Carbon nanotube, a supported catalyst comprising the same, and fuel cell using the same

A technology for supporting catalysts and carbon nanotubes, applied in the field of carbon nanotubes, can solve the problems that carbon nanotubes do not have surface resistance and cannot be used as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

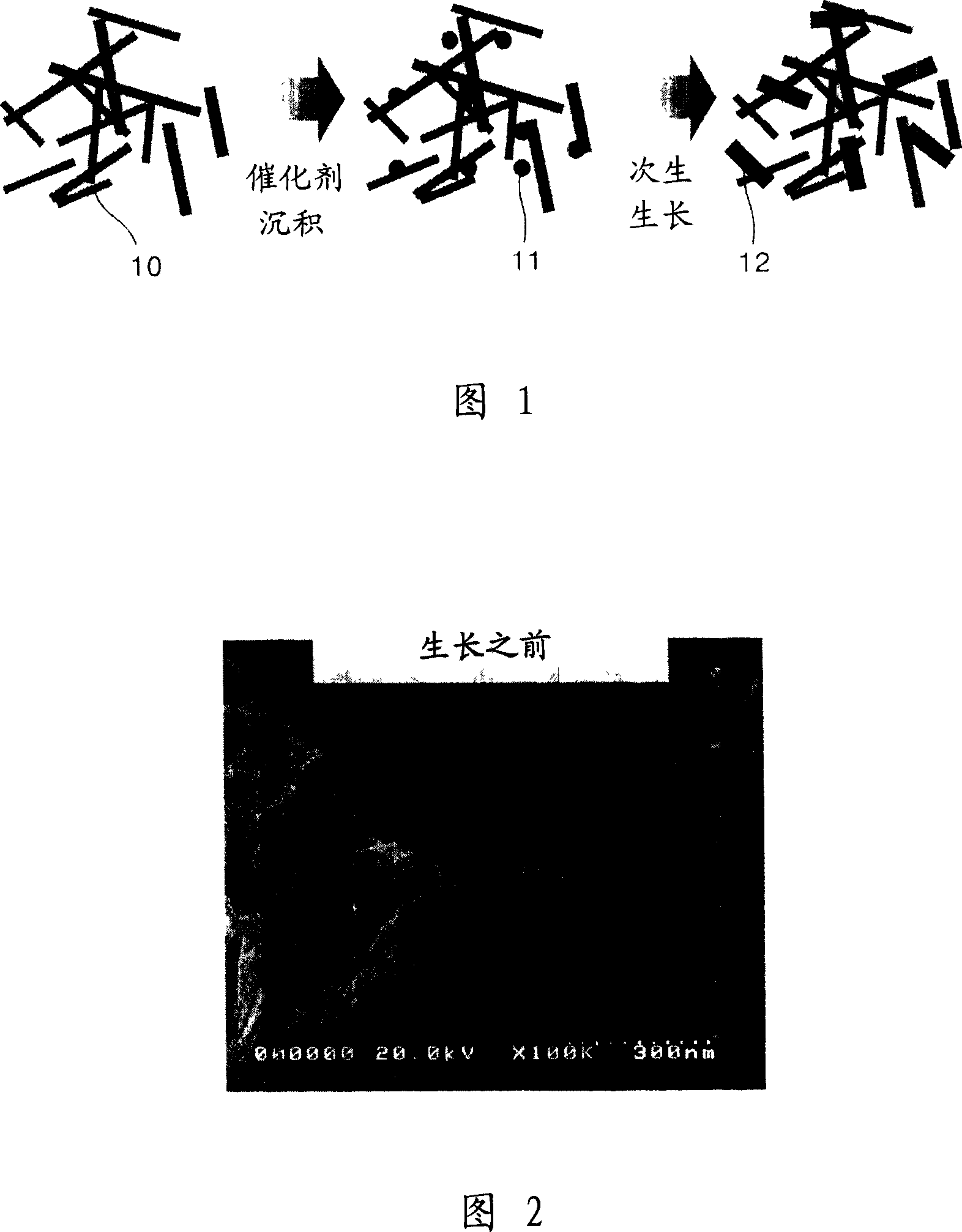

[0048] Preparation Example 1: Preparation of Carbon Nanotubes

[0049] At 100 °C, 0.25 g of SWNT(CNI) and 0.09 g of NiCl as a nickel catalyst precursor 2 ·6H 2 O(or Ni(CH 3 COO) 2 ) was mixed with 100 g of water and 80 g of ethylene glycol for 24 hours. The liquid mixture is then dried. Subsequently, the dried mixture was subjected to thermal vapor deposition using acetylene gas at 650°C. As secondary growth, MWNTs were grown for 10 minutes to produce carbon nanotubes.

[0050] 2 and 3 are scanning electron micrographs of carbon nanotubes prepared according to Preparation Example 1 before and after secondary growth, respectively.

[0051] In Figures 2 and 3, MWNTs are mixed with SWNTs.

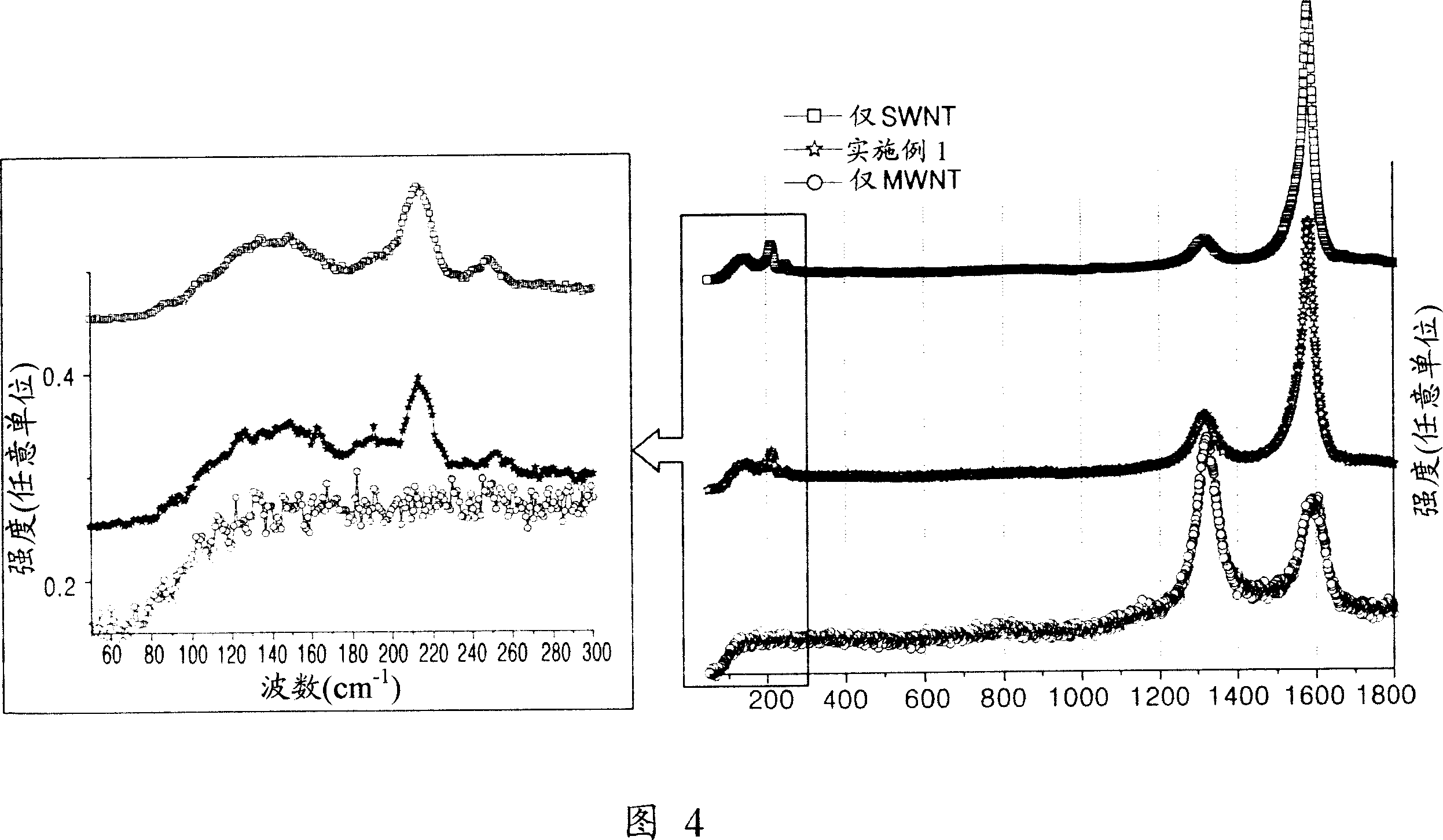

[0052] The carbon nanotubes prepared according to Preparation Example 1 were analyzed by Raman analysis, and the results are shown in FIG. 4 . The Raman analysis spectra of SWNTs and MWNTs are shown in Fig. 4 together.

[0053] Referring to Figure 4, SWNTs show a G peak (~1600cm -1 ...

Embodiment 1

[0057] Embodiment 1: the preparation of fuel cell

[0058] 0.5 g of the carbon nanotubes of Preparation Example 1 were put into a plastic tape. Independently, the 0.9616gH 2 PtCl 6 Dissolve in 1.5ml acetone. The solution was poured into a plastic strip containing the carbon nanotubes and mixed.

[0059] The mixture was air-dried for 4 hours and then placed in a crucible. The mixture in the crucible was dried overnight in a desiccator at 60°C. Next, the crucible was heat-treated at 60°C for 12 hours, at 200°C for 5 hours, and at 250°C for 2 hours, and then nitrogen was supplied to the crucible for 10 minutes. Then, while raising the temperature to 200° C., hydrogen was supplied to the crucible instead of nitrogen. The temperature was maintained at 200°C for 2 hours to reduce the platinum chloride on the carbon support. Subsequently, nitrogen was supplied into the crucible instead of hydrogen, and then the temperature was increased to 250°C at 5°C / min. The temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com