Flexible particle diverter and preparation method thereof

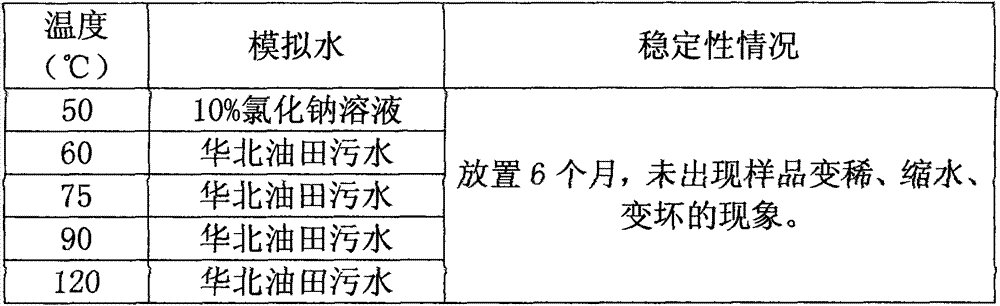

A technology of flexible particles and diverting agents, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of high toxicity, high particle hardness, and large damage to the wellbore wall, and achieve the effect of long stabilization time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A flexible particle diverting agent, which comprises the following raw materials formulated in parts by weight: 30 parts of polyacrylate liquid rubber, 100 parts of bisphenol A epoxy resin, 0.05 parts of peroxide initiator and epoxy resin 0.5 parts of curing agent; the polyacrylate liquid rubber includes the following raw materials according to the preparation: n-butanol, butyl acrylate, ethyl acrylate, glycidyl acrylate, azobisisobutyronitrile and nitrogen; the peroxide The compound initiator is benzoyl peroxide; the epoxy resin curing agent is polysebacic anhydride. The polyacrylate liquid rubber comprises the following raw materials formulated in parts by weight: 20 parts of n-butanol, 5 parts of butyl acrylate, 5 parts of ethyl acrylate, 2.5 parts of glycidyl acrylate, 0.01 parts of azobisisobutyronitrile parts and 20 parts of nitrogen. The preparation method comprises the following steps:

[0053] 1. Put butyl acrylate, ethyl acrylate and glycidyl acrylate into n...

Embodiment 2

[0061] A flexible particle diverting agent, which comprises the following raw materials formulated in parts by weight: 5 parts of polyacrylate liquid rubber, 110 parts of bisphenol A type epoxy resin, 0.08 parts of peroxide initiator and epoxy resin 1.3 parts of curing agent; the polyacrylate liquid rubber comprises the following raw materials according to the preparation: n-butanol, butyl acrylate, ethyl acrylate, glycidyl acrylate, azobisisobutyronitrile and nitrogen; the peroxide The compound initiator is tert-butyl peroxybenzoate; the epoxy resin curing agent is polyazelaic anhydride. The polyacrylate liquid rubber comprises the following raw materials formulated in parts by weight: 20 parts of n-butanol, 5 parts of butyl acrylate, 5 parts of ethyl acrylate, 2.5 parts of glycidyl acrylate, 0.01 parts of azobisisobutyronitrile parts and 20 parts of nitrogen. The preparation method comprises the following steps:

[0062] 1. Put butyl acrylate, ethyl acrylate and glycidyl a...

Embodiment 3

[0070] A flexible particle diverting agent, which comprises the following raw materials formulated in parts by weight: 40 parts of polyacrylate liquid rubber, 120 parts of bisphenol A type epoxy resin, 0.1 part of peroxide initiator and epoxy resin 2 parts of curing agent; the polyacrylate liquid rubber includes the following raw materials according to the preparation: n-butanol, butyl acrylate, ethyl acrylate, glycidyl acrylate, azobisisobutyronitrile and nitrogen; the peroxide The compound initiator is benzoyl peroxide; the epoxy resin curing agent is maleic anhydride. The polyacrylate liquid rubber comprises the following raw materials formulated in parts by weight: 20 parts of n-butanol, 5 parts of butyl acrylate, 5 parts of ethyl acrylate, 2.5 parts of glycidyl acrylate, 0.01 parts of azobisisobutyronitrile parts and 20 parts of nitrogen. The preparation method comprises the following steps:

[0071] 1. Put butyl acrylate, ethyl acrylate and glycidyl acrylate into n-but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com