Vertical automatic loading and unloading system device and method

A system device, vertical technology, applied in the direction of loading and unloading equipment, launching devices, motor vehicles, etc., can solve the problems of danger, loss of goods, poor safety, etc., achieve a high degree of automation, avoid danger, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

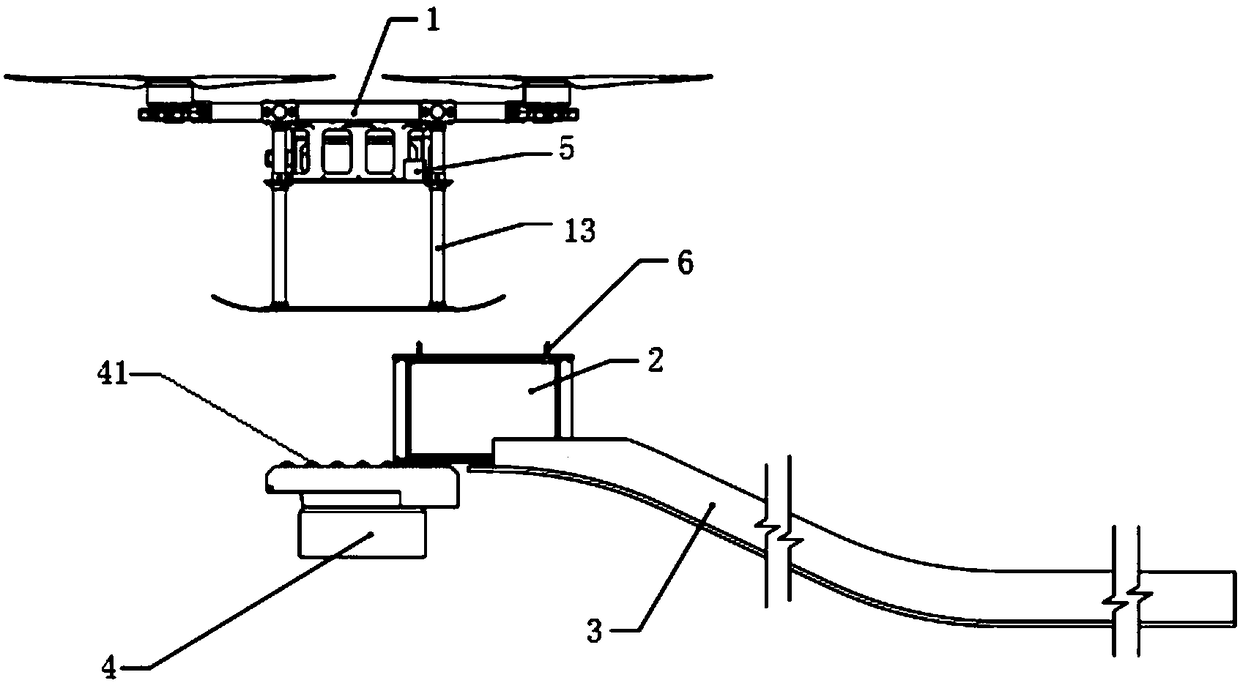

[0044] figure 1 A schematic diagram of the vertical automatic loading and unloading system device in Embodiment 1 of the present invention is shown.

[0045] like figure 1 As shown, a vertical automatic loading and unloading system device includes a drone 1, a cargo box 2, a transmission track 3, and an elevator 4 used as cargo equipment. The elevator 4 moves the container 2 by lifting in the vertical direction to complete the process of loading to the elevator or unloading from the elevator to the transfer track 3 .

[0046] The UAV 1 includes a locking mechanism 5, and the container 2 used with the UAV 1 has a vertical deadbolt 6, which is a vertically articulated deadbolt. The locking mechanism 5 is engaged and locked, so that the cargo box 2 is hooked and fixed to the drone 1 .

[0047] The elevator 4 comprises horizontal rollers 41 . The elevator 4 transports the container 2 on the elevator 4 to the transmission track 3 by horizontally rolling the horizontal roller 41...

Embodiment approach 2

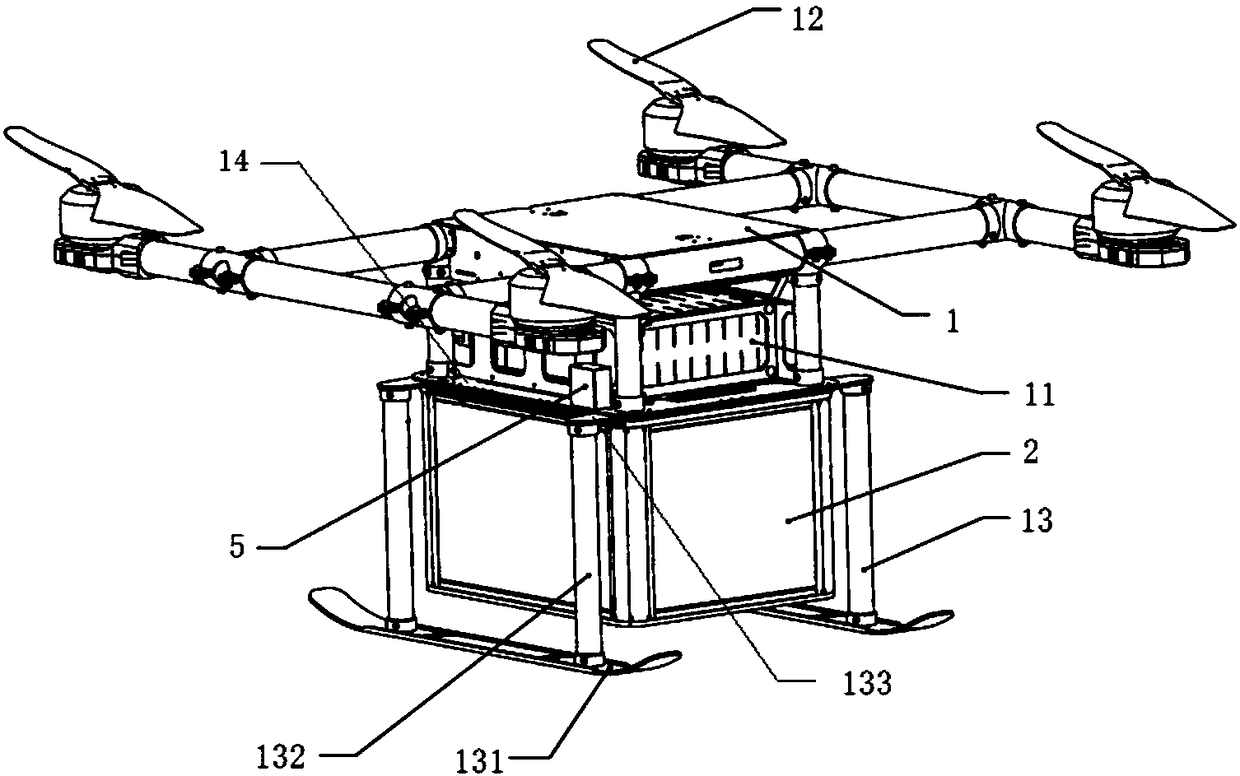

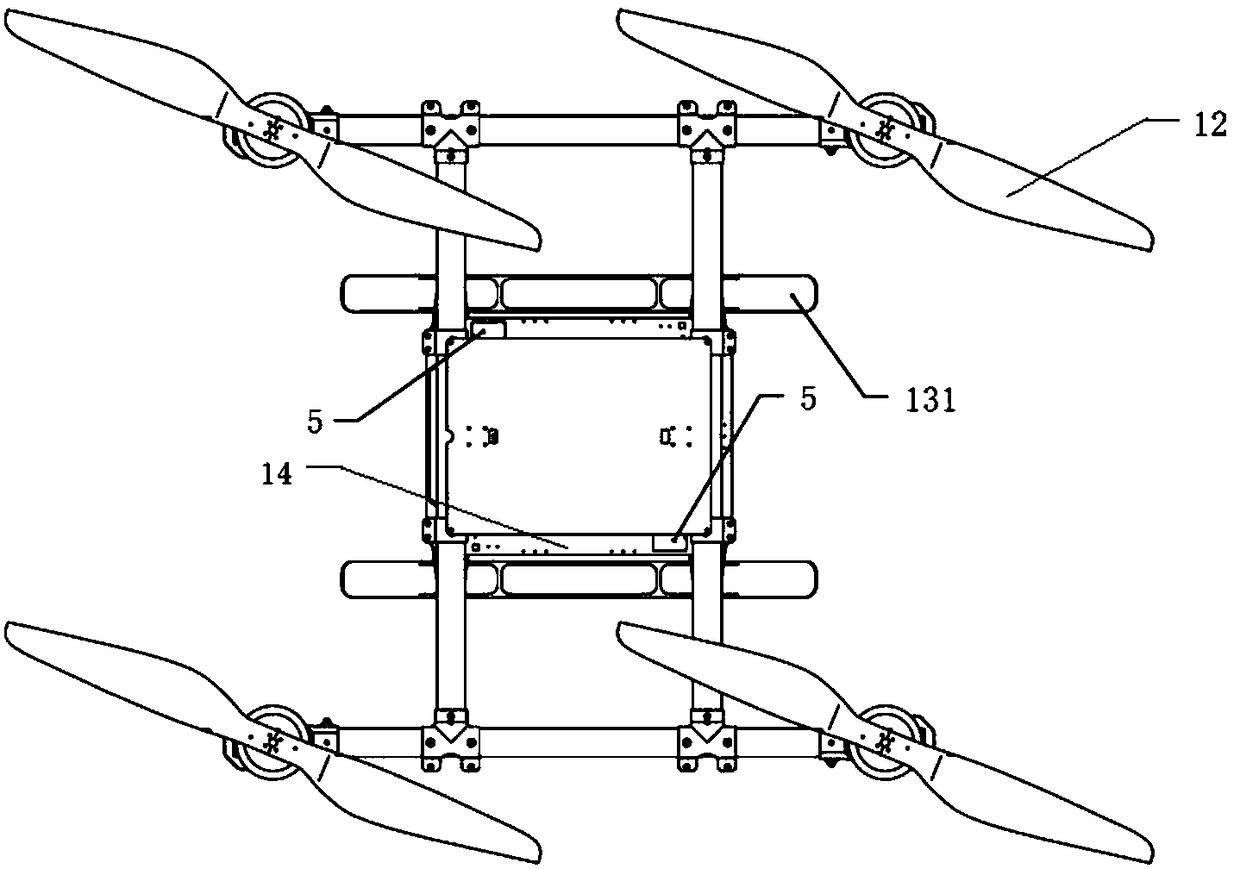

[0062] A method of vertical automatic loading, using such as figure 2 The system device shown is carried out, including the following steps:

[0063] The elevator 4 lifts the cargo box 2 to rise in the vertical direction, aligns the vertical lock tongue 6 on the top of the cargo box 2 with the locking mechanism 5 of the drone 1 in the vertical direction, and then continues to lift until the vertical lock tongue 6 slides completely Enter locking mechanism 5 inside and carry out interlocking locking. Through the locking of the locking mechanism 5, the cargo box 2 is fixed between the bottom of the fuselage 11 of the drone, the bottom plate of the drone 14 and the landing gear base 131, and the loading is completed.

Embodiment approach 3

[0065] A method for vertical automatic unloading, using such as figure 2 The system device shown is carried out, including the following steps:

[0066] Elevator 4 rises to below the unmanned aerial vehicle 1 carrying cargo box 2. When the UAV 1 receives the unlocking command, the electric drive causes the vertical lock tongue 6 interlocking with the locking mechanism 5 to pop up, and the unlocking process is completed, and the cargo box 2 is separated from the UAV 1 and separated from the UAV 1. Lifts 4 contacts. The elevator 4 carries the container 2 and descends to be level with the transmission track 3, and then the horizontal roller 41 on the elevator 4 rolls to transport the container to the transmission track 3 to complete unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com