Steel cord corrector

A technology of steel cord and correction machine, applied in the field of correction device, can solve the problems of high cost and poor effect, and achieve the effect of convenient operation and stable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

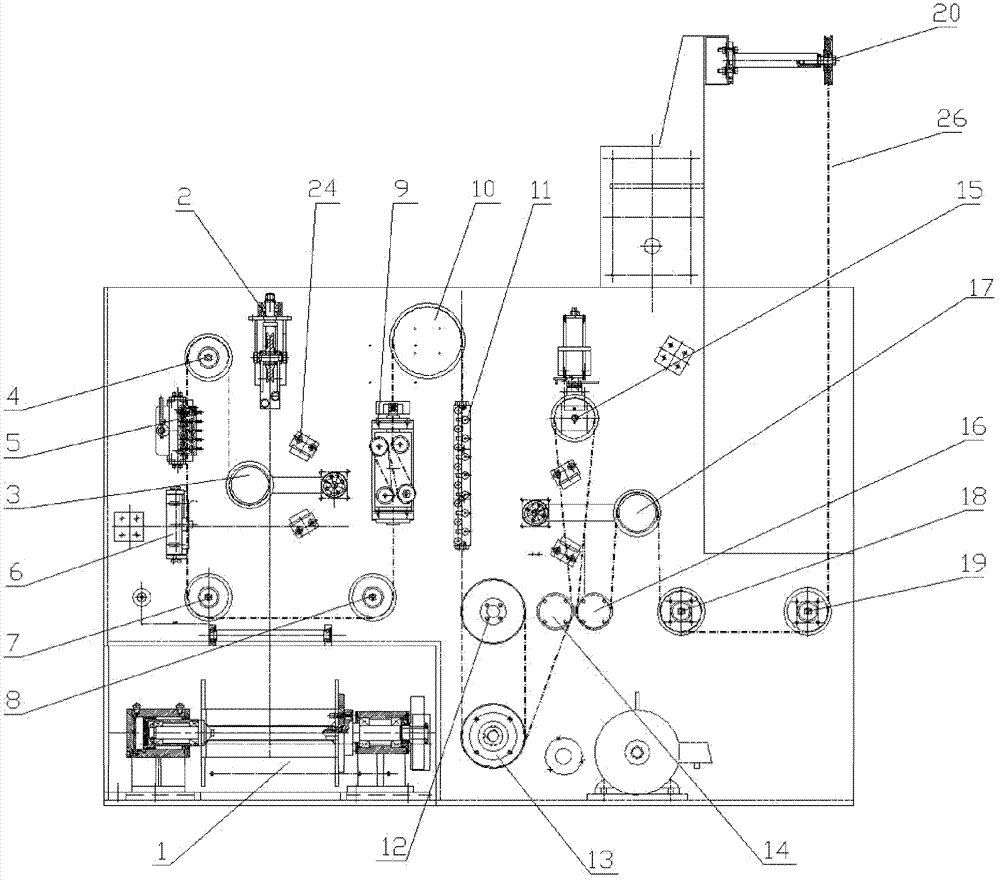

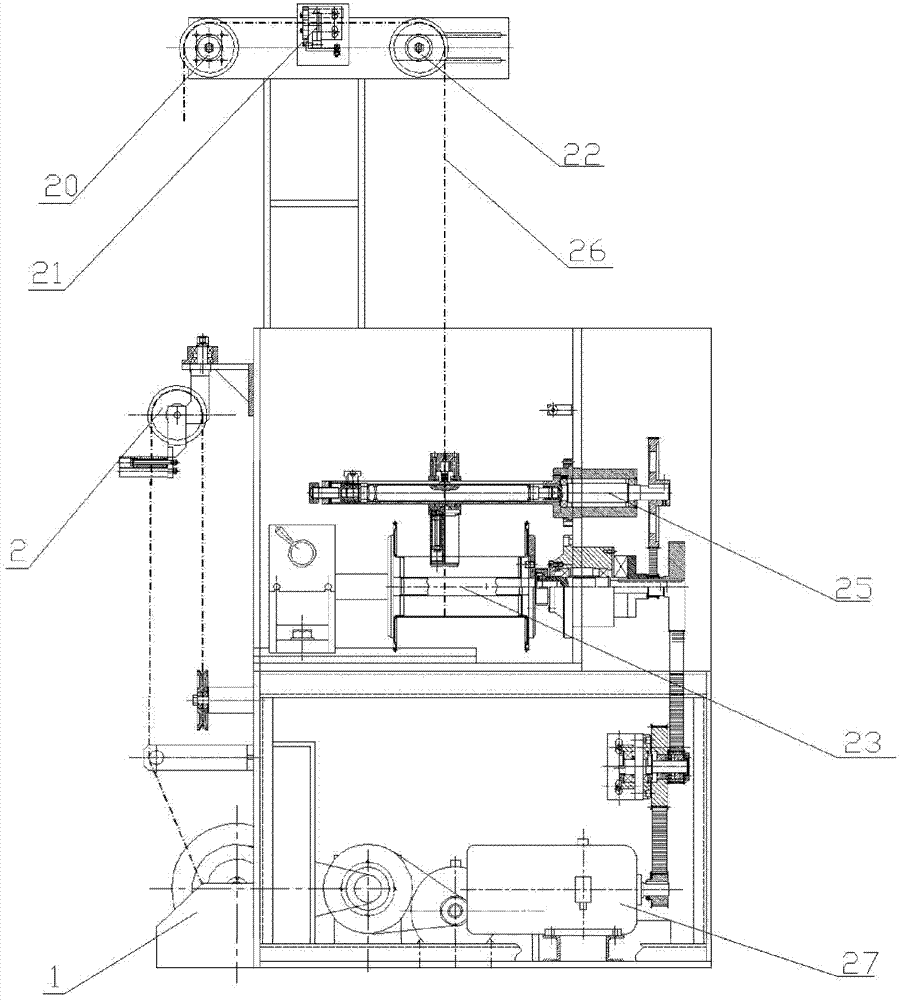

[0019] The device includes pay-off I-shaped wheel 1, wire passing wheel, pneumatic tension arm, straightener, residual torsion adjuster 9, appearance quality adjuster 11, residual torsion detector 15, door mold broken wire detector 21, wire take-up The I-shaped wheel 23 and the steel cord 26 are unwound by the pay-off I-shaped wheel 1 and pass through the wire passing wheel 1 2, and the steel cord 26 coming out of the wire passing wheel 1 2 enters the wire passing wheel 2 through the pay-off pneumatic tension arm 3 4. The steel cord 26 coming out of the wire passing wheel 2 4 sequentially passes through the straightener, the wire passing wheel 3 7, the wire passing wheel 4 8, the residual twist adjuster 9, the wire passing wheel 5 10, the appearance quality adjuster 11, Passive traction thread pulley 12, active traction thread thread pulley 13, thread thread pulley six 14, residual torsion detector 15, thread thread pulley seven 16, thread take-up pneumatic tension arm 17, thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com