Multi-head quick attachment fixture and multi-board quick attachment method

An attached and fast technology, applied in the field of automated processing equipment, can solve problems such as error-prone, labor-intensive, and time-consuming, and achieve the effect of improving production efficiency, improving automation level, and meeting small and diverse production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

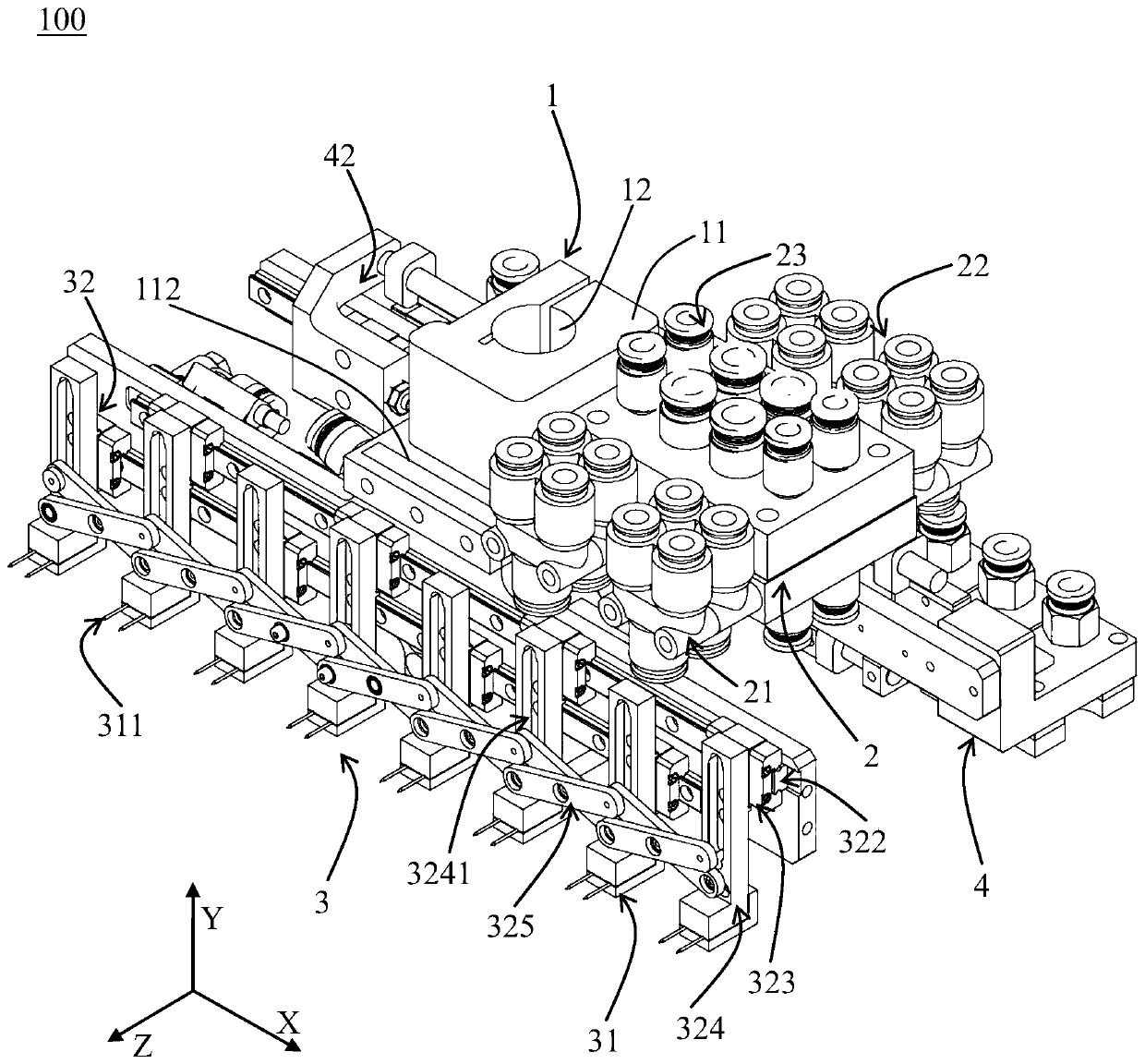

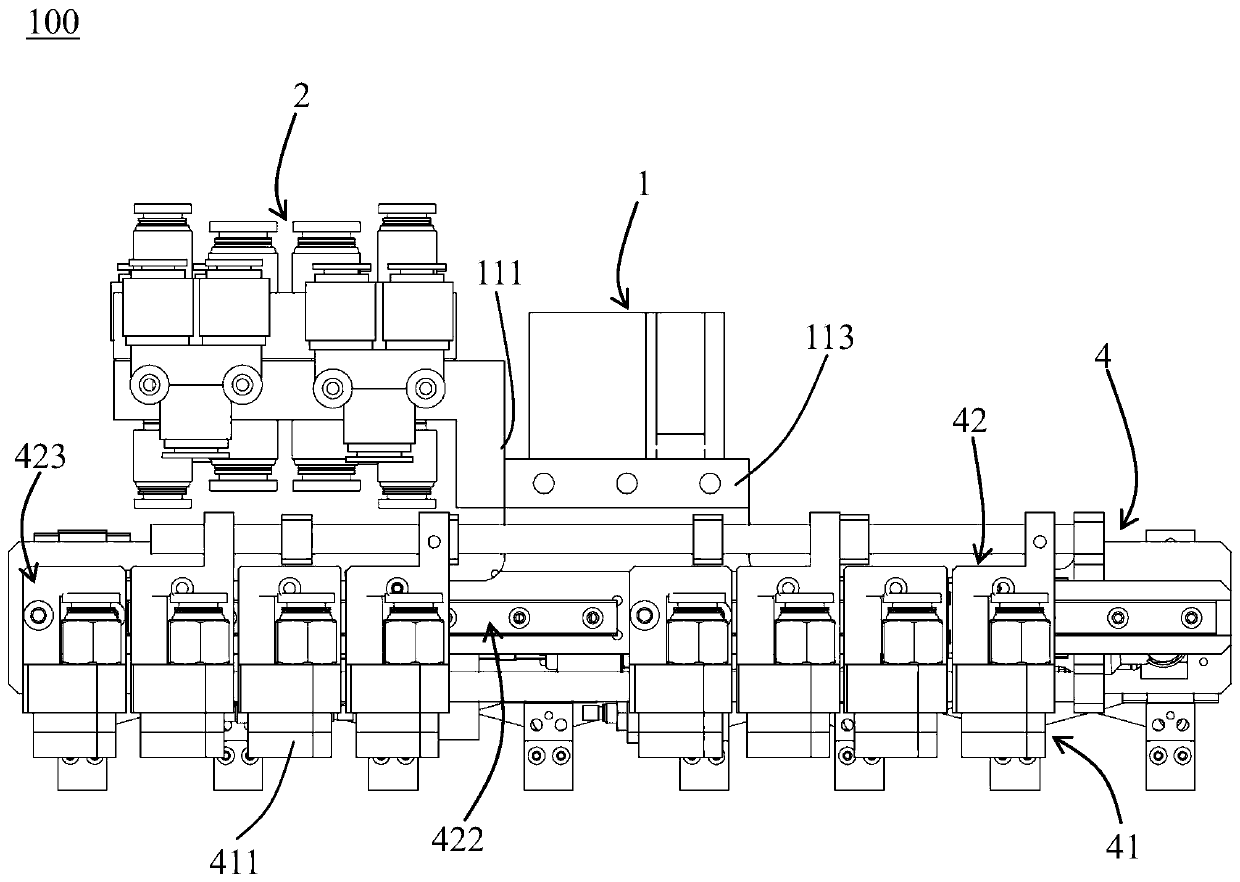

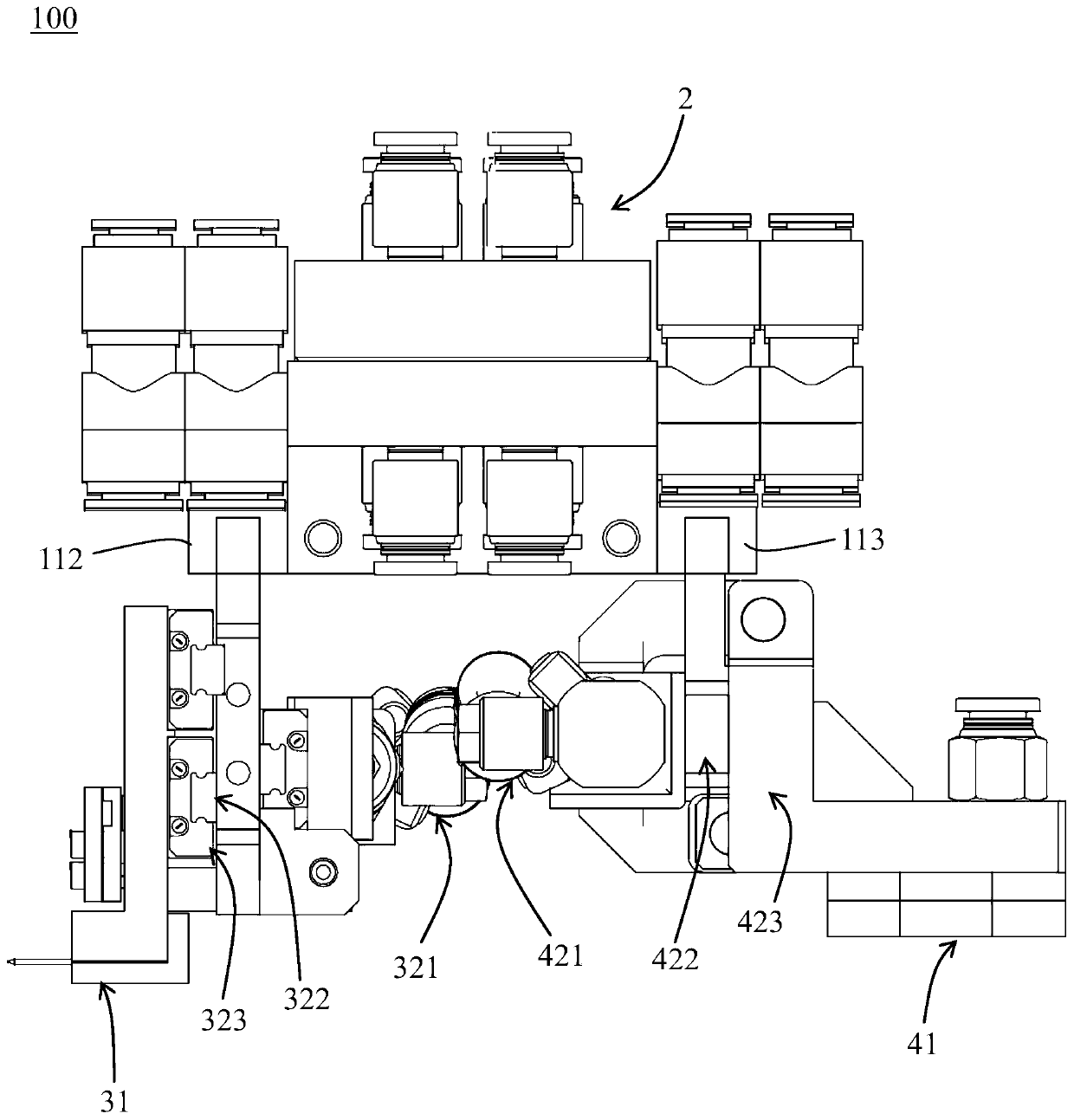

[0023] Such as Figure 1 to Figure 3 As shown, the multi-head quick attachment fixture 100 according to an embodiment of the present invention includes a manipulator holding bracket 1 , a trachea multi-stage quick interface module 2 , a block separation module 3 and a sheet separation module 4 .

[0024] The manipulator holding bracket 1 includes a boss body 11 that can move with the manipulator (not shown) and a clamping hole 12 for fixedly connecting the manipulator. The clamping hole 12 is arranged in the boss body 11, such as the middle part, the boss The main body 11 has a mounting side portion 111 and a first fixing portion 112 and a second fixing portion 113 opposite to each other. The mounting side portion 111 is located between the first fixing portion 112 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com