Pay-off apparatus for superfine wires

A wire-releasing device and wire technology, applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as wire breakage, stranded wire quality and pass rate drop, breakage, etc., so that the wire-releasing process is smooth and not easy to break The effect of maintaining stable thread and pay-off tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

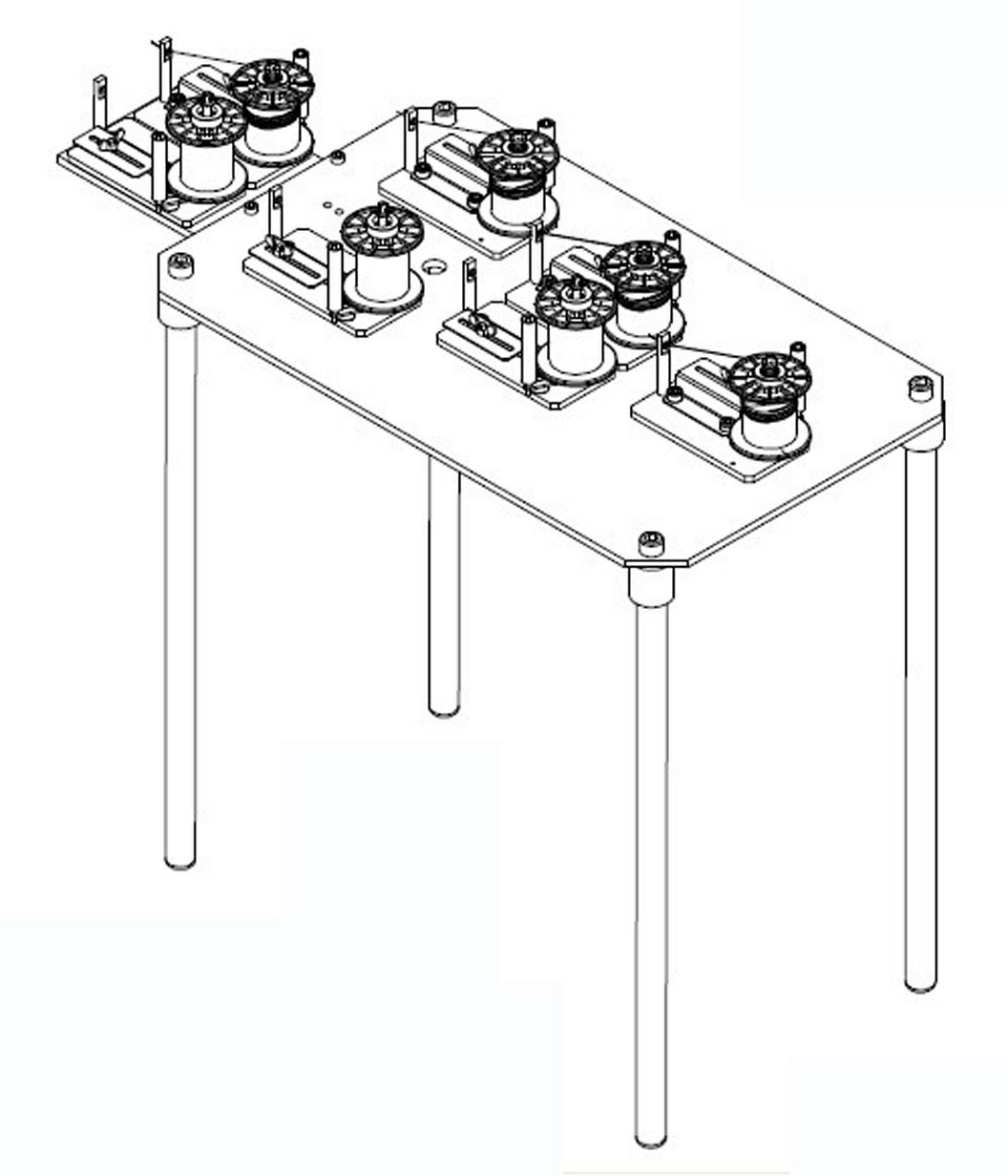

[0026] like figure 1 As shown, the pay-off device of this embodiment is used for the pay-off of ultra-fine wires, and includes seven pay-off racks; five pay-off racks are horizontally arranged on the workbench, arranged in three rows in a golden shape, and the remaining The two pay-off racks are horizontally arranged on the outer protruding surface protruding from the workbench. The number and arrangement of these pay-off racks can be arranged arbitrarily according to the needs of actual twisting, so that the twisting process is convenient and it is better not to be entangled and knotted between the lines.

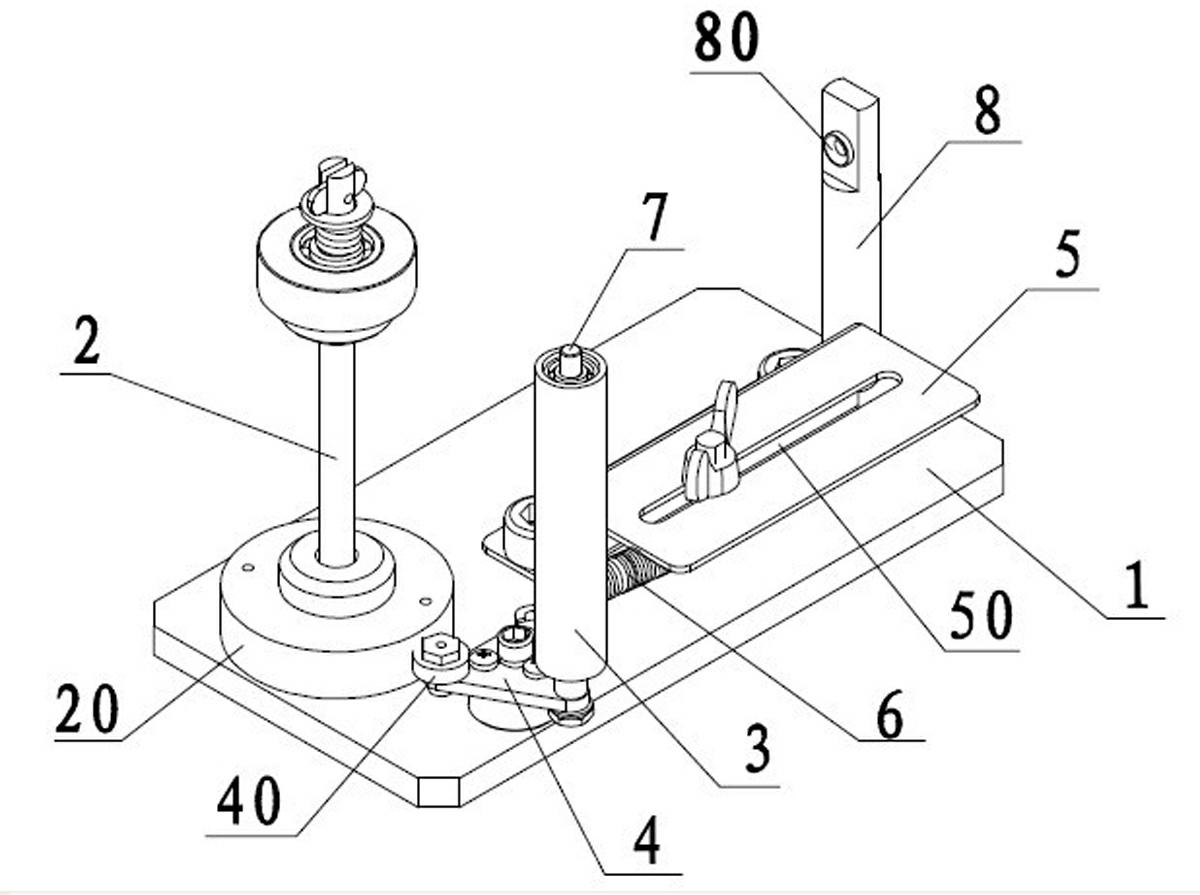

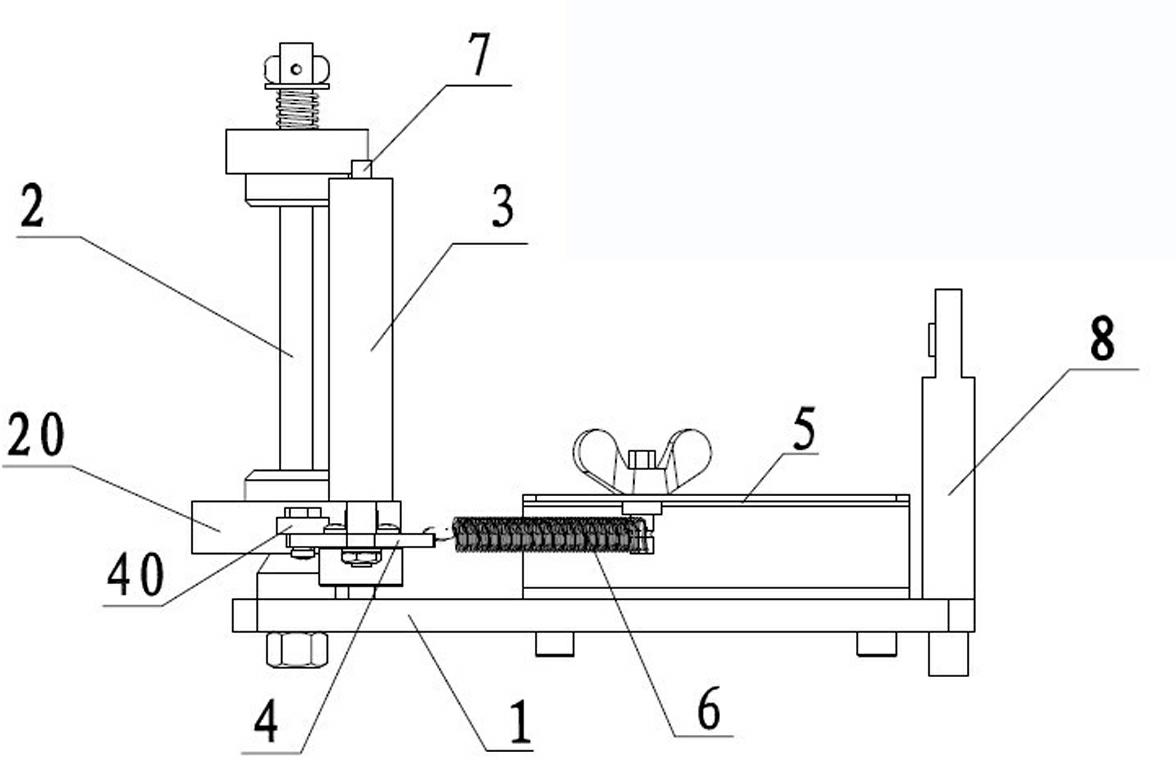

[0027] like Figure 2~5 As shown, the pay-off frame includes a base 1, which is vertically arranged at one end of the base 1, and is used to cover a pay-off main shaft 2 with a reel 9 wound with a very fine wire, and a fixed shaft 7, which is set on the fixed shaft 7, the traction guide roller 3 that is used to pull the ultra-fine wire when unwinding, the pole 8 tha...

Embodiment 2

[0032] by Figure 6 The installation of the wire reel shown and the way of paying off the wire are described as follows to the working process of the pay-off stand of embodiment 1:

[0033] Set the wire reel 9 of the ultra-fine wire on the pay-off spindle 2, and hold it by the rotating tray 20. The extension spring 6 is locked at a certain position on the guide rail 50 of the fixed plate 5 and maintains a certain tension, so that the adjustment disc 4 The friction wheel 40 is against the edge of the rotating tray 20 and gives a pressure to the rotating tray 20. Since the position of the extension spring 6 on the guide rail 50 is adjustable, the pressure of the friction wheel 40 on the rotating tray 20 is also adjustable. This pressure needs to be adjusted in advance. After testing or calculation, it is obtained to keep the tension of the ultra-fine wire at the best value when paying off, so as to balance the paying off.

[0034] When unwinding, the ultra-fine wire is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com