Discharge hopper and method of discharing trays filled with rod-shaped articles

A technology for unloading hoppers and brackets, which is applied in the field of unloading hoppers and unloading brackets with rod-shaped products, which can solve the problems of uneven unloading operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

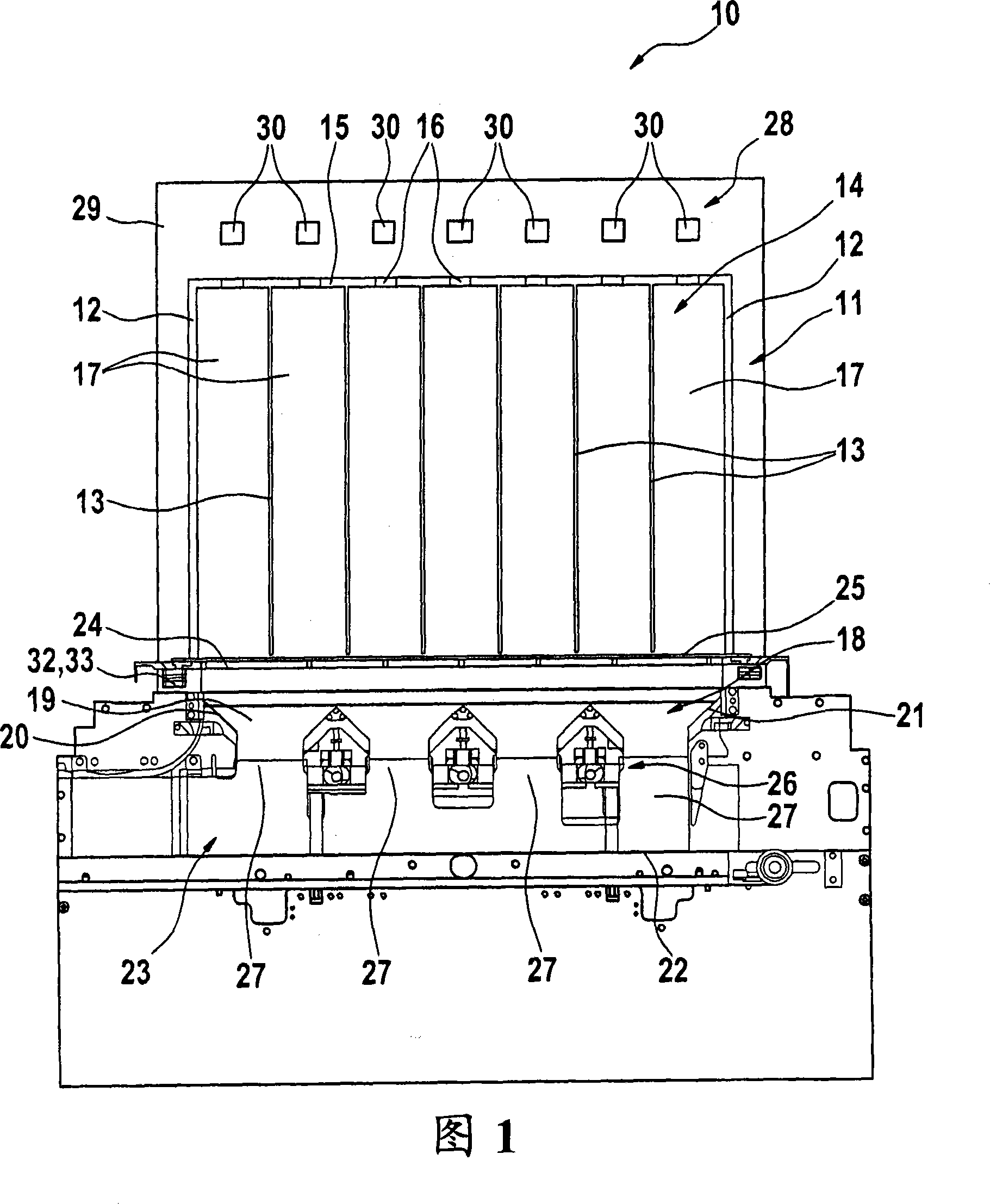

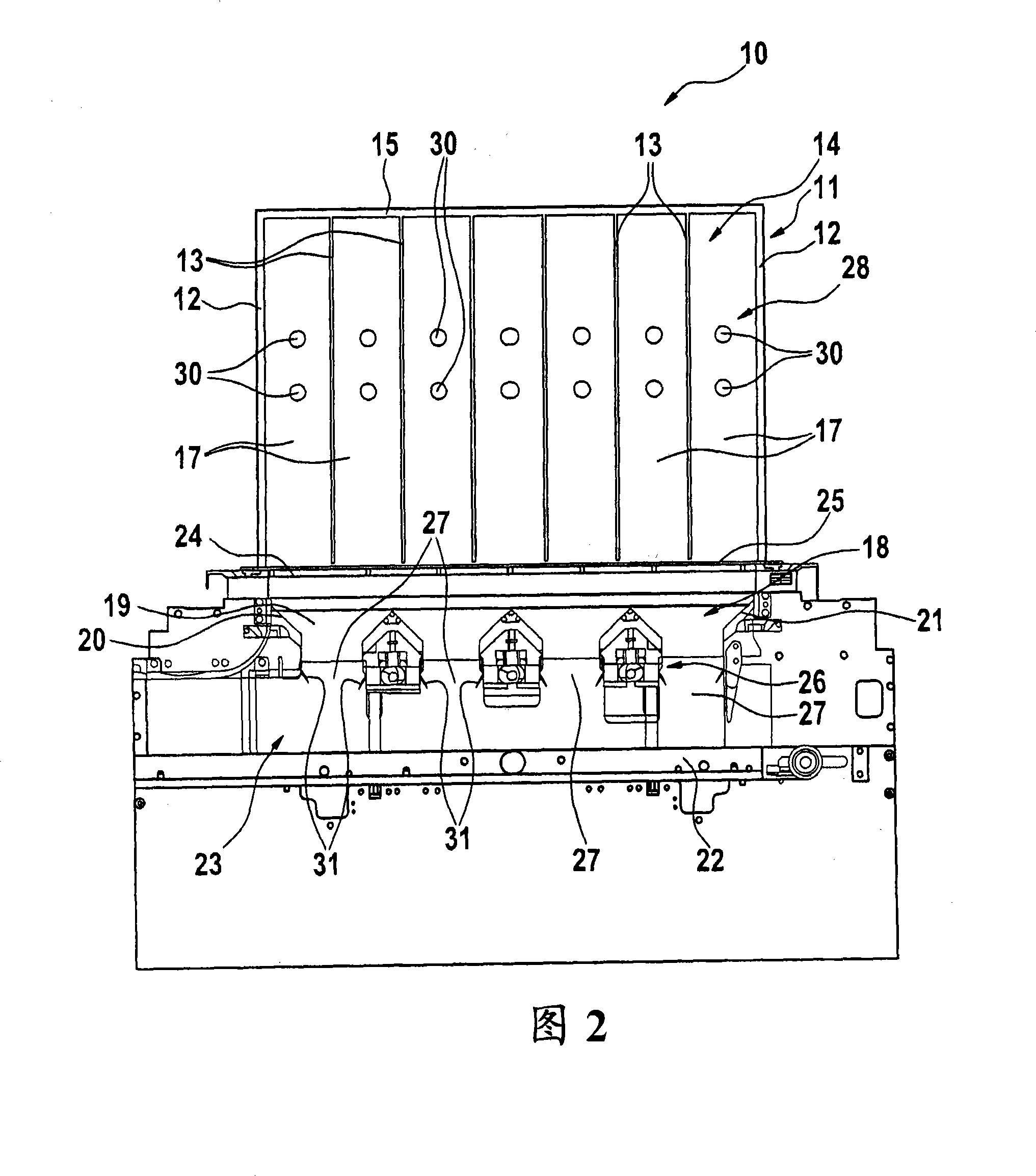

[0015] The unloading hopper is used for unloading the brackets or shaft brackets with rod-shaped products.

[0016] FIG. 1 shows a first embodiment of such a dump hopper 10 designed to unload shaft carriages 11 . The shaft bracket 11 has a side wall 12 , a shaft wall 13 parallel to the side wall 12 , a rear wall 14 and a bottom wall 15 . The bottom wall may have openings 16 (see FIG. 1 ) or be at least translucent to allow monitoring means as described below to detect the level within the wellbore 17 . The same is true for the rear wall 14 . The discharge hopper 10 has a receiving chamber 18 comprising a rear wall 19 , a front wall not shown for better clarity and side walls 20 , 21 . At the bottom, the receiving chamber 18 is delimited by a conveying member 22 which can be driven in both directions and which is arranged at a distance from the receiving chamber 18 so as to form a slot 23 . At the top end, the receiving chamber 18 is open in the direction of the shaft bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com