Patents

Literature

64results about How to "Smooth pay-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

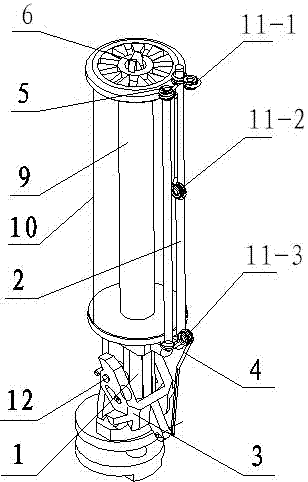

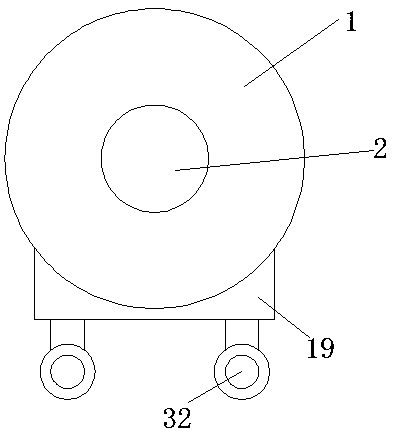

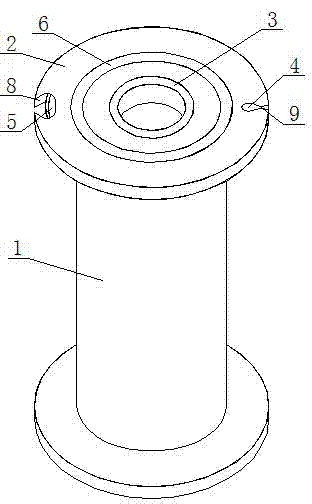

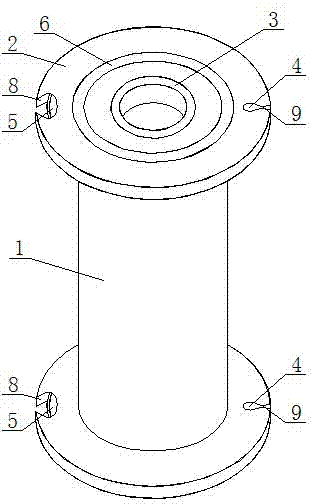

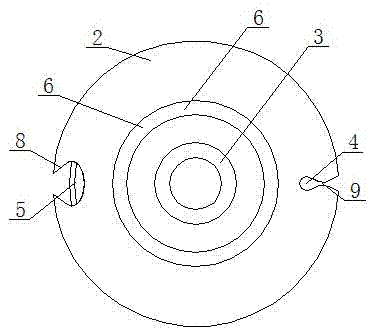

Pay-off frame for ultrathin guide line

ActiveCN102602740AStable pay-off tensionNot easy to disconnectFilament handlingPull forceEngineering

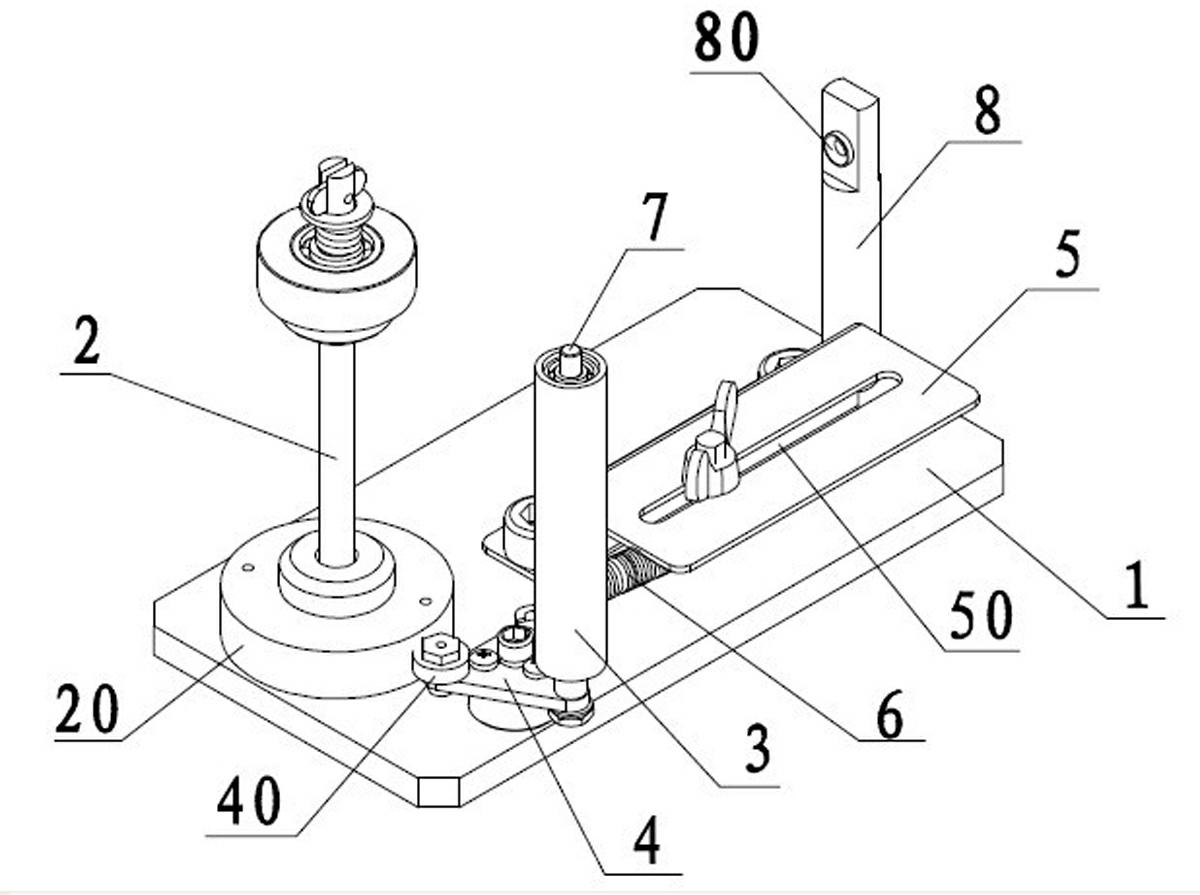

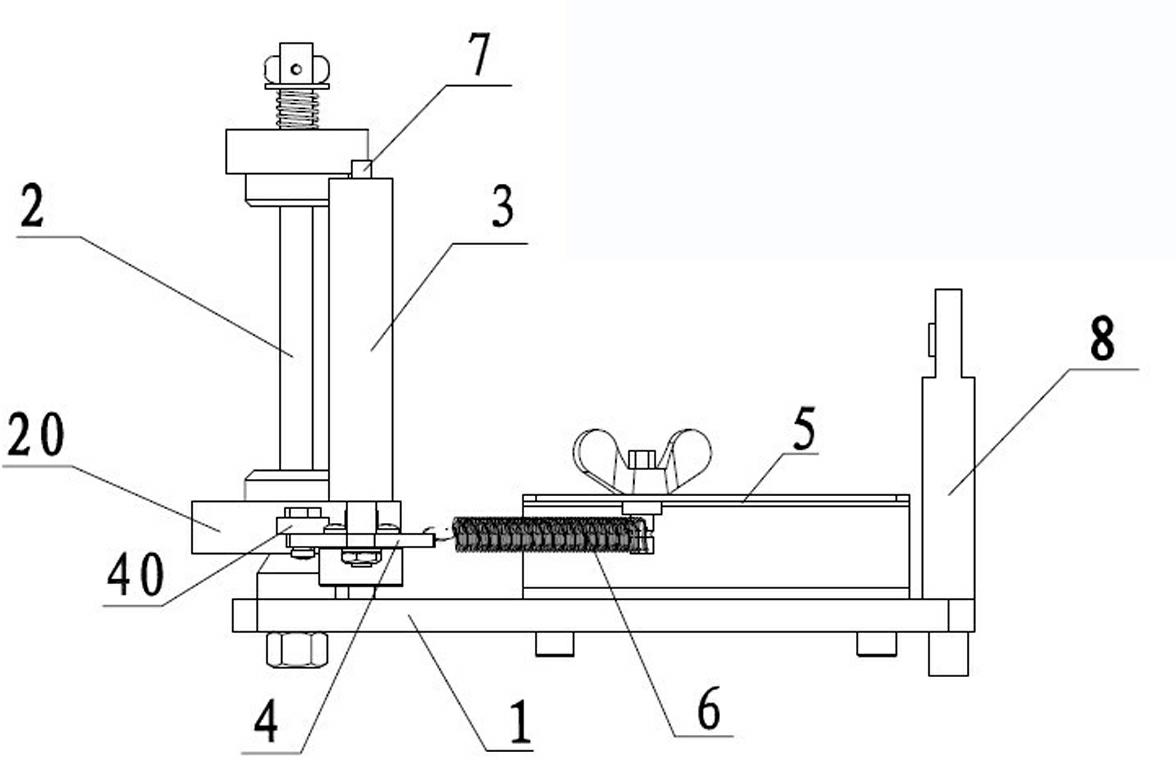

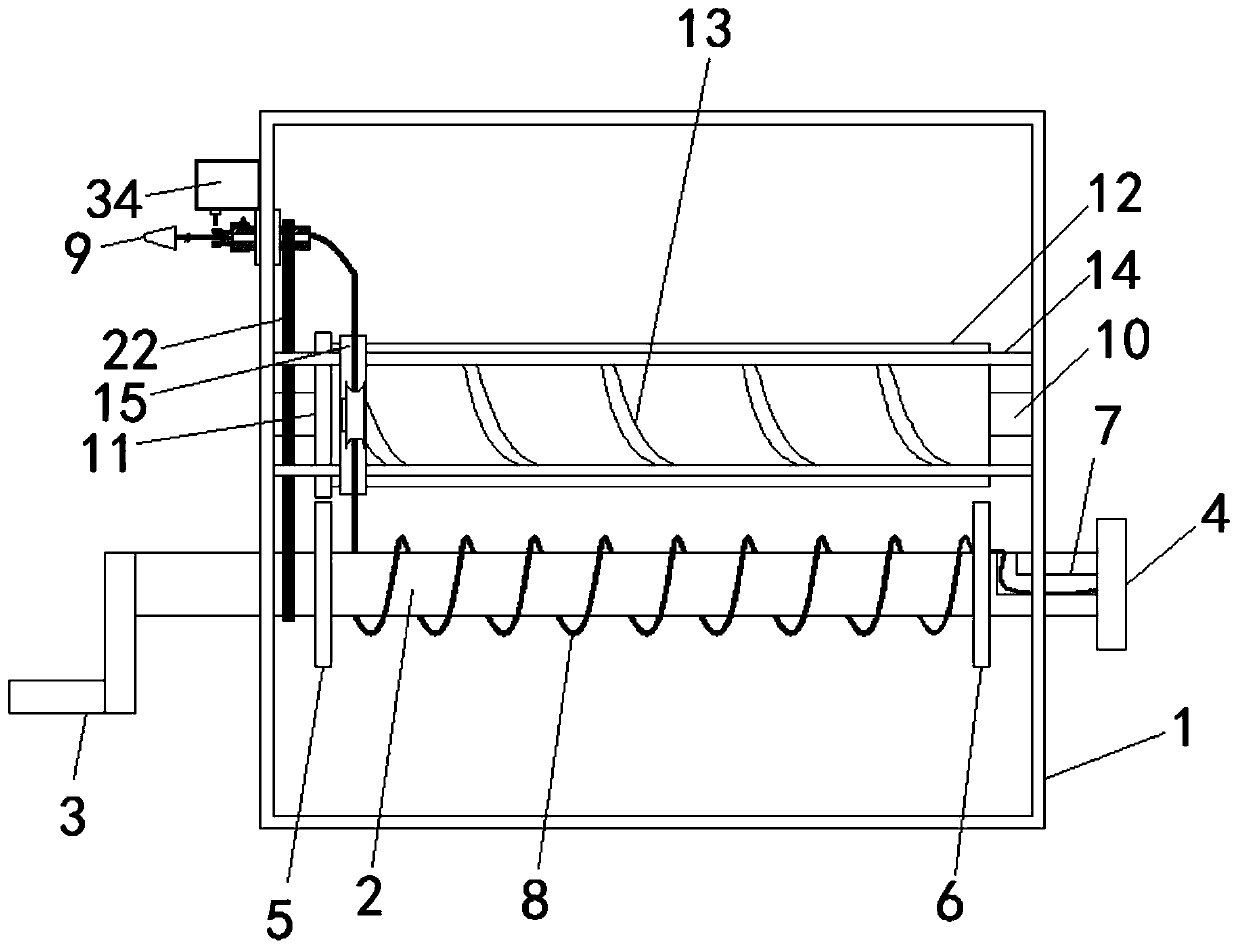

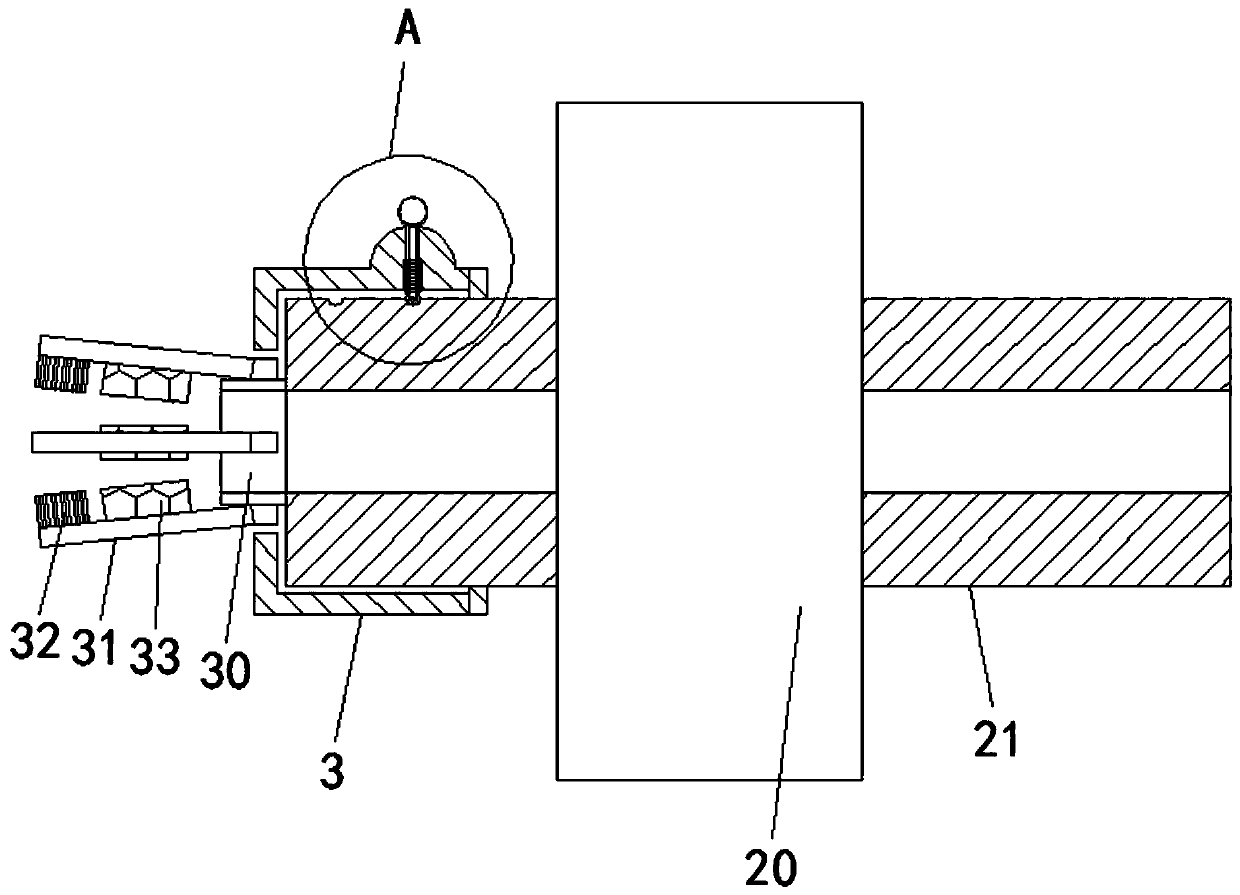

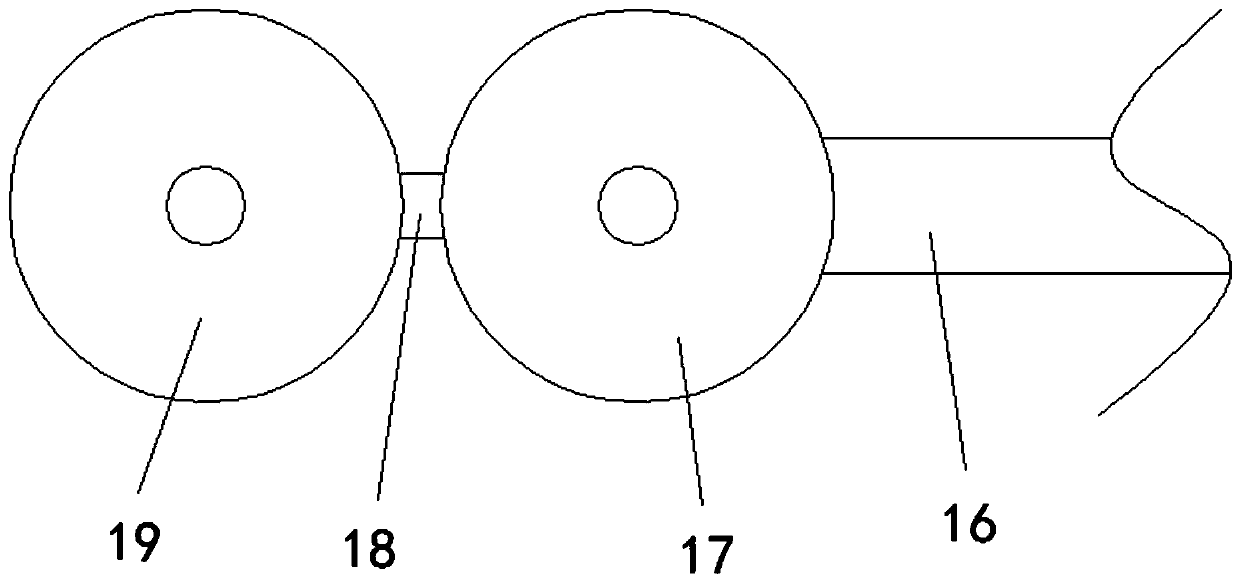

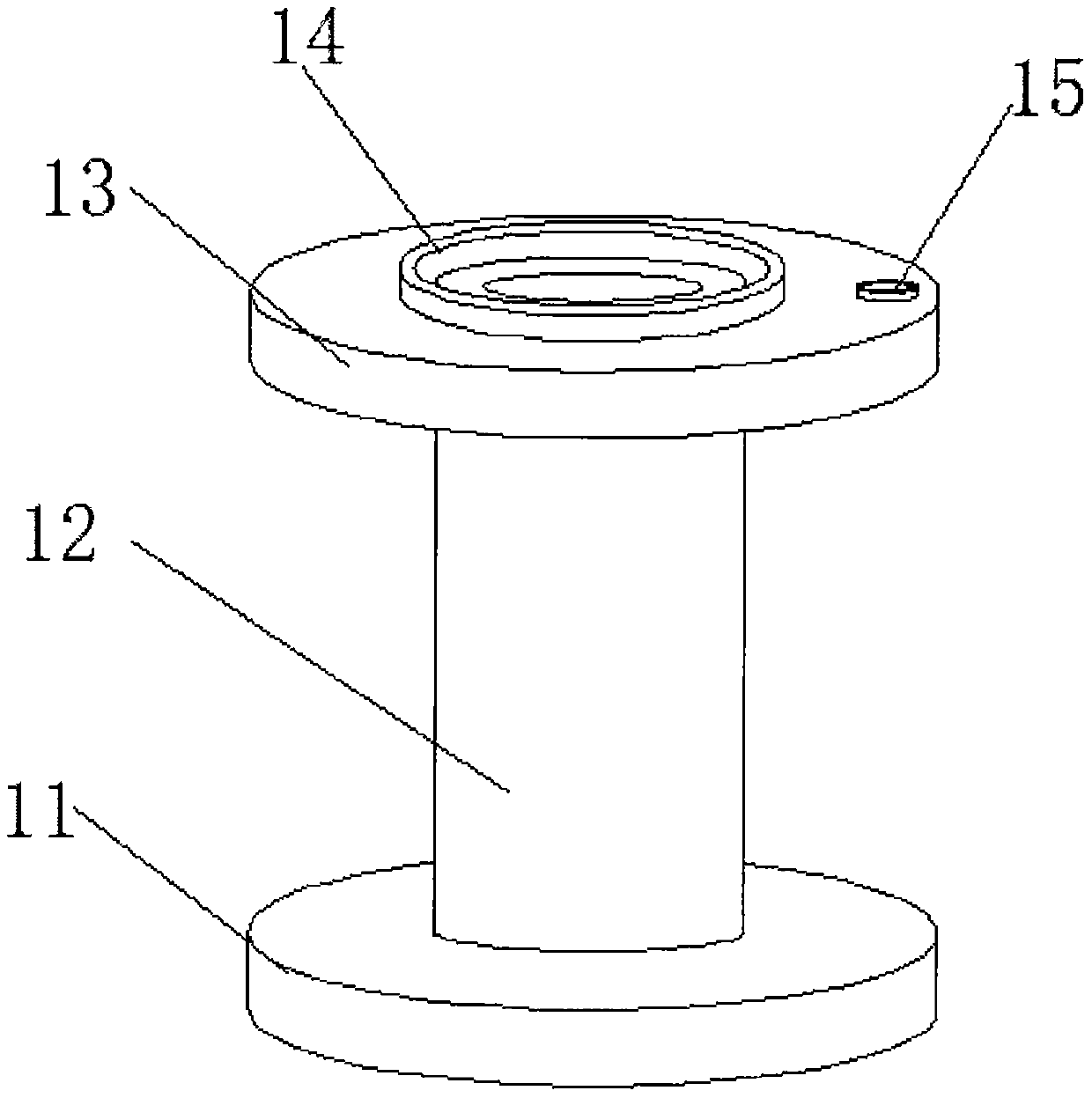

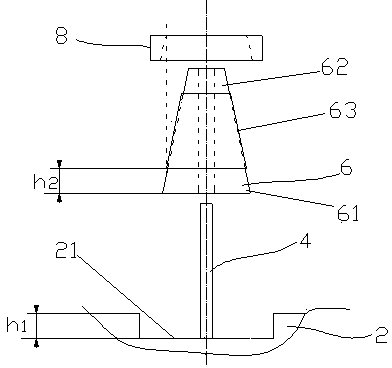

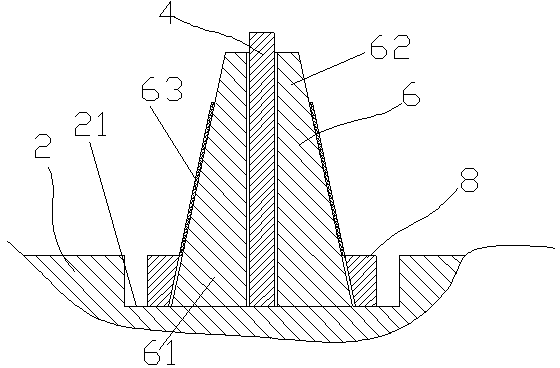

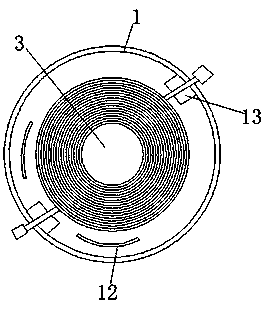

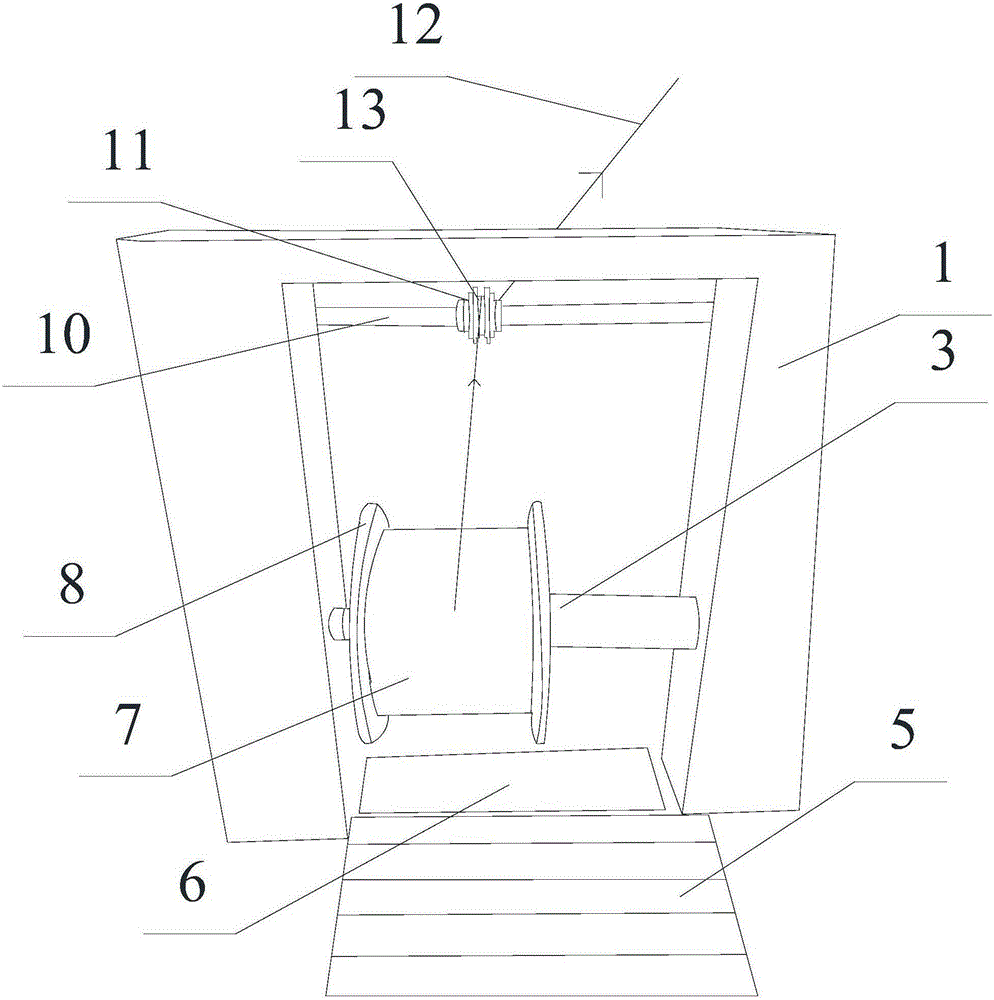

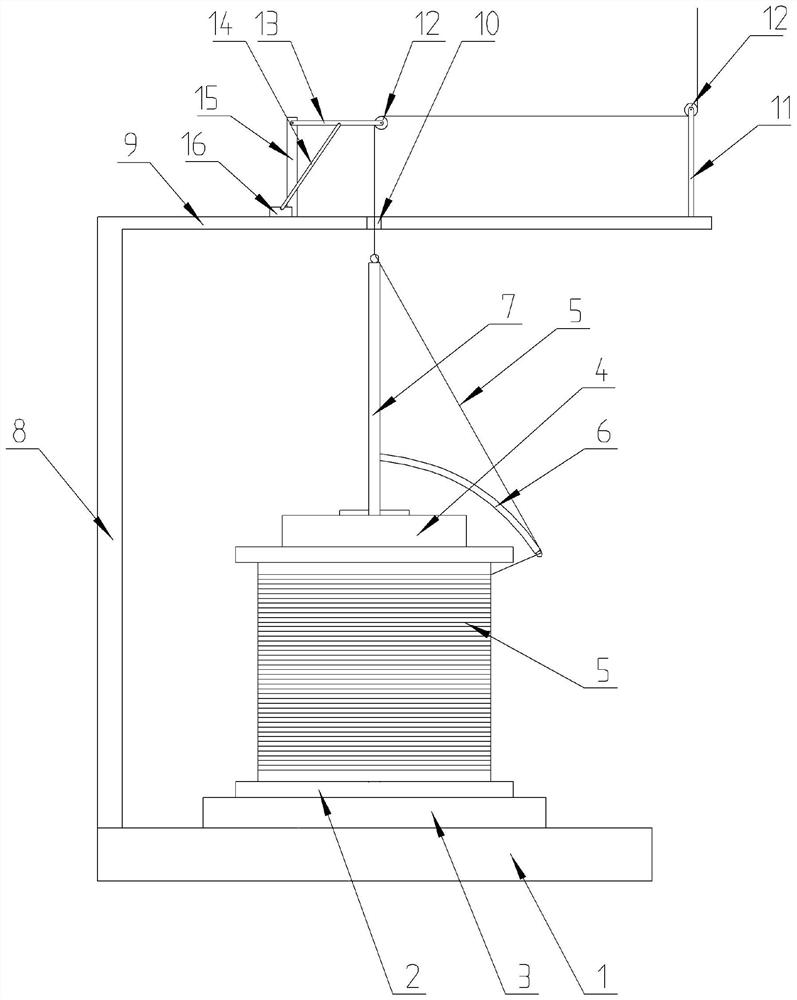

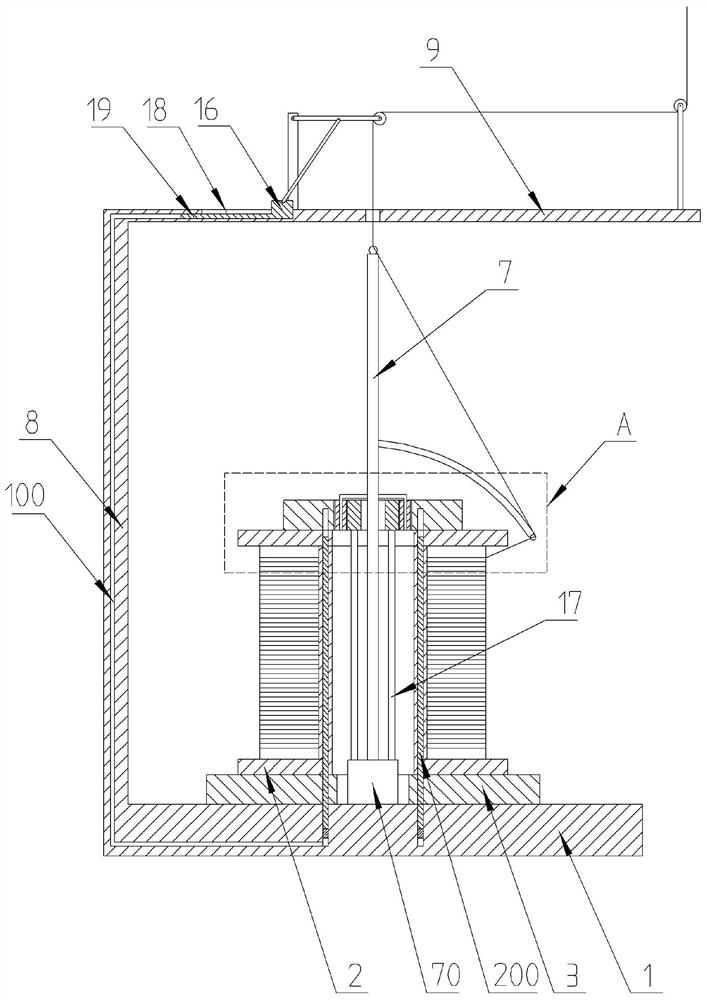

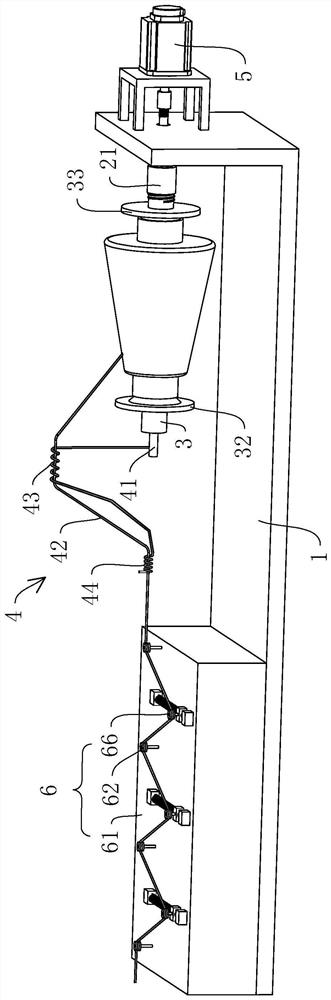

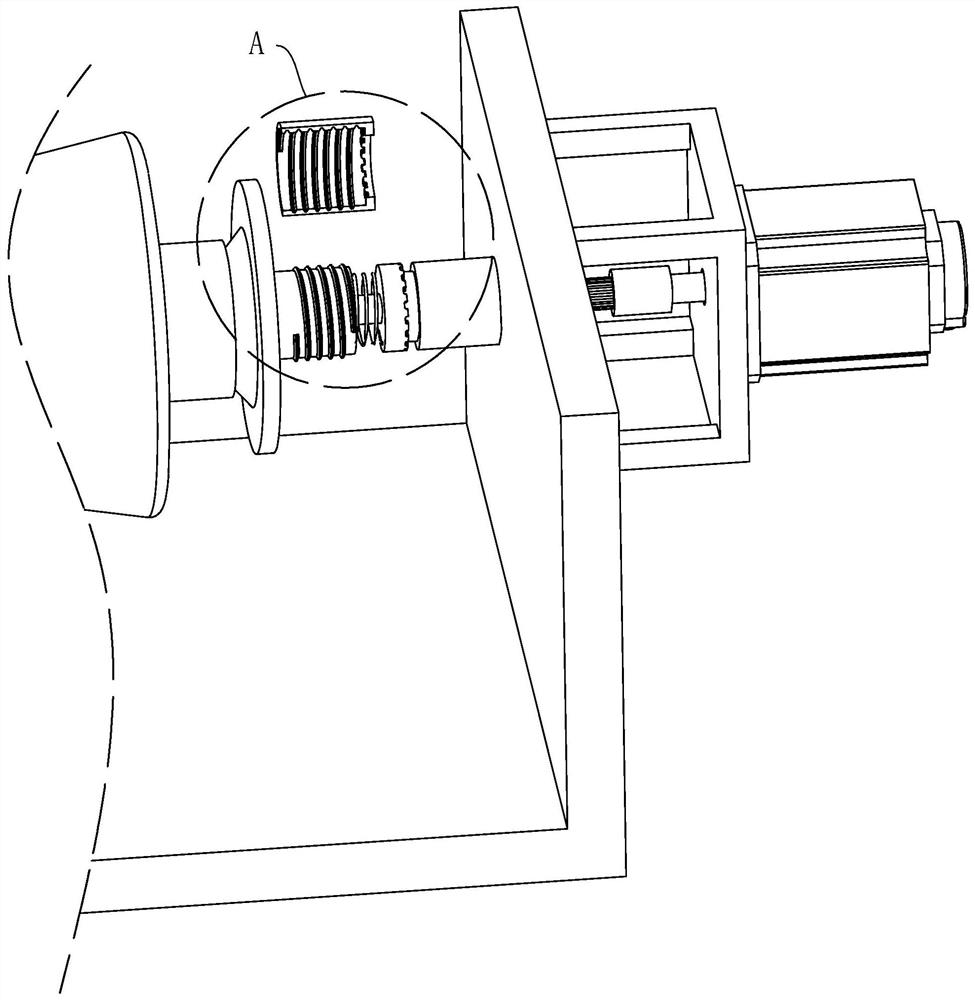

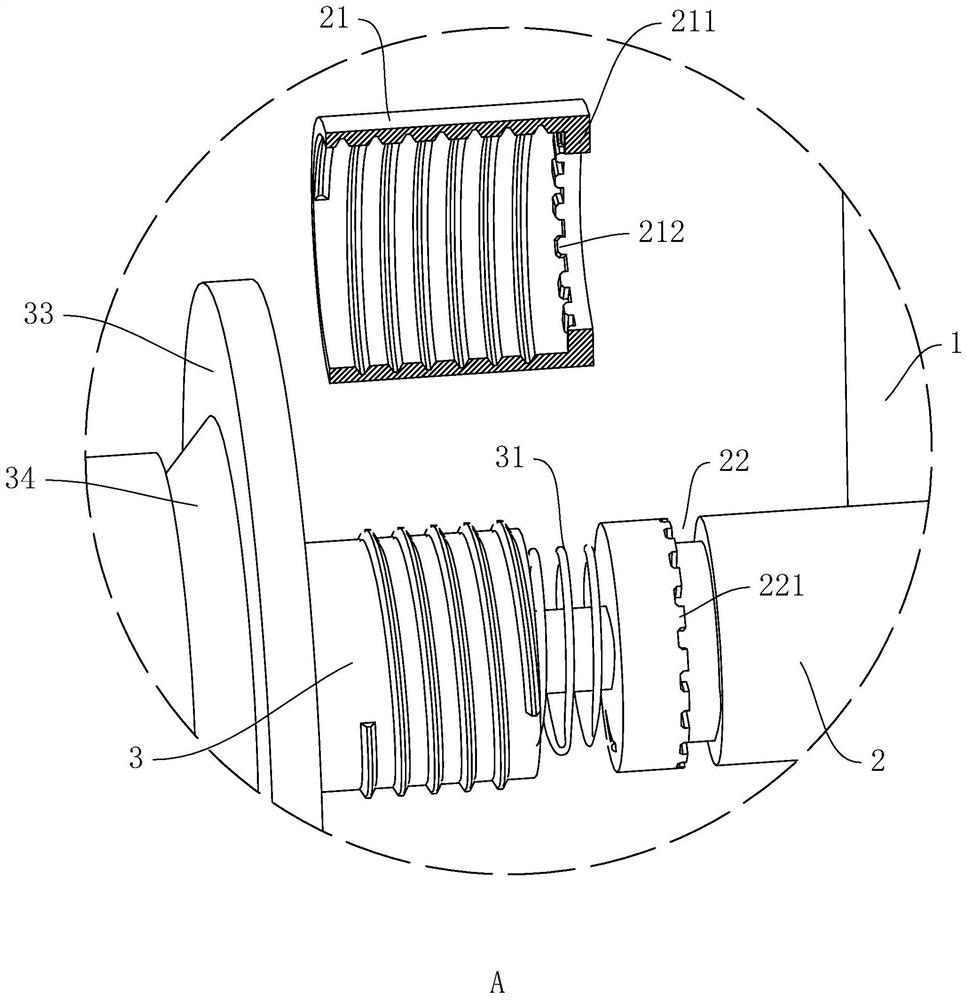

The invention relates to a pay-off frame for an ultrathin guide line. The pay-off frame comprises a base, a main pay-off shaft, a traction guide roller and a tension spring adjusting mechanism, wherein a rotary tray capable of rotating axially by surrounding the main pay-off shaft is arranged at the lower part of the main pay-off shaft; the tension spring adjusting mechanism comprises an adjusting tray, a fixing plate and a tension spring connected between the adjusting tray and the fixing plate; and the adjusting tray is also provided with a friction wheel capable of rubbing and contacting the edge of the rotary tray, and the traction guide roller is arranged on the adjusting tray. When the pay-off speed is normal, the friction wheel props against the edge of the rotary tray so as to provide friction force and pressure to the rotary tray; when the pay-off speed is increased, the tension force of the ultrathin guide line on the traction guide roller is increased, so that the traction guide roller drives the adjusting tray to overcome the tension force of the tension spring, so that the moving tendency of the adjusting tray far away from the rotary tray is increased, the friction force and the pressure of the friction wheel to the rotary tray are reduced, furthermore, the pay-off speed of the ultrathin guide line is increased, the pay-off tension force falls back so as to be kept stable. According to the pay-off frame, the tension force is balanced and the line is not easy to break in the pay-off process.

Owner:苏州久隆新材料科技有限公司

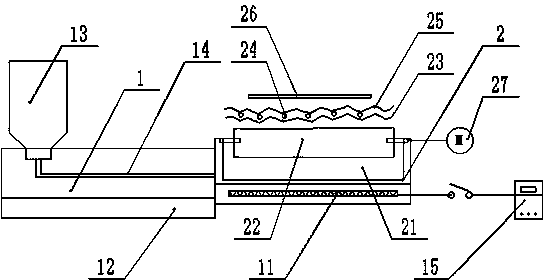

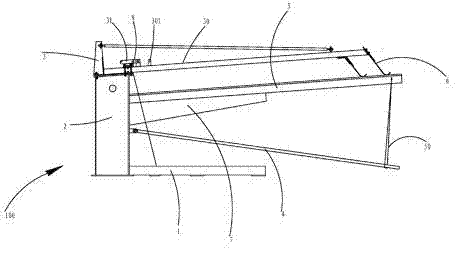

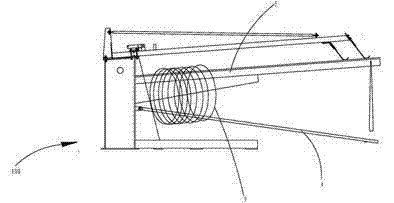

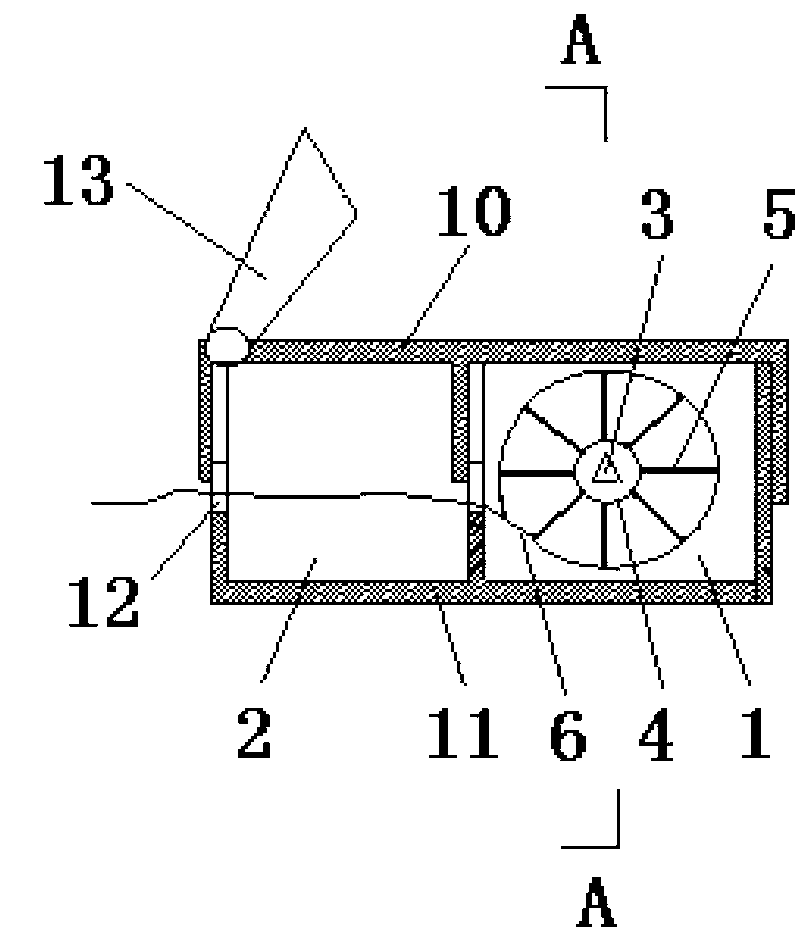

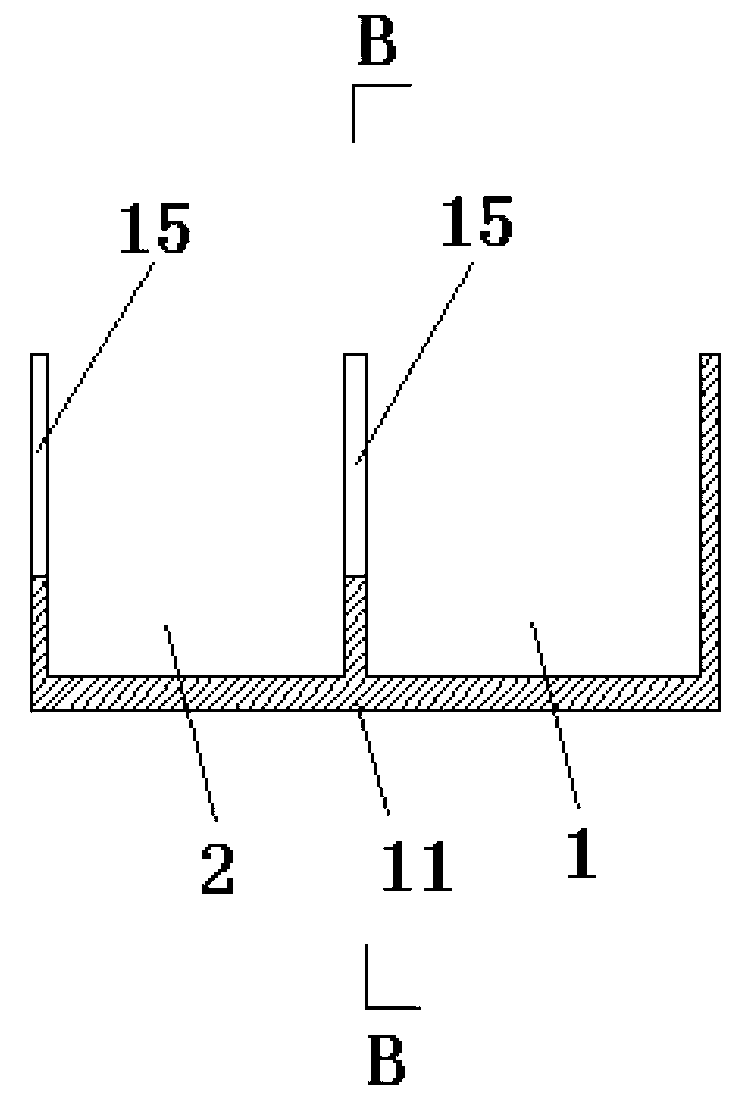

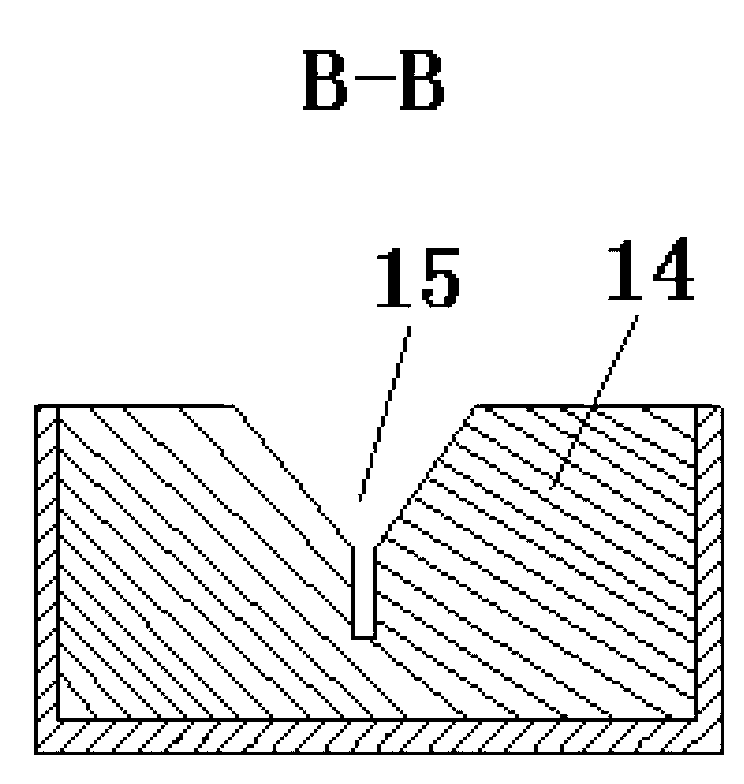

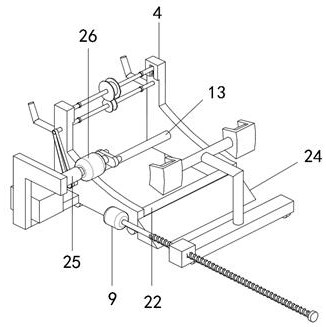

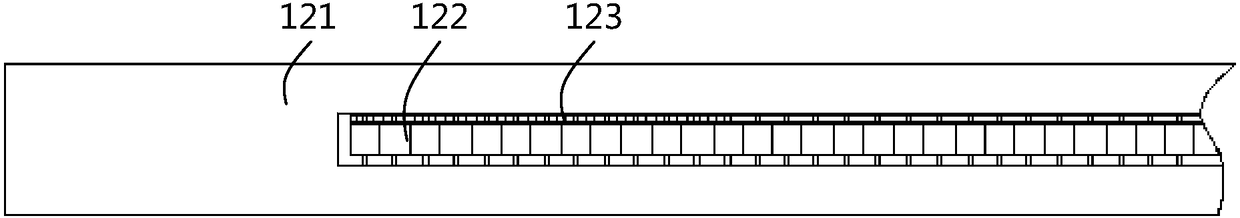

Roll shaft type varnished wire surface lubricant coating device and application thereof

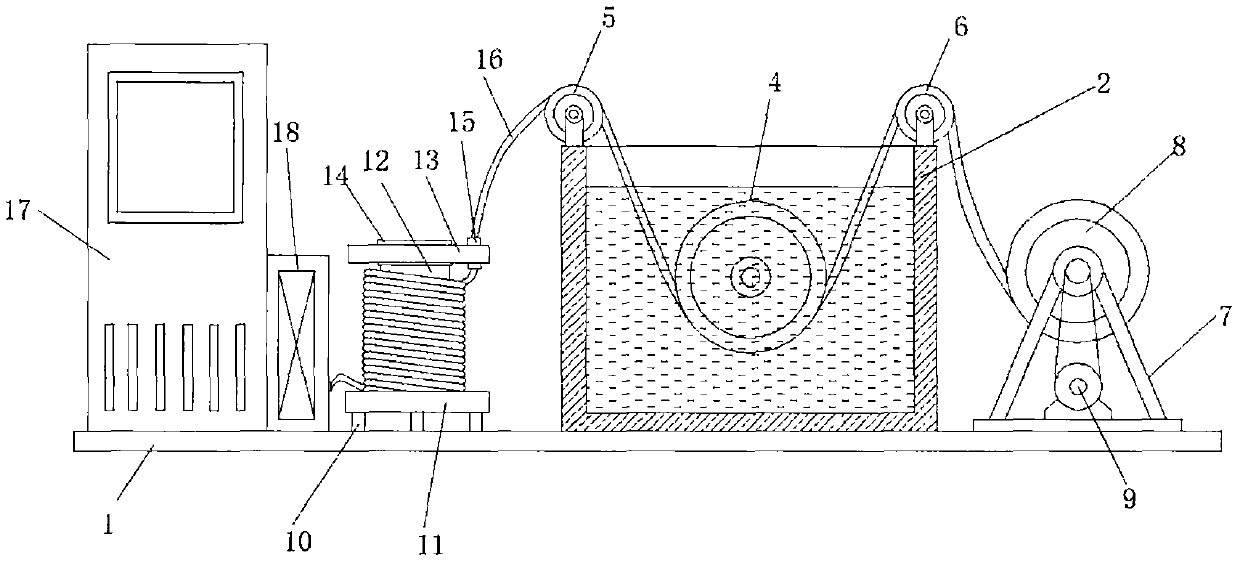

ActiveCN103928197AGuaranteed cleanlinessGuaranteed uniformityLiquid surface applicatorsInsulated cablesSolventFriction force

The invention discloses a roll shaft type varnished wire surface lubricant coating device and the application of the roll shaft type varnished wire surface lubricant coating device. The roll shaft type varnished wire surface lubricant coating device comprises a fusion unit used for converting solid lubricant into liquid lubricant through heating fusion and a coating unit used for evenly coating the surface of a varnished wire with the lubricant. The solid lubricant is heated through the fusion unit, felt is coated with the liquid lubricant through a roll shaft, the liquid lubricant permeates the felt, and the surface of the varnished wire is coated with the liquid lubricant; problems, caused by 120 # solvent, of environmental pollution, potential safety hazards and cost increase are avoided, the cleanness of the lubricant and the evenness of lubricant coating are guaranteed, the surface smoothness of the varnished wire is improved, the friction force between the varnished wire and a tool device is reduced, the requirement for an efficient, continuous and automatic varnished wire winding technology can be satisfied, smooth paying off in the process of winding is guaranteed, and the device and the application are particularly suitable for manufacturing the varnished wire with the diameter ranging from 0.07 mm to 1.0 mm.

Owner:浙江三行电气科技有限公司

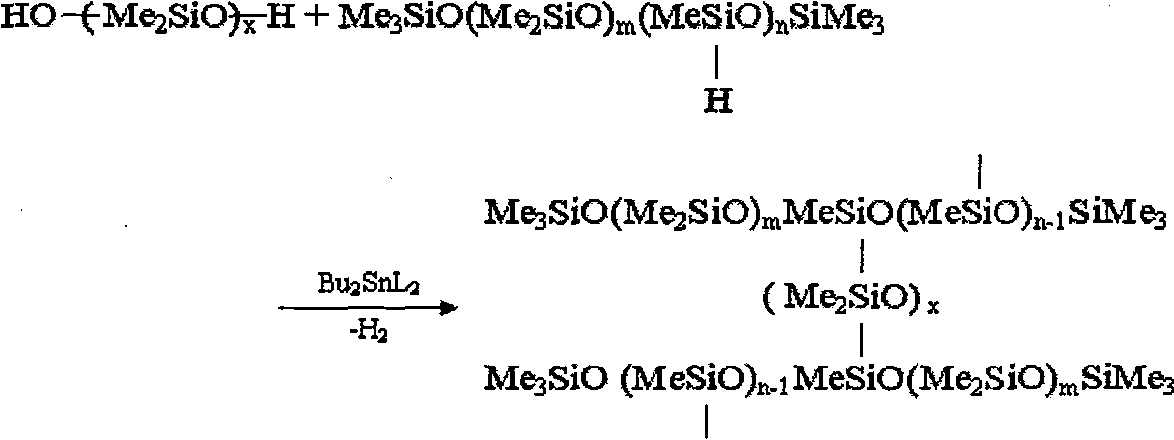

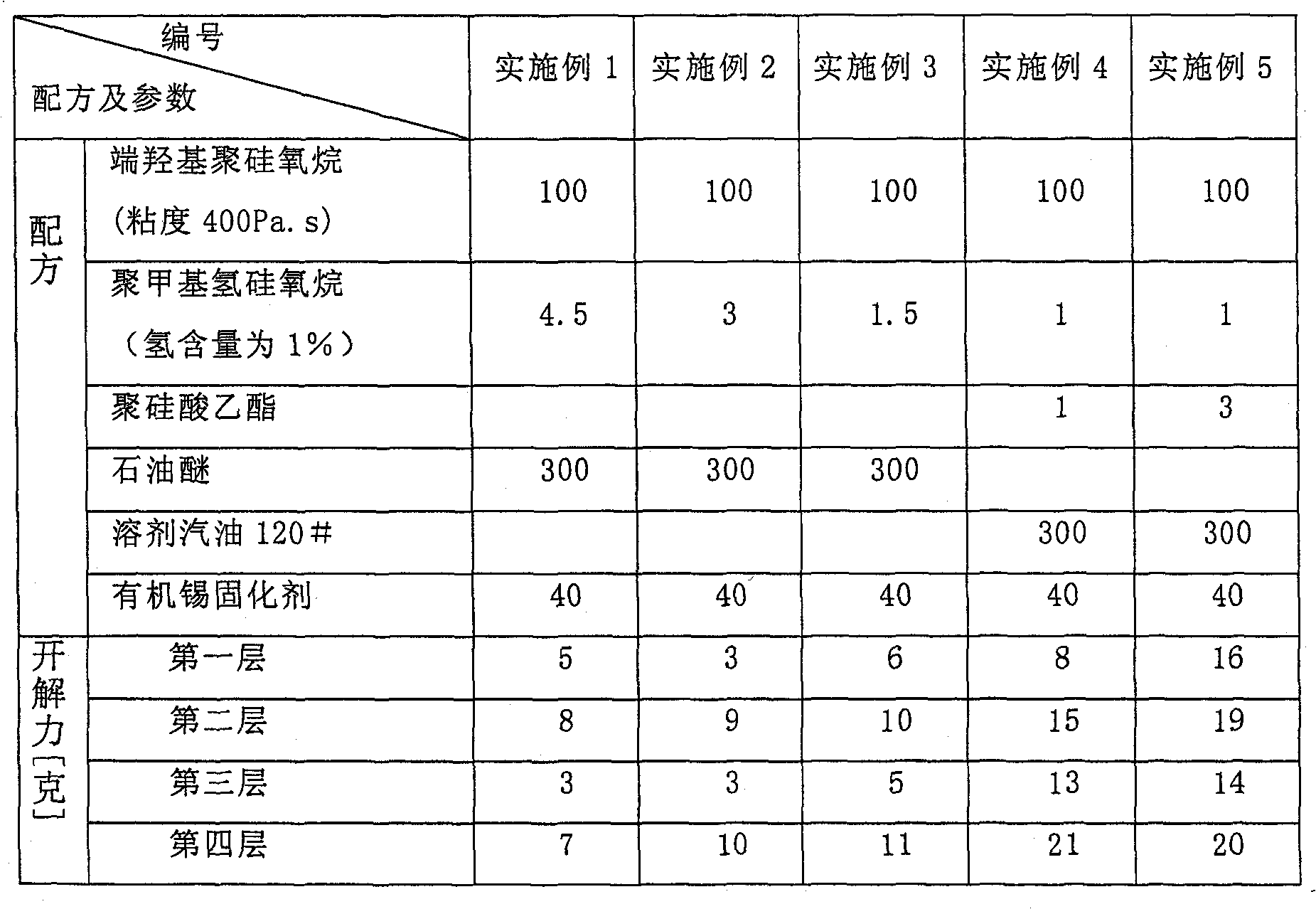

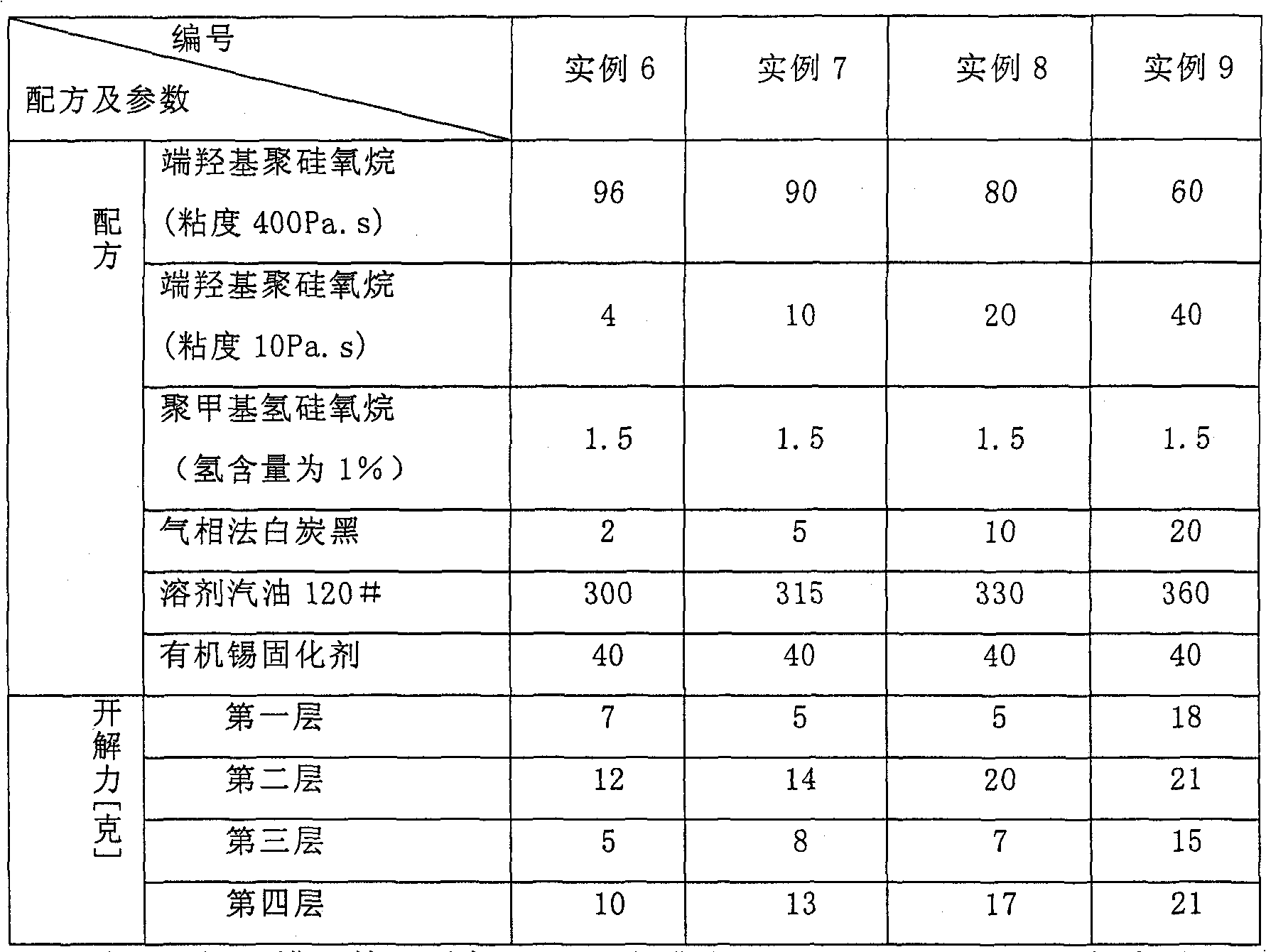

Organic silicon dehydrogenation condensed type optical cable adhesive and use method thereof

ActiveCN101781545AHigh degree of reaction completionImprove work performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymethylhydrosiloxaneSolvent

The invention relates to a dehydrogenation condensed type optical cable adhesive and a use method thereof. The A component substance of the adhesive is a sizing material obtained by the steps of taking hydroxy-terminated polydimethylsiloxane as a basic polymer, adding polymethyl hydrogen siloxane and fumed silica and mixing evenly; and the B component substance of the adhesive is an organic tin curing agent prepared by dissolving dibutyltin dilaurate in 120# solvent gasoline or petroleum ether. When in use, the A component substance of the sizing material is dissolved in the 120# solvent gasoline or the petroleum ether with the boiling range of 90 to 120 DEG C in advance, then the mixture is coated on the surface of an optical cable by brush coating or dip coating after the solution and the curing agent are mixed evenly, and an optical cable winding is prepared by winding after curing. The adhesive has moderate bonding strength, ageing resistance and high / low-temperature resistance, the inherent shape of the bonded optical cable winding can keep stable in the processes of storage, transportation and paying off, the resistance generated when the optical cable winding is paid off at high speed is also minimum without the deviation of the coils of the optical cable, and the signal transmission of the optical cable is also not influenced.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

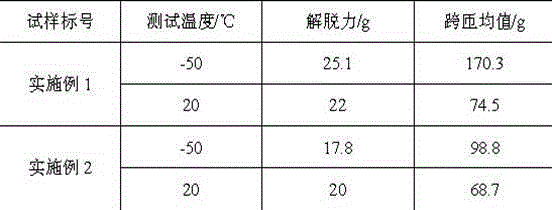

Preparation method of adhesive assorted with liquid crystal coated optical cable

InactiveCN102719216AImprove low temperature performanceSmooth pay-offNon-macromolecular adhesive additivesAdhesive cementSiloxane

The invention provides a preparation method of an adhesive assorted with a liquid crystal coated optical cable. In the preparation method of the adhesive assorted with the liquid crystal coated optical cable, alpha, omega-terminal hydroxyl polymethyl vinylphenyl silicone rubber or alpha, omega-terminal hydroxyl polydimethyl diethyl siloxane with good low temperature performance is taken as a main material, nano-filler-reinforced silicone rubber adhesive is used for improving mechanical properties thereof, and according to a vulcanization mechanism of a dealcoholized room temperature vulcanization silicone rubber, room temperature vulcanization silicone rubber adhesive with excellent low temperature performance and moderate releasing force is prepared. When the adhesive is used for winding an optical cable coil, releasing forces at normal temperature and low temperature are moderate and wires can be smoothly unwound, thus meeting requirements of practical application and particularly meeting a requirement on the releasing force in a low temperature environment.

Owner:BEIJING UNIV OF CHEM TECH

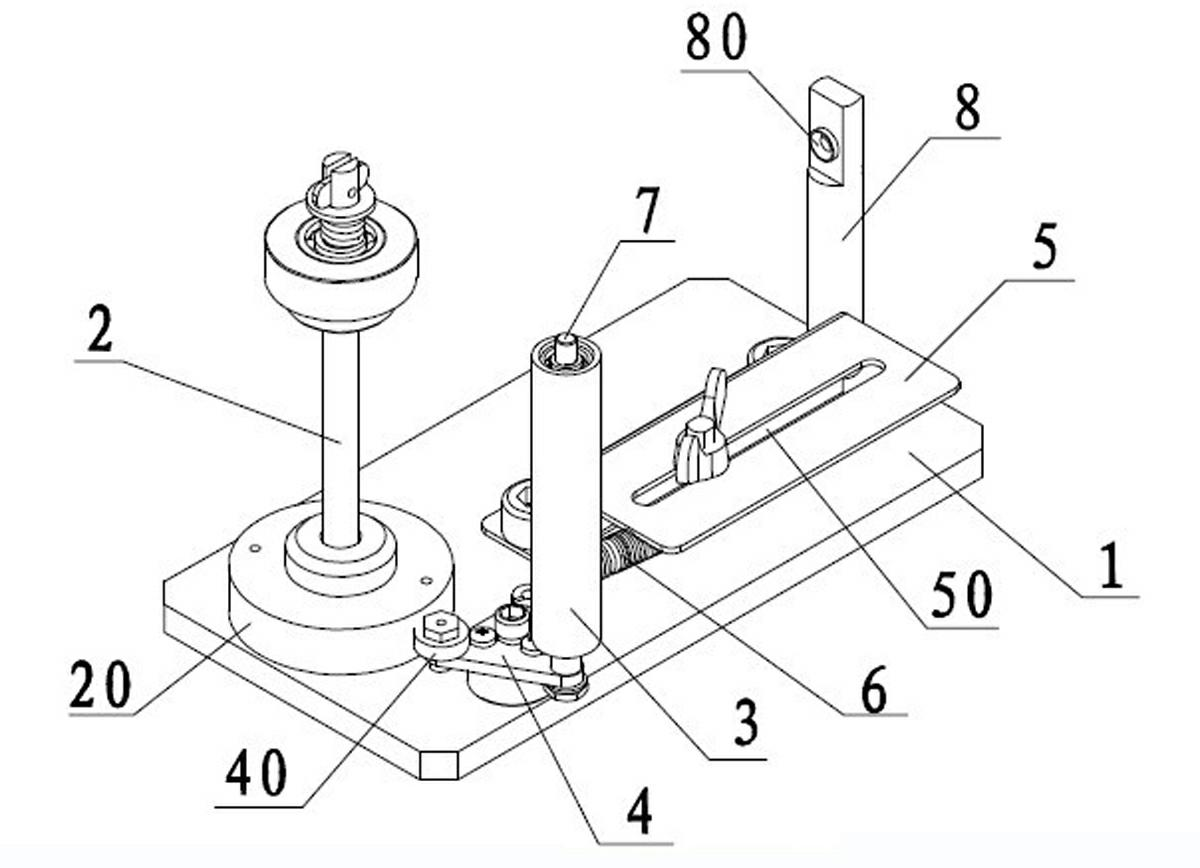

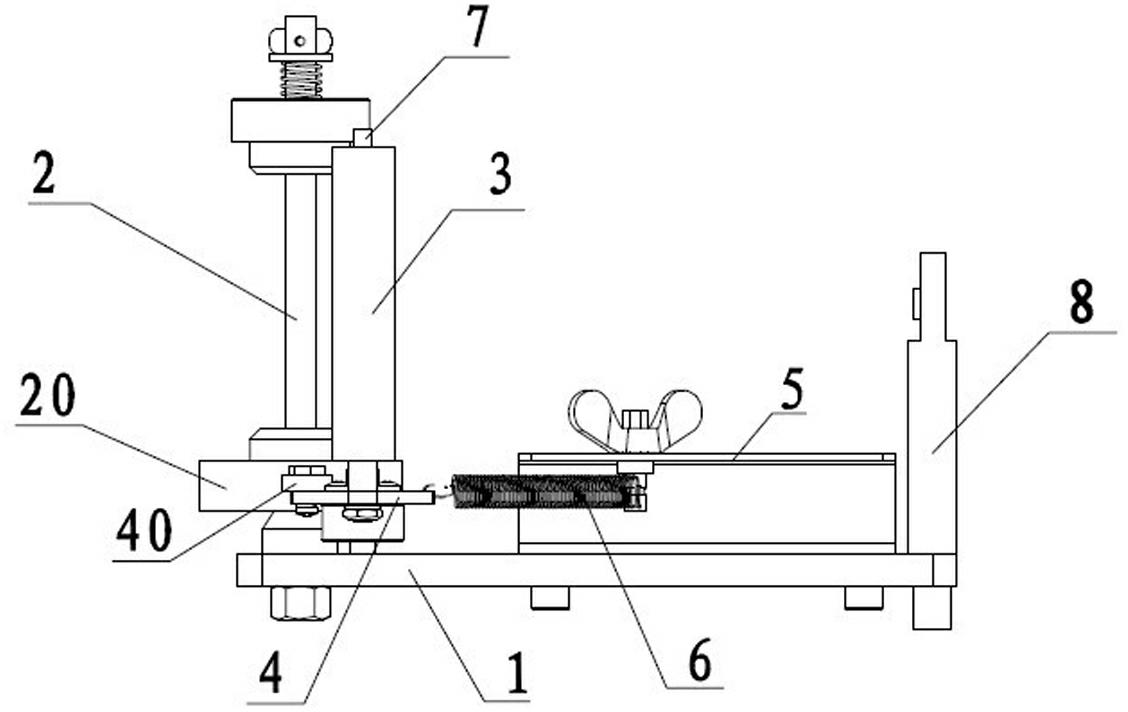

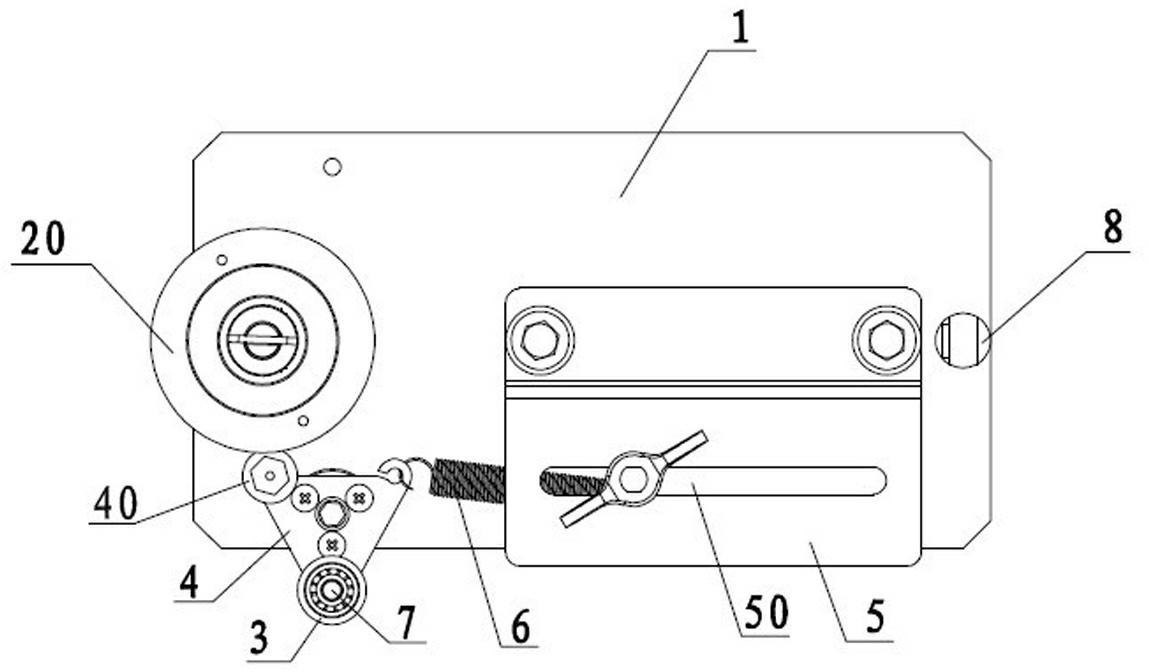

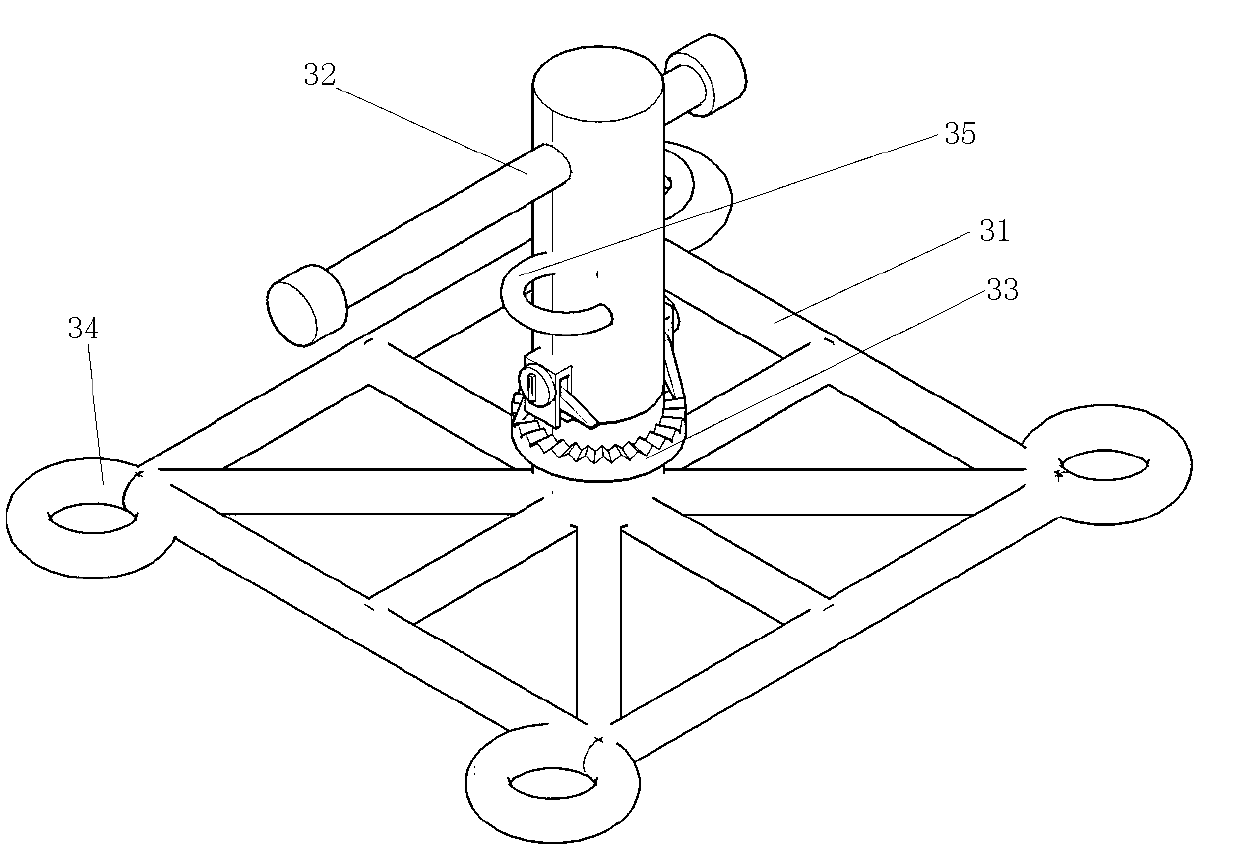

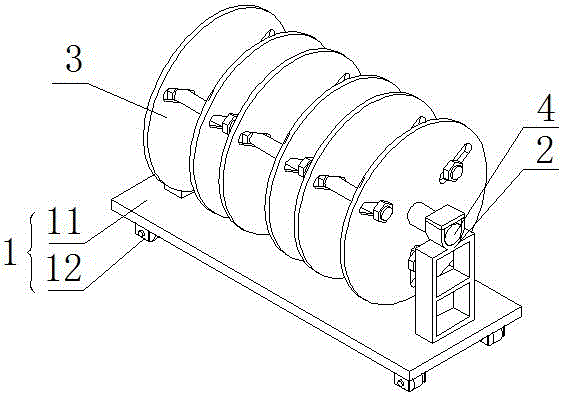

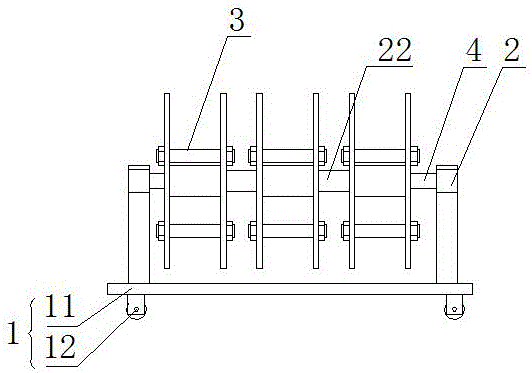

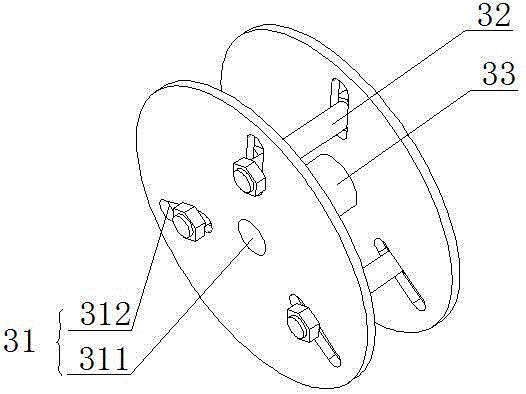

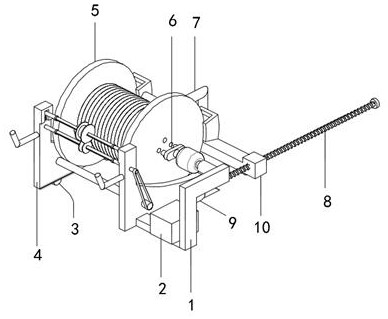

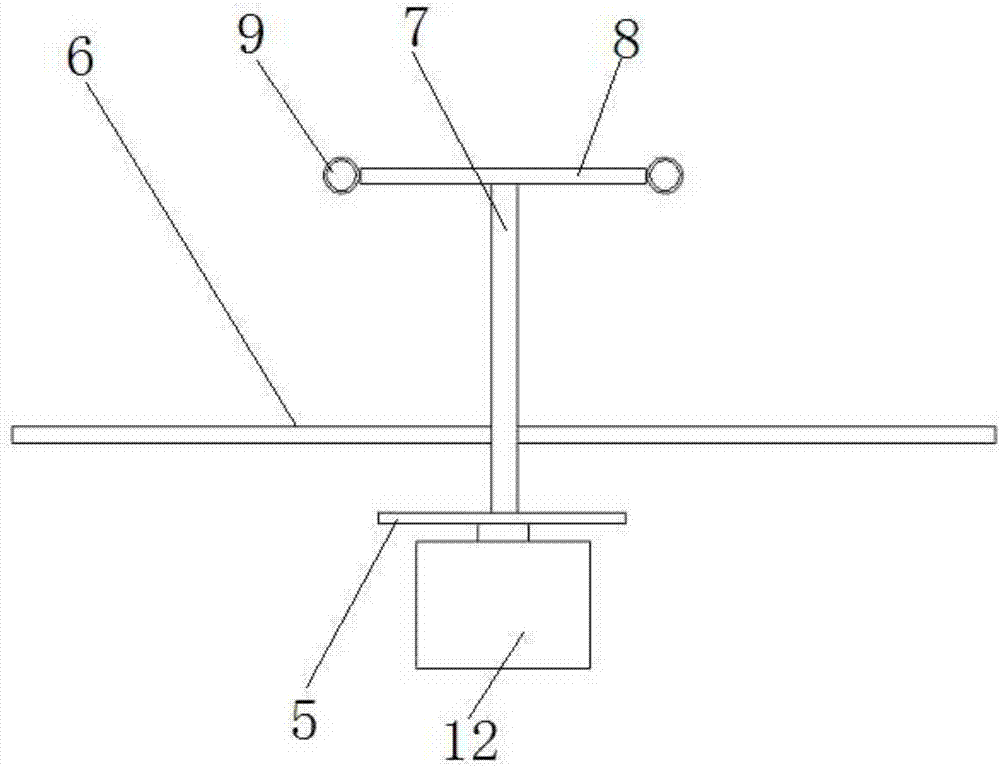

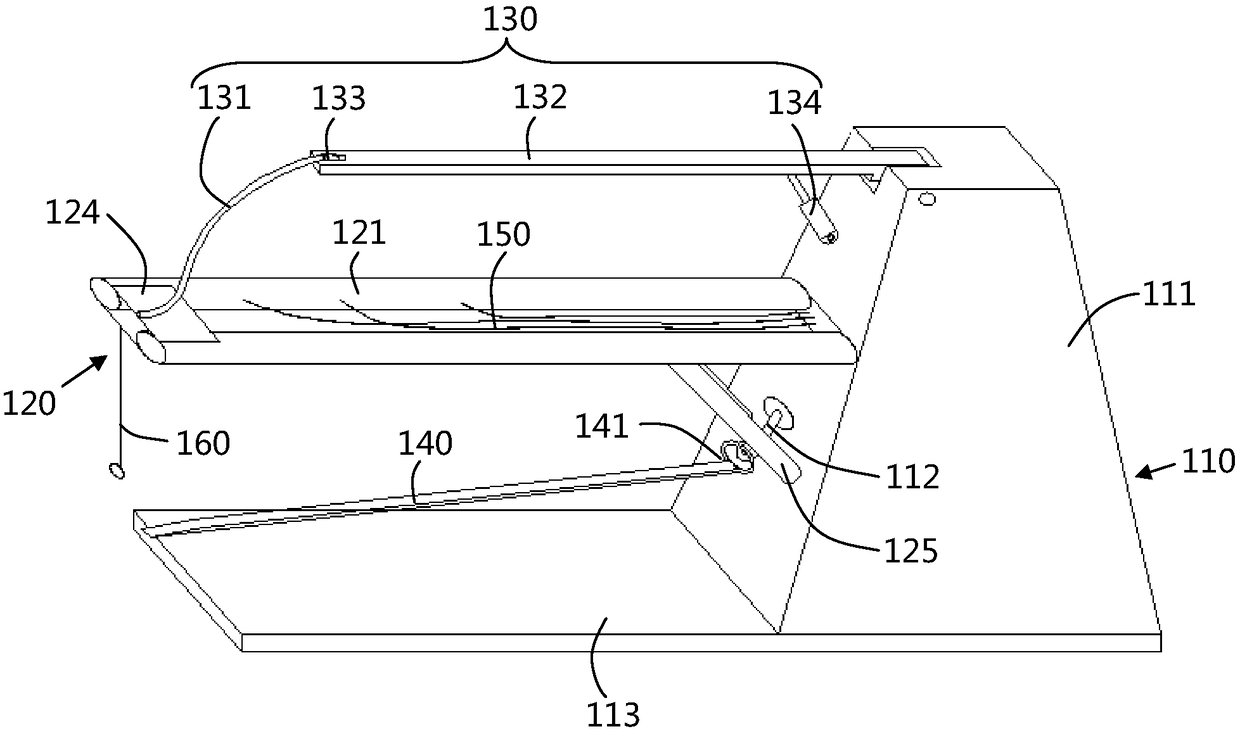

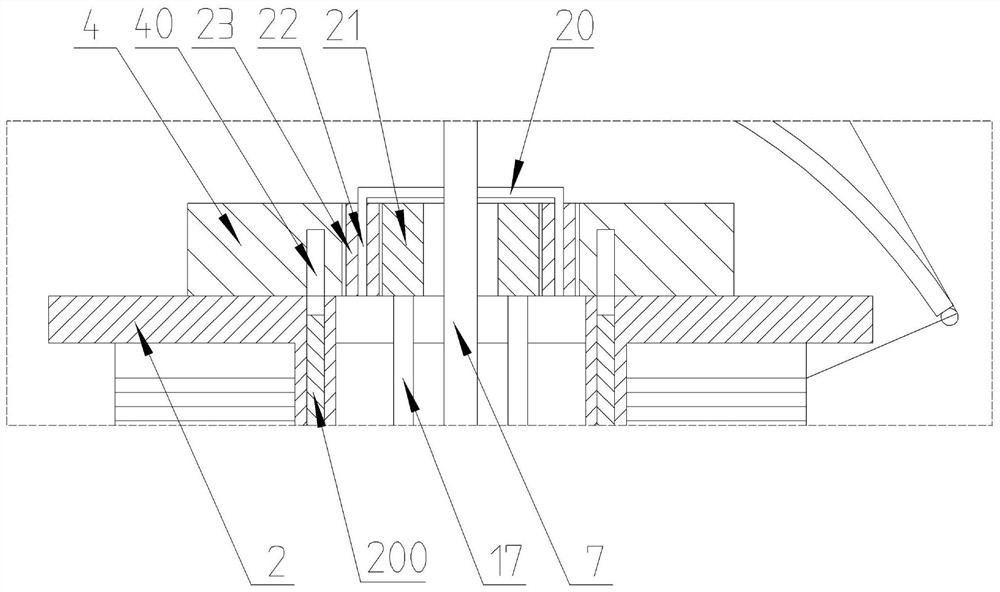

Pay-off apparatus for superfine wires

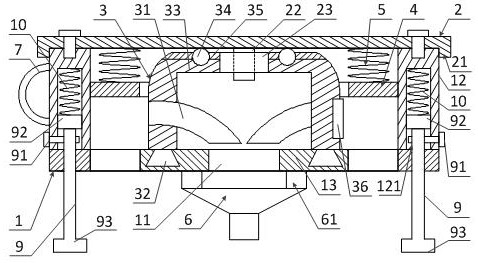

ActiveCN102610325AStable pay-off tensionNot easy to disconnectCable/conductor manufacturePull forcePhysics

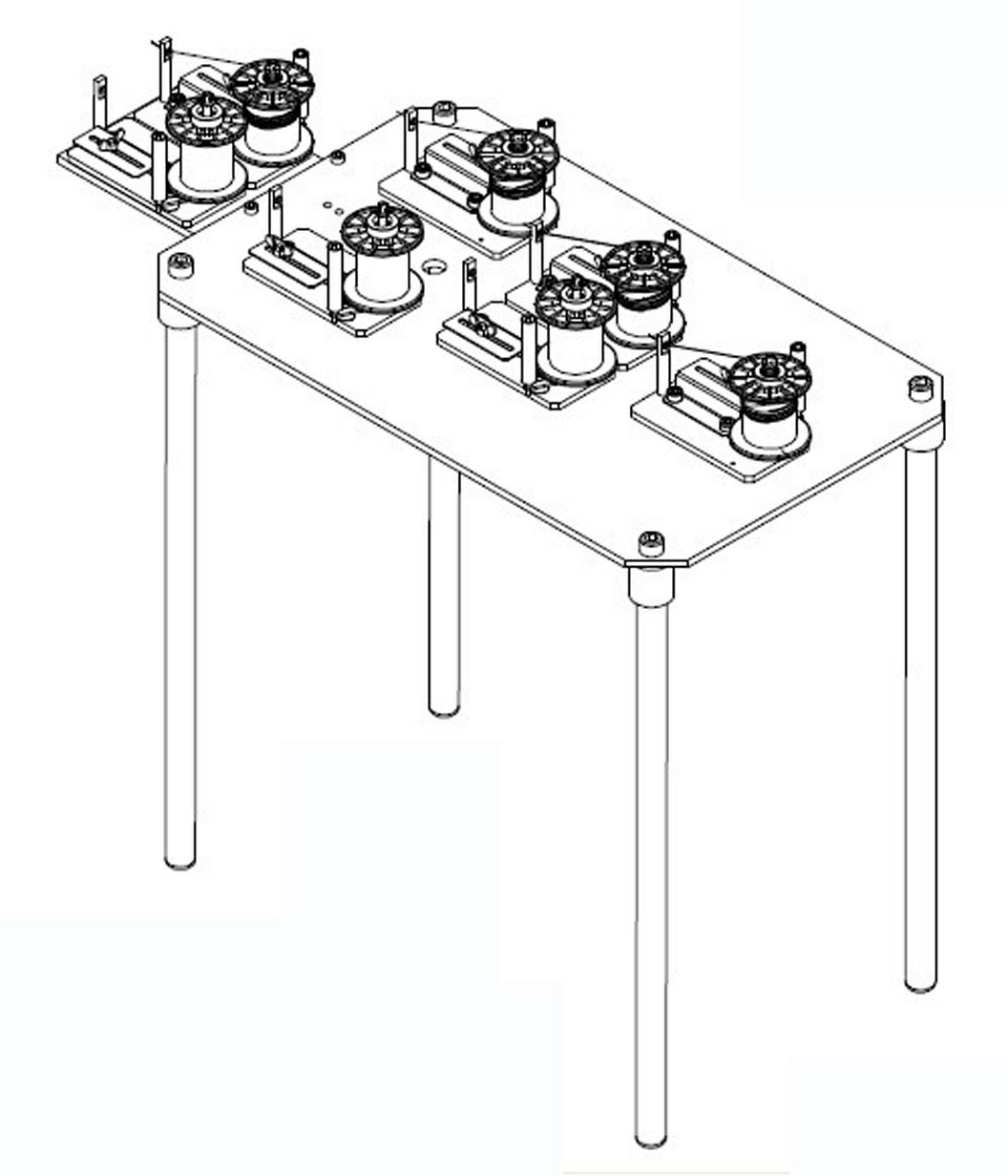

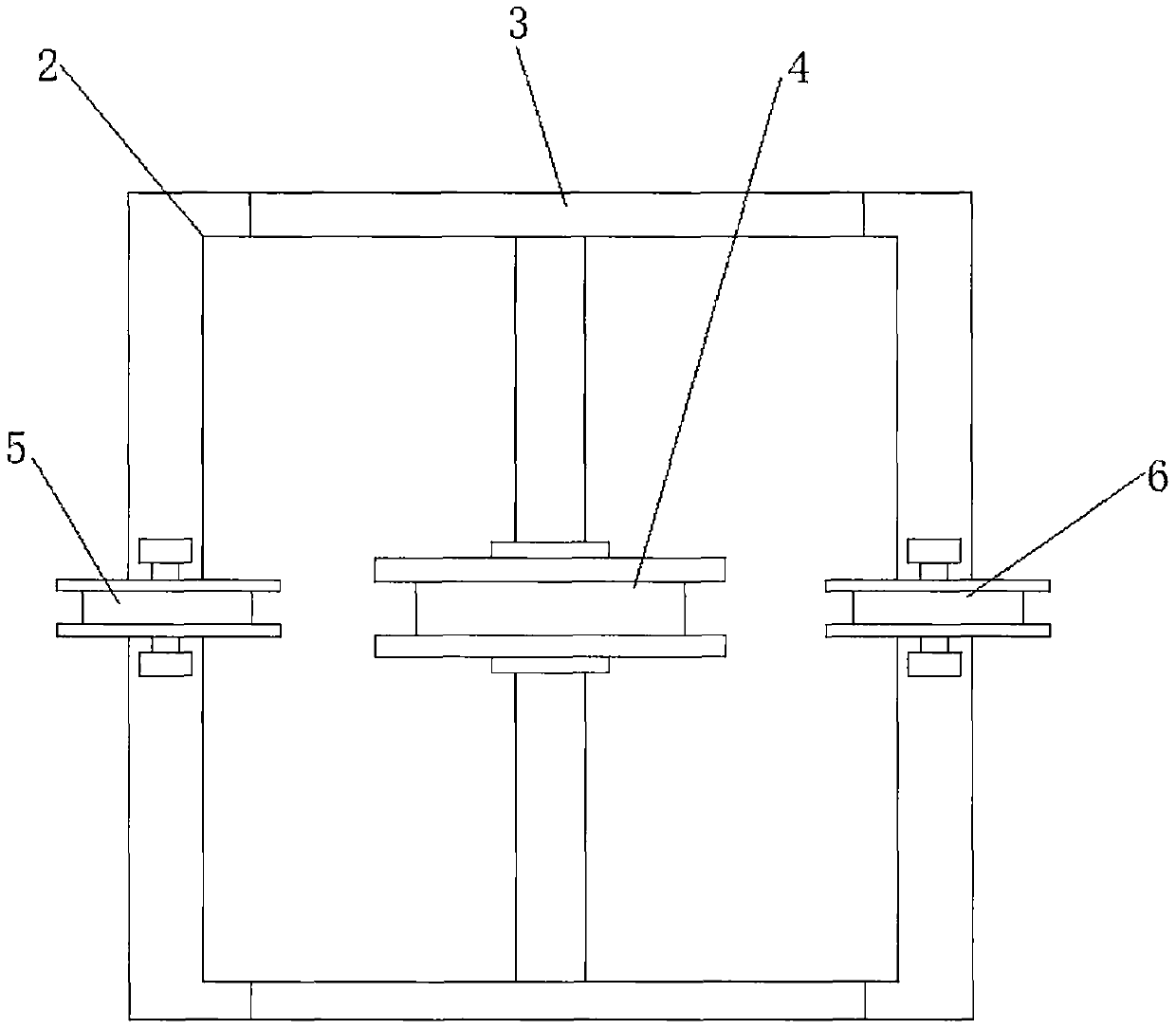

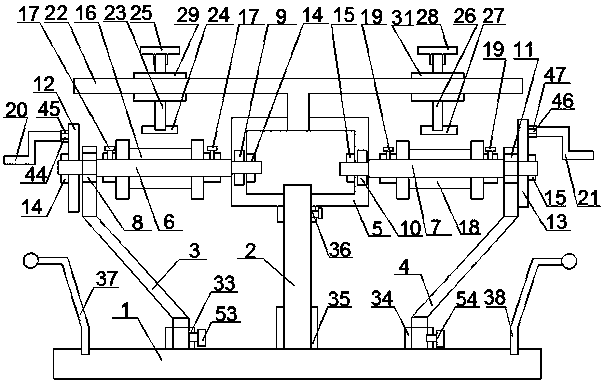

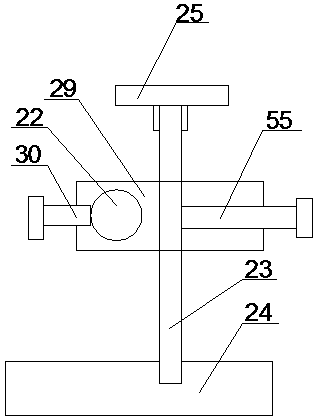

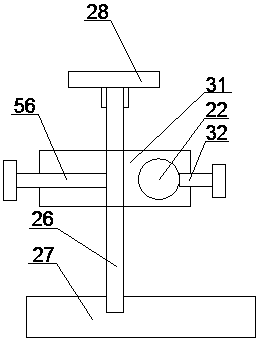

The invention relates to a pay-off apparatus for superfine wires, which comprises a plurality of pay-off stands, wherein each pay-off stand comprises a base, a pay-off spindle, a traction guide roller and a tension spring adjusting mechanism, wherein the lower part of the pay-off spindle is provided with a rotating tray which can rotate around the axial direction of the pay-off spindle; the tension spring adjusting mechanism comprises an adjusting disc, a fixed plate and a tension spring connected between the adjusting disc and the fixed plate; and the adjusting disc is also provided with a friction wheel which is in friction contact with the rotating tray, and the traction guide roller is arranged on the adjusting disc. In general, the rotating tray overcomes the friction force and pressure of the friction wheel and then carries out wire pay-off normally; when the pay-off speed increases, the tensile force of a superfine wire on the traction guide roller increases firstly so as to drive the adjusting disc to have a trend that the tensile force of the tension spring is overcome and the adjusting disc is away from the rotating tray, so that the friction force and pressure between the friction wheel and the rotating tray are reduced, and the pay-off speed of the superfine wire increases; and finally, the pay-off tensile force falls back and keeps stable. By using the pay-off apparatus disclosed by the invention, the tensile force in a pay-off process is balanced, and a situation of wire breakage is not easily caused.

Owner:苏州久隆新材料科技有限公司

Vertical pay-off brake device

InactiveCN103662978AAvoid autorotationSmooth pay-offFilament handlingEngineeringMechanical engineering

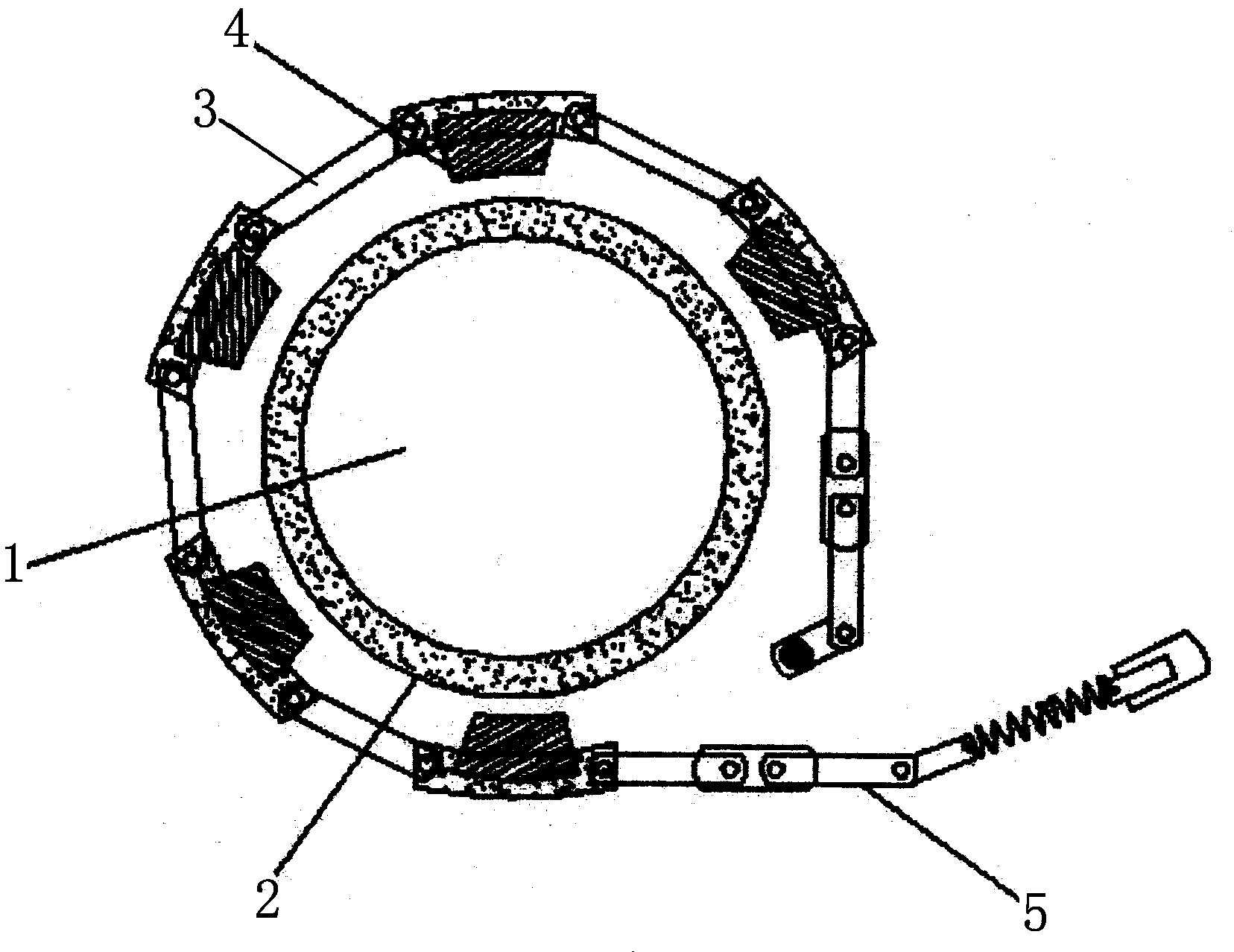

The invention discloses a vertical pay-off brake device. The vertical pay-off brake device is characterized in that one end of a pay-off rack is sleeved with a brake sleeve, the outside of the brake sleeve is provided with a brake tape, a plurality of brake pads are evenly arranged on the inner edge of the brake tape and correspond to the brake sleeve, one end of the brake tape is fixed, and the other end of the brake tape is provided with a lever compressing mechanism. According to the arrangement, a spool is mounted on the pay-off rack, and the brake pads tightly press against the brake sleeve; when a coarse-specification spool is subjected to paying off, pay-off tension is set by stepping down the lever compressing mechanism to loosen the brake pads; accordingly, self-rotation of the spool caused by inertia is avoided and smooth pay-off is achieved.

Owner:SHANDONG DAYE

Electronic information transmitting antenna with uniform winding function

ActiveCN111056386AWind evenlyNot subject to wear and tearFlexible lead accommodationGear wheelReciprocating motion

The invention relates to the technical field of electronic information, and discloses an electronic information transmitting antenna with a uniform winding function. The antenna comprises a cable box.A winding shaft is rotatably inserted into the lower part of the cable box. A rotating shaft is rotatably connected with the inner cavity of the cable box and is positioned above the winding shaft. Adriven gear is arranged on the left portion of the rotating shaft. The right side of the driven gear is fixedly connected with a guide cylinder connected with the rotating shaft in a sleeving mode. Aguide groove is formed in the guide cylinder. A bearing is fixedly installed on the left wall of the cable box. A guide pipe is fixedly connected with the inner cavity of the bearing. The left portion of the guide pipe is movably sleeved by a sliding sleeve. According to the electronic information transmitting antenna with the uniform winding function, the winding shaft drives the guide cylinderto rotate; the guide cylinder enables a sliding block to reciprocate left and right through the guide groove; the guide pipe and the sliding sleeve are arranged in a matched mode, and bristles with elastic pieces are arranged on the guide pipe in a matched mode; and the effects of evenly winding, protecting a cable against abrasion and conveniently keeping large cleaning strength on a cable are achieved.

Owner:长峰电子科技(深圳)有限公司

Motor lubricating oil

InactiveCN103695108AImprove general performanceImprove solubilityLubricant compositionSolubilityPolyvinyl alcohol

The invention discloses motor lubricating oil. The motor lubricating oil is characterized in that the motor lubricating oil is prepared from the following components in parts by weight: 0.01-0.5 part of paraffin, 5-13 parts of methylene dichloride, 3-9 parts of trichloromethane, 11-19 parts of n-pentane, 3-9 parts of polyvinyl alcohol, 5-10 parts of normal heptane, 3-5 parts of boric acid, 1-2 parts of sodium benzoate, 0.05-6.4 parts of polyvinylpyrrolidone, 3-6 parts of 1-butyl-3-methylimidazole hexafluorophosphate, 3-12 parts of n-pentane and 40-80 parts of petroleum ether. The motor lubricating oil has the beneficial effects that the lubricating oil has strong universality and good solubility, the concentration of the blended lubricating oil is uniform, the lubricating oil has no sediment or precipitation when being stored for a long time and has good effect, the lubricating oil has no visible residue after liquid components are volatilized, and the lubricating oil has no destructive effect on insulation, can be coated uniformly, has low friction coefficient and low price.

Owner:QINGDAO HUIERTONG TRADING

Cable soaking alarm device

InactiveCN110530577AIncreased water immersion detection efficiencyWon't tangleDetection of fluid at leakage pointEngineeringAlarm device

The invention discloses a cable soaking alarm device, which comprises a supporting bottom plate, wherein a detection water tank is fixedly arranged in the middle of the supporting bottom plate; tempered glass is embedded into two corresponding lateral surfaces of the detection water tank; an opening is arranged in the upper side of the detection water tank; a line pressing wheel is rotationally arranged in the middle of an inner cavity through a supporting rod; a first guide roller and a second guide roller are arranged at positions, which are located in the opening, on the two side walls of the detection water tank respectively; a winding device is fixedly arranged on one side, which is located at the detection water tank, of the supporting bottom plate; and a pay-off device is fixedly arranged on the supporting bottom plate on one side, far away from the winding device, of the detection water tank. According to the cable soaking alarm device, the winding device is wound with a cableprotection sleeve, when detection water passes through the cable protection sleeve filled with air, a fracture position bubbles, and the detection personnel can accurately judge the fracture position,and furthermore, the pay-off device can smoothly pay off, the cable protection sleeve cannot be wound together, and the soaking detection efficiency of the cable is improved.

Owner:王俊虎

Large-capacity super-spun-yarn cursory spindle of high speed machine

The invention provides a large-capacity super-spun-yarn cursory spindle of a high speed machine, belonging to the cursory spindle of a braiding machine. A brake pin is arranged in a spindle seat of the cursory spindle; the bottom part of the brake pin is provided with a short compressed spring; a line weight is connected with the spindle seat through a pin and one end of the line weight is connected with a connecting rod; one side of the spindle seat is connected with a guide column and the guide column is sleeved with the connecting rod; the upper end of the spindle seat is connected with a bobbin shaft and the upper end of the bobbin shaft is provided with a clamping cap; a long compressed spring is arranged in the bobbin shaft and a bobbin is sleeved on the bobbin shaft; the upper end of the guide column is connected with a fixed frame and the fixed frame is connected with an upper threading device; and the middle part of the guide column is connected with a guide column threading device and a lower threading device is connected with the lower part of the guide column. The large-capacity super-spun-yarn cursory spindle of the high speed machine, disclosed by the invention, has the advantages of large bobbin capacity, small spindle friction resistance, light paying-off, smoothness in yarn discharging and no yarn breakage in paying-off and braiding processes of super spun yarns, can run at a high speed without yarn breakage, so that raw materials are saved; the clamping cap is in a 'Y' shape, the bobbin is convenient to load and unload and the yarn exchanging time is saved; and therefore, the braiding quality and the production quality are improved.

Owner:韩百峰

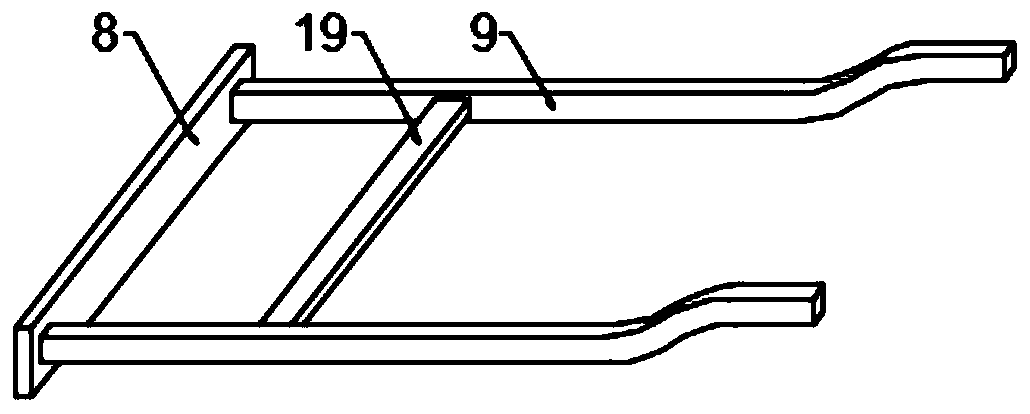

Wire discharging frame

The invention discloses a wire discharging frame. The wire discharging frame comprises a base, a body part which protrudes from the base, and a rotating part and a thread pressing rod which are arranged on the body part, wherein the rotating part and the thread pressing rod can rotate relative to the body part; a hanging rod which is integrated with the body part protrudes from the body part; the rotating part is provided with an installation rod; and at least one elastic piece is arranged at the front end of the installation rod. By using the wire discharging frame, a steel wire rod can be naturally loosened after a binding belt is opened, and due to the elastic piece, the wire rod can only be sprung one circle by one circle, so that the phenomenon that a plurality of circles are twisted is avoided, and a wire can be discharged smoothly.

Owner:ZHANGJIAGANG HENGCHANG WELDING MATERIALS

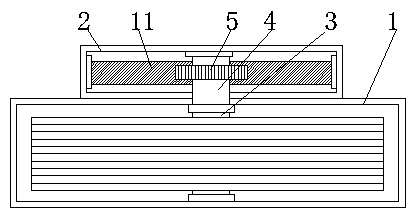

Ink fountain with convenience in line changing for building construction

ActiveCN103231358APrevent slidingEasy to put inOther workshop equipmentEngineeringMechanical engineering

The invention discloses an ink fountain with convenience in line changing for building construction, which aims to solve the problems that the line in a conventional ink fountain is complex in changing and easy to jam. The ink fountain comprises an ink fountain box formed by a lower bottom groove and an upper close cover, wherein a line wheel chamber and an ink storing chamber are arranged inside the ink fountain box; a line wheel rocking handle shaft with a polygonal radial section is movably mounted in the line wheel chamber; a line wheel shaft penetrates and is coaxial with the line wheel rocking handle shaft; a plurality of line wheel blades are mounted along the circumference of the line wheel shaft; a ink line is wound on the plurality of blades; and one end of the ink line penetrates out of the ink storing chamber after being wound on the blades. According to the ink fountain provided by the invention, the ink fountain box of the ink fountain is formed by the lower bottom groove and the upper close cover, during line changing, a box body is opened to change the line directly; the line wheel rocking handle shaft is non-cylindrical, so as to avoid relative sliding between the line wheel rocking handle shaft and the line wheel shaft during processes of line releasing or line winding; and meanwhile, line fastening holes, which are formed in the line wheel blades, facilitate penetration of the ink line, so that the phenomenon that the line winding is messed to form a mixed ball is avoided.

Owner:SHAANXI COAL & CHEM CONSTR GRP CO LTD

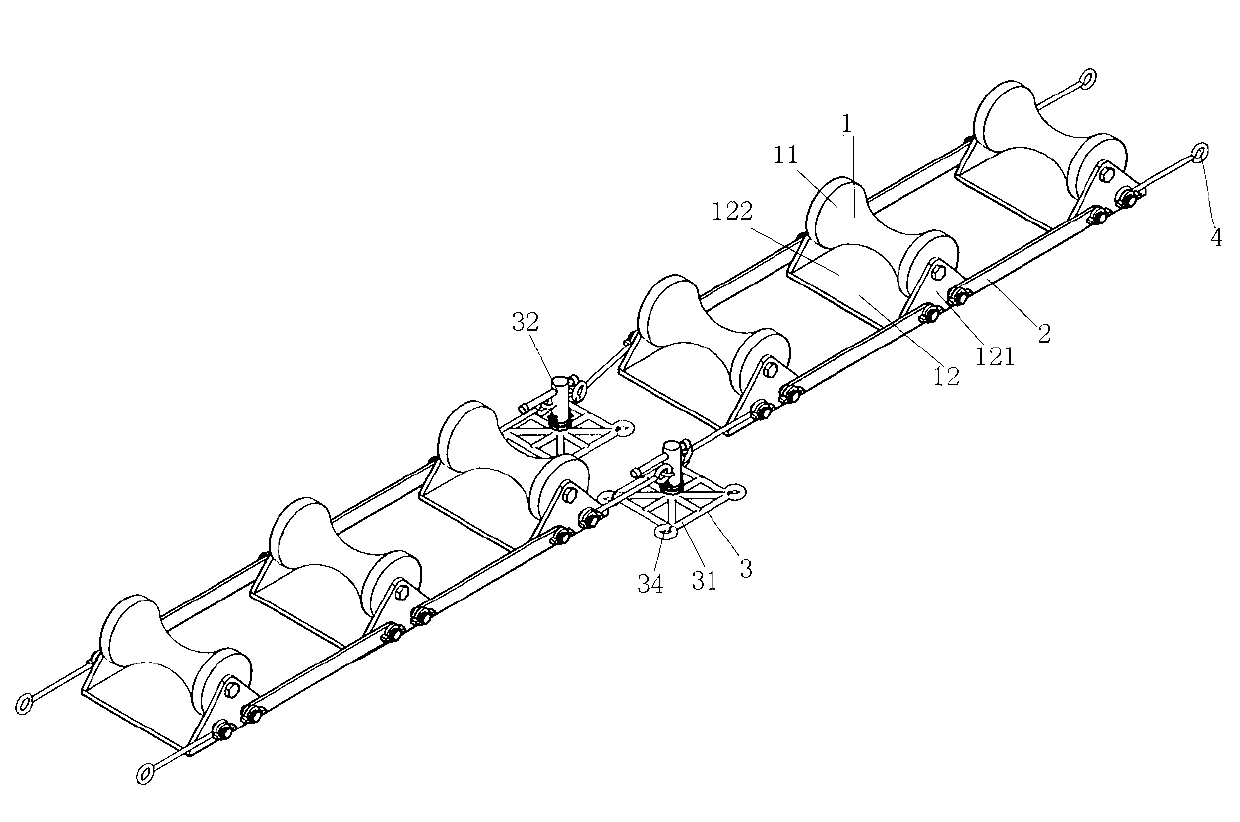

Connection row pulley for large-section cable paying off

ActiveCN103138207AIncreased load-bearing capacityPrevent rollingApparatus for laying cablesTraveling blockSteel rope

The invention relates to a connection row pulley for large-section cable paying off. The connection row pulley comprises a plurality of single pulley bodies, adjacent single pulley bodies are connected through pulley fixing boards, the single pulley bodies at the head end and the tail end are respectively connected with a steel rope sleeve, each single pulley body comprises a pulley wheel and a supporting iron board, each supporting iron board is composed of two triangular side boards and a rectangular bottom board, and the side boards are connected with the pulley wheels through bolts. According to the connection row pulley, the plurality of single pulley bodies are connected through the pulley fixing boards in series, the length of each connection row pulley can achieve 10-20 meters, and rolling and malposition of each single pulley body are avoided. Contacting areas of the pulley wheels and cables are greatly enlarged, a paying off process is smooth, the pulley fixing boards are made of steel, bearing performance of the connection row pulley is increased, the pulley fixing boards are connected with the single pulley bodies through the bolts, and installation, disassembly and conveying are convenient and rapid.

Owner:LIAOYANG POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Adjustable pay-off rack

InactiveCN106743977AAvoid damageGuaranteed mechanical strengthFilament handlingSocial benefitsEconomic benefits

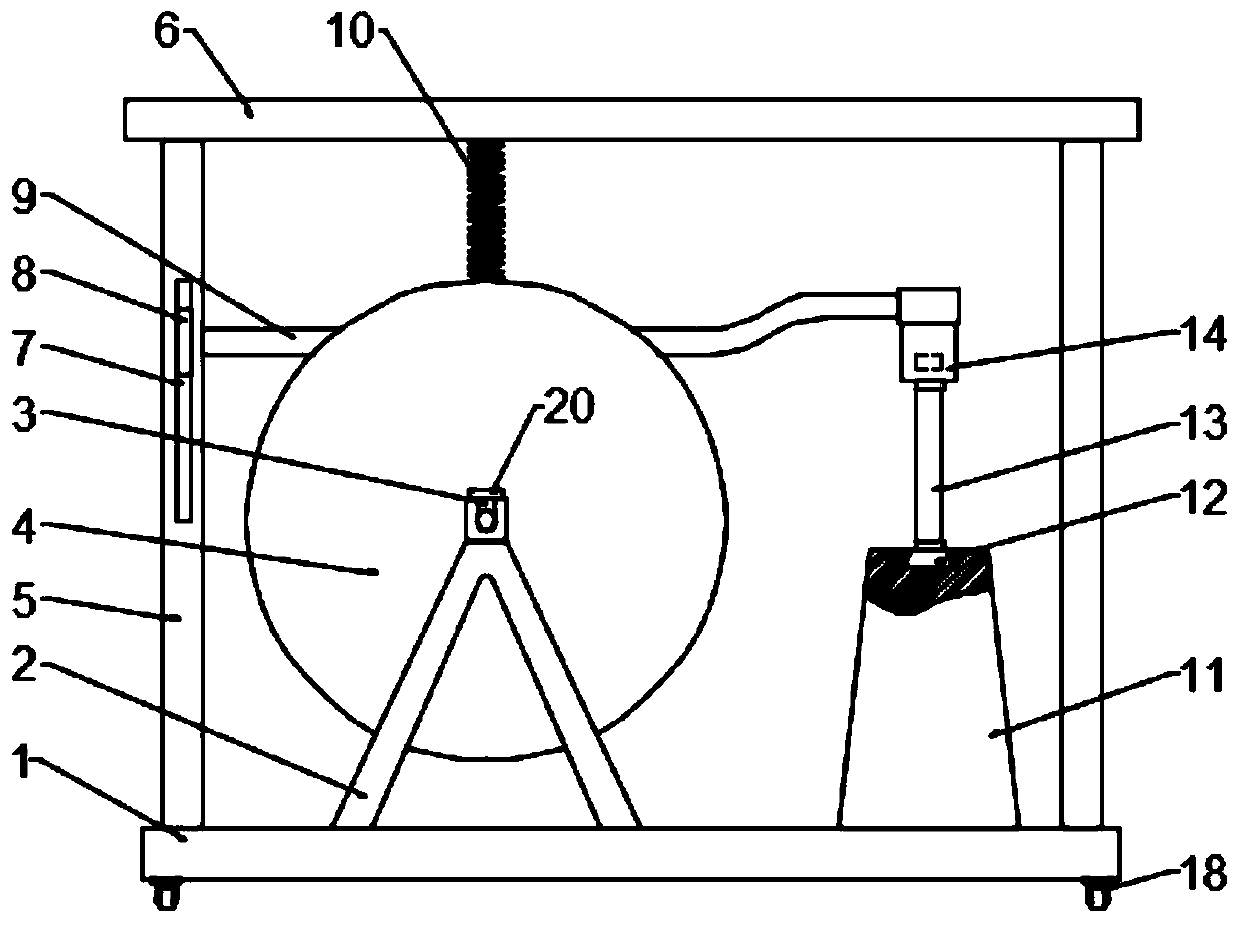

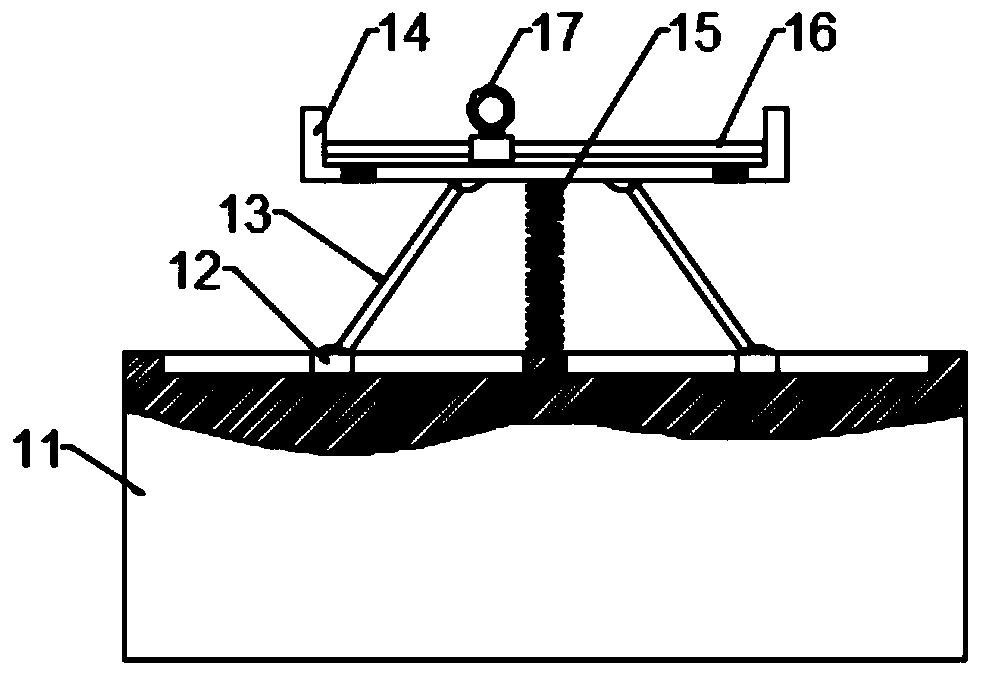

The invention provides an adjustable pay-off rack, and relates to the technical field of cable construction. The adjustable pay-off rack comprises a base, a shaft base, a supporting shaft and one or more pay-off discs arranged on the supporting shaft. Each pay-off disc comprises two circular wire discs with center holes and studs. The supporting shaft penetrates the center holes. Each circular wire disc is provided with three or more long slotted holes or three or more rows of holes. A plurality of circular holes correspond to each row of holes. The long slotted holes or the holes in each row are evenly distributed in the circumference direction and arranged in the radial direction of the corresponding circular wire disc. The studs penetrate the long slotted holes or the circular holes corresponding to the two circular wire discs, and the two ends of each stud are locked through nuts. The adjustable pay-off rack is easy to operate and is suitable for various specifications of wire rolls with axis holes different in size. An operator can move and use the adjustable pay-off rack conveniently in the operation process, pay-off operation is smooth, damage caused by small circle forming in the pay-off process is avoided, mechanical strength and electric conduction performance of wires are guaranteed, the pay-off operation difficulty is lowered, the work efficiency of the operator is improved, and good social benefits and economic benefits are achieved.

Owner:国网河北省电力有限公司宁晋县供电分公司

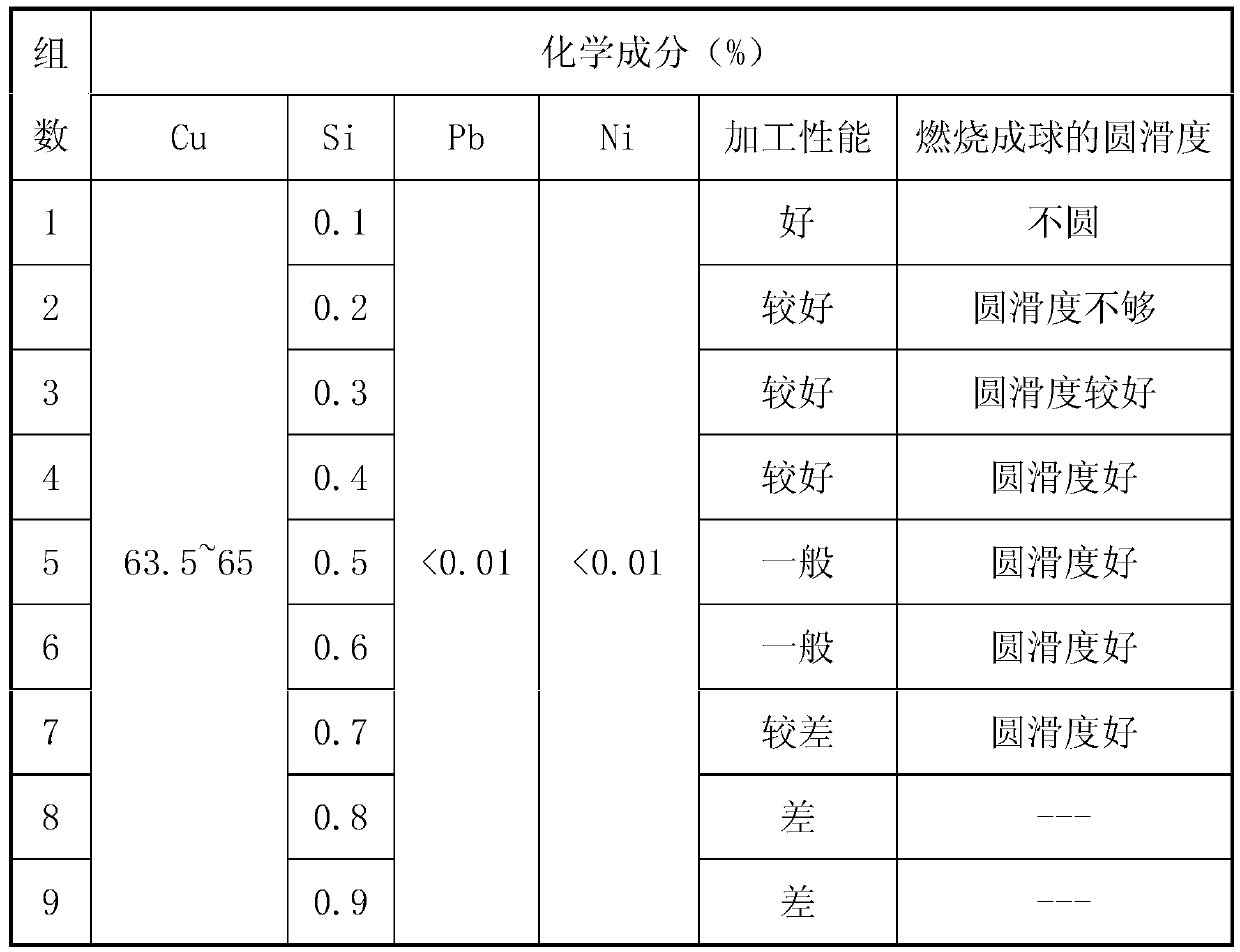

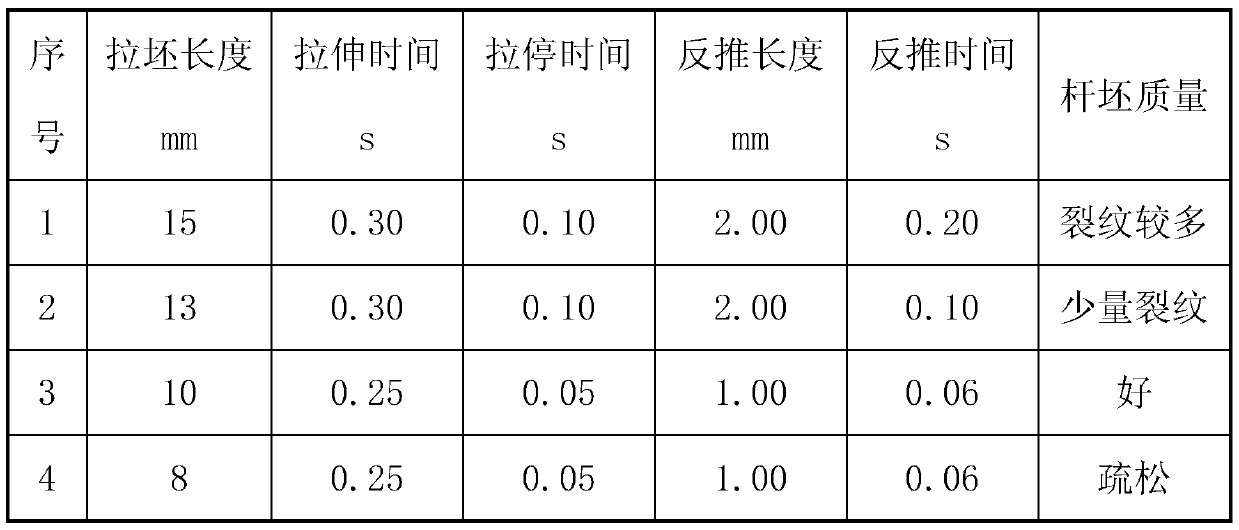

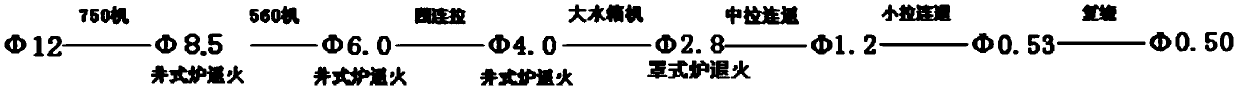

A kind of brass wire rod and the processing method of described brass wire rod

The invention provides a brass wire applied to the technical field of production and processing of wires. The invention simultaneously relates to a processing method of the brass wire. The brass wire comprises the following components: Cu, Sn, Si and Zn, wherein the Cu element accounts for 63.5%-65% by weight, the Sn element accounts for 0.8-1.2% by weight, the Si element accounts for 0.10-0.50% by weight, and the balance is the Zn. In the brass wire and the processing method, provided by the invention, the mechanical performance value of the brass wire is controlled at 650-750MPa, a sphere formed by combustion is smooth and full, the problem of brittle failure caused by over-hard performance can be avoided, and the brass wire can not be processed into a ball needle due to the influence of relatively soft performance. When the brass wire is formed, a rewinding machine is adopted for taking up, and the diameter degree is good; and when the brass wire is machined by a customer, the paying-off is smooth, the wire wrapping phenomenon can be avoided, and the brass wire can completely meet the requirements of jewelry processed from the brass wires in jewelry industry.

Owner:安徽鑫科铜业有限公司

Low-friction seal mechanical lubricating oil

InactiveCN103710091AImprove general performanceImprove solubilityLubricant compositionSolubilityThio-

The invention discloses a kind of low-friction seal mechanical lubricating oil. The lubricating oil is characterized by comprising the following materials, by weight, 5-18 parts of n-pentane, 0.05-0.7 parts of polyurethane, 3-7 parts of sodium citrate, 11-29 parts of oleic acid, 1-15 parts of acetophenone, 0.5-2 parts of hydrophobic silicon oxide, 1-4 parts of thio-alkyl amino calcium phosphate, 1-4 parts of sorbic furfuryl alcohol anhydride monooleate, 0.01-1 part of phosphate esters and ammonium salt derivatives thereof, 0.1-0.7 part of imidazoline, 10-25 parts of benzyl alcohol and 45-79 parts of petroleum ether. The beneficial effects of the lubricating oil are that, the lubricating oil has strong versatility, and good dissolvability; the ready mixed lubricating oil has a uniform concentration; no deposition and precipitation are generated after storage for a long time, the effects are good, and after the liquid components are volatilized, there are no visible residues; the lubricating oil has no destructive effects on insulation; the coating of the lubricating oil is uniform, the friction coefficient is small, and the cost is low.

Owner:QINGDAO HUIERTONG TRADING

Stable yarn frame for spinning

The invention relates to a stable yarn frame for spinning. The stable yarn frame comprises a tabular base and a plurality of yarn uprights. The sequentially arrayed yarn uprights are vertically arranged on the base and are used for sleeving yarn bobbins. Each yarn bobbin is in the shape of a circular truncated cone with big end down. The bottom of each yarn bobbin has a bare portion with a certain height. The stable yarn frame is characterized in that grooves are formed in positions, corresponding to the yarn uprights, of the base; the uprights are arranged in the corresponding grooves of the base; the diameter of each cylindrical groove is larger than the outer diameter of the bottom of each yarn bobbin. Through the grooves, good limiting and protecting effects to the yarn bobbins jumping in a certain height range during rotating are achieved, and the situation that the yarn bobbins fly from the yarn uprights directly due to high-speed rotation is avoided; the grooves are easy to process, increased cost is low, and influences on normal mounting and demounting of the yarn bobbins are not caused.

Owner:WUJIANG JIUMEI MICROFIBER WEAVING

Pay-off equipment for power cable laying

The invention discloses pay-off equipment for power cable laying, and relates to pay-off equipment. The pay-off equipment comprises fixed bottom plate, the left side above the fixed bottom plate is fixedly connected with a bobbin connecting bracket; a groove is formed in the top of the bobbin connecting bracket; a cable shaft is rotationally placed on the inner side of the groove; stand columns are fixedly connected to the upper portion of the fixed bottom plate in a bilateral symmetry mode. An upper beam is fixedly connected to the top of the stand column, a limiting sliding groove is formedin the left stand column, a limiting sliding plate is slidably connected into the limiting sliding groove, adjusting rods are fixedly connected to the right side of the limiting sliding plate in a front-back symmetrical mode and matched with cables on the cable shaft, and a first spring is fixedly connected to the upper beam. The cable pay-off equipment is simple in structure and convenient to use, the adjusting rods are pressed through the first spring, so that a limiting ring on a sliding support is always kept at the same height as the cable through the adjusting rods in the pay-off process, the situation that the cable is wound in the pay-off process is avoided, and the whole equipment is smooth in pay-off and high in efficiency.

Owner:魏洋洋

Pay-off mechanism for electric power construction

ActiveCN111917064AThe unwinding process is smoothNot easy to get stuckArrangements using take-up reel/drumApparatus for overhead lines/cablesEngineeringStructural engineering

The invention discloses a pay-off mechanism for electric power construction, and provides the following scheme for solving the problems that an existing pay-off mechanism for electric power construction is prone to being jammed due to changes of the position of a cable end when a cable is drawn out, pay-off efficiency is reduced, and the sheath of the cable is abraded when jamming is caused, and the pay-off mechanism comprises a wire coil, universal wheels, an inclined plate, a base and a movable plate. A first supporting rod and a second supporting rod are connected to the outer wall of one side of the base through bearings, one end of the first supporting rod penetrates through the outer wall of one side of the base to be sleeved with a crawler belt, and a first rotating shaft is connected to the top of the outer wall of one side of the base through a bearing. Sliding strips are bonded to the outer walls of the first rotating shaft and the second rotating shaft, and the small wire feeding wheel and the large wire feeding wheel can slide on the outer walls of the first rotating shaft and the second rotating shaft through the sliding strips, so the small wire feeding wheel and thelarge wire feeding wheel can transversely move along with the positions of wire ends when cables are drawn out, the pay-off process is smooth and not prone to blockage, and cable skin abrasion is avoided, and the cable is protected.

Owner:国网安徽省电力有限公司怀远县供电公司

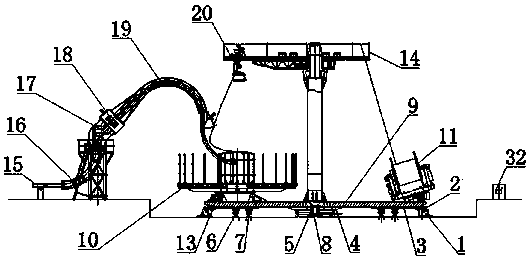

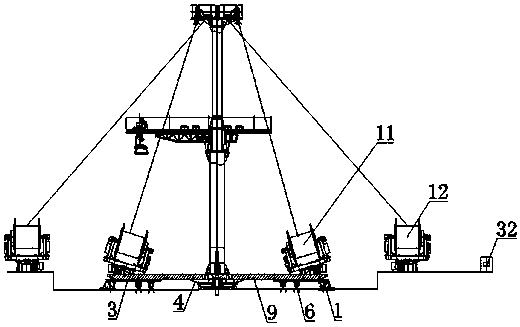

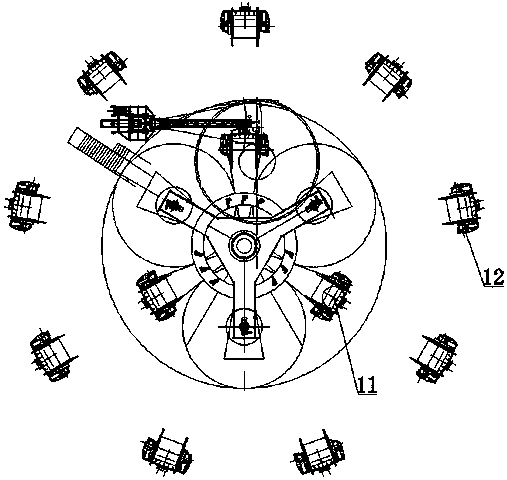

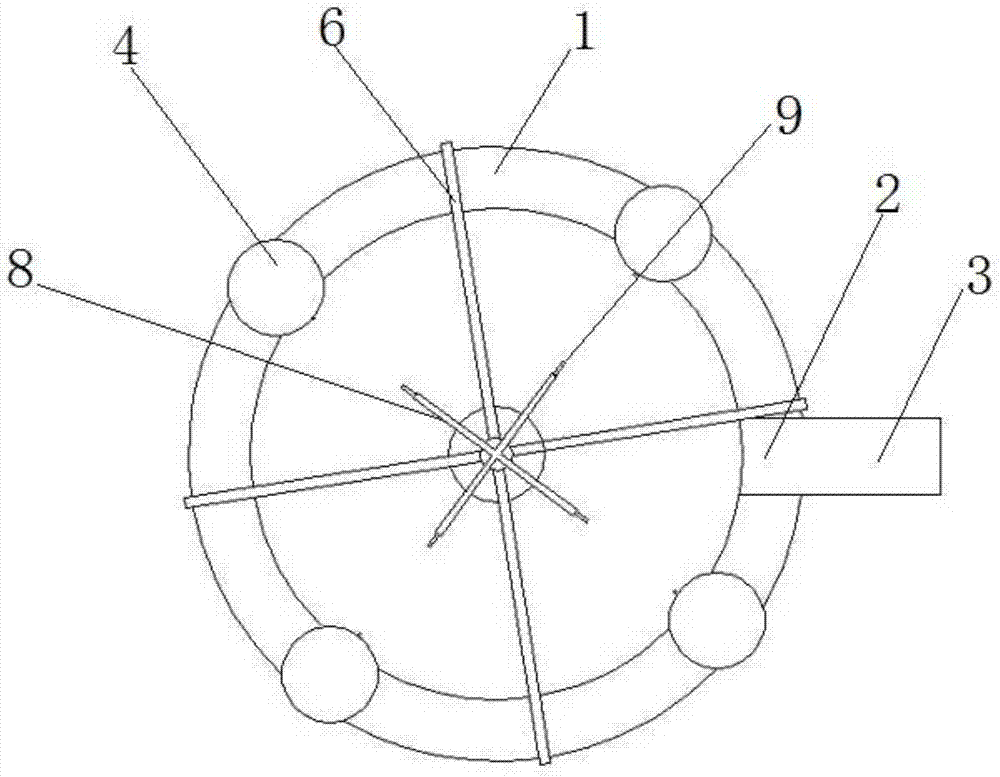

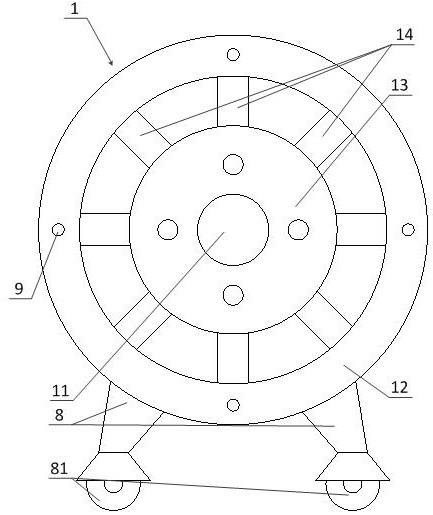

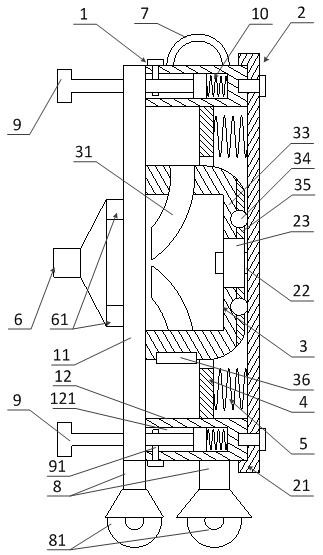

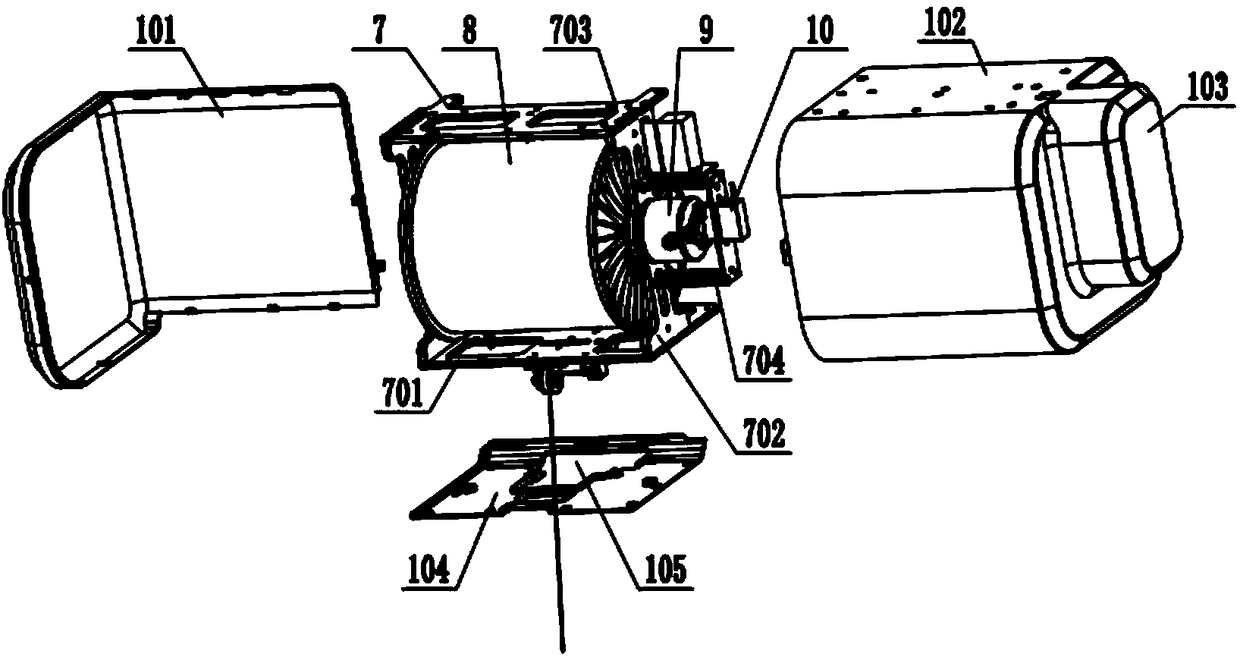

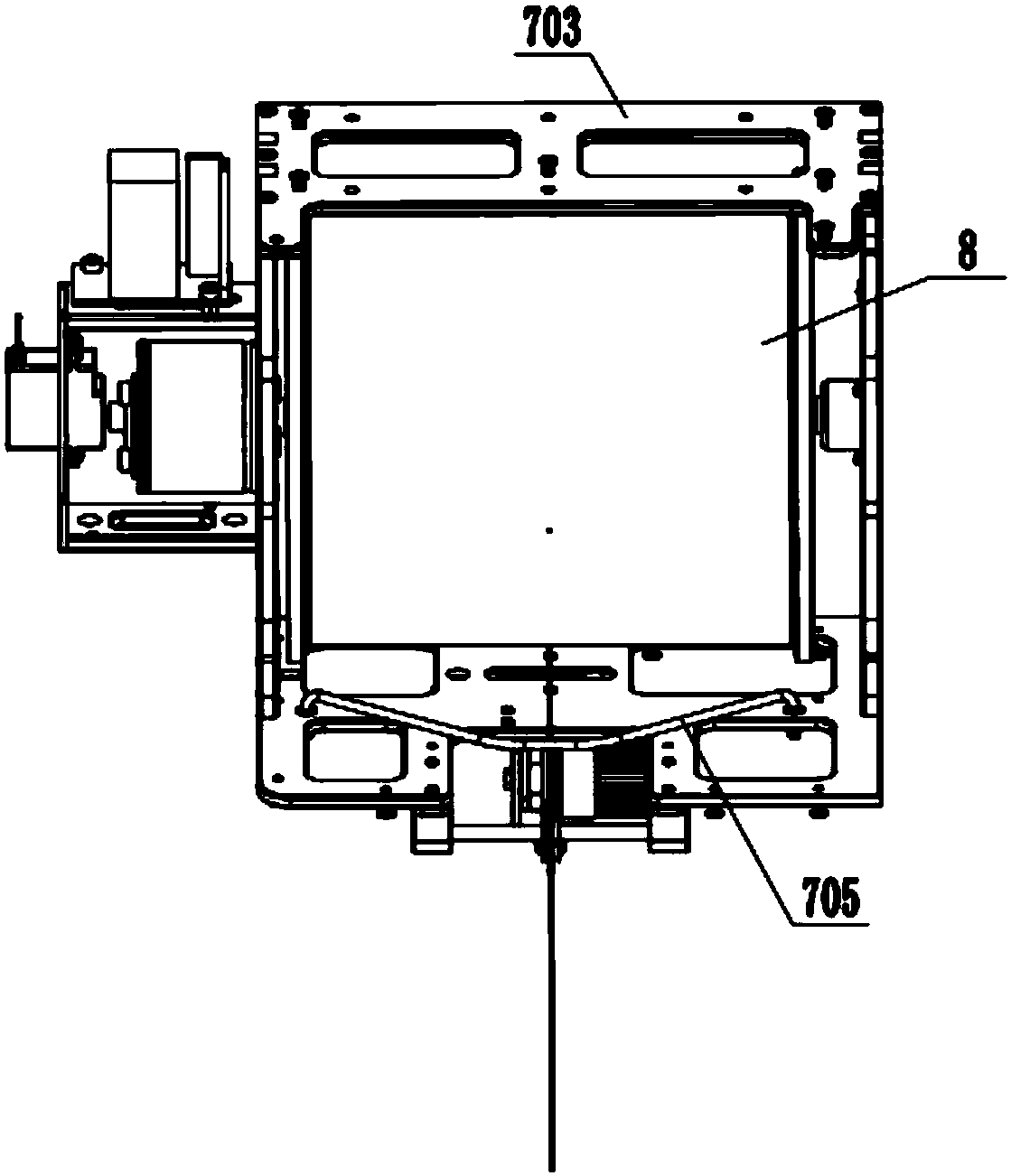

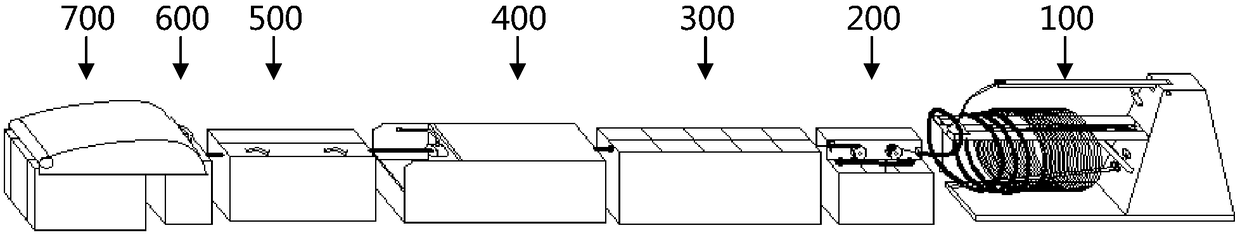

A multifunctional vertical twisting and twisting machine

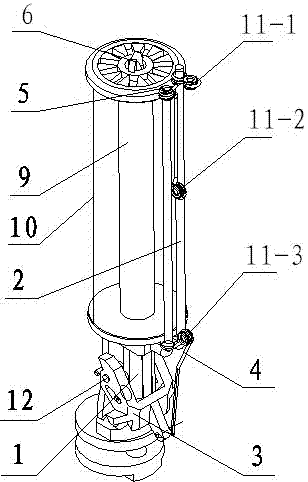

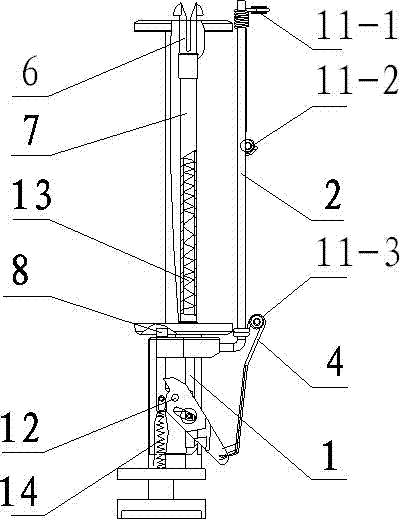

ActiveCN105139966BImprove boot utilizationLow input costCable/conductor manufactureCable machineEngineering

Owner:万达集团股份有限公司 +1

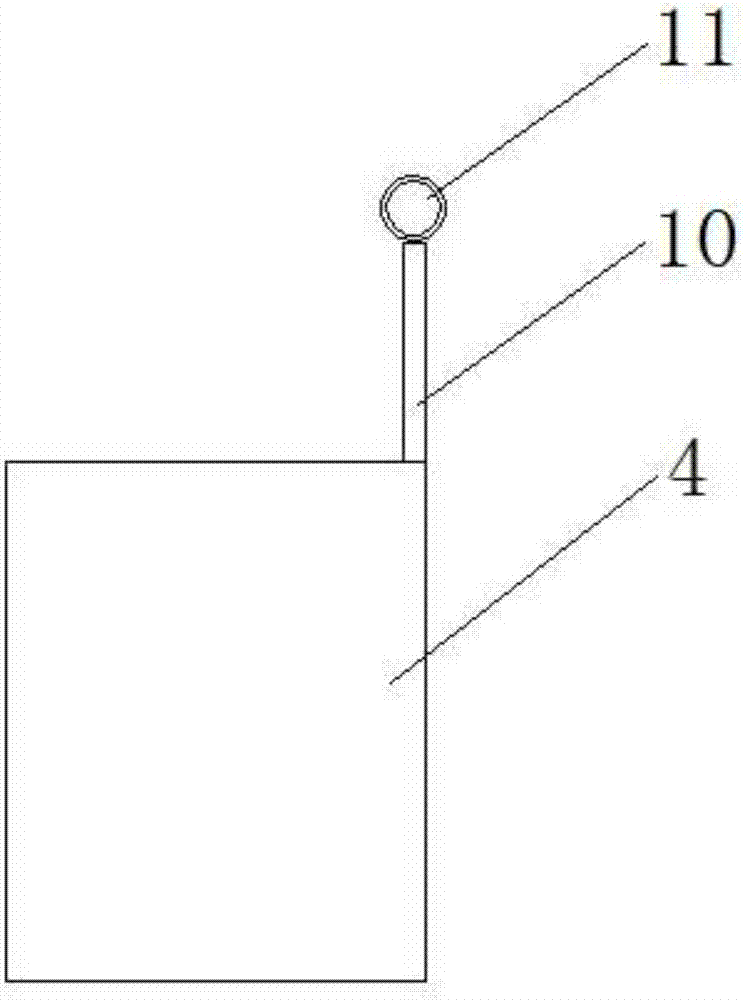

Copper wire releasing device capable of quickly replacing wire barrels

The invention discloses a copper wire pay-off device capable of quickly replacing a wire barrel, which comprises an annular slide rail, a gap, an inlet track, a wire barrel, a turntable, a lever, a first support rod, a horizontal bar, and a first wire passing collar , the second pole and the second wire passing collar, the annular slide rail is provided with a plurality of wire barrels, the edge of the annular slide rail is provided with a gap, the gap is provided with an inlet track, and the annular slide rail A turntable is arranged in the center of the rail, and a first vertical support rod is arranged on the turntable, at least one cross bar is arranged at the top of the first support rod, and first wire passing collars are provided at both ends of the cross bar , the side wall of the first pole is provided with at least one driving rod, the length of the driving rod is greater than the radius of the circular slide rail, and the top of the edge of the line barrel is provided with a vertical second pole, the second The top of the pole is provided with a second wire passing collar. The invention has the advantages of simple structure, convenient use, fast pay-off speed, smooth pay-off and convenient replacement of the wire barrel.

Owner:蒙玛特(天津)铜业有限公司

High-safety-performance steel strand paying-off device for construction

The invention provides a high-safety-performance steel strand paying-off device for construction. The steel strand paying-off device comprises a hollow shell body, a cover plate, and a rotating drum;the hollow shell body is open at one end, and a paying-off hole is formed in the sealed end; the cover plate is connected with the open end of the hollow shell body in a detachable mode so a hollow cavity is defined by the cover plate and the hollow shell body; the rotating drum is arranged inside the hollow cavity so a steel strand is wound on the outer wall of the rotating drum; two ends of therotating drum are respectively connected with the hollow shell body and the cover plate in a rotatable mode; an arc-shaped pipe is arranged on the rotating drum and penetrates through the rotating drum; and the arc-shaped pipe communicates with the paying-off hole. Support for the steel strand is realized by the rotating drum, the steel strand is wound on the rotating drum, and constraining forceof the steel strand can be released in advance on the rotating drum, so safety in the paying-off process of the steel strand is guaranteed and the steel strand is prevented from catapulting and injuring a person; the situation that no intertwining or knotting is caused in the paying-off process of the steel strand can be ensured, and paying off is convenient; and smooth paying-off of the steel strand can be ensured and the steel strand can be prevented from being exposed to rain and becoming rusty.

Owner:CHINA MCC 2 GRP CO LTD

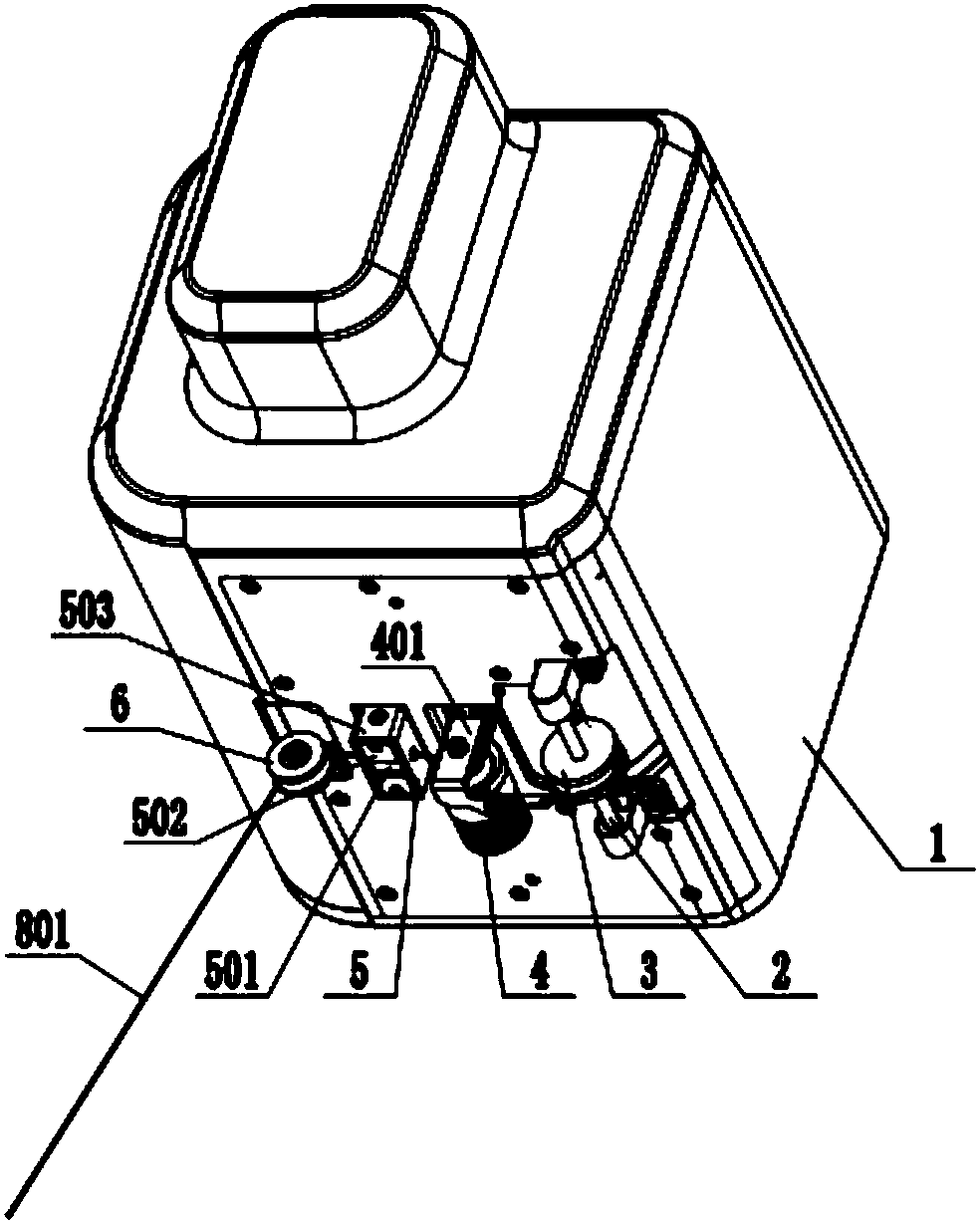

Automatic wire stringing and breaking device for a UAV (unmanned aerial vehicle)

PendingCN108233260AAvoid long-hanging situations on treesQuality assuranceApparatus for cutting/splicing cablesApparatus for overhead lines/cablesWire rodElectricity

The invention discloses an automatic wire stringing and breaking device for a UAV (unmanned aerial vehicle), and relates to the technical field of wire stringing of an electric power system. The device comprises data radios, the UAV and a wire wheel, wherein the data radios are wirelessly connected with the UAV; the wire wheel is mounted on a wire wheel support frame, a damper and a steering gearare arranged on the wire wheel support frame, and the damper is connected with the wire wheel and the steering gear; a casing is arranged on the outer side of the wire wheel support frame, the upper end of the casing is connected with the center of the bottom of the UAV, and the upper side and the lower side of the casing are connected with the wire wheel support frame; a wire rod, an electronic keyhole wire clamping device, a wire breaking device and a wire passing pulley II are arranged in the middle of the lower end of the wire wheel support frame sequentially and are arranged on the outerside of the casing; a wire passing pulley I is arranged on the wire rod, and the wire passing pulley I, the electronic keyhole wire clamping device, the wire breaking device and the wire passing pulley II are connected sequentially through a wire on the wire wheel; the UAV is electrically connected with the steering gear and the wire breaking device.

Owner:SHANDONG ELECTRIC POWER TRANSMISSION & SUBSTATION ENG CO +1

Pay-off device for power construction

InactiveCN110182646ASmooth pay-offEfficient pay-off processFilament handlingEngineeringElectric power

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

Deadbeat wire-drawing production equipment

The invention discloses deadbeat wire-drawing production equipment and belongs to the technical field of steel wire production line. The equipment of the invention comprises a wire rod pay-off device,a decorticator, a dryer, a cold-drawing machine and a wire-drawing reeling machine, which are arranged along the wire-drawing direction. The wire-drawing reeling machine and the cold-drawing machineare provided with a protective cover, the opening direction of which is opposite to the wire-drawing direction. The protective cover is arranged over the wire-drawing reeling machine and the cold-drawing machine. One side of the protective cover is sleeved with a hinge installed on the wire-drawing reeling machine, and the other side of the protective cover is a free end. By the wire rod pay-off device, a wire rod can be naturally loosened after the wrapping tape is opened, and the wire rod can be limited to be loosened round and round. Thus, multi-turn winding and knotting are avoided, smoothpay-off is ensured, and the wire rod pay-off device is safe and reliable to use. The protective cover is sleeved through the hinge and is detachably arranged on the equipment. The whole protective cover can be detached and then suspended away by a travelling crane or a crane. Equipment damage will be avoided, and consumption of spare parts is lowered.

Owner:MAANSHAN FASTEN SCI & TECH CO LTD

Rope feeding device for ship

InactiveCN111268028ARealize pay-offAchieve normal workWaterborne vesselsMarine engineeringGear wheel

The invention provides a rope feeding device for a ship, which comprises a rope box, wherein a control box is mounted on the surface of the rope box, a rotating shaft rod is movably connected in the rope box, the top of the rotating shaft rod penetrates through the rope box and extends into the control box, a rotating shaft is connected to the top of the rotating shaft rod, the top of the rotatingshaft is movably connected with the top of an inner cavity of the control box through a bearing pedestal, and a rotating gear is mounted on the surface of the rotating shaft. According to the rope feeding device for the ship, worms on the two sides are driven by a driving motor to rotate, two threaded rods are enabled to rotate along with the worms, a rotary gear is driven to rotate, the rotatingshaft rod can rotate clockwise or anticlockwise, the pay-off or take-up work of a thick rope is achieved, the operation is simple, the thick rope is prevented from being wound disorderly in the pay-off or take-up process through the arrangement of a groove, the thick rope is enabled to be paid off or taken up orderly, the thick rope is enabled to be paid off or taken up stably through the arrangement of a limiting device, the thick rope is prevented from being knotted, the operation is simple, the use is convenient, and the thick rope is enabled to be arranged orderly.

Owner:刘海涛

Copper wire unwinding device with buffering function

The invention discloses a copper wire unwinding device with a buffering function. The copper wire unwinding device comprises a bracket used for mounting a wire roll and promoting the wire roll to unwound a wire, wherein a positioning shaft capable of being disassembled is arranged on the bracket, the wire roll is movably mounted on the bracket through being arranged on the positioning shaft in a sleeving manner, a cross beam parallel with the positioning shaft is further fixed to the bracket, the cross beam is positioned above the wire roll, a moving wheel capable of moving along the cross beam is arranged on the cross beam in a sleeving manner, and one circle of sliding groove for guiding the wire on the wire roll is formed in the radial direction of the moving wheel. The copper wire unwinding device has the advantages that the cross beam parallel with the positioning shaft is fixed to the bracket, the moving wheel is adopted on the cross beam, the wire is unwound through the sliding groove of the moving wheel, buffering can be provided for the wire roll, and the wire of the wire roll is smoothly and sequentially unwound.

Owner:任晓东

Pay-off device of wire drawing machine for cable production

The invention relates to the technical field of production of electric wires and cables, and particularly discloses a pay-off device of a wire drawing machine for cable production. The pay-off devicecomprises an upper pay-off reel, a lower pay-off reel and a base, wherein the upper pay-off reel and the lower pay-off reel are respectively provided with central holes corresponding to an inner holeof a pay-off barrel; a central shaft penetrates through the inner hole of the pay-off reel; the central shaft upwards penetrates out of the central hole of the upper pay-off reel; a pay-off rod is fixed at the position, above the upper pay-off reel, of the central shaft; the free end of the pay-off rod and the top of the central shaft are provided with threading rings for threading; sliding channels are formed in the barrel wall of the pay-off barrel; an upper positioning hole aligned with the top of each sliding channel is formed in the upper pay-off reel; a lower positioning hole aligned with the bottom of each sliding channel is formed in the lower pay-off reel; fixing holes aligned with the lower positioning holes are formed in the base; and positioning rods are slidably connected in the sliding channels. According to the pay-off device of the wire drawing machine for cable production, the problem that a copper wire is disordered on the pay-off barrel due to the fact that the copper wire is continuously paid off when the copper wire is broken can be solved.

Owner:CHONGQING EASTFUL ELECTRIC WIRE & CABLE CO LTD

Sewing thread spool

InactiveCN103485089AImprove securityQuick and easy slide inHand sewing toolsEngineeringSewing machine

The invention discloses a sewing thread spool. The sewing thread spool comprises a cylindrical spool body, baffle plates and a magnetic inner ring, wherein the baffle plates which are integrally formed with the spool body are arranged at the two ends of the spool body, openings in the middle parts of the two baffle plates are communicated with an inner cavity of the spool body, threading holes and grooves are formed in the baffle plates by being close to the edges, blades are arranged in the grooves, and according to the technical key points, thread inlets communicated with the threading holes are formed in the edges of the baffle plates, a partition plate is arranged in the inner cavity of the spool body, the magnetic inner ring is arranged at the opening in the middle of one baffle plate, and a space defined by the inner wall of the spool body which is close to one side of the magnetic inner ring and the partition plate serves as a needle keeping chamber. According to the sewing thread spool disclosed by the invention, a sewing thread can fast and conveniently slide into the threading holes, the spool can rotate and pay off normally on a sewing machine, and the situation that the blades are exposed to cause scratches is avoided, so that the use is safe.

Owner:WUXI X RES PROD DESIGN & RES

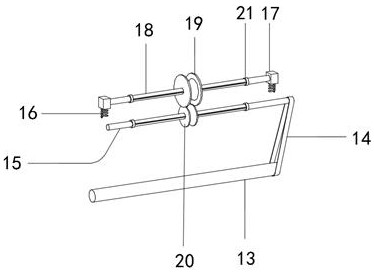

Pay-off rack of doubling machine

The invention relates to the technical field of textile equipment, in particular to a doubling machine pay-off rack which comprises a base, a bobbin fixing shaft arranged on the base and a thread guide arranged on the bobbin fixing shaft. The thread guide device comprises a thread guide frame rotationally arranged on the bobbin fixing shaft, and a first thread guide ring and a second thread guide ring which are arranged on the thread guide frame; the rotating axis of the wire guide frame coincides with the axis of the bobbin fixing shaft. The first wire guide ring is located on one side of the axis of the bobbin fixing shaft, and the second wire guide ring is located on the axis of the bobbin fixing shaft. When the pay-off rack works, the pay-off work can be completed only by pulling the yarn, and the matching degree of the pay-off speed and the subsequent doubling speed can be effectively guaranteed, so that the doubling quality is guaranteed, and the improvement of the quality of subsequent textile cloth is facilitated.

Owner:常熟市华瑞针纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com