Dry-type mixing device

A mixing device, dry technology, applied in unloading devices, raw material supply devices for sales, clay preparation devices, etc., can solve the problems of segregation, uneven mixing of dry-mixed mortar, and increased material density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

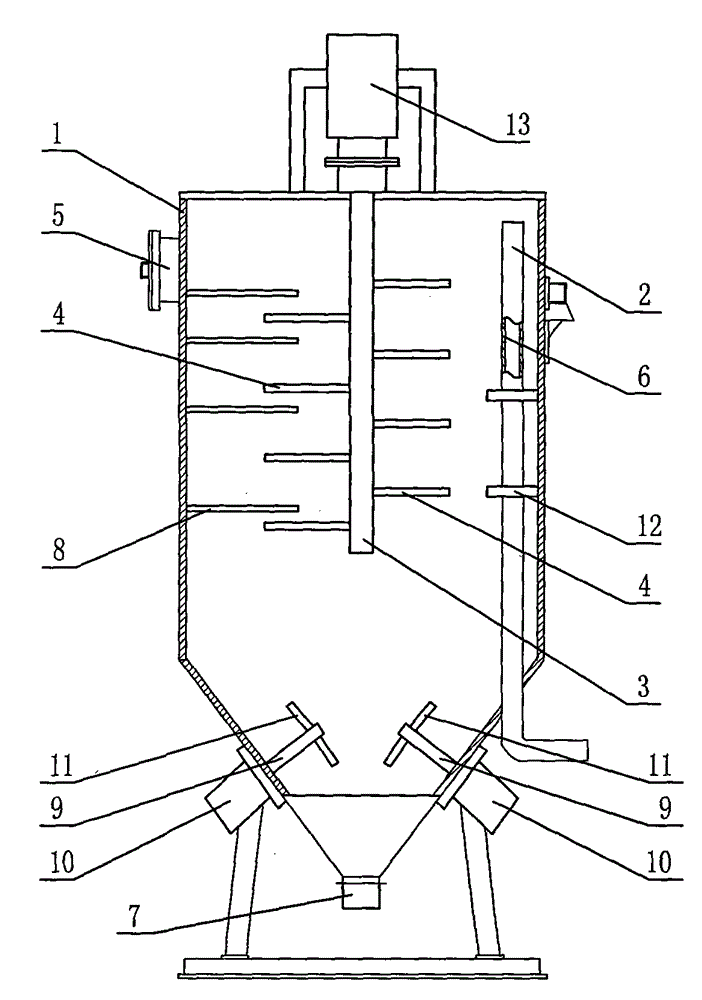

[0009] Such as figure 1 The shown dry mixing device includes a mixing tank 1 connected with a feed pipe 2 inserted into its inner cavity from its lower part, and the top of the feed pipe 2 is close to the mixing tank 1 The inner top of the feed pipe 2 can be open, that is, the top can also inject small particle materials into the mixing tank, and the top of the feed pipe 2 can also be closed, according to the ratio of the material and the feed To control whether the top of the feeding pipe 2 is open or not, the bottom of the feeding pipe 2 is the feeding port, and the section of the feeding pipe 2 located in the mixing tank 1 is provided with a plurality of discharge holes 6 from top to bottom. On the feed pipe 2 below each discharge hole 6, a baffle plate arranged obliquely downward is fixedly installed, and a stirring shaft 3 driven by a power device is rotatably connected in the mixing tank body 1, and the power device is The motor 12 connected to the top of the mixing tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com