Raw material preparation device for production of refractory material

A refractory material and preparation device technology, applied in the field of refractory material production, can solve the problems of manpower and material resources consumption, poor raw material processing effect, blanking blockage, etc., and achieve the effects of improving production efficiency, saving manpower and material resources, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

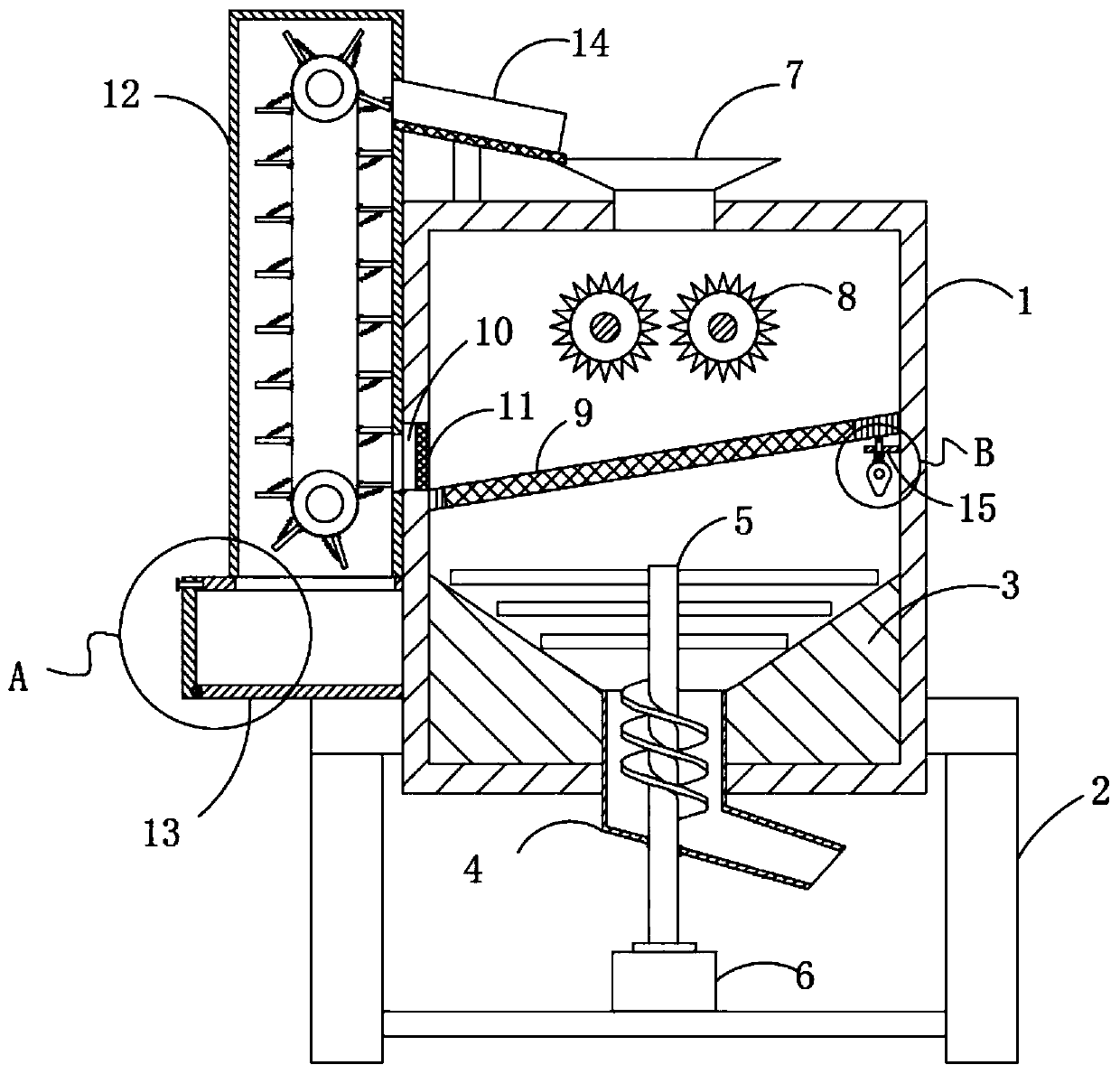

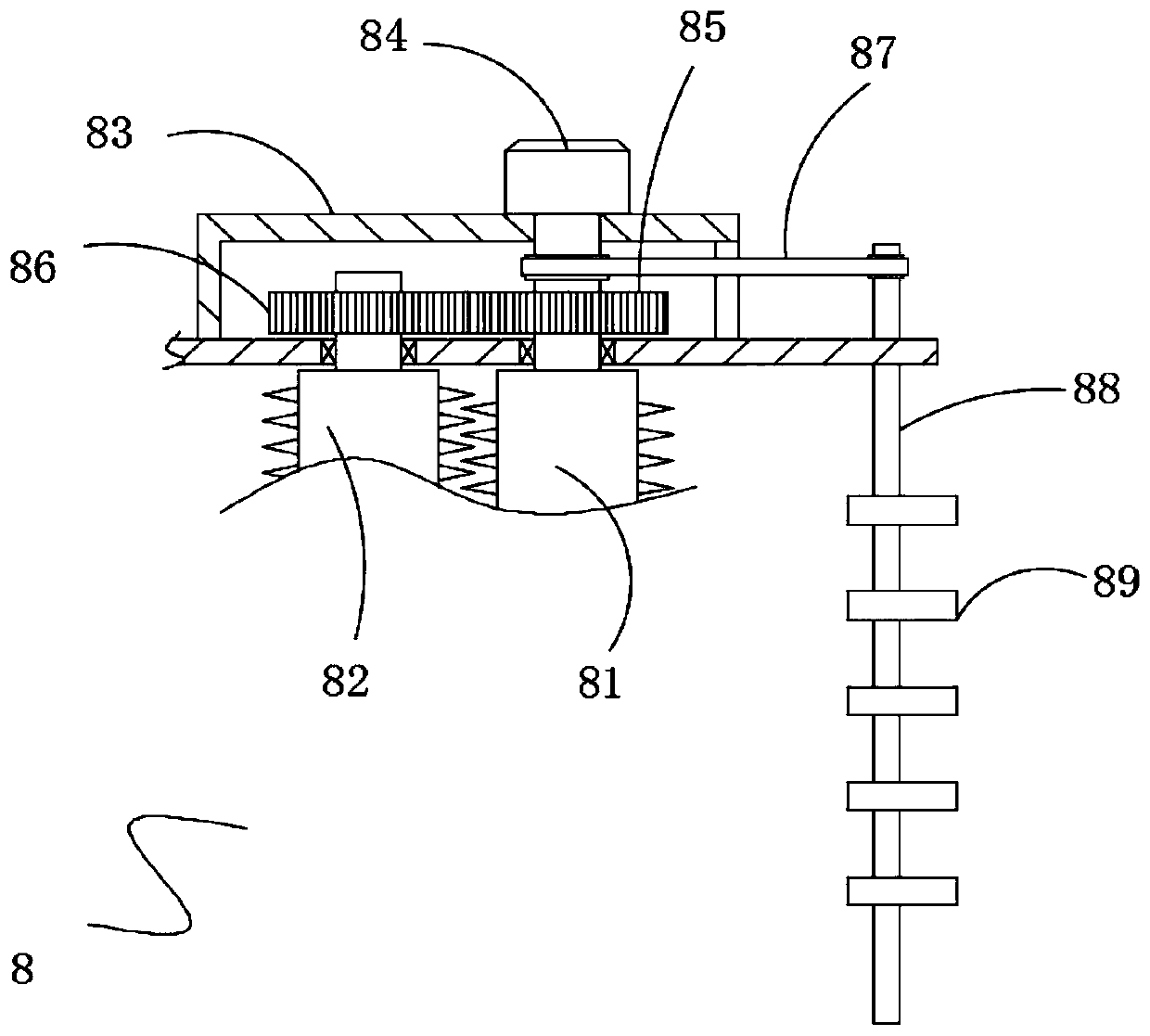

[0031] Such as Figure 1 to Figure 7 As shown, the present invention provides a raw material preparation device for refractory production, including a pretreatment box 1, a bracket 2 is arranged at the bottom of the pretreatment box 1, a discharge hopper 3 is provided at the lower part of the inner cavity of the pretreatment box 1, and a discharge hopper 3 The narrow mouth end is connected with a blanking inclined tube 4, the lower part of the inner cavity of the pretreatment box 1 is provided with a multifunctional stirring rod 5, the support 2 is provided with a stirring motor 6, and the bottom end of the multifunctional stirring rod 5 runs through the bottom wall of the blanking inclined tube 4 Connect the output shaft end of the stirring motor 6, the top of the pretreatment box 1 is provided with a feed hopper 7, the upper part of the inner cavity of the pretreatment box 1 is provided with a crushing mechanism 8, and the lower side of the crushing mechanism 8 is provided wi...

Embodiment 2

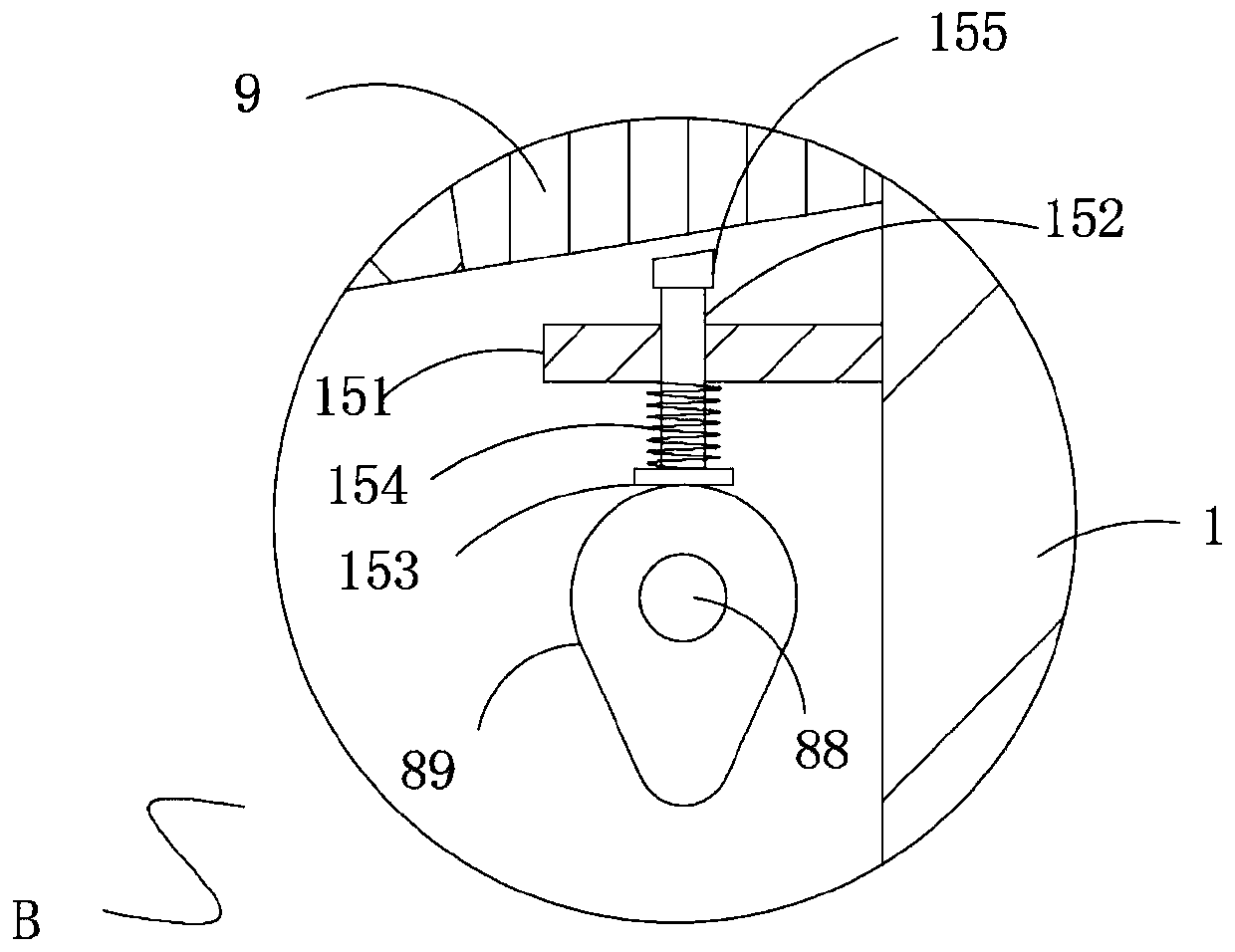

[0041] Such as Figure 1 to Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as image 3 As shown, the vibrating blanking mechanism 15 includes a fixed frame 151, the fixed frame 151 is fixedly connected to the right side wall of the pretreatment box 1, the fixed frame 151 slides through and is provided with a ram 152, and the bottom end of the lance 152 is provided with a ram 153 , the first spring 154 is sleeved on the ram 152, the first spring 154 is located between the ram 153 and the fixed frame 151, the top of the ram 152 is provided with a ram 155, and the ram 153 slides against the cam 89;

[0042] By vibrating the feeding mechanism 15, it is possible to promote the suffici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com