Apparatuses, system and methods for forming pressed articles and pressed articles formed thereby

一种制品、限制工具的技术,应用在压紧粉末领域,能够解决高百分比破损等问题,达到快压紧循环、避免不利分层的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

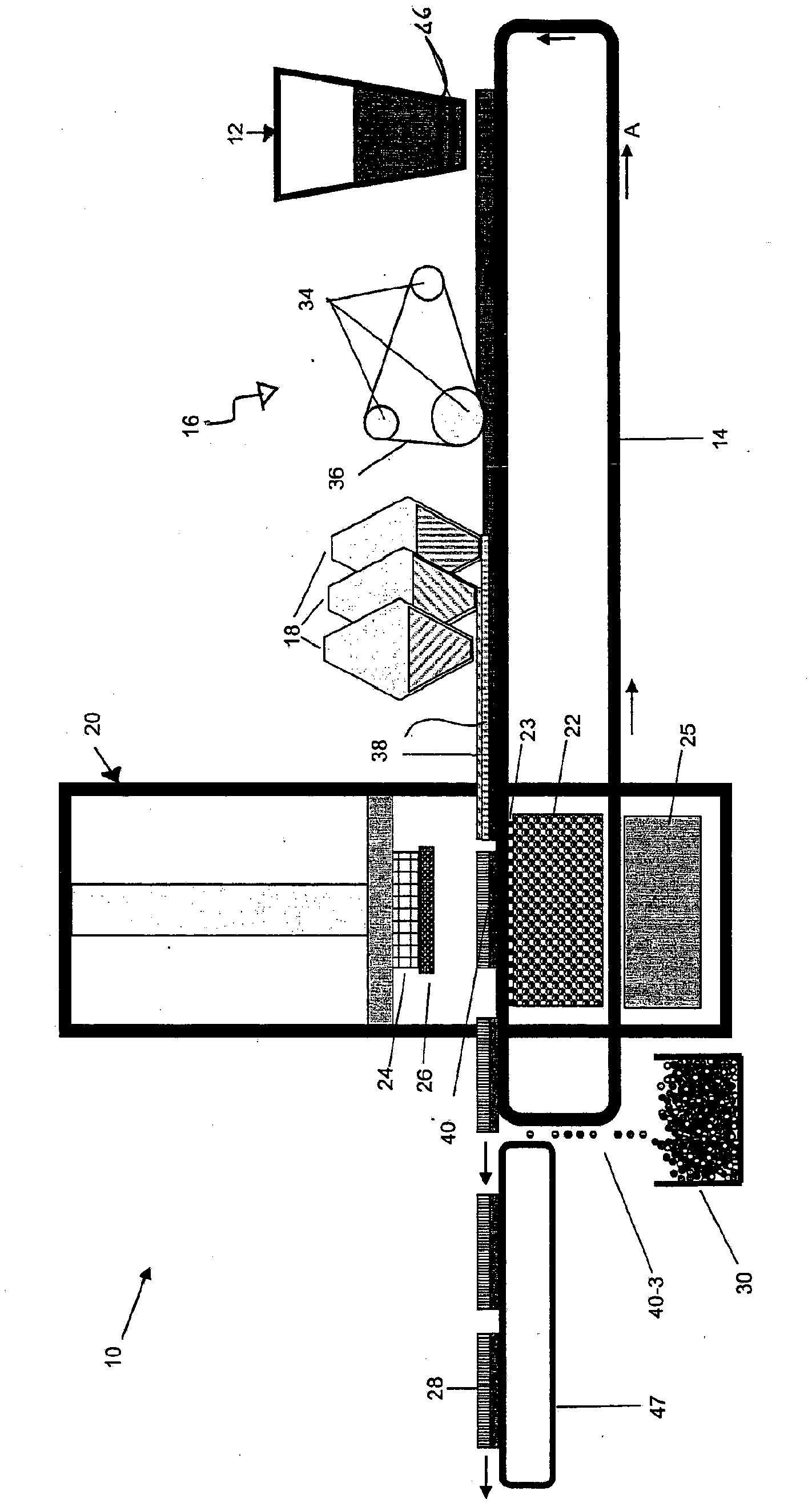

[0147] According to the invention, a system 10 for forming compacted articles by compacting powders or granules comprises:

[0148] Powder discharge assembly 12;

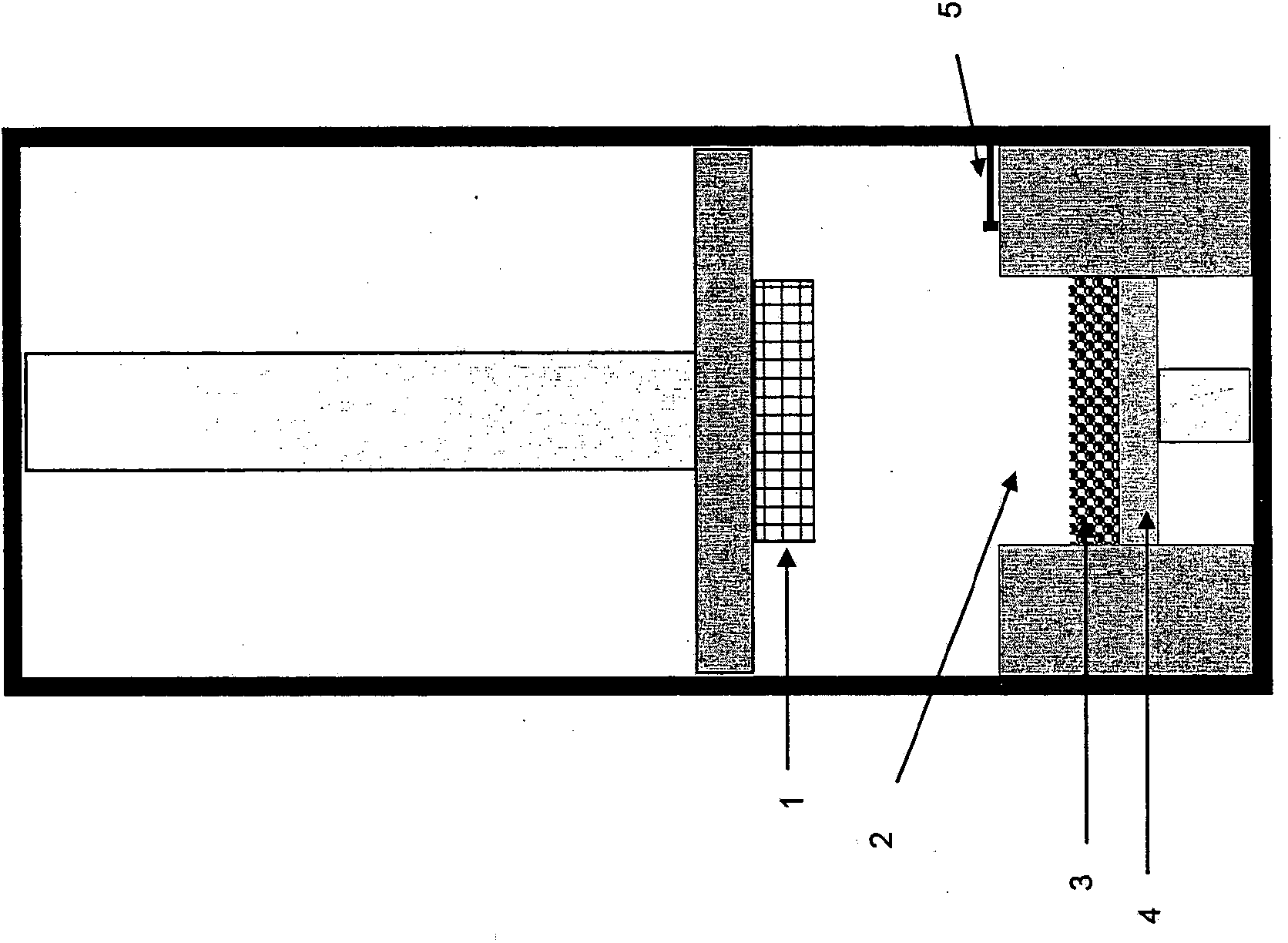

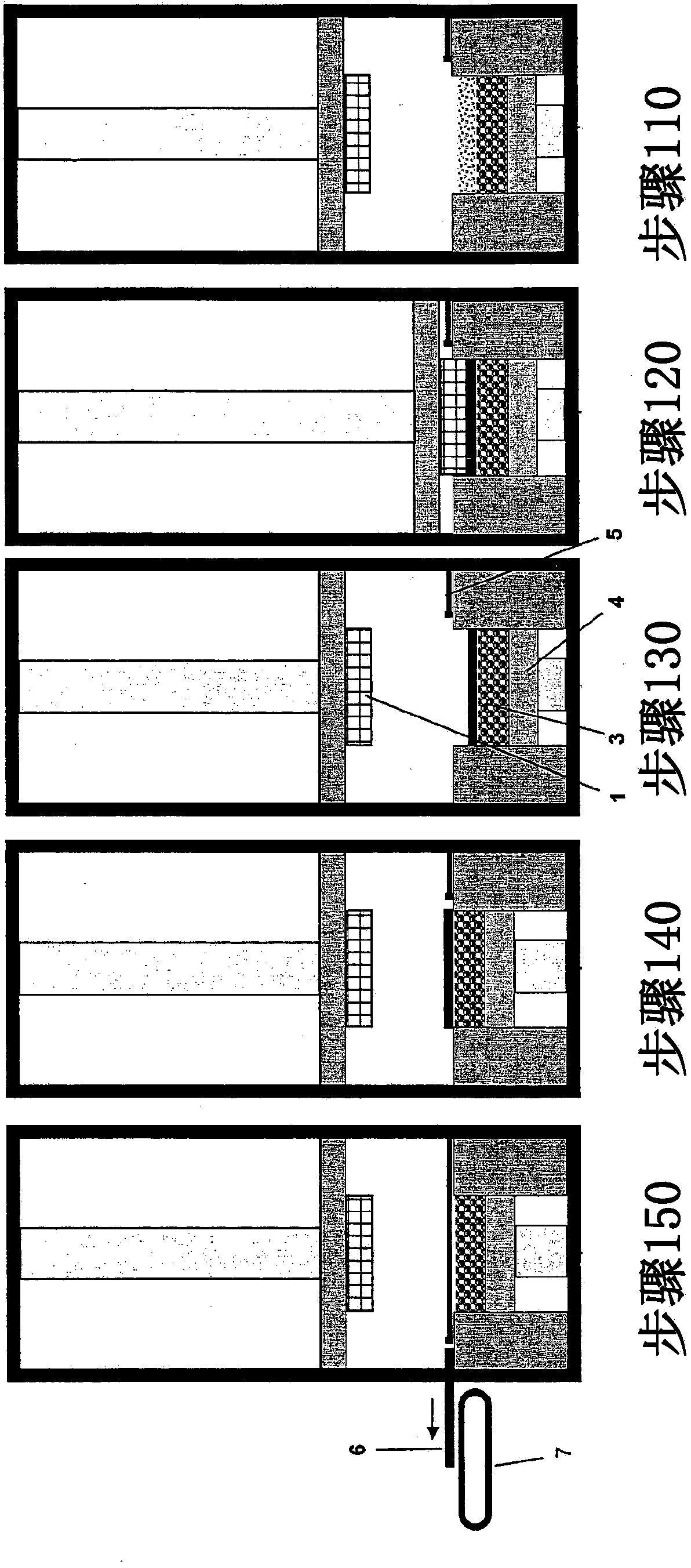

[0149] A cavityless compression assembly 20 comprising:

[0150] a bottom plate 22 substantially the same size as or larger than the compacted product,

[0151] Confinement tools to separate a portion of the powder,

[0152] top punch 24; and

[0153] Conveyor 14 for transporting powder.

[0154] 1. Custom design vibrating feeder / powder discharge assembly / vibrating feeding tool

[0155] In a preferred embodiment of the invention, the powder discharge assembly 12 includes a vibrating feeder, such as a hopper, which is filled with particulate fly ash or other ceramic composition. The outlet of the feeder is equipped with an oscillating comb 46 through which powdery and granular material falls uniformly onto a belt or any other type of conveyor 14 . The combs move parallel to each other to prevent accumulation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com