Concrete for road construction and preparation method of concrete

A technology for road construction and concrete, which is applied in the field of concrete, can solve the problems that the compressive strength and splitting strength need to be improved, and achieve the effect of reasonable production process design, high splitting strength, and favorable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A concrete for road construction, which is composed of the following materials by weight ratio: 50 parts of cement, 38 parts of sand, 22 parts of mineral powder, 29 parts of stones, 20 parts of water, 2 parts of plant fiber, 1.5 parts of water reducing agent and 4 parts of montmorillonite earth.

[0030] A kind of concrete for road construction, concrete preparation method is as follows:

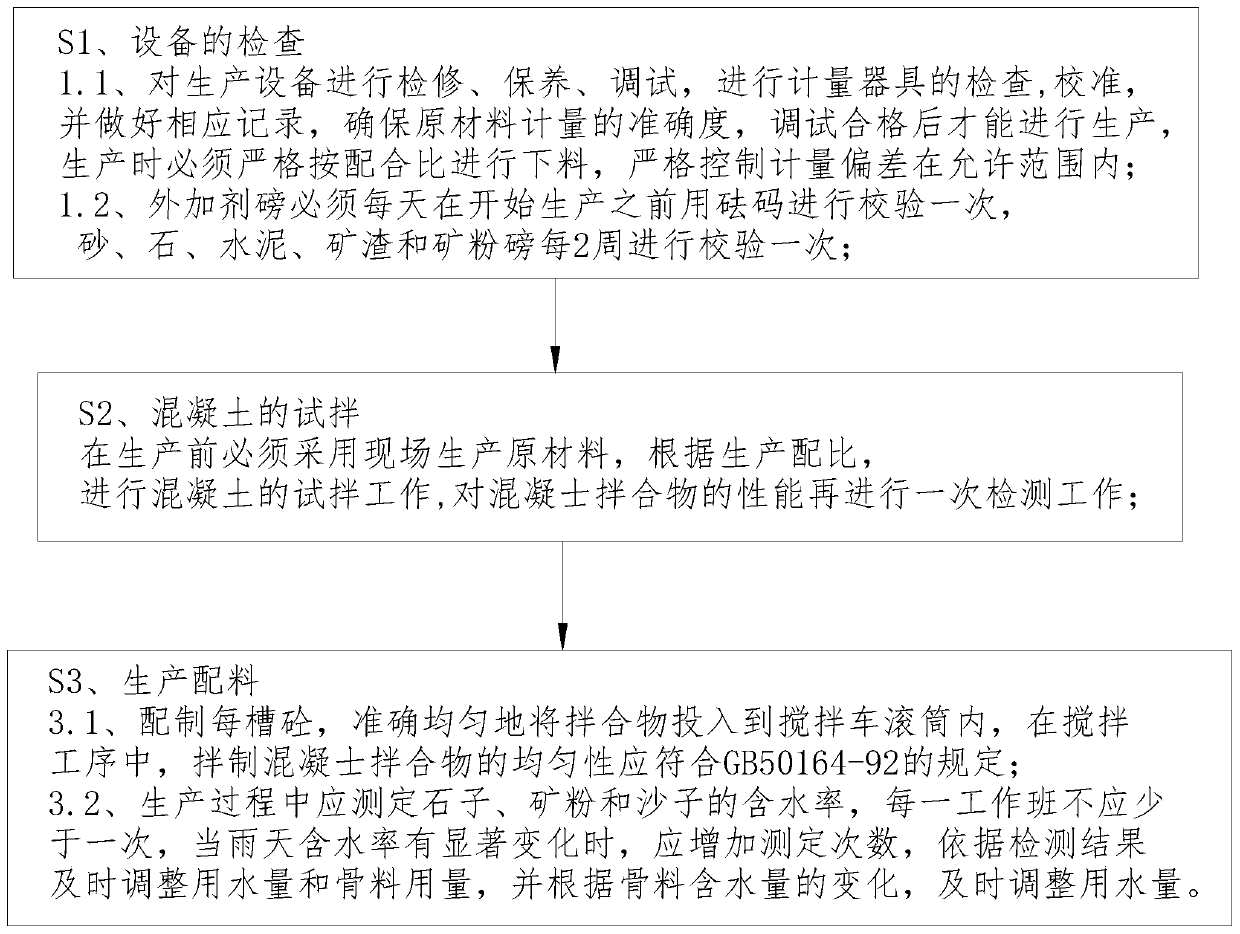

[0031] S1. Inspection of equipment

[0032] 1.1. Overhaul, maintain, and debug the production equipment, check and calibrate the measuring instruments, and make corresponding records to ensure the accuracy of raw material measurement. Production can only be carried out after the debugging is qualified. During production, the material must be cut strictly according to the mix ratio , strictly control the measurement deviation within the allowable range;

[0033] 1.2. The admixture pounds must be checked with weights once a day before starting production, and the sand, stone, cement, ...

Embodiment 2

[0044] In an optional embodiment, it is composed of the following materials by weight ratio: 55 parts of cement, 37 parts of sand, 28 parts of mineral powder, 60 parts of stones, 29 parts of water, 2.8 parts of plant fiber, 1.9 parts of water reducer and 3.5 parts Montmorillonite.

[0045] A kind of concrete for road construction, concrete preparation method is as follows:

[0046] S1. Inspection of equipment

[0047] 1.1. Overhaul, maintain, and debug the production equipment, check and calibrate the measuring instruments, and make corresponding records to ensure the accuracy of raw material measurement. Production can only be carried out after the debugging is qualified. During production, the material must be cut strictly according to the mix ratio , strictly control the measurement deviation within the allowable range;

[0048] 1.2. The admixture pounds must be checked with weights once a day before starting production, and the sand, stone, cement, slag and mineral powde...

Embodiment 3

[0059] In an optional embodiment, it is composed of the following materials by weight ratio: 45 parts of cement, 35 parts of sand, 23 parts of mineral powder, 55 parts of stone, 34 parts of water, 1.5 parts of plant fiber, 1.5 parts of water reducer and 2.7 parts Montmorillonite.

[0060] A kind of concrete for road construction, concrete preparation method is as follows:

[0061] S1. Inspection of equipment

[0062] 1.1. Overhaul, maintain, and debug the production equipment, check and calibrate the measuring instruments, and make corresponding records to ensure the accuracy of raw material measurement. Production can only be carried out after the debugging is qualified. During production, the material must be cut strictly according to the mix ratio , strictly control the measurement deviation within the allowable range;

[0063] 1.2. The admixture pounds must be checked with weights once a day before starting production, and the sand, stone, cement, slag and mineral powder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com