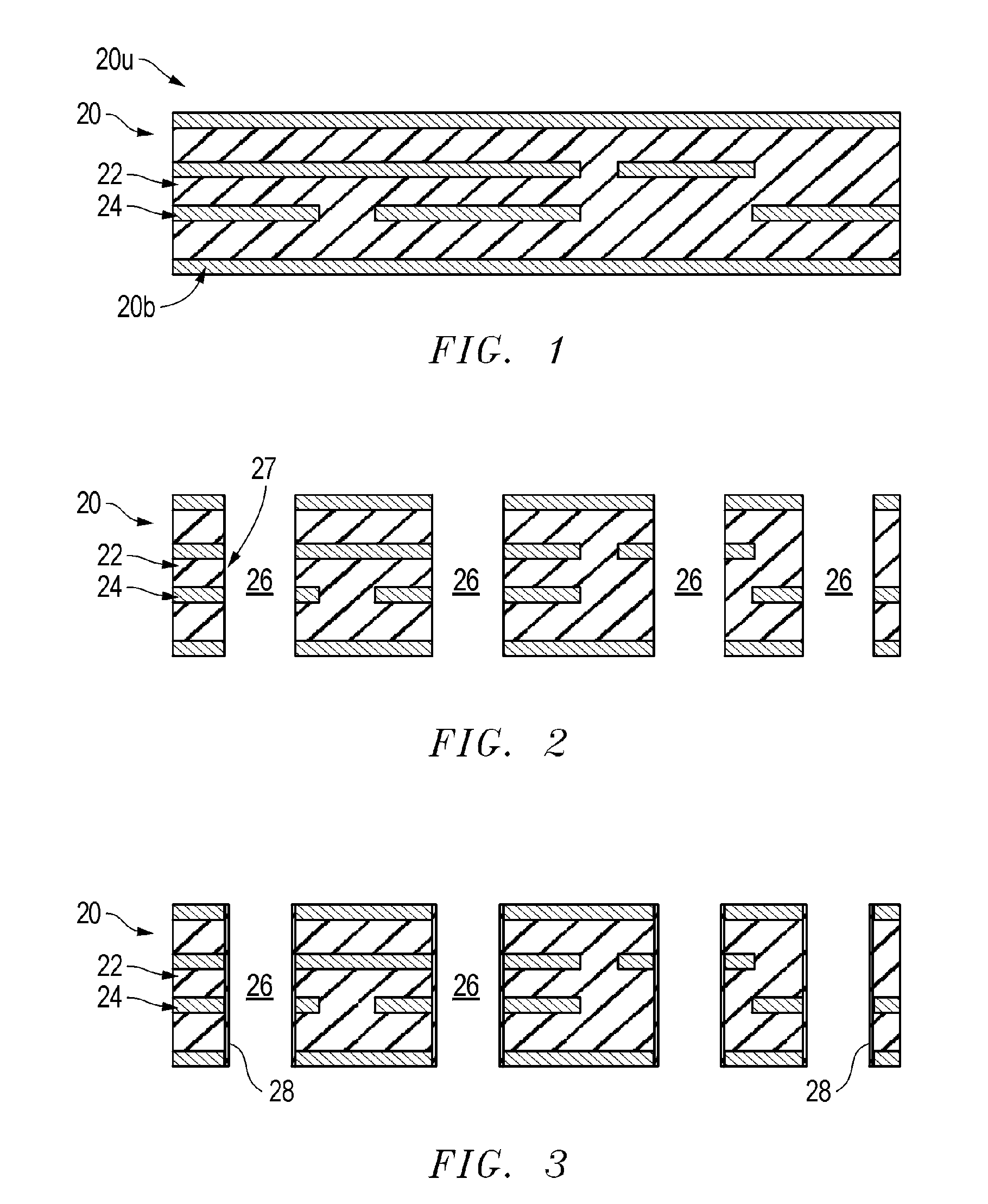

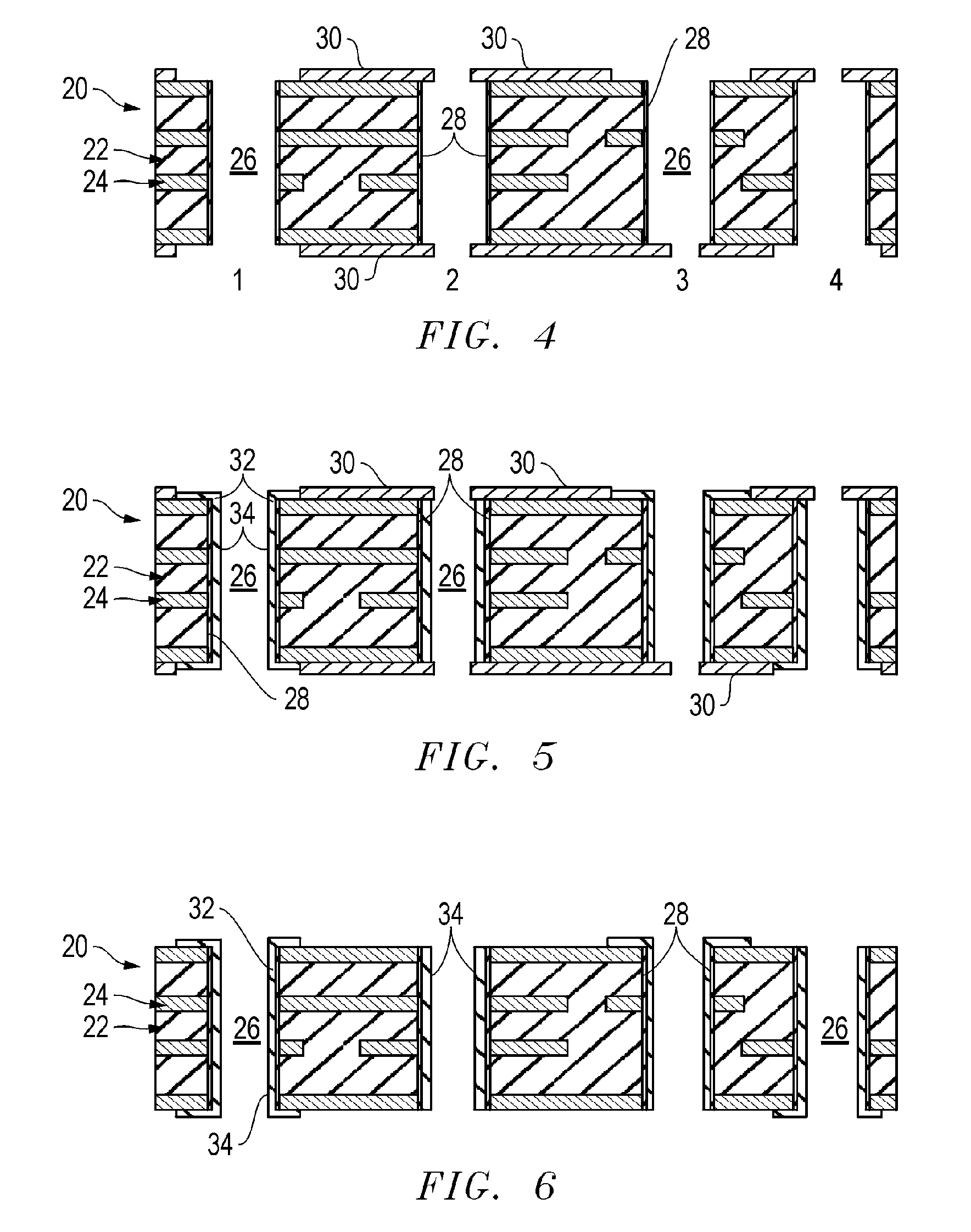

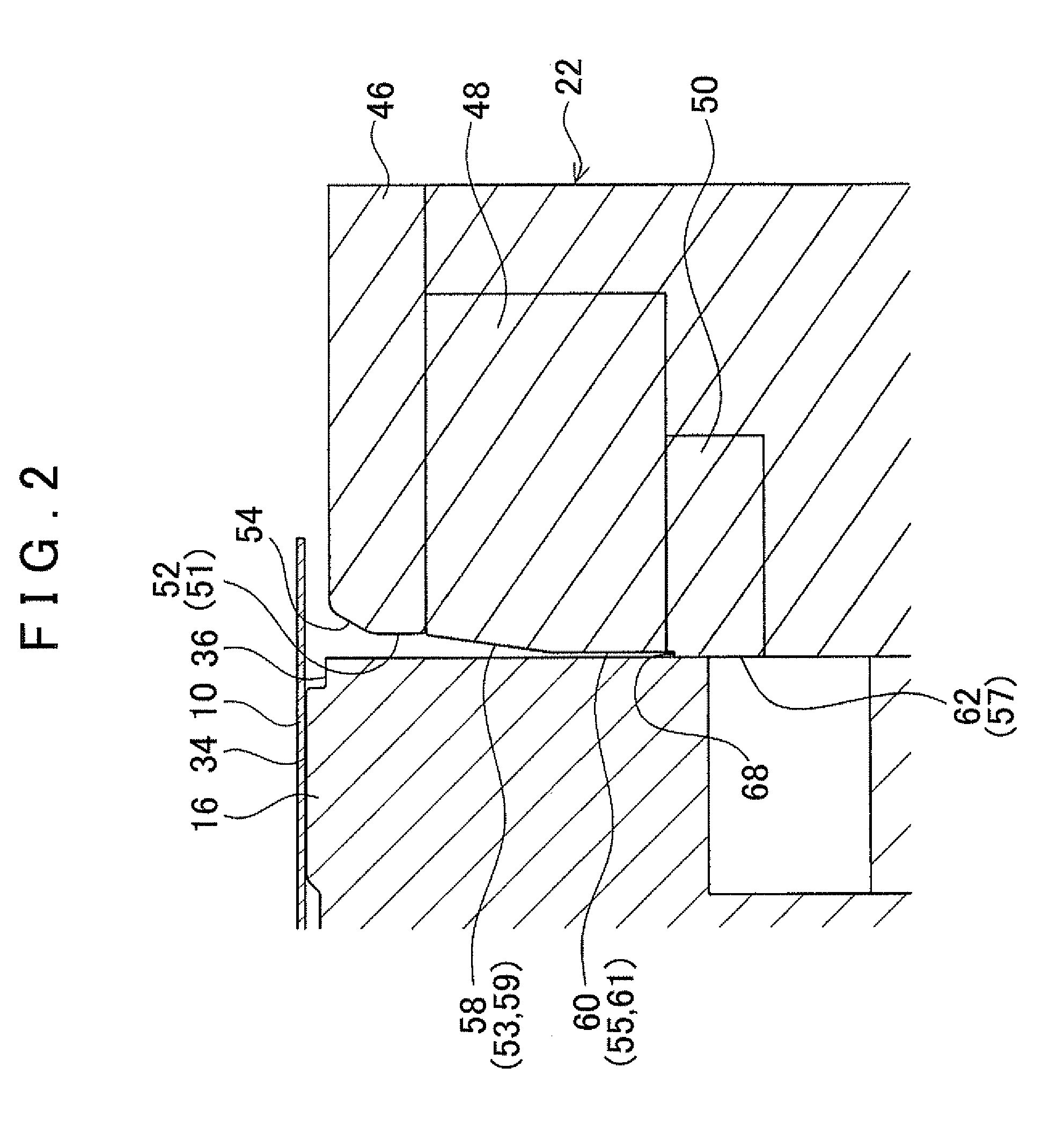

Controlled depth etched vias

InactiveUS20070062730A1Reduce signal lossStrict controlPrinted circuit aspectsPrinted circuit manufactureResistDielectric

A printed circuit board (20) includes a sub-assembly having dielectric (22) and conductive layers (24). A hole (26) extends into the sub-assembly. Metal plating (32) is applied on a barrel (27) of the hole (26). A conductive layer (32) and an etch resist (34) are applied to a first photoresist (30) on the hole barrel (27). The first photoresist (30) is removed and a second photoresist (36) is applied leaving areas to be controlled depth etched exposed. The exposed areas (38) are chemically etched. The second layer of photoresist (36) is removed and a second chemical etch operation is performed to define previously plated features (40) on the sub-assembly (20). The etch resist (34) is then removed.

Owner:LITTON SYST INC

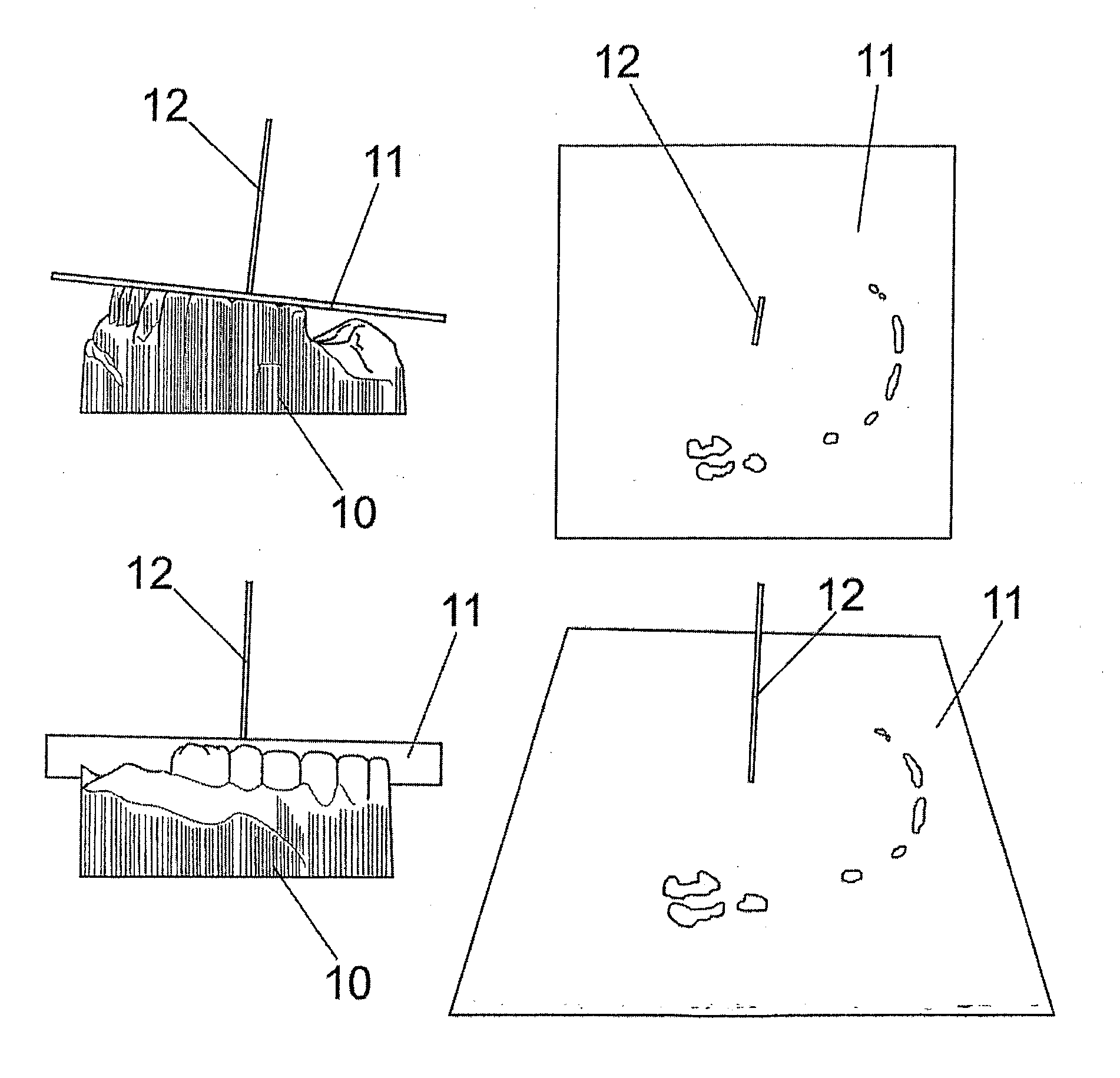

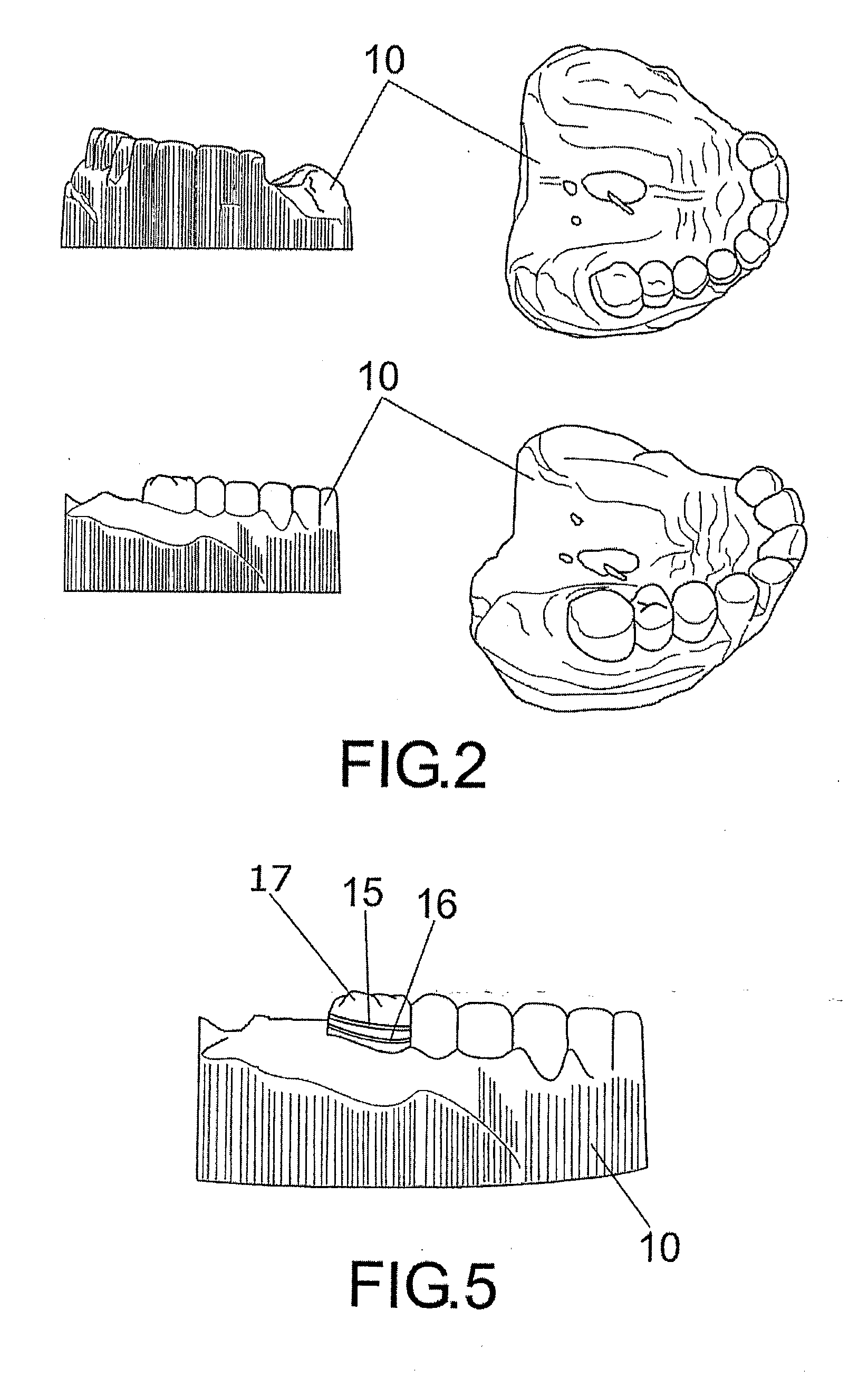

Method for manufacturing digitally-designed removable dental prostheses and system required for this purpose

The system, object of the invention consists of a unit for scanning a mould produced from the sample from a patient's mouth, an image which is sent to digital generation equipment of a removable dental prosthesis, producing a file that is transmitted to metal piece manufacturing equipment by means of sintered powder applying a high-energy ray. The design stages consist of the relief of the mould, the calculation of the insertion axis, the paralleling of the teeth, designing of the elements or components of the prosthesis such as lattice, clamp, stop, major connector, minor connector, bristle, pearls, lingual bars, extrusion of the different elements designed, smoothing of the sharp edges, elimination of the superpositions of the different elements designed and conversion of a closed continuous connected surface to a three-dimensional one.

Owner:GARCIA APARICIO JUAN CARLOS

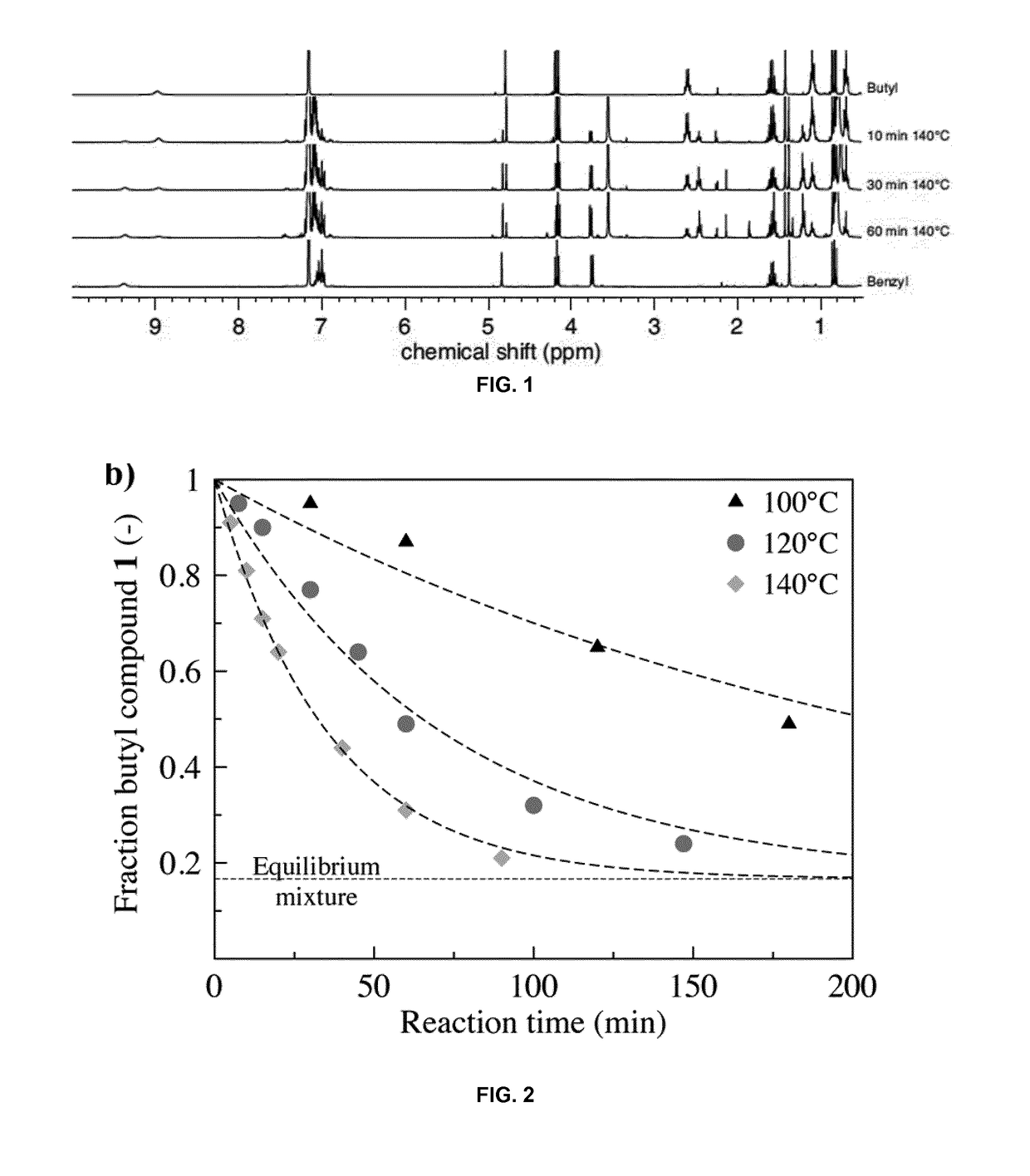

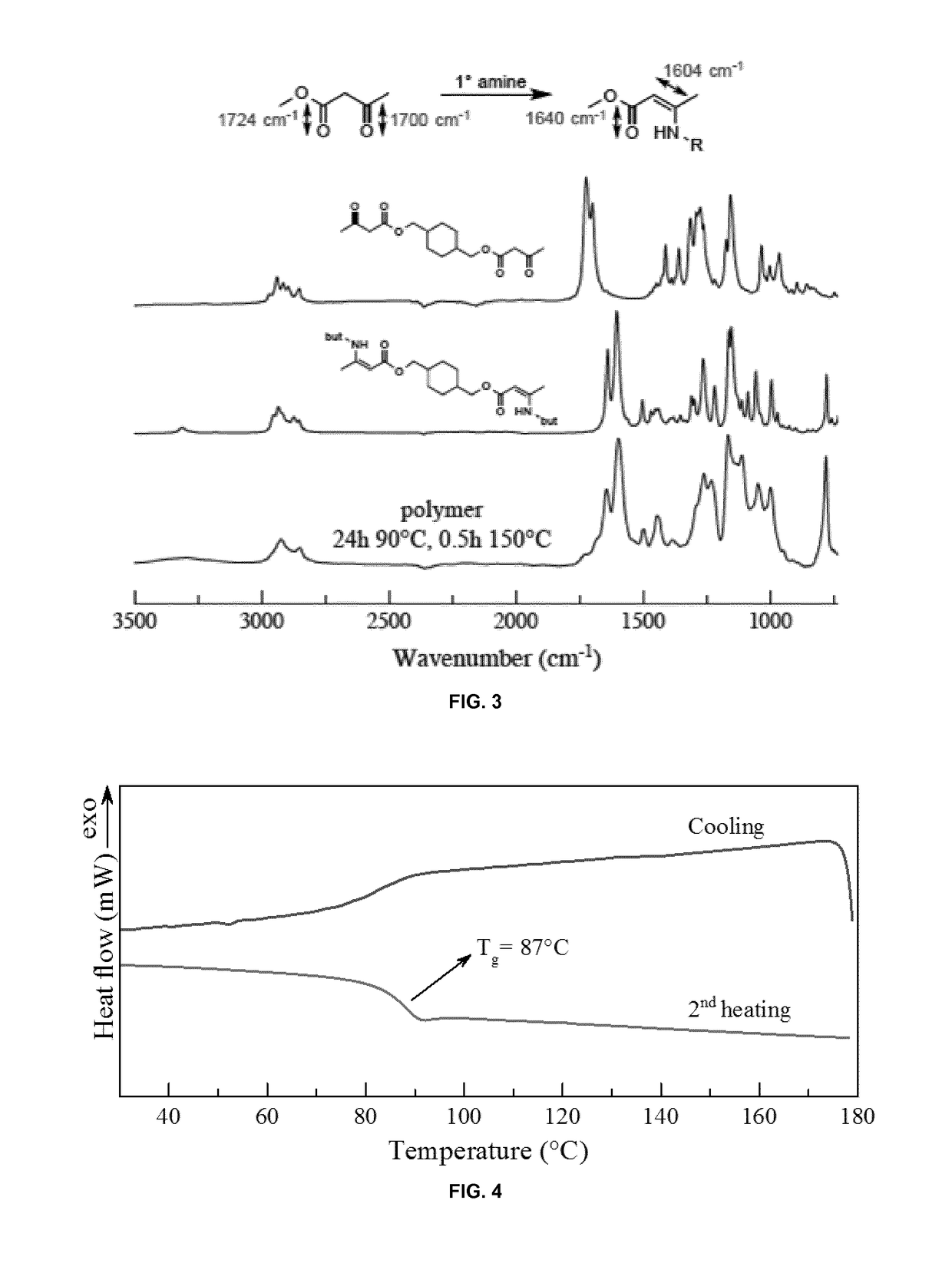

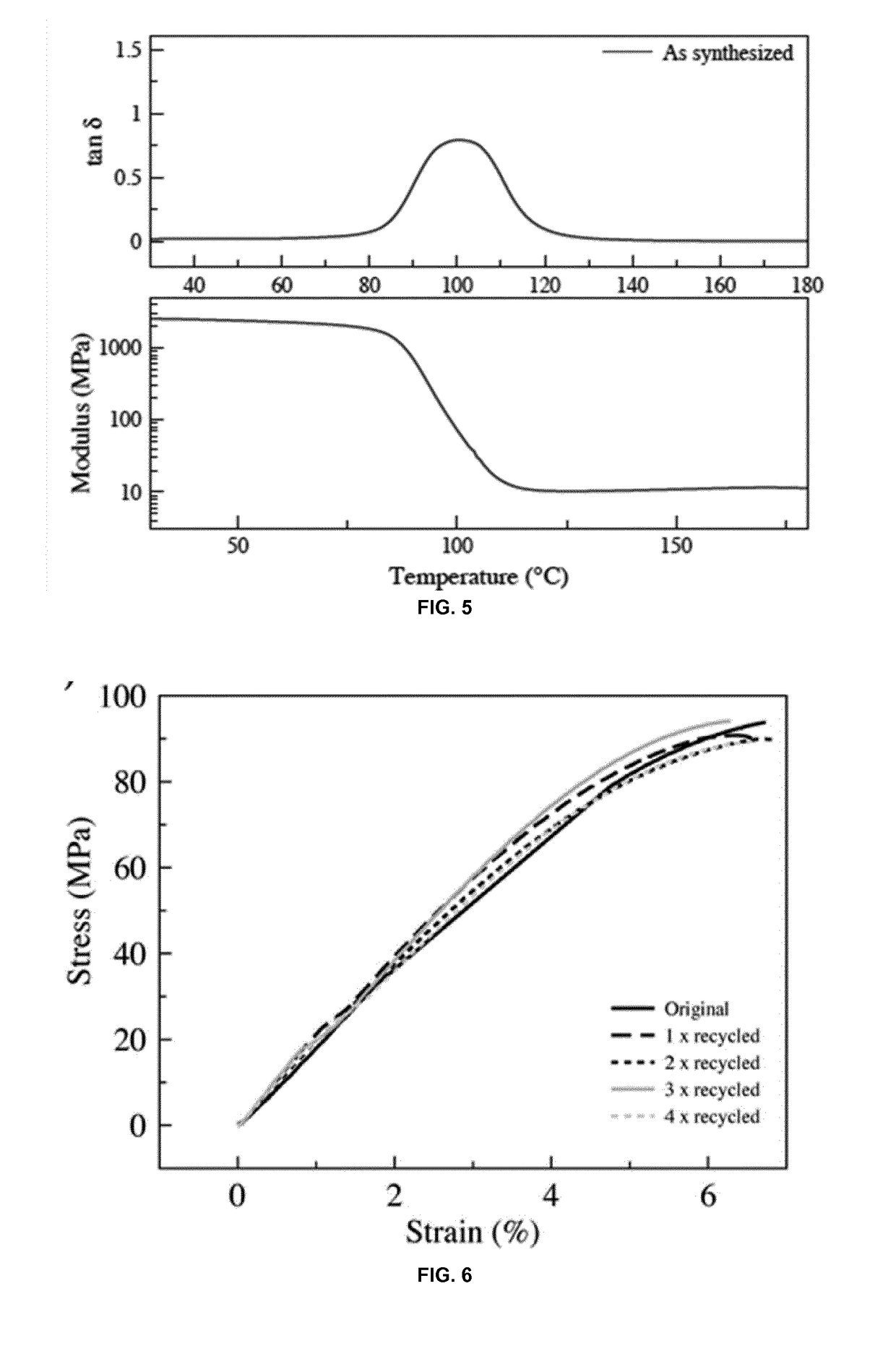

Compositions comprising a polymeric network

ActiveUS20170327625A1Allow for manufactureEasy to storeProductsOrganic chemistryCompound aPolymer science

The present invention relates to a composition comprising a polymeric network having at least one unit of formula (I), (II), and / or (III); (I) (II) (III) wherein said composition is obtained by contacting at least one compound A comprising at least two functions selected from the group of function of formula X—C(═O)—CHR1—C(═O)—R2, —C(═O)—C—R2; or —C(═O)—CR1═CR2—NR4R5; wherein at least 25% by weight of compounds A have a functionality ≦5, with % by weight relative to the total weight of compounds A; with at least one compound B comprising at least one NH2, or NH3+ groups; wherein X, R1, R2, R3, R4, R5, L1 and L2 have the same meaning as that defined in the claims. The present invention also relates to a compound comprising at least two units and at most 5 units of formula (I), (II), and / or (III); wherein R1, R2, R3, X, L1 and L2 have the same meaning as that defined in the claims. The present invention also relates to processes for preparing said composition and said compounds, to material, articles, and polymers comprising or using said compositions and compounds, and the use thereof.

Owner:UNIV GENT +2

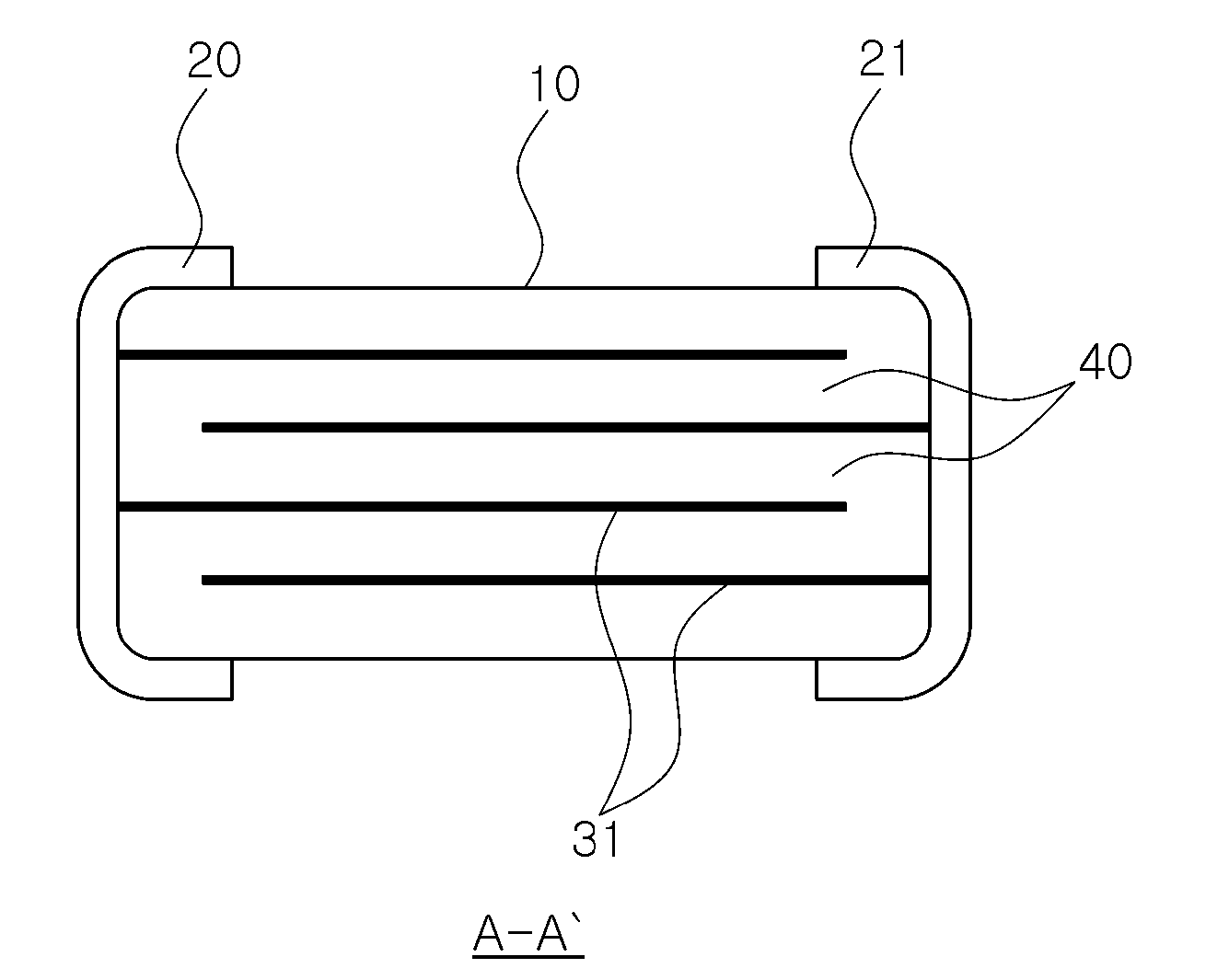

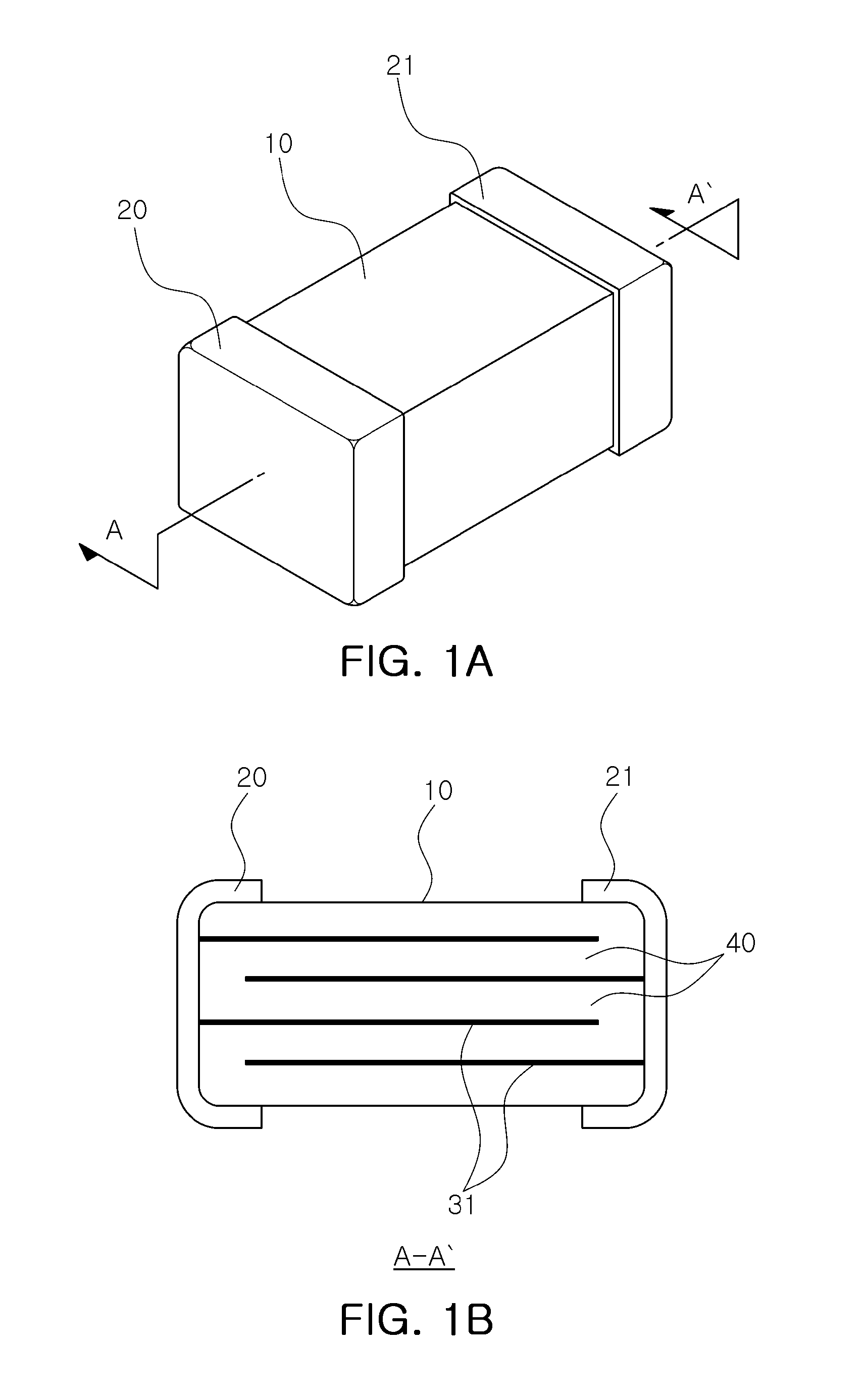

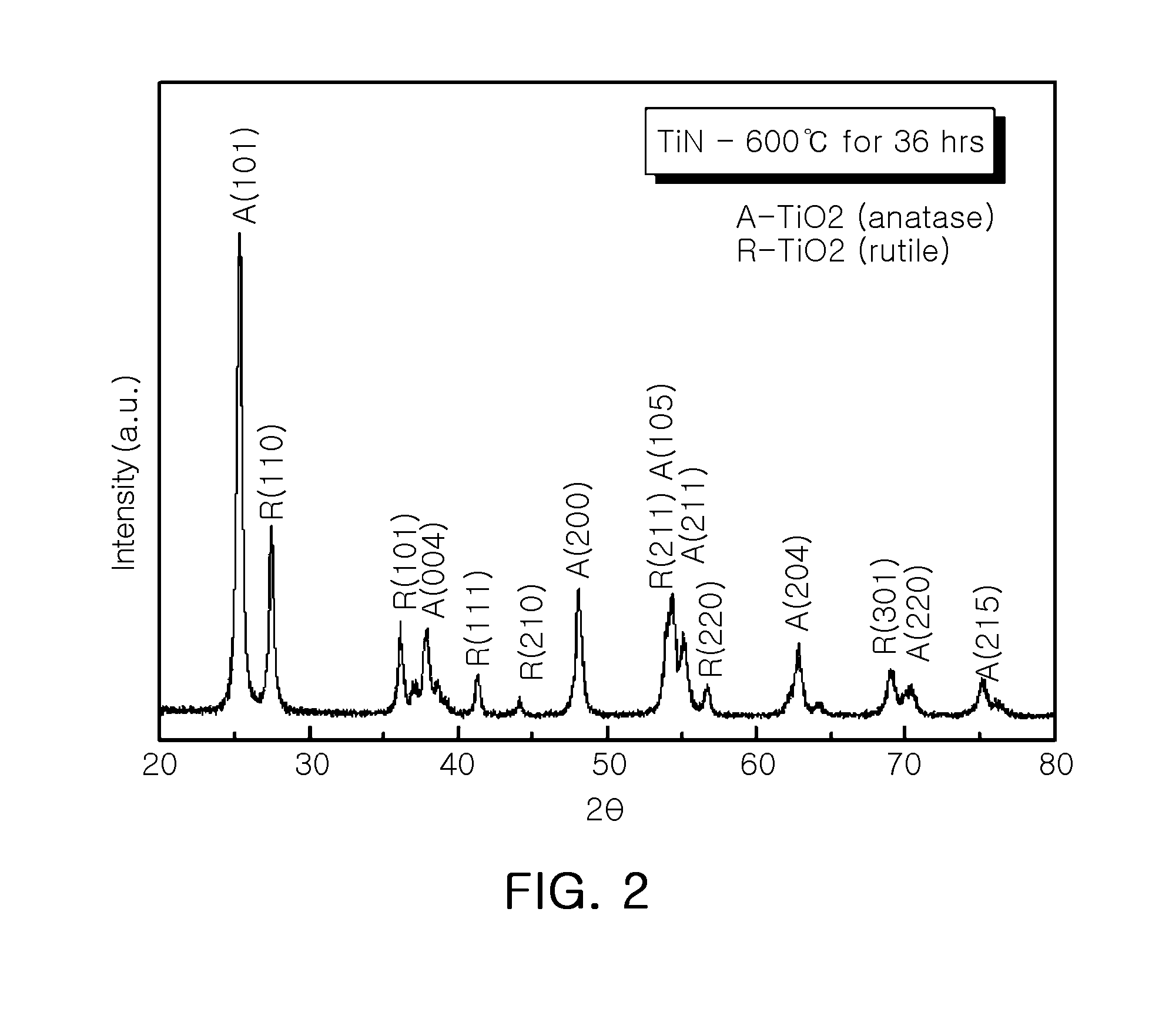

Conductive paste for internal electrode of multilayer ceramic electronic component and multilayer ceramic electronic component using the same

InactiveUS20130038983A1Allow for manufactureMaterial nanotechnologyFixed capacitor electrodesSilicon nitrideBoron nitride

There is provided a conductive paste for an internal electrode of a multilayer ceramic electronic component and a multilayer ceramic electronic component using the same. One or more nitride powders containing a nitride selected from the group consisting of silicon nitride, boron nitride, aluminum nitride, a vanadium nitride are added to the conductive paste for an internal electrode to increase a shrinkage initiation temperature of the internal electrodes. Accordingly, the reliability of the multilayer ceramic electronic component can be improved by using the conductive paste for an internal electrode.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

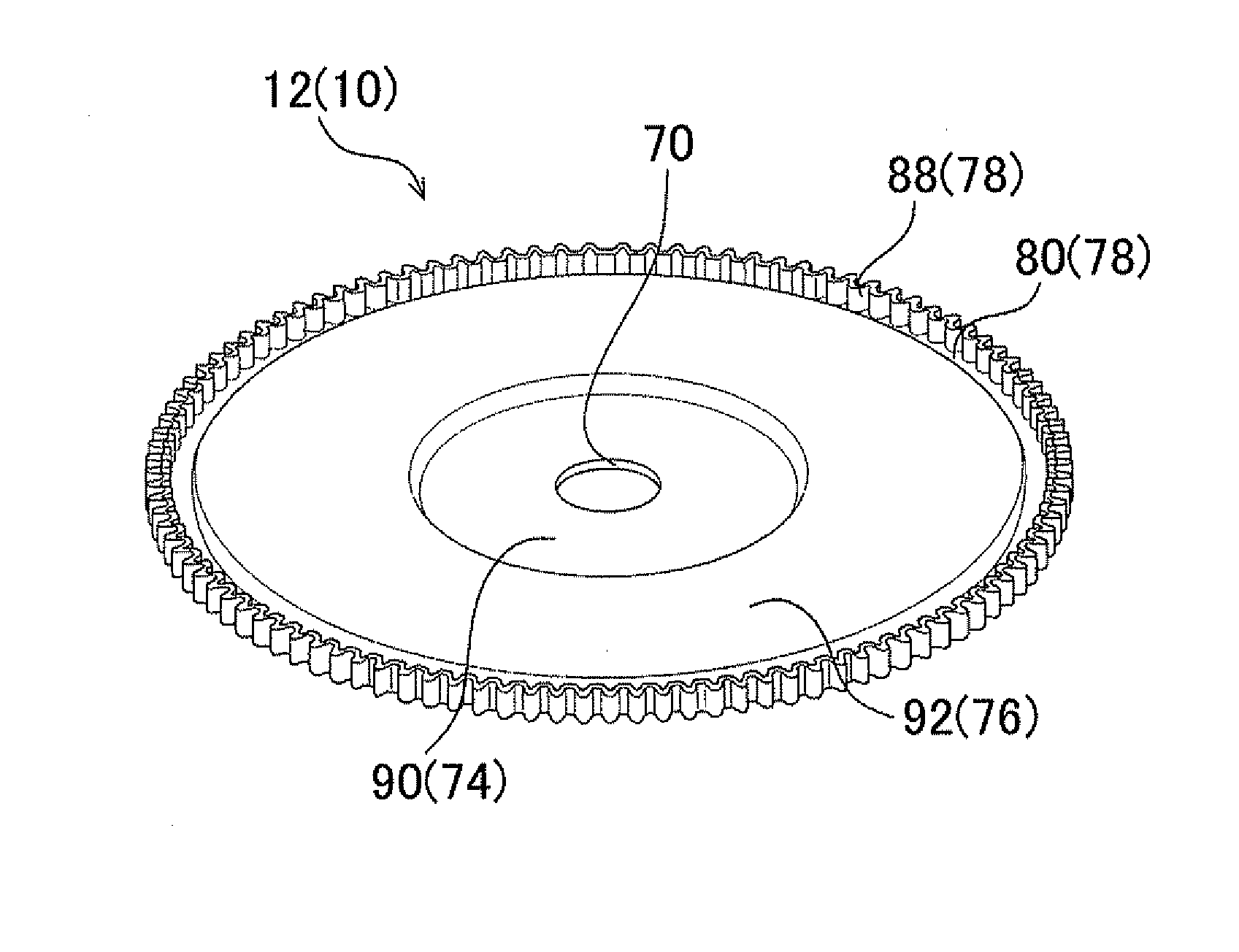

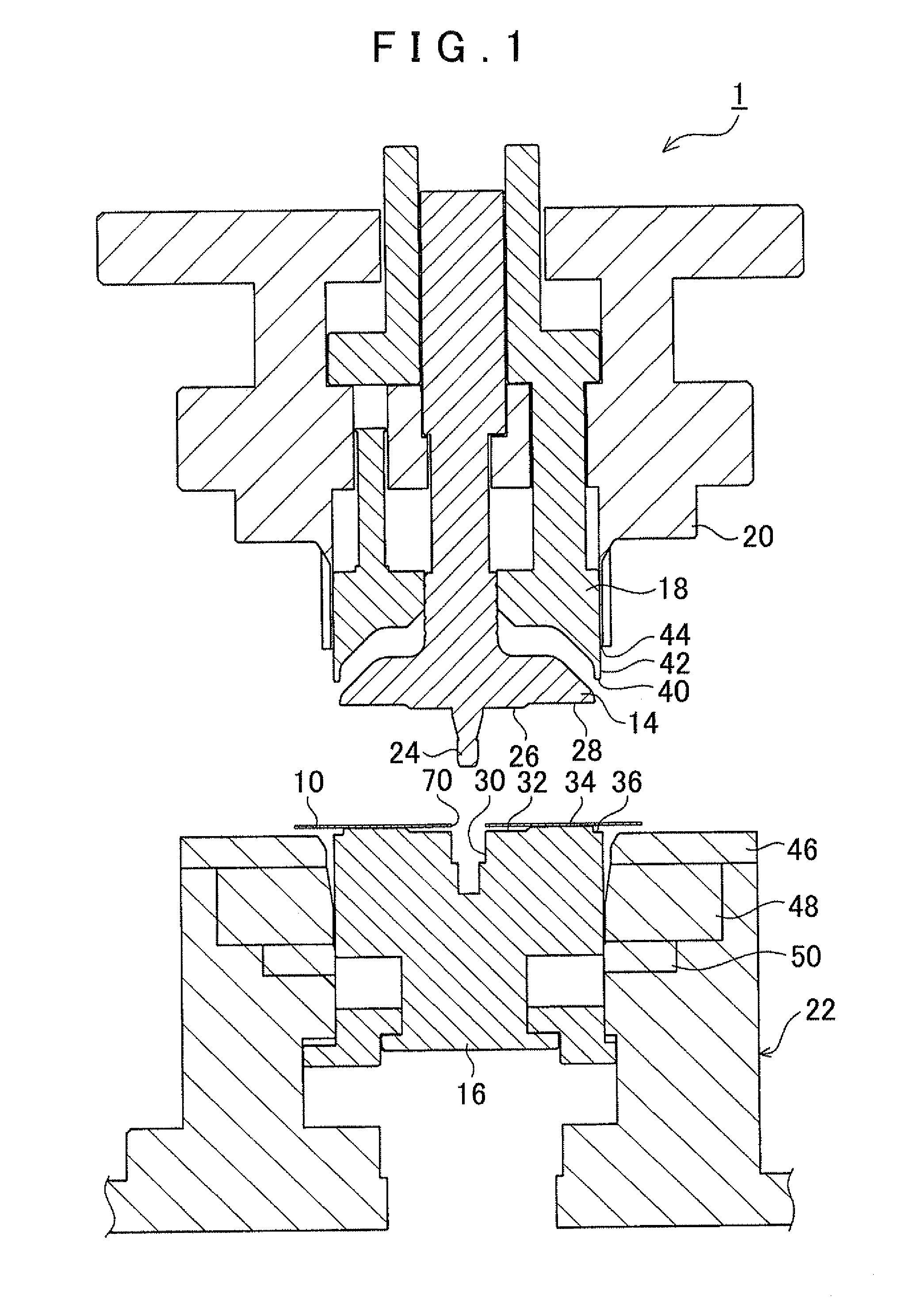

Manufacturing method for toothed part and manufacturing device for toothed part

InactiveUS20120240405A1Simple structureAllow for manufactureGear wheelsForging/hammering/pressing machinesEngineeringMechanical engineering

A manufacturing method for a toothed part including a bottom surface portion and a side wall portion provided to extend upright from an outer peripheral end portion of the bottom surface portion, the side wall portion being fanned with teeth. The manufacturing method includes a half drawing process of performing draw shaping on a material having a disk shape to form the bottom surface portion and the side wall portion, an inside diameter of which becomes larger in a direction away from the bottom surface portion; and a tooth shaping process of forming the teeth in the side wall portion.

Owner:AISIN AW CO LTD

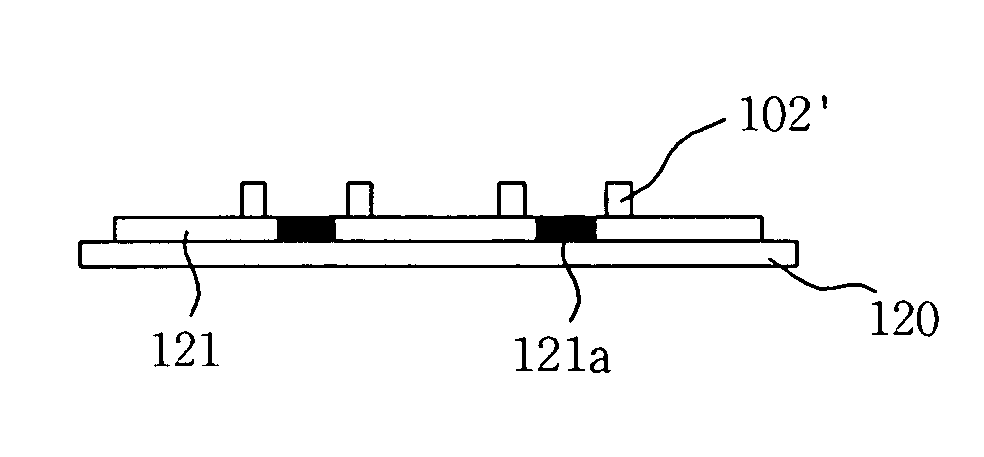

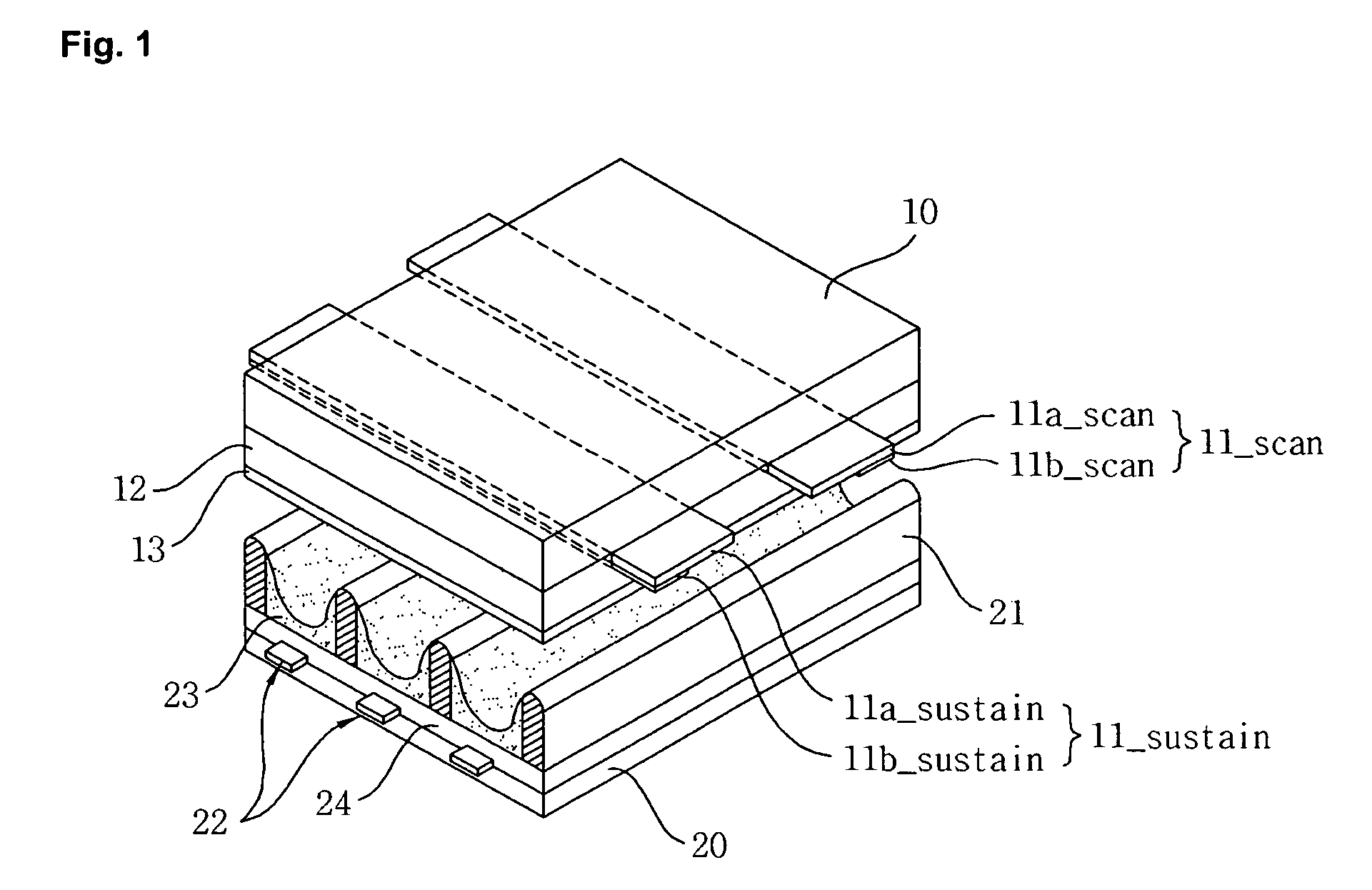

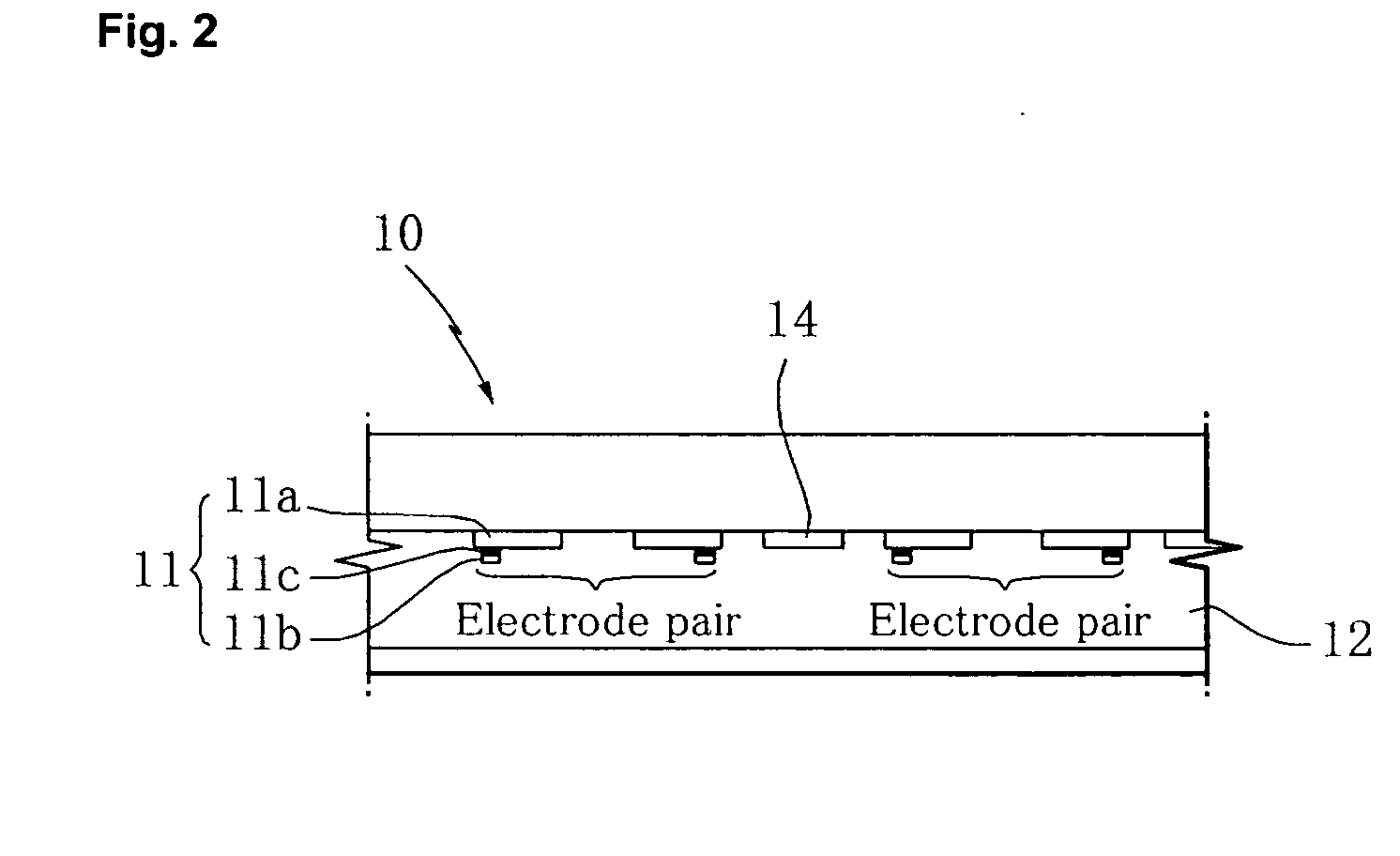

Sheet for manufacturing plasma display apparatus and method for manufacturing plasma display

InactiveUS20060038955A1Low costShorten the timeAddress electrodesSustain/scan electrodesMetallurgyPhotoresist

Provided are a sheet for manufacturing a plasma display apparatus, and a method for manufacturing the plasma display apparatus. The sheet includes a base film; a photoresist layer formed on the base film; an electrode material layer formed on the photoresist layer; and a cover film formed on the electrode material layer.

Owner:LG ELECTRONICS INC

Inflation valve with pneumatic assist

ActiveUS7673647B2Allow for manufactureEliminate needOpening closed containersBottle/container closureGas cylinderHigh intensity

Owner:HALKEY ROBERTS CORP

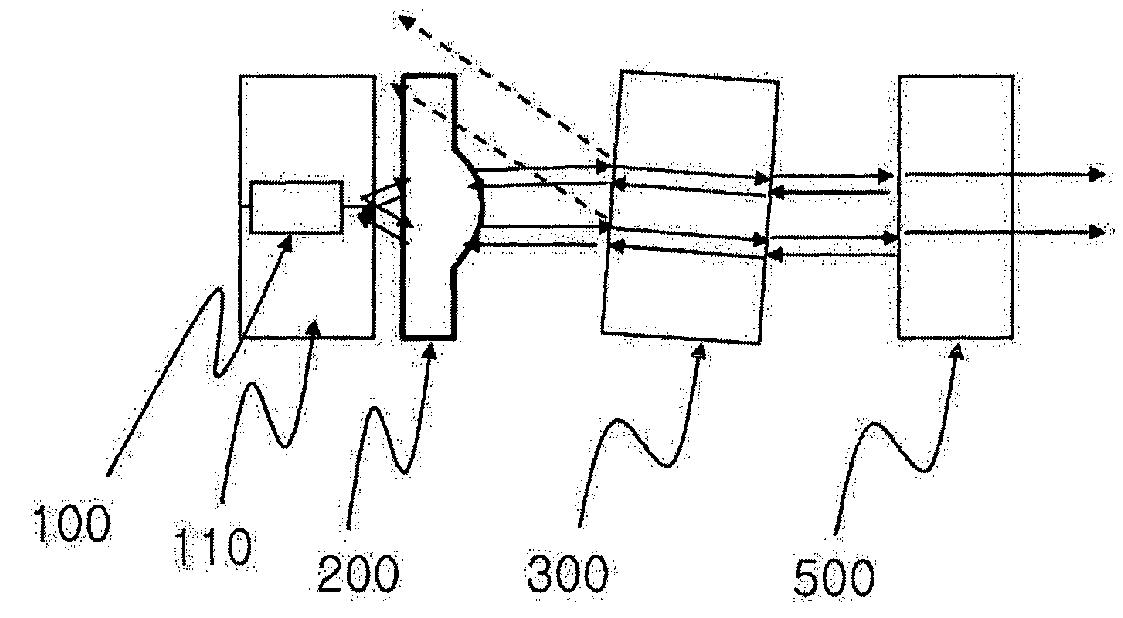

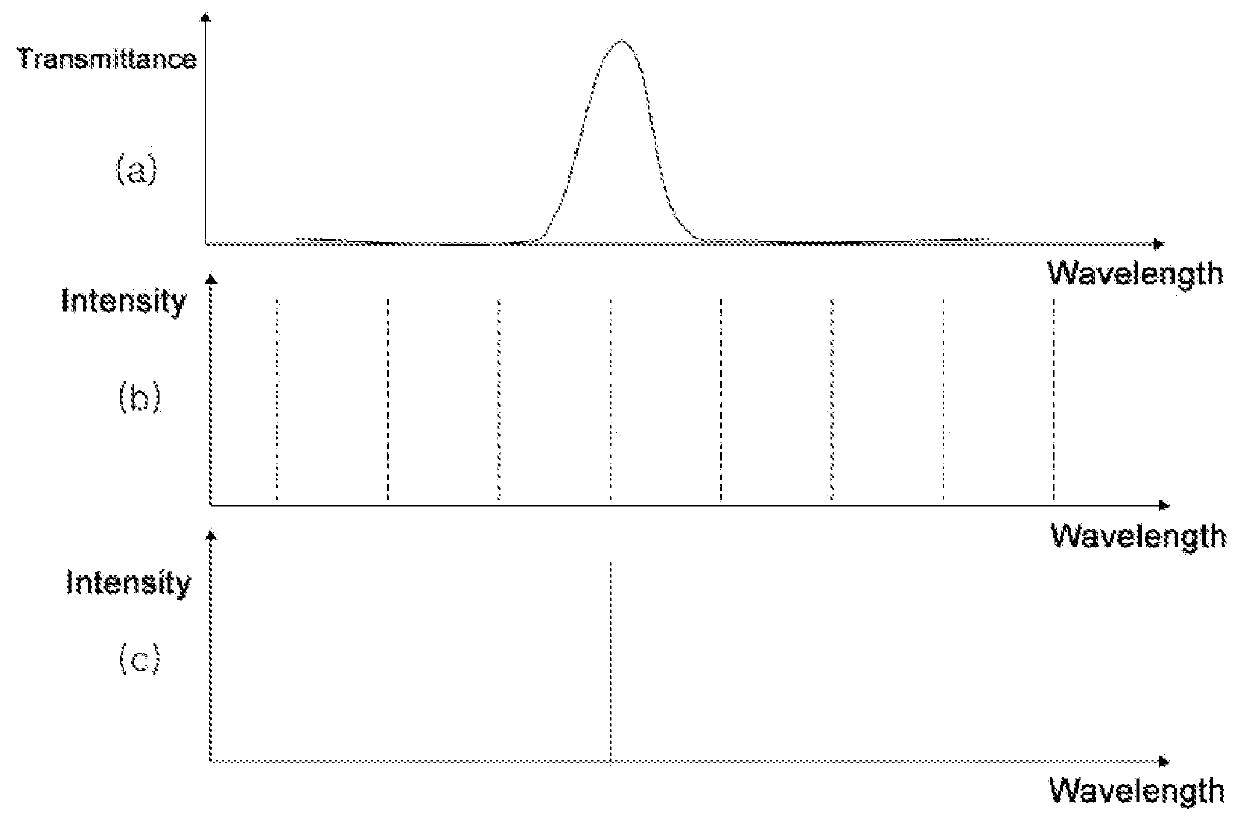

Wavelength-tunable laser

ActiveUS20160056608A1Low costSimple methodLaser detailsLaser optical resonator constructionRefractive indexLight beam

The present invention relates to a wavelength-tunable laser, which can tune an oscillating laser wavelength and can be manufactured in a small size, comprising: a laser diode chip (100) for emitting a laser beam; a partial reflection mirror (500) for optical feedback, which partially reflects the beam emitted from the laser diode chip (100) so as to enable the reflected beam to be fed back to the laser diode chip (100); a collimation lens (200) provided on an optical path between the laser diode chip (100) and the partial reflection mirror (500) for optical feedback so as to collimate the beam emitted from the laser diode chip (100); a wavelength-tunable selective filter (300) for converting the wavelength transmitted according to the temperature; a phase compensator (350) of which a refractive index is changed according to the temperature and which offsets a change in the refractive index according to the temperature of the semiconductor laser diode chip (100) or the wavelength-tunable selective filter (300); and a 45 degree reflection mirror (400) for switching the direction of the laser beam from the laser beam traveling in the horizontal direction with respect to a bottom surface of a package, to the laser beam traveling in the vertical direction with respect to the bottom surface of the package, wherein the laser diode chip (100), the wavelength-tunable selective filter (300), and the phase compensator (350) are disposed at an upper part of a thermoelectric element (900) so as to change the wavelength oscillating according to a change in the temperature of the thermoelectric element (900).

Owner:PHOVEL

Thermoset/supramolecular hybrid composites and resins that can be hot-formed and recycled

ActiveUS9359467B2Easy to handleEasy to storePlastic recyclingTransesterificationCompound (substance)

Owner:ARKEMA FRANCE SA +1

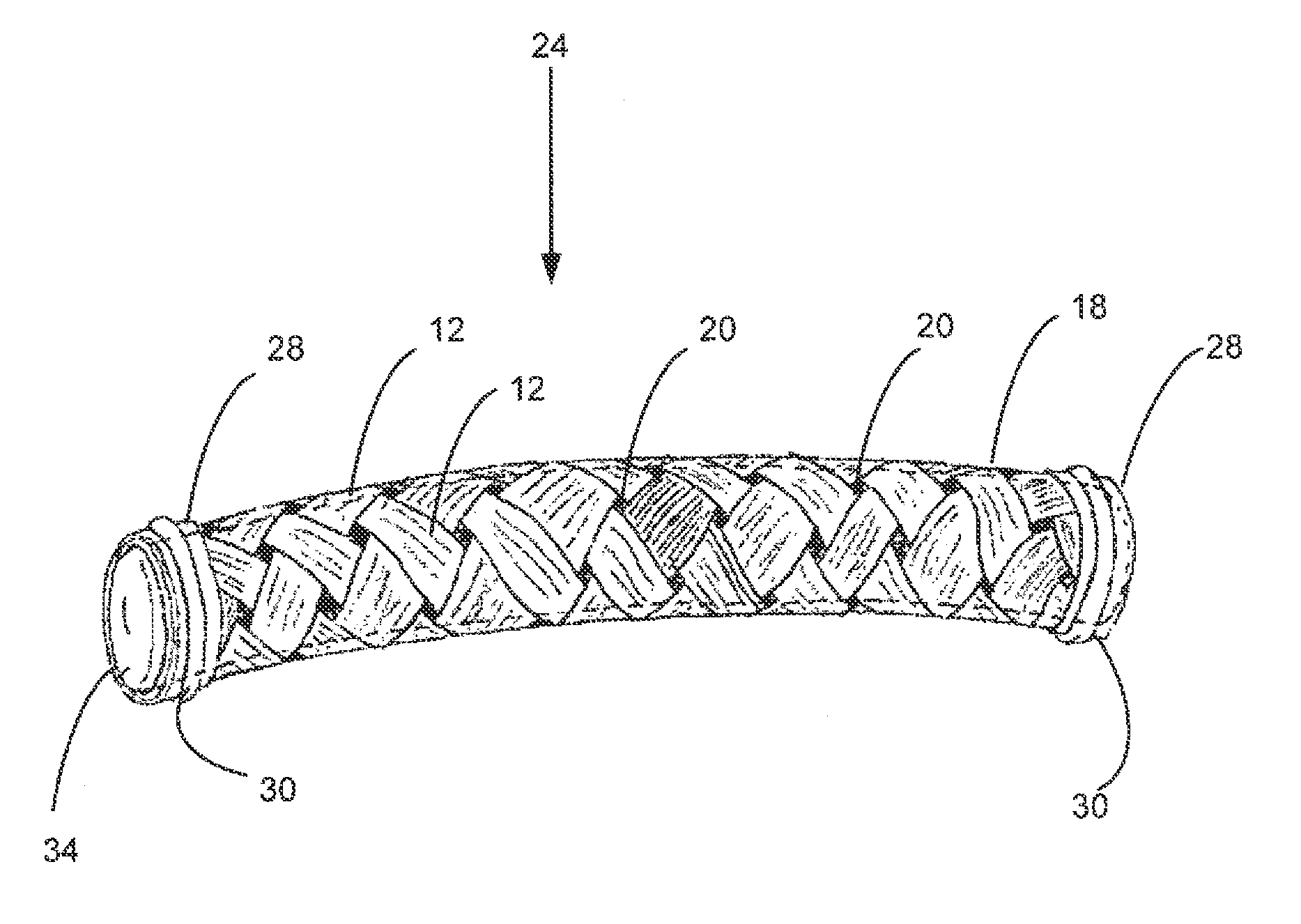

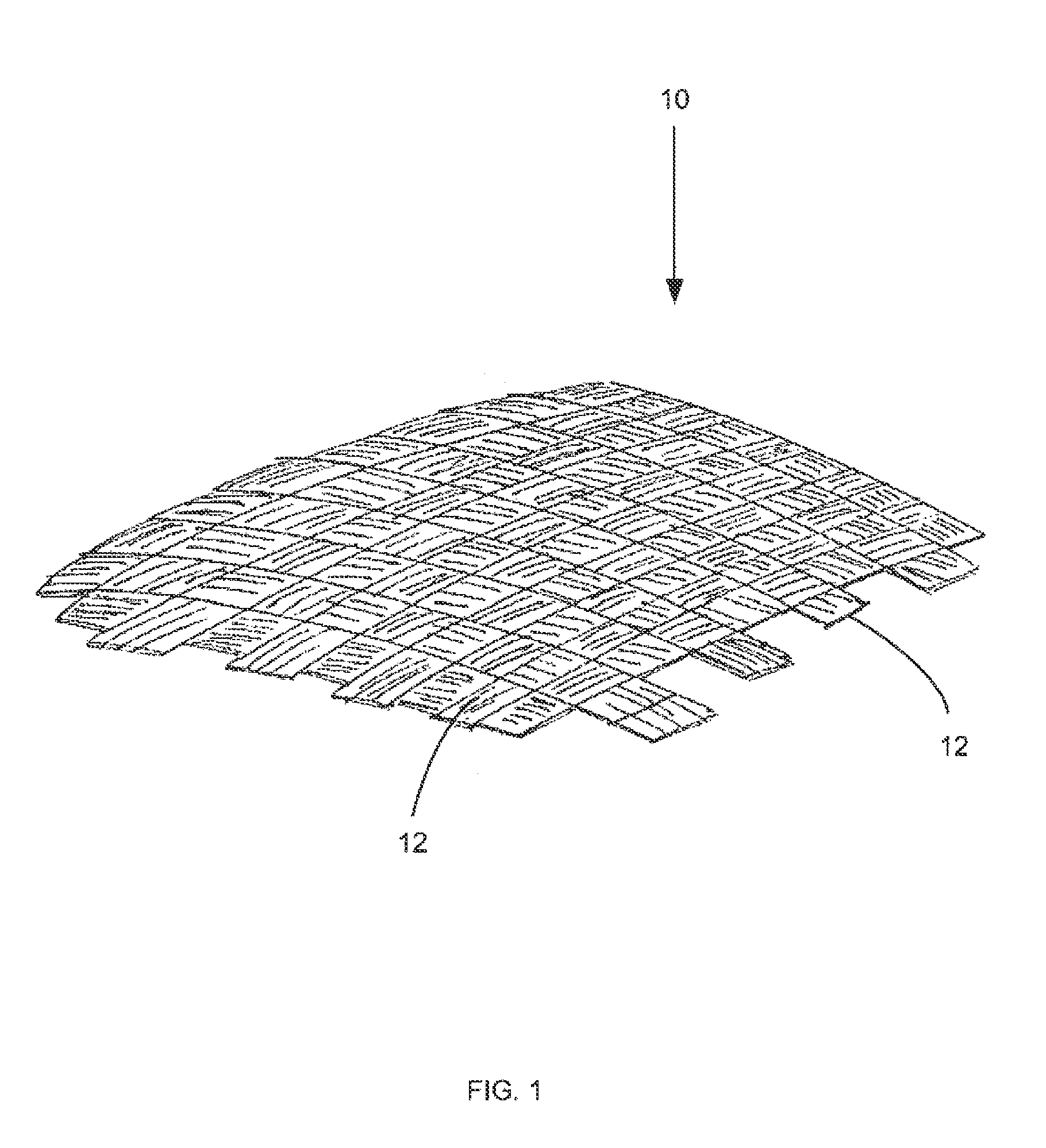

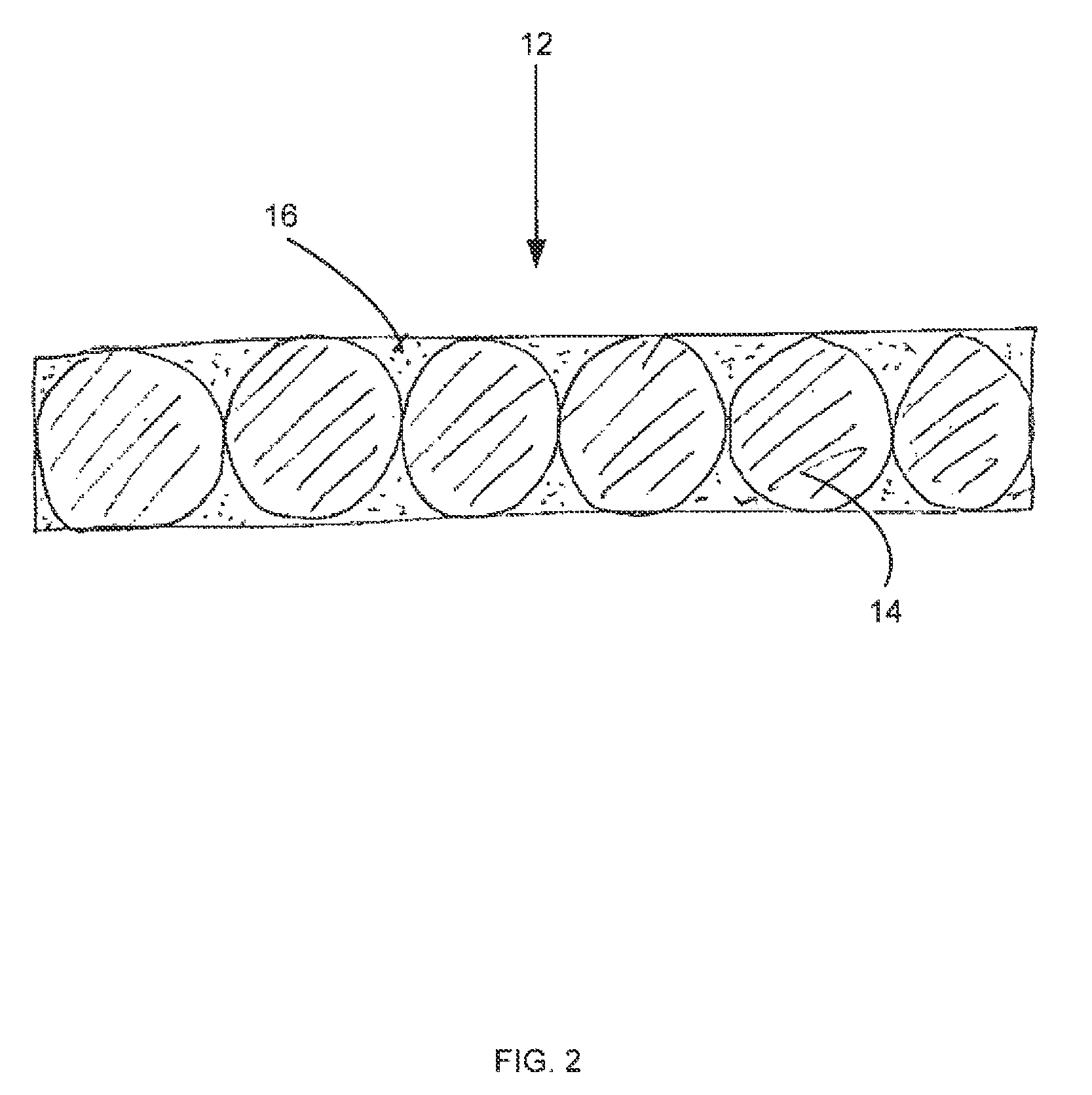

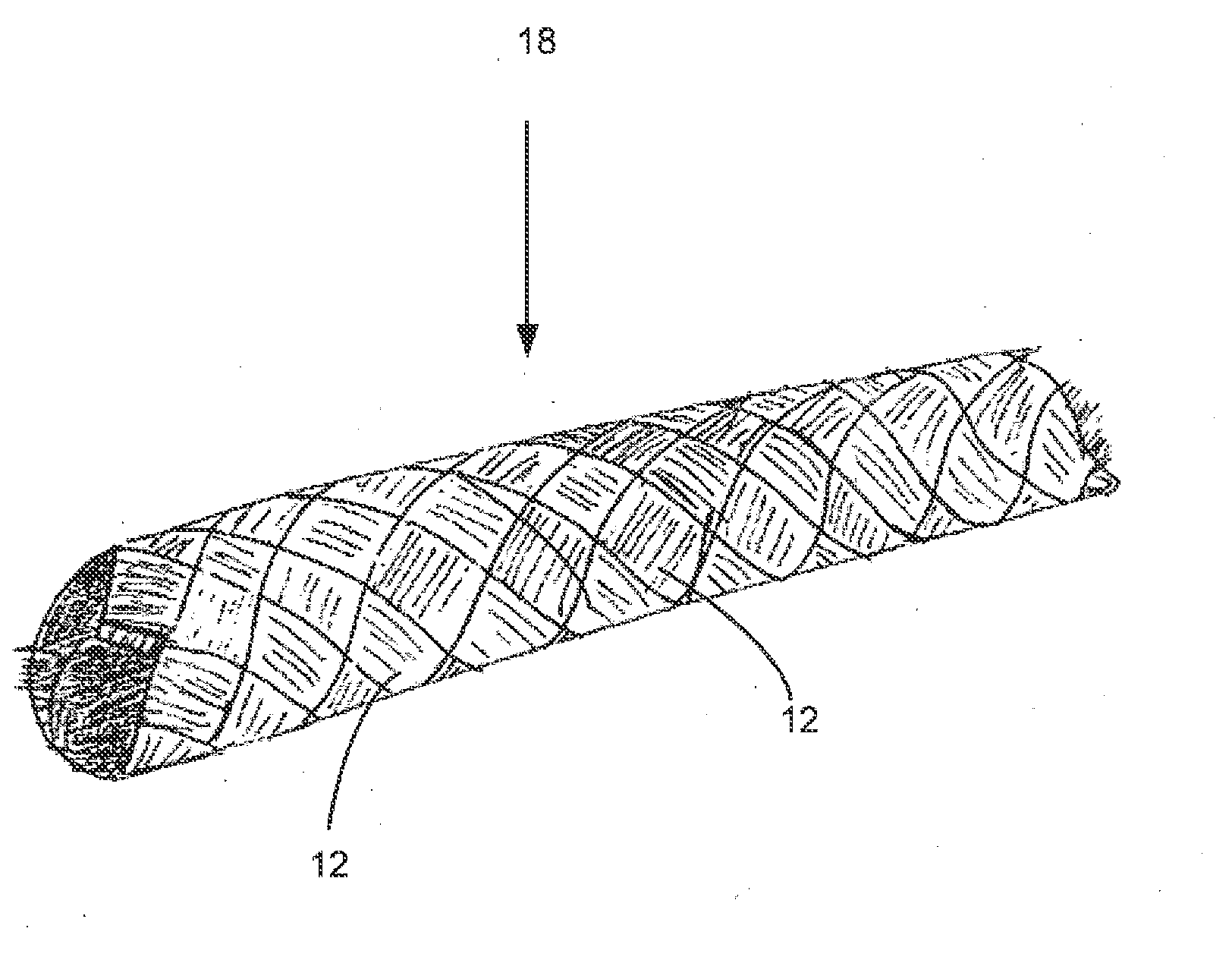

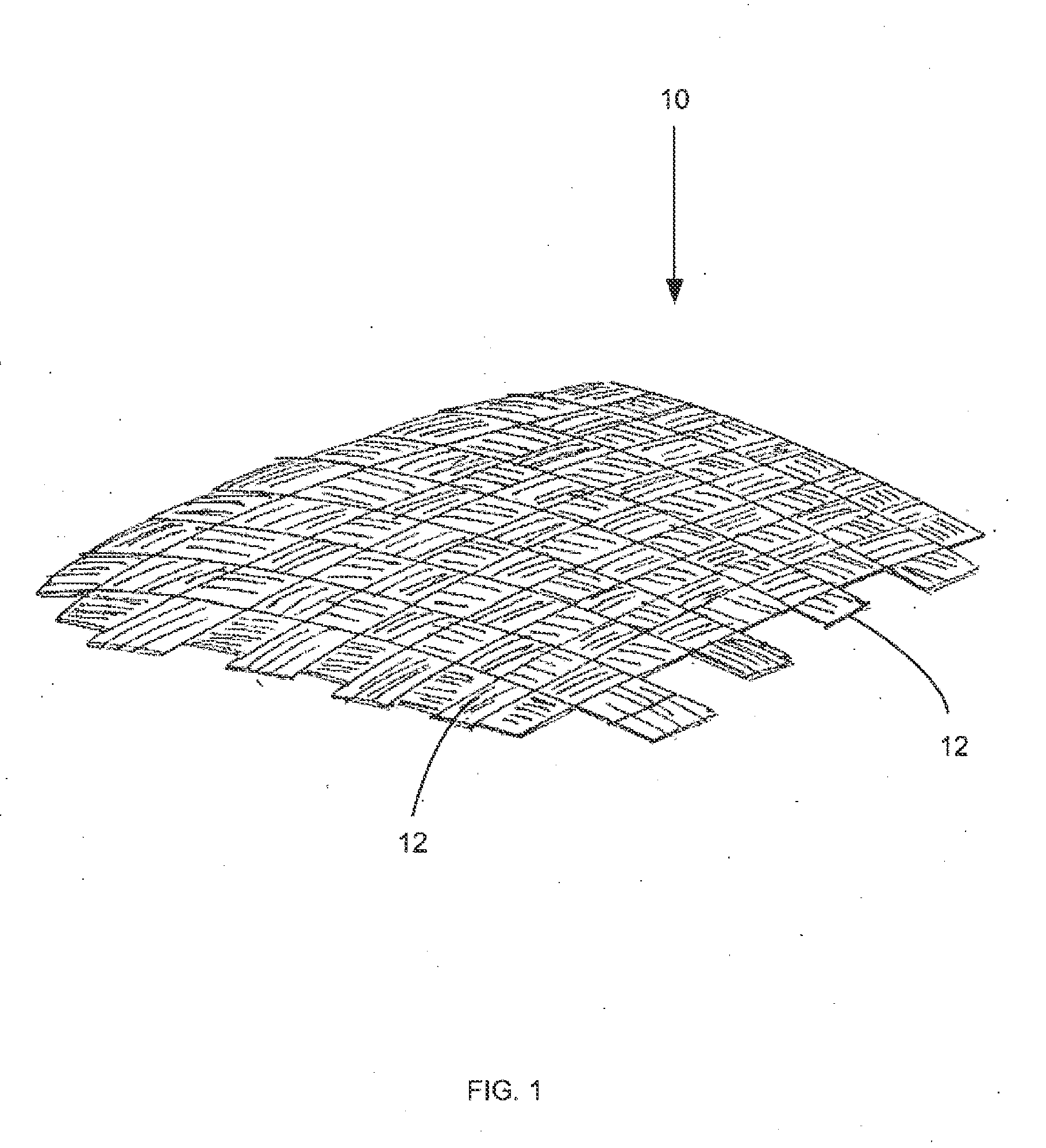

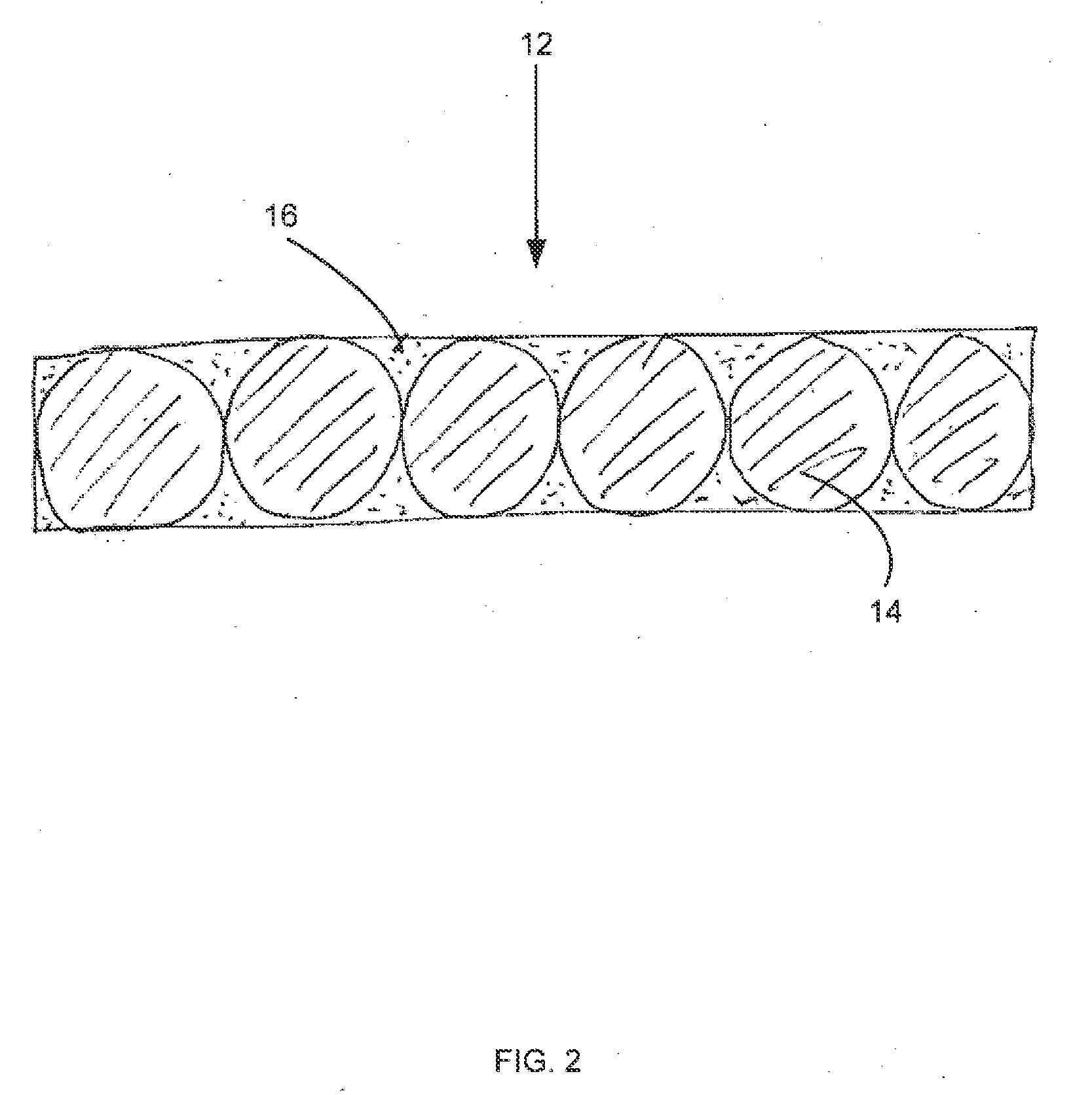

Composite material, composite part and methods for making such

ActiveUS8302522B2Allow for manufactureAvoid crackingDucting arrangementsFlexible pipesThermoplastic matrixMaterials science

A composite material comprising a plurality of fiber tape strips woven or braided together. Each of the plurality of fiber tape strips is made of a single layer of unidirectional fibers. The fibers are at least partially embedded in a thermoplastic matrix. A tubular composite part is made from this composite material and of an internal film. A method of manufacturing the composite material comprises weaving or braiding the fiber tape strips, especially in the form of a tube. A method of manufacturing a composite part comprises pressurizing the film inside the tube while heating both the tube and the film up to their forming temperature so as to bond the film to the woven fiber tape strips.

Owner:HUTCHINSON AERONAUTIQUE & IND LIMITEE HUTCHINSON AEROSPACE & IND

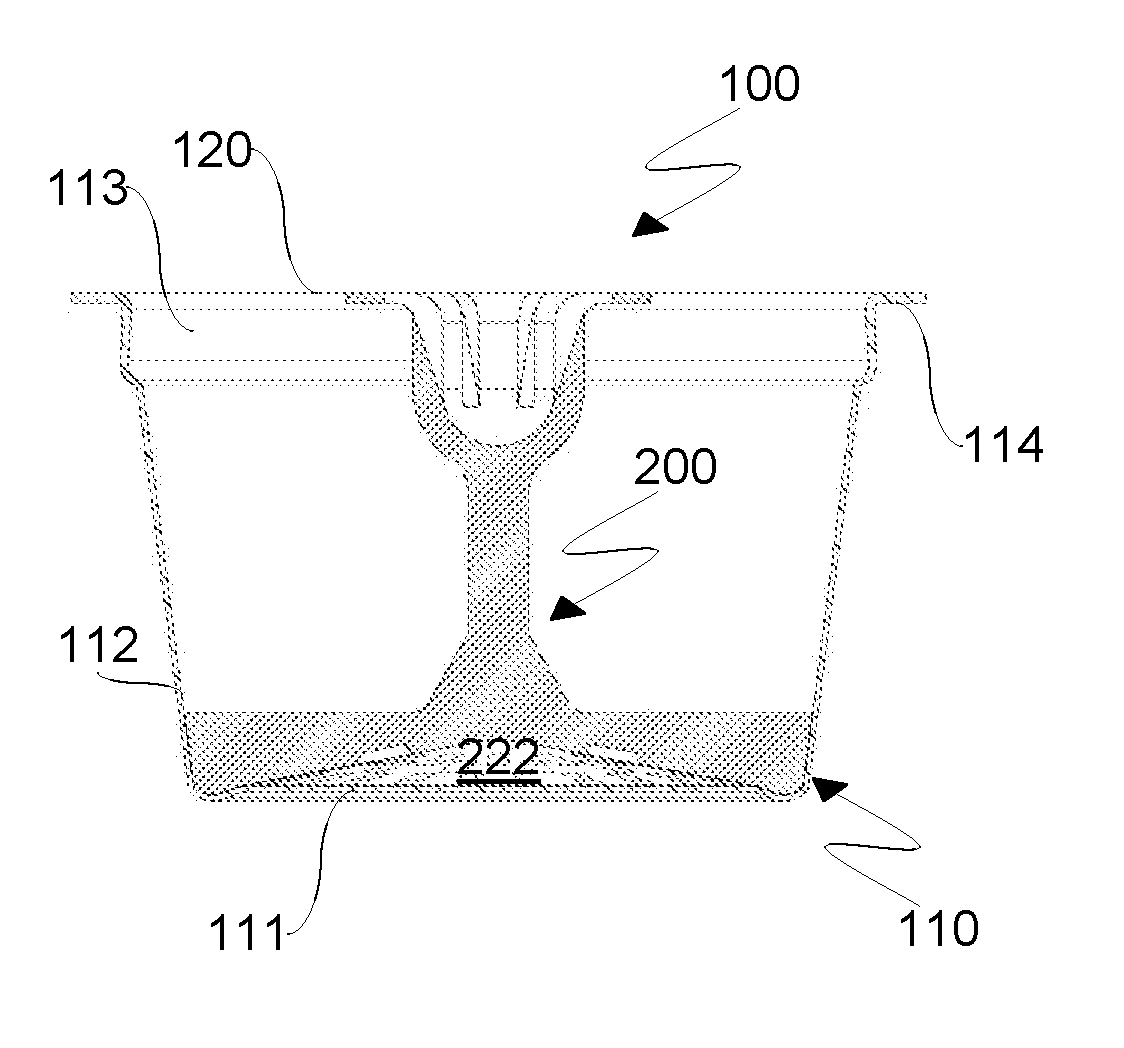

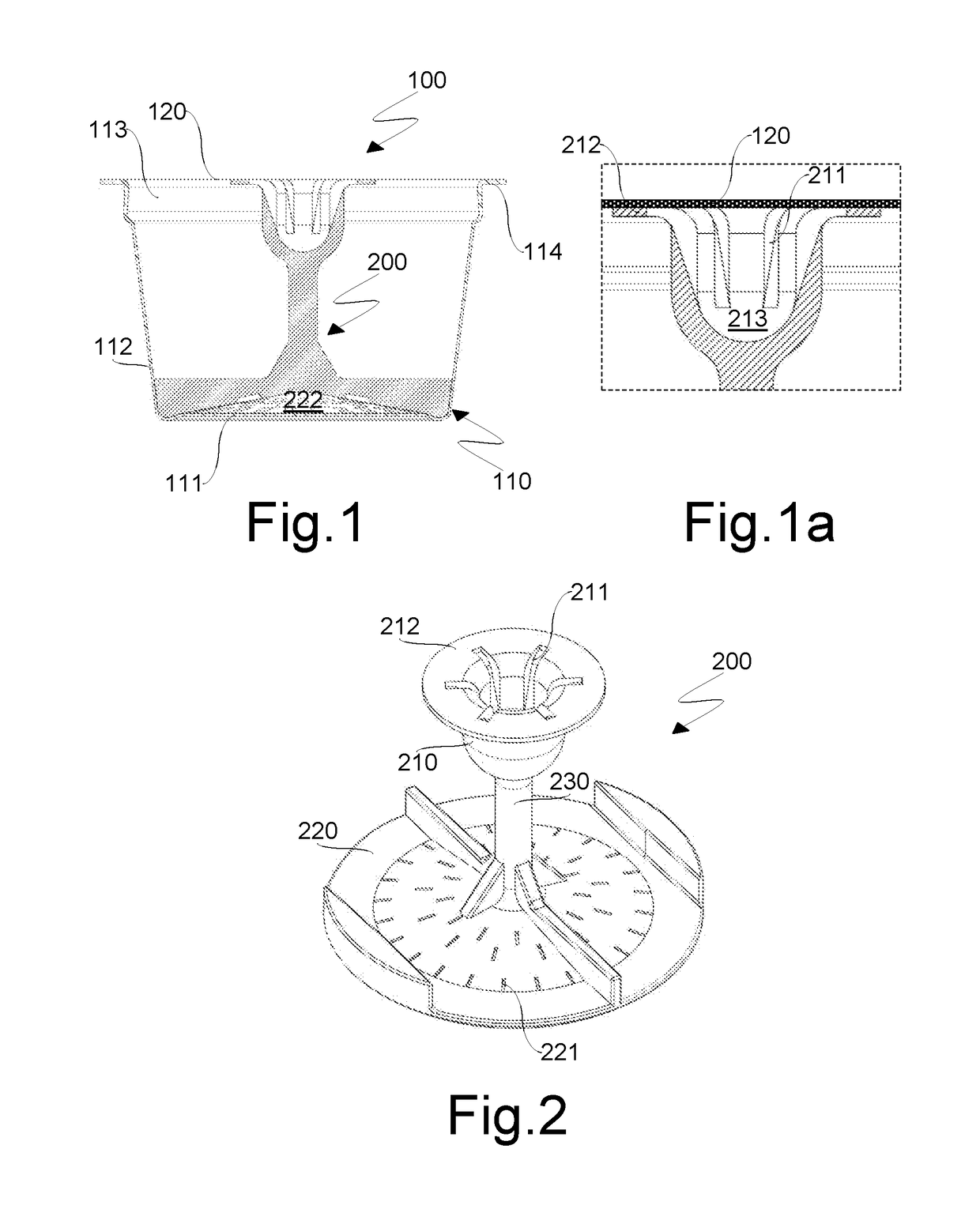

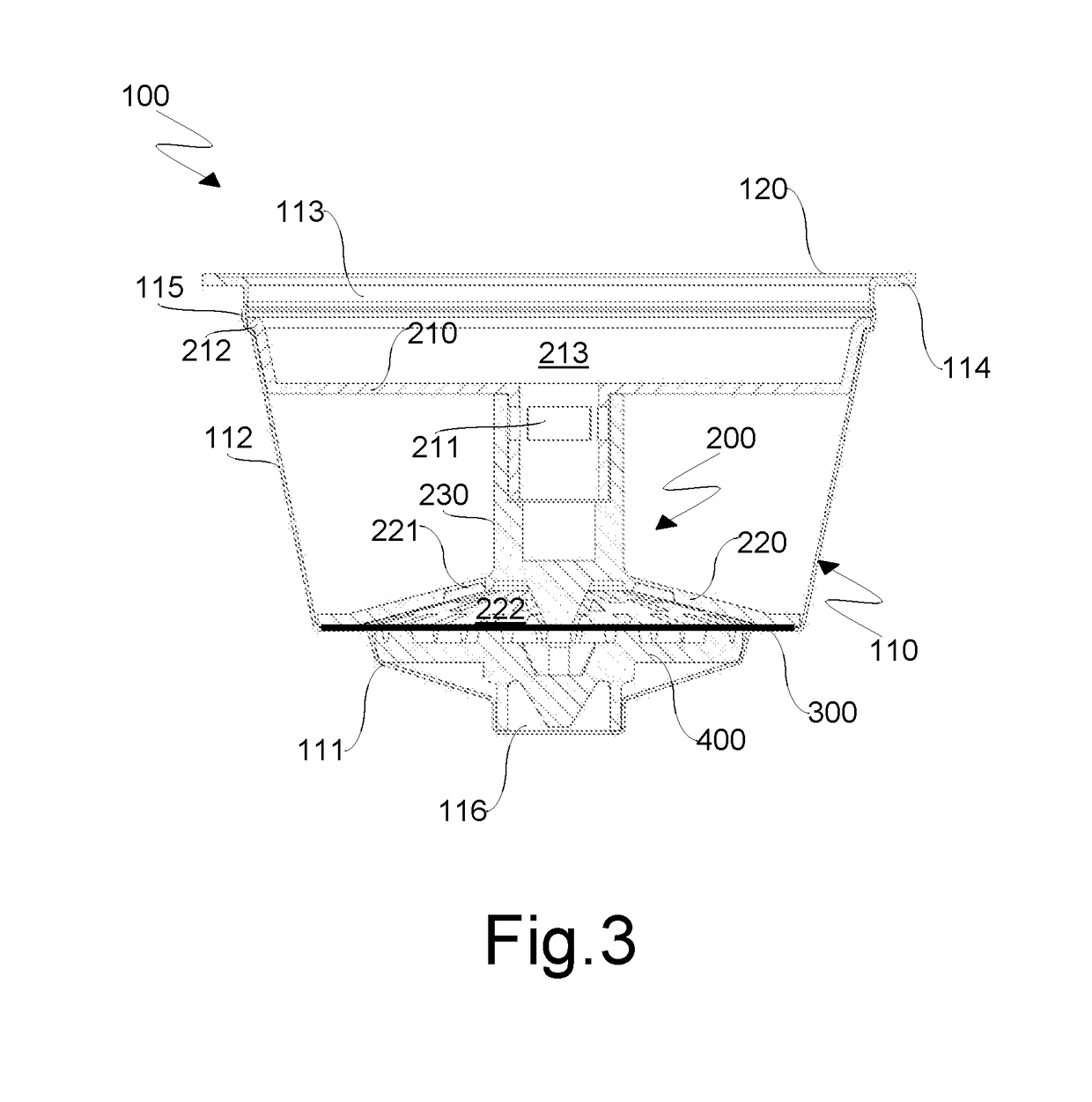

Disposable capsule for machines for preparing infused beverages

InactiveUS20180134485A1Allow for manufactureSimplifying manufacturing and assembly equipmentPackagingDistributorSurgery

A disposable capsule for use in machines for preparing infused beverages is disclosed. The capsule includes i) a cup-shaped hollow body adapted to receive a measured dose of a granulate or particulate product ii) a lid tightly fixed on a flange of the body; and iii) a distributor-collector insert. The insert stretches out axially from a base to a top of the body and has a glass-shaped portion arranged close to the top, a disk-shaped portion arranged at the base and a rod-shaped portion which connects the glass-shaped portion to the disk-shaped portion. The glass-shaped portion also has a plurality of through openings formed in a radial direction and the disk-shaped portion has a plurality of through openings formed in the axial direction.

Owner:IMPER

Composite material, composite part and methods for making such

ActiveUS20100269673A1Allow for manufactureAvoid crackingDucting arrangementsLamination ancillary operationsThermoplastic matrixMaterials science

A composite material comprising a plurality of fiber tape strips woven or braided together. Each of the plurality of fiber tape strips is made of a single layer of unidirectional fibers. The fibers are at least partially embedded in a thermoplastic matrix. A tubular composite part is made from this composite material and of an internal film. A method of manufacturing the composite material comprises weaving or braiding the fiber tape strips, especially in the form of a tube. A method of manufacturing a composite part comprises pressurizing the film inside the tube while heating both the tube and the film up to their forming temperature so as to bond the film to the woven fiber tape strips.

Owner:HUTCHINSON AERONAUTIQUE & IND LIMITEE HUTCHINSON AEROSPACE & IND

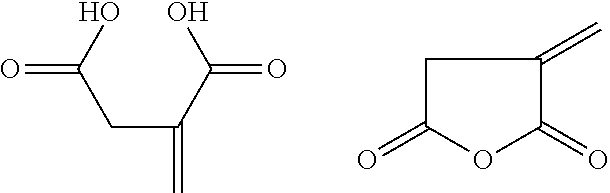

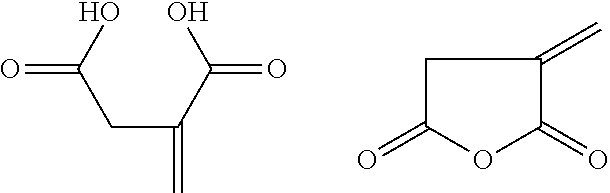

Composition for the prevention or removal of insoluble salt deposits

InactiveUS8415285B2Allow for manufactureDissolve fastInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsOrganic acidSolubility

Owner:ITACONIX

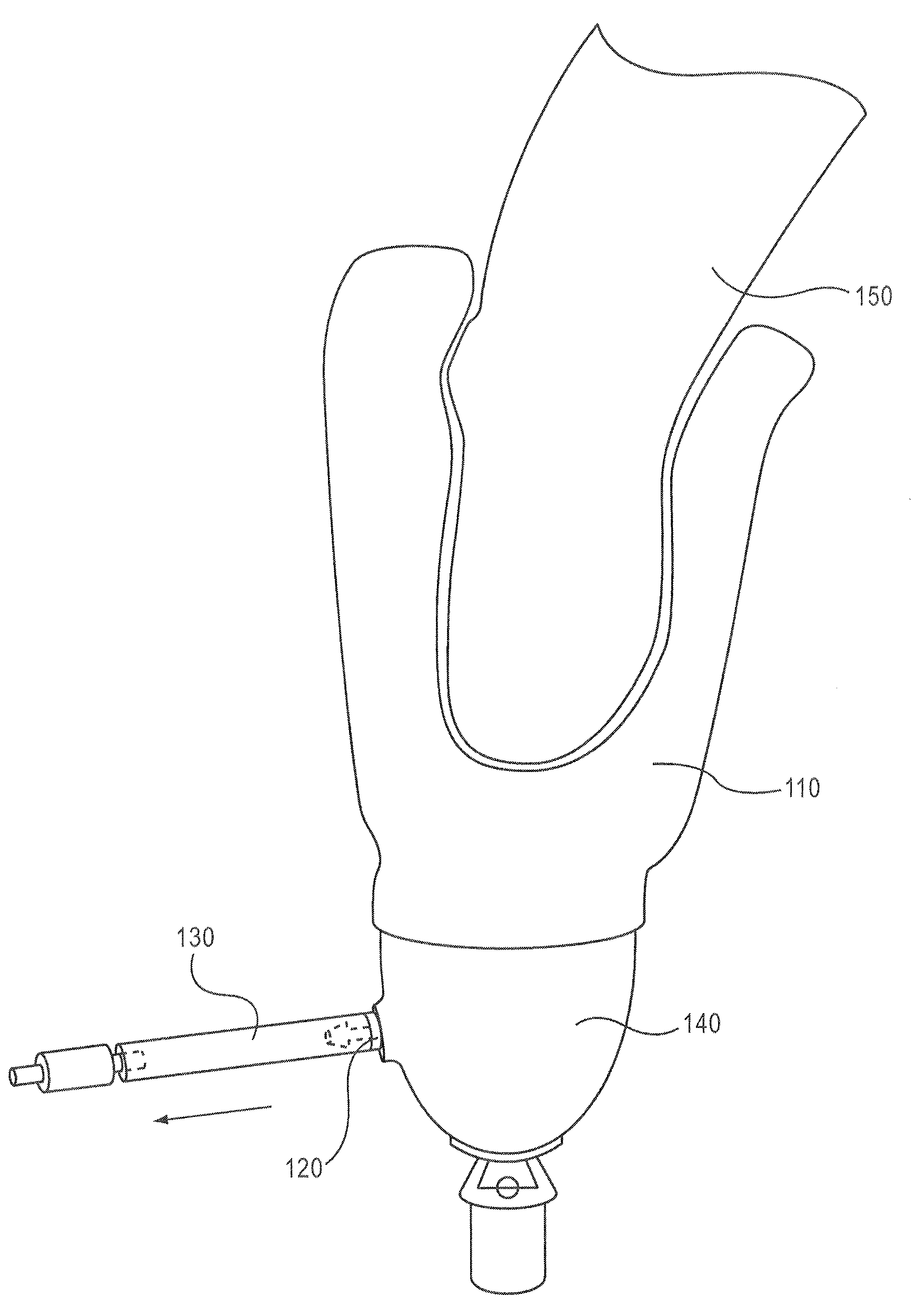

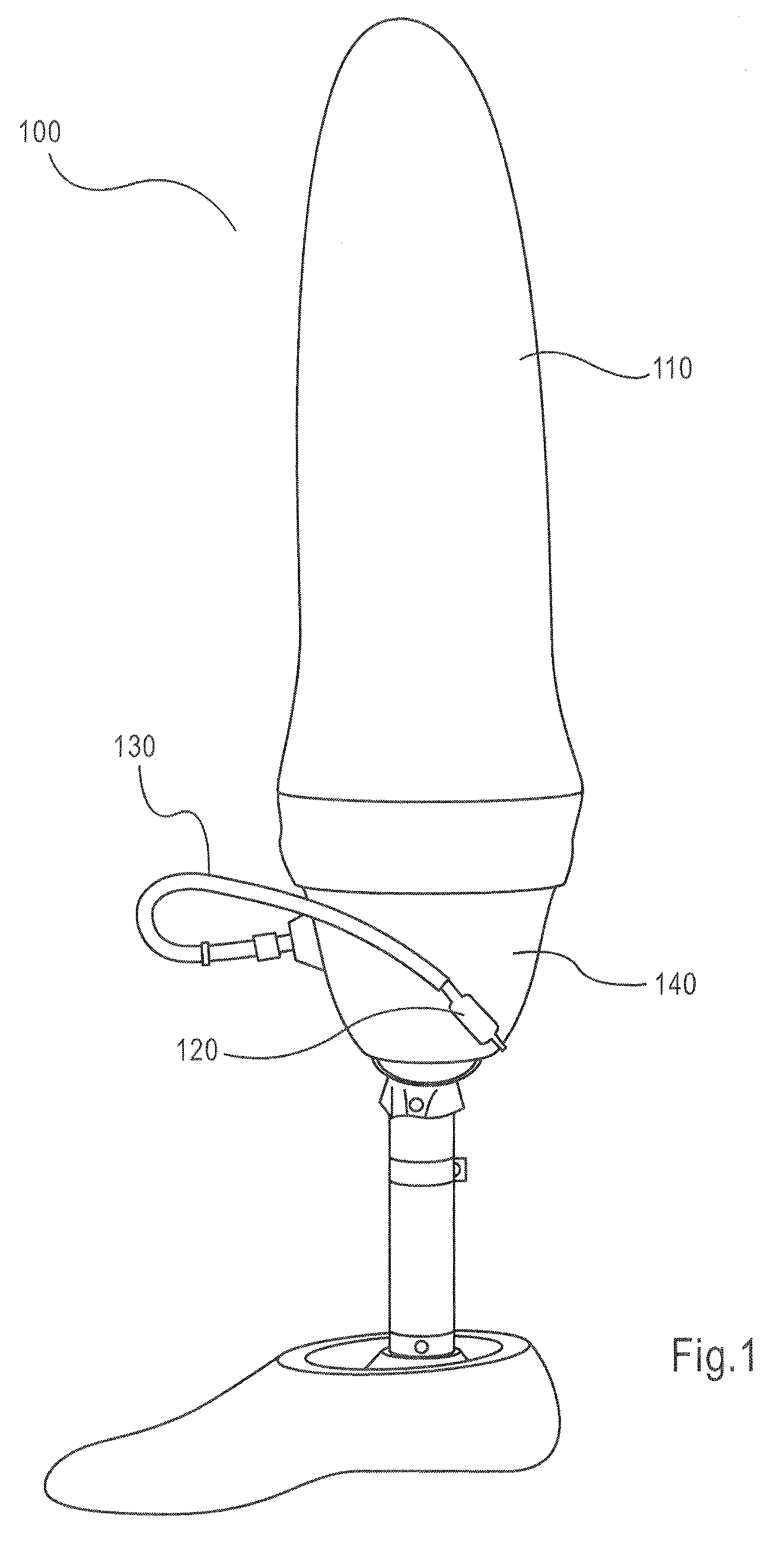

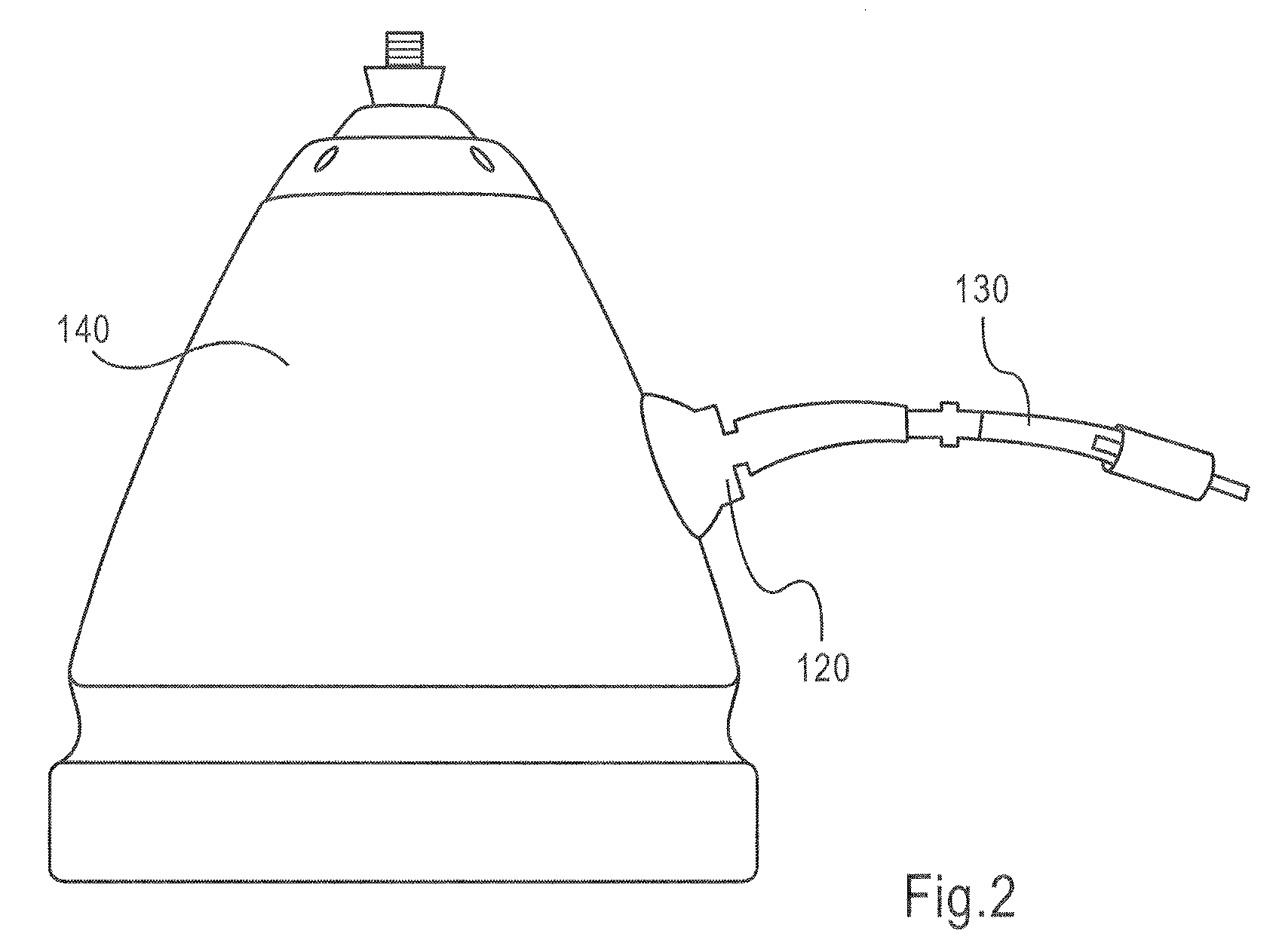

Vacuum based impression and alignment device and method

InactiveUS20090143868A1Accurate impressionPerfect accurate staticArtificial legsResidual limbVALVE PORT

A malleable bag connected to a one-way valve can be used to provide a prosthesis with an accurate impression of a residual limb and to perfect accurate static and dynamic alignment of the prosthesis on a patient. Methods and systems allow to rapidly and accurately capture an impression of a residual limb, including soft tissue compression due to the weight of the patient.

Owner:CENT FOR INT REHABILITATION

Composition for the prevention or removal of insoluble salt deposits

InactiveUS20120302484A1Lower Level RequirementsEcological profileInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSolubilityOrganic acid

The present invention provides compositions, in particular blocks, tablets and gels, for the prevention or removal of insoluble salt deposits comprising: a) an organic acid with two carboxylic acid functional groups obtainable by fermentation, selected from the list of itaconic acid, itaconic acid anhydride, succinic acid, succinic anhydride and combinations thereof, and b) at least one compound determining the release of said acid from said composition, said compound is selected from a list comprising: i) a hygroscopic compound, ii) a carbonate source, iii) an acid solubility retarding compound, iv) a compound with melting point situated between 60° C.-95° C., and combinations thereof. The invention further provides uses of the compositions for the prevention or removal of insoluble salt deposits. The invention also provides a method of manufacturing such compositions and a method for the prevention or removal of insoluble salt deposits with a product of the invention.

Owner:ITACONIX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com