Patents

Literature

38results about How to "Improve stranding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

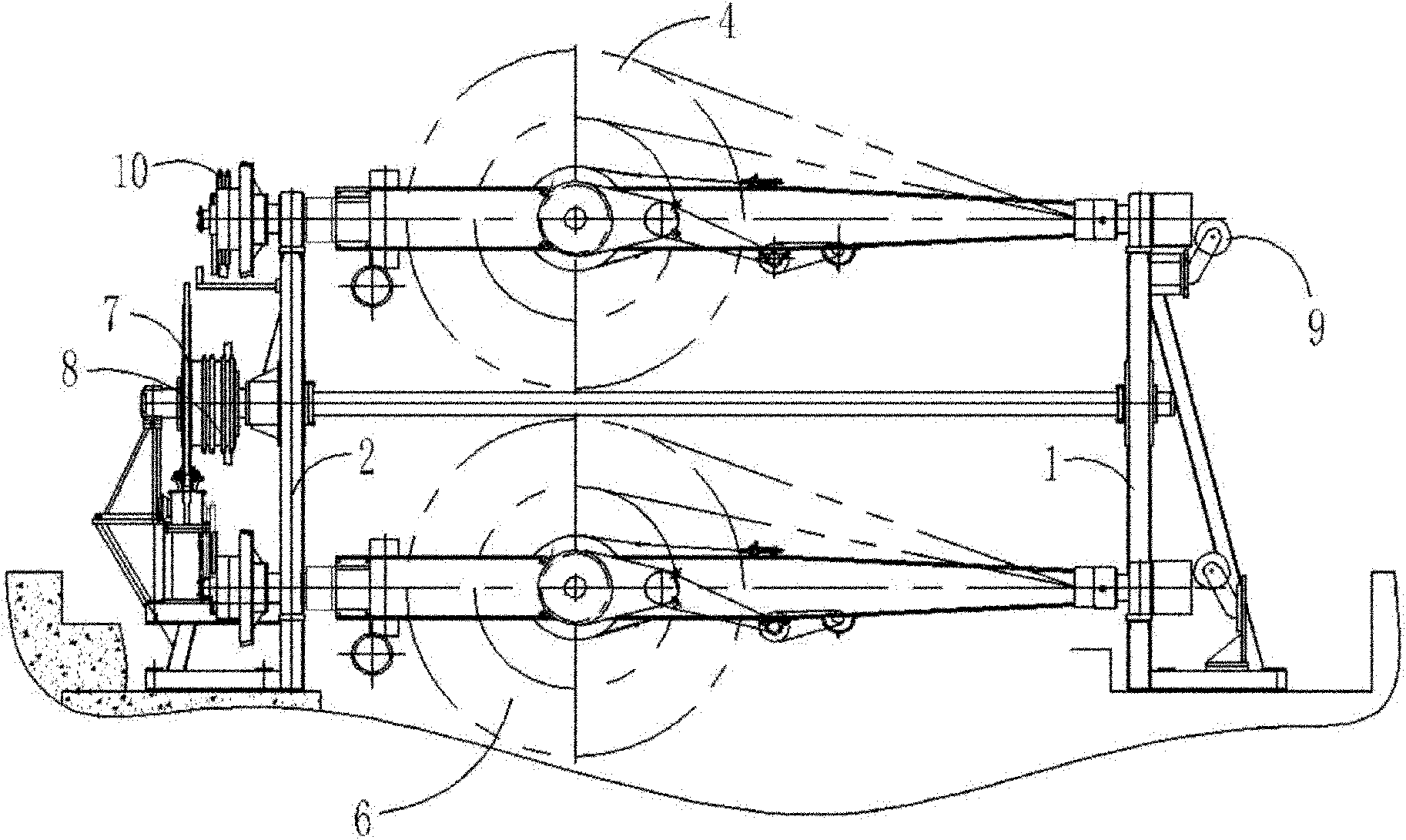

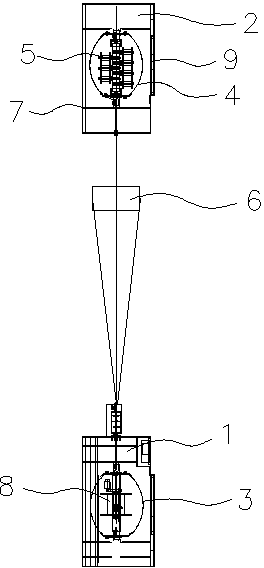

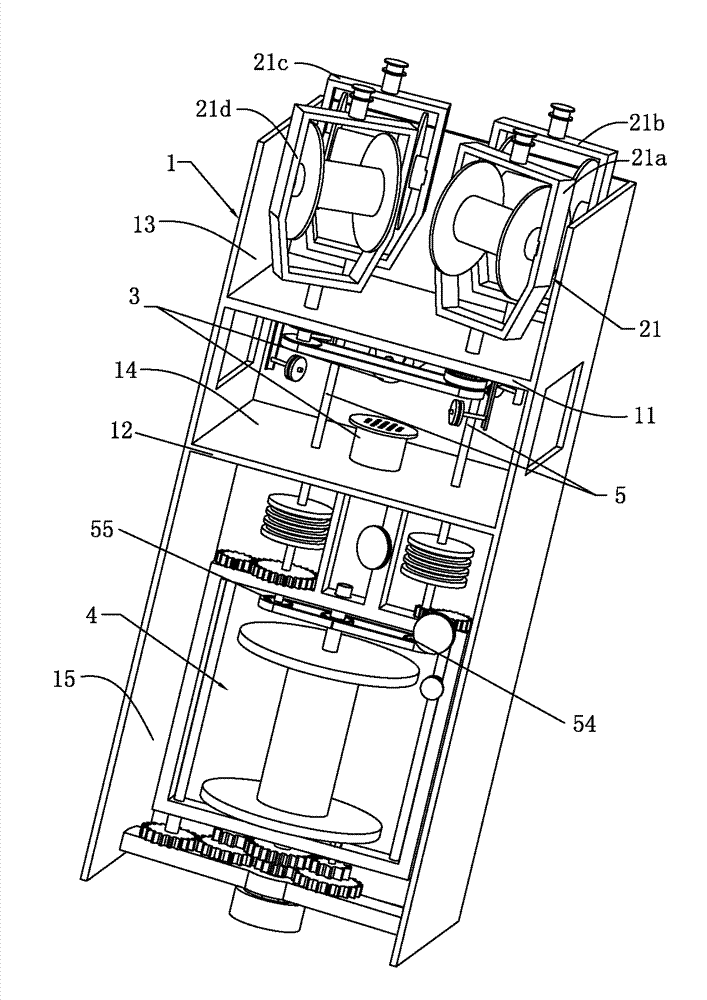

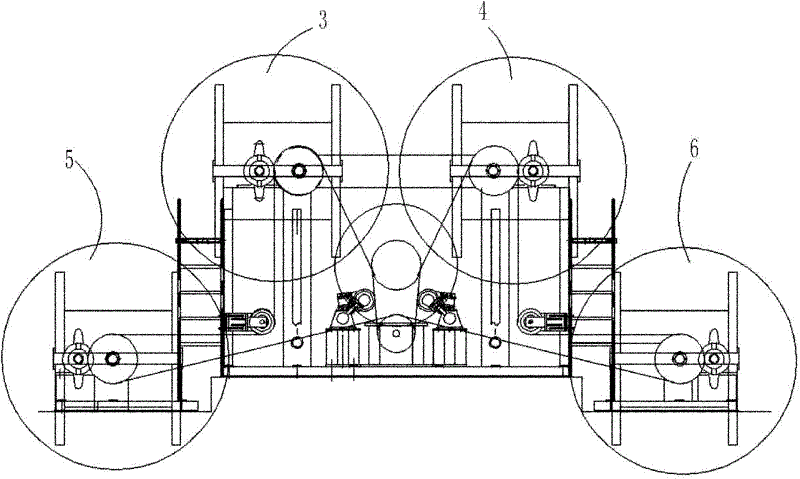

Back twist strander

ActiveCN102354583AEliminate torsional stressThere will be no jumping phenomenonCable/conductor manufactureTransmitted powerGear wheel

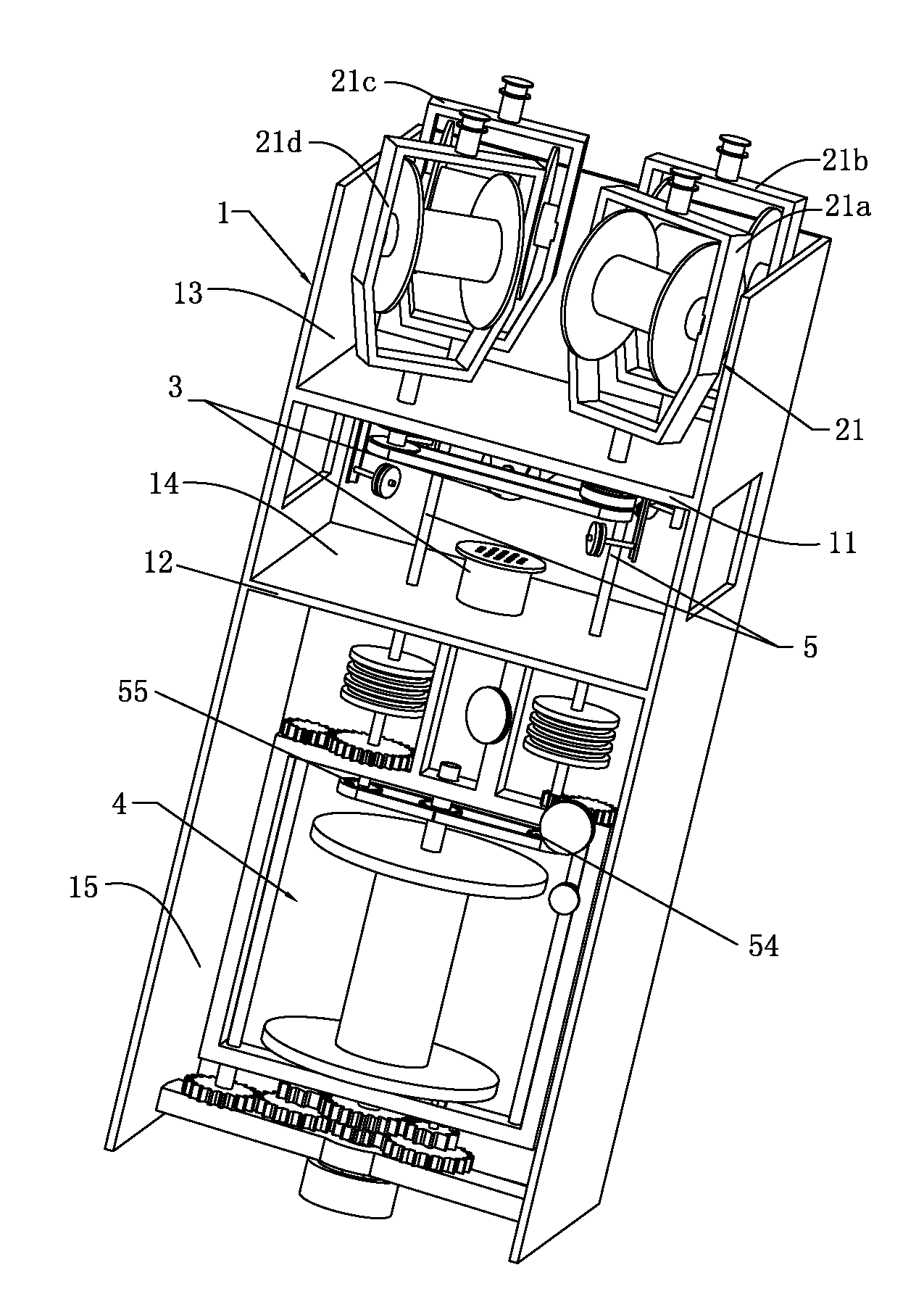

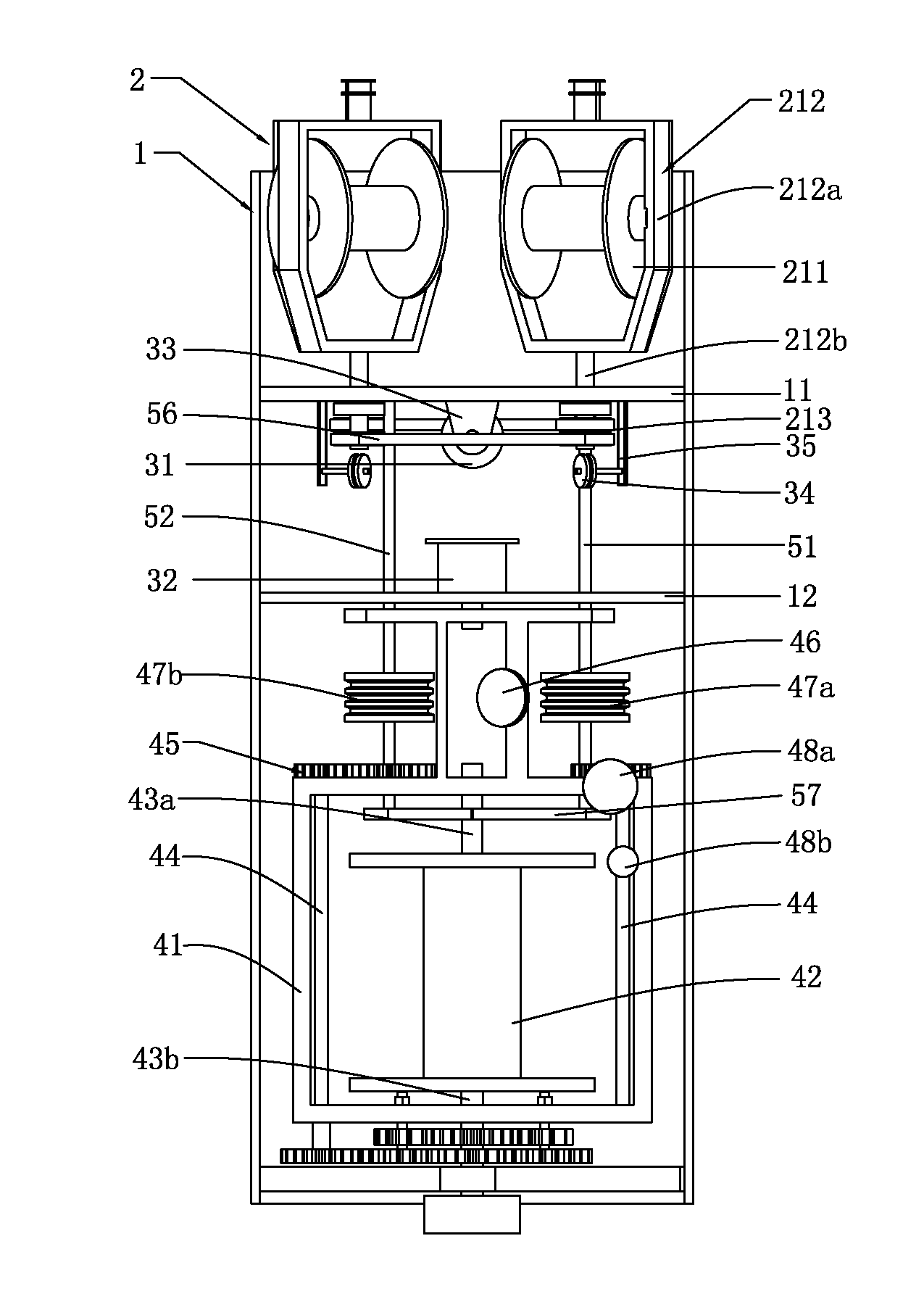

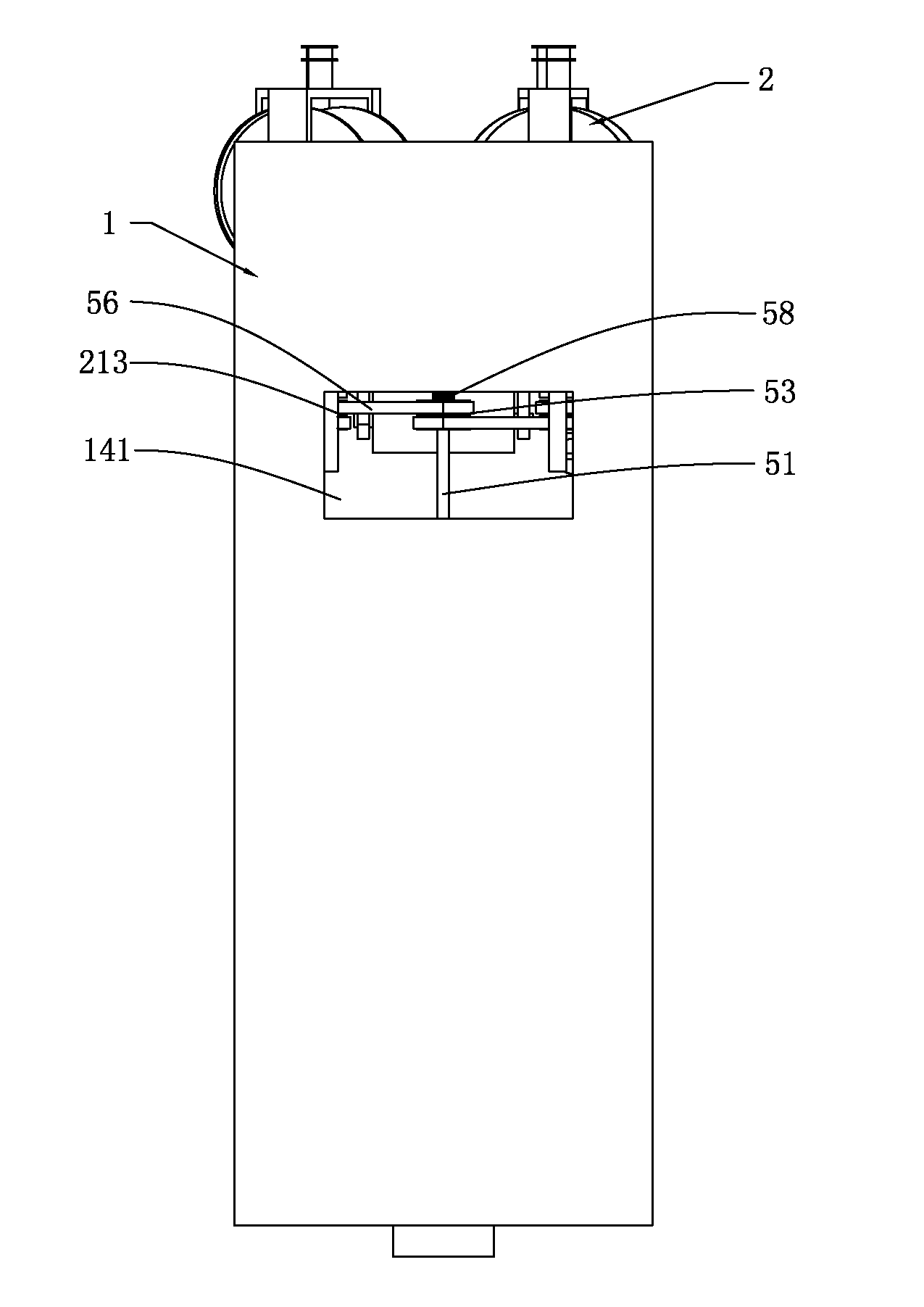

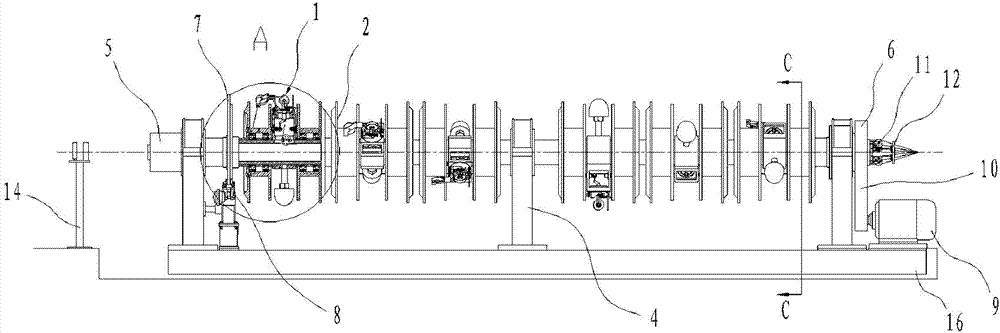

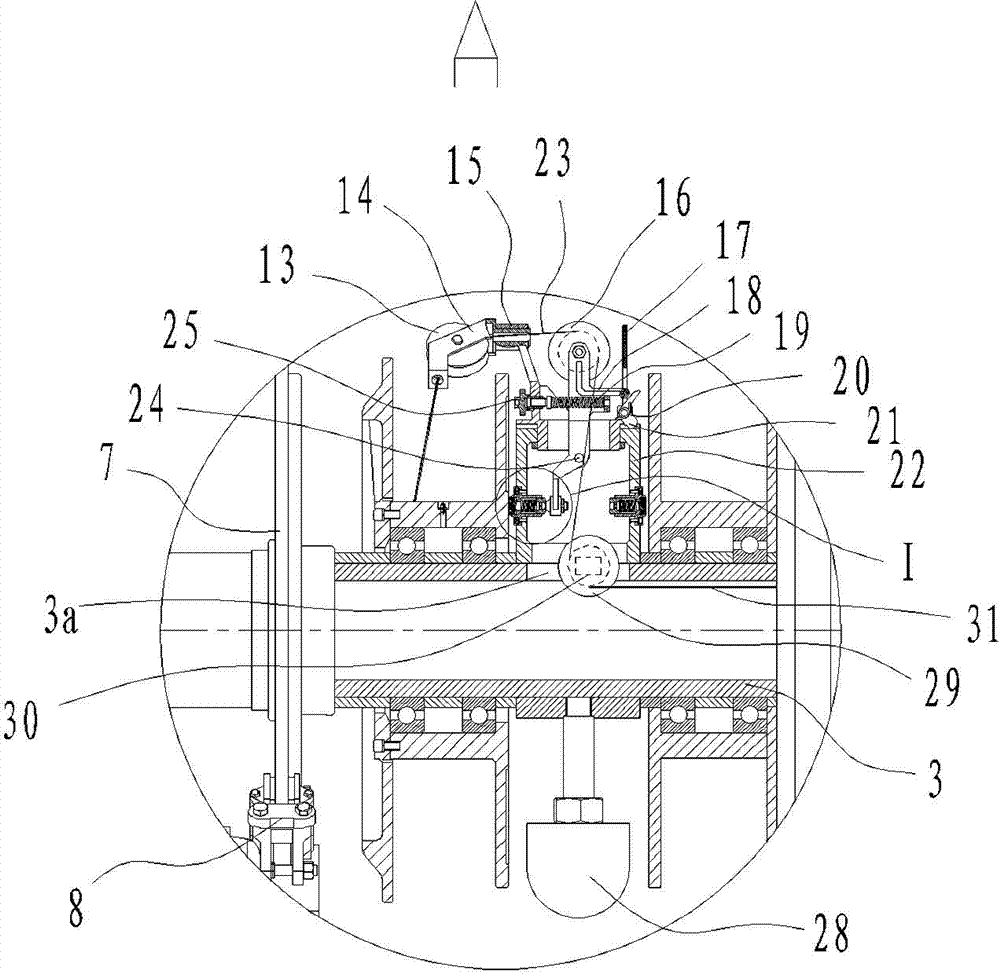

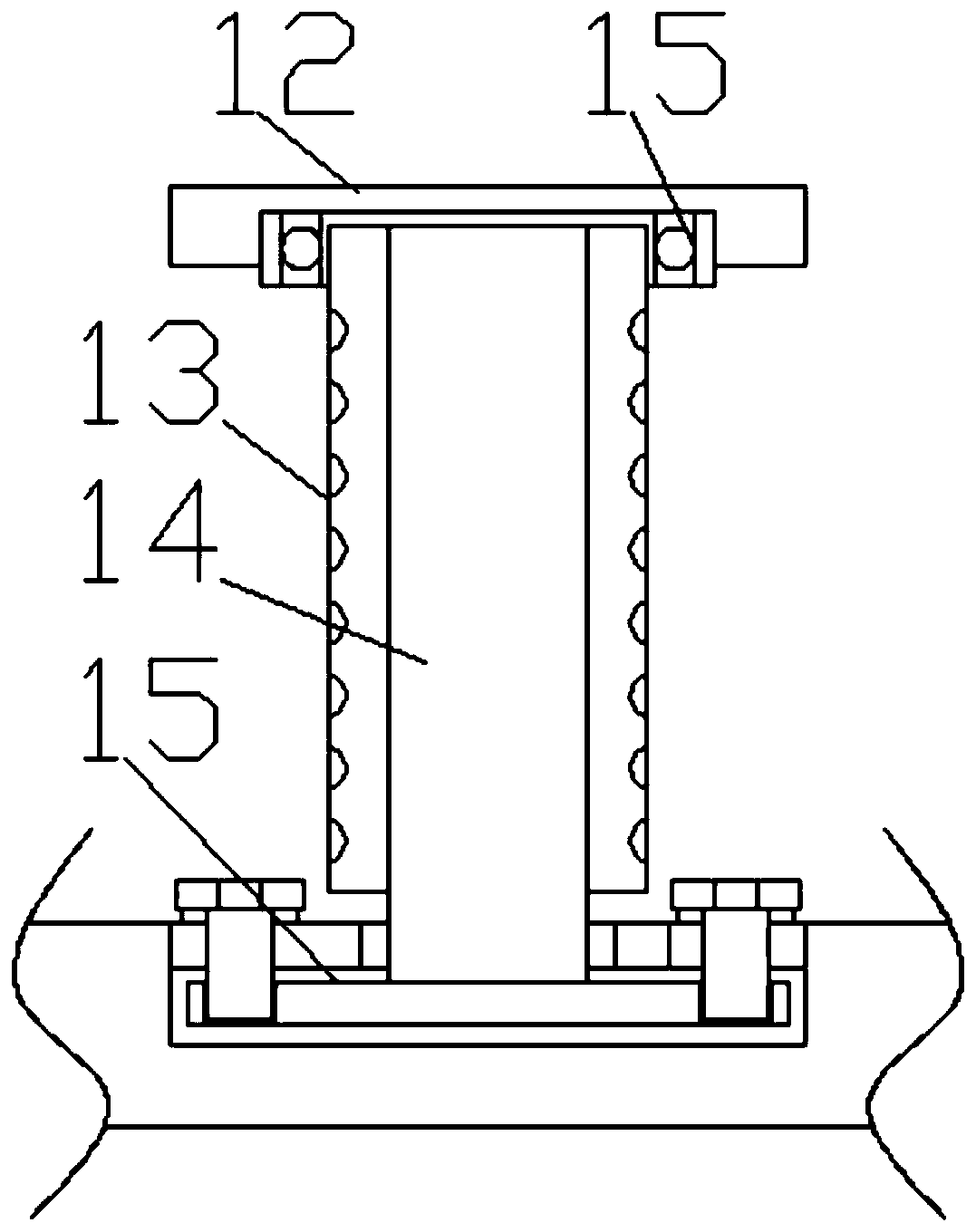

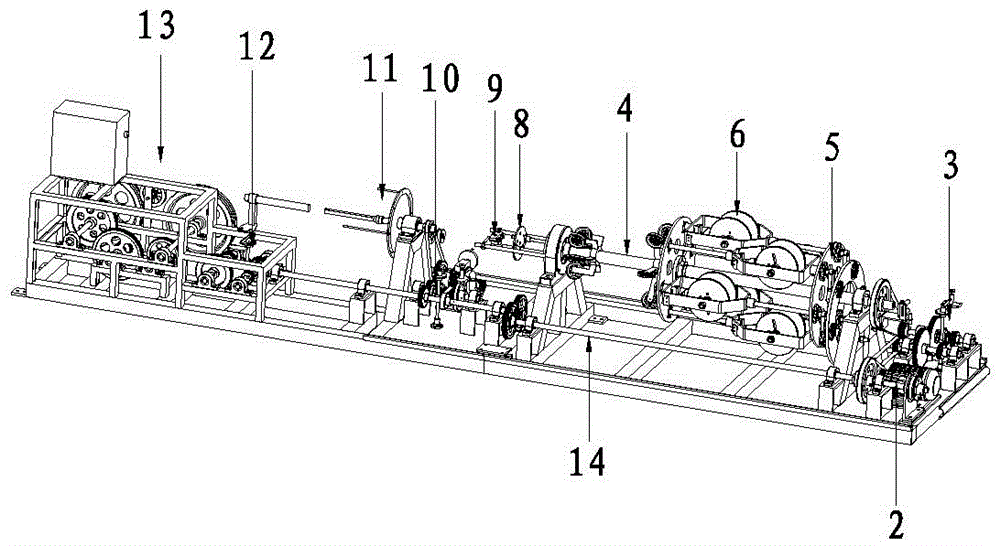

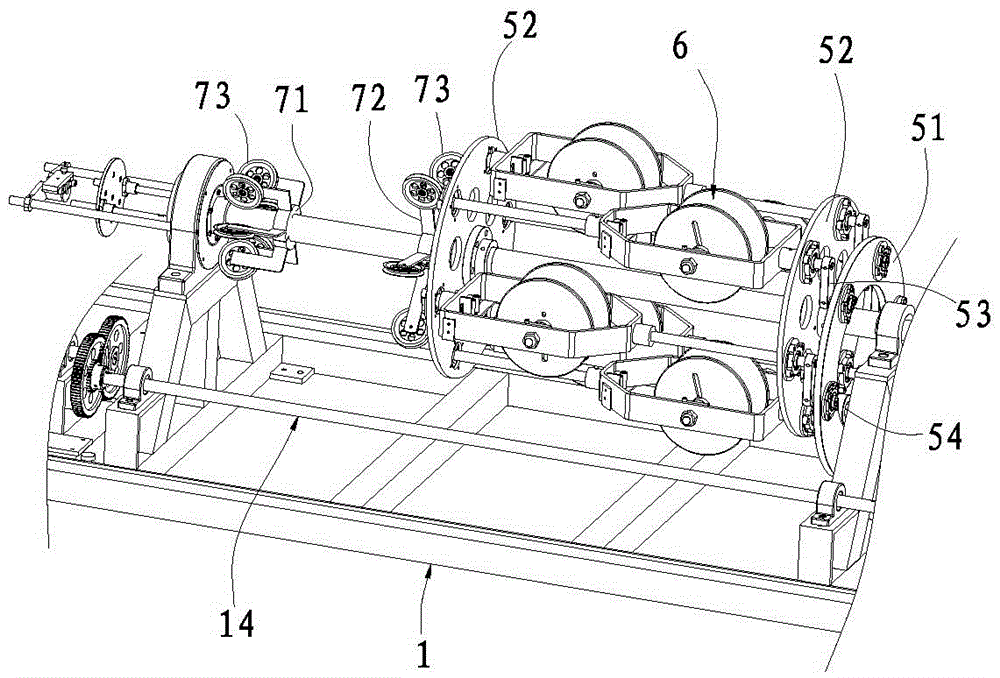

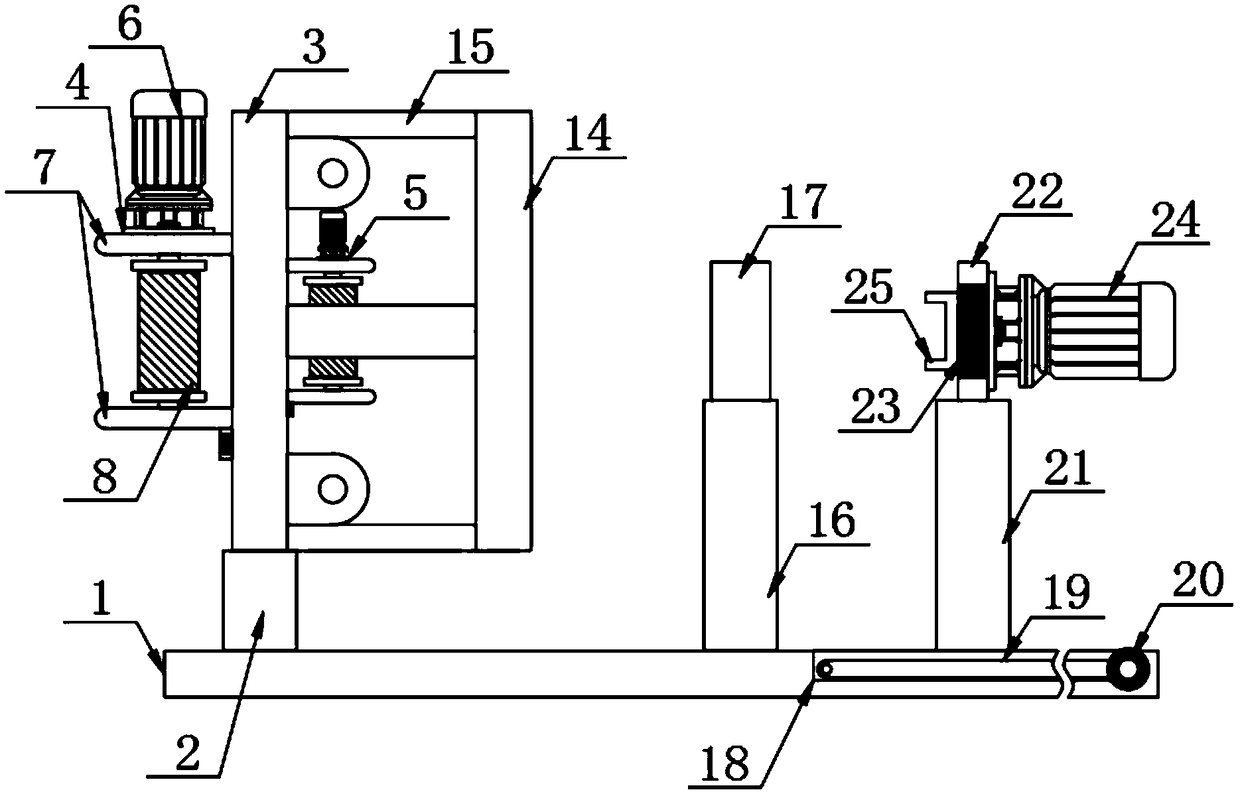

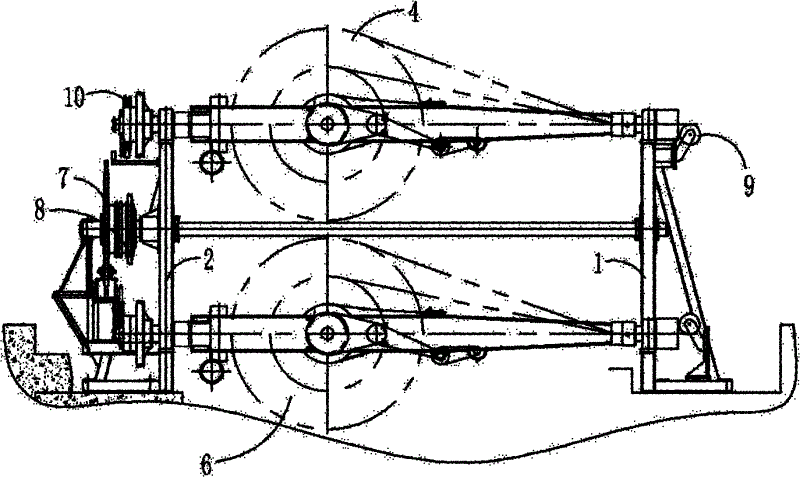

The invention relates to the technical field of stranders, in particular to a back twist strander capable of eliminating torsion stress. The back twist strander comprises a stand, a feeding device, a stranding device, a transmission device and a coiling device, wherein the stand is provided with a first working plate and a second working plate which divide the stand into three working chambers. The back twist strander provided by the invention achieves the aim of eliminating torsion stress generated in the total stranding process of wires through controlling the rotating speed of a feeding end to be consistent with the rotating speed at a coiling end by using the same transmission device. The transmission device of the back twist strander transmits power through a synchronous transmissionrod as well as a synchronous gear and a synchronous belt which are in the same specification. The back twist strander is simple and compact in structure, capable of totally stranding a plurality of wires, varied in stranding way and high in stranding quality, and no jumping phenomenon is caused in the total stranding process of the wires.

Owner:HUBEI YINGTONG ELECTRONICS +1

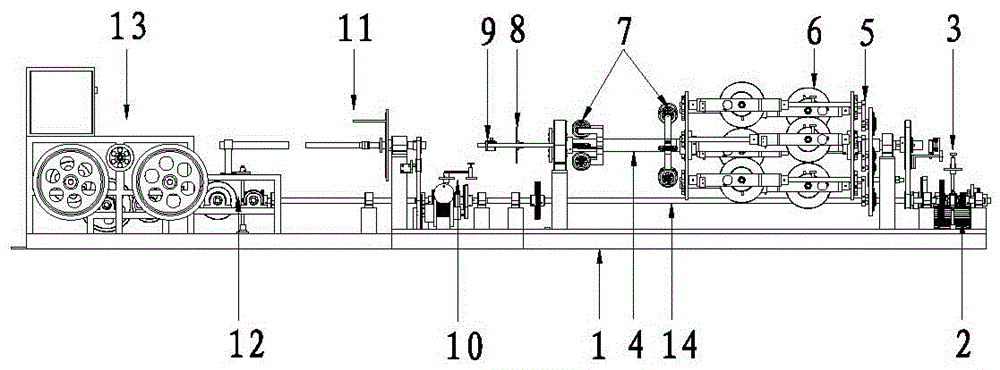

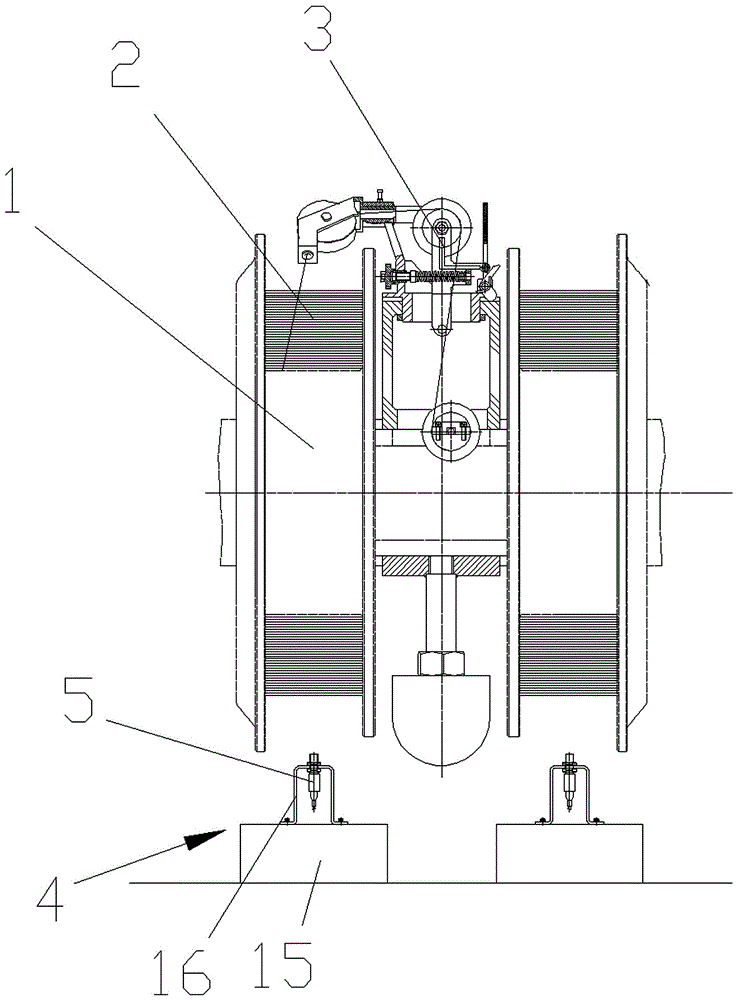

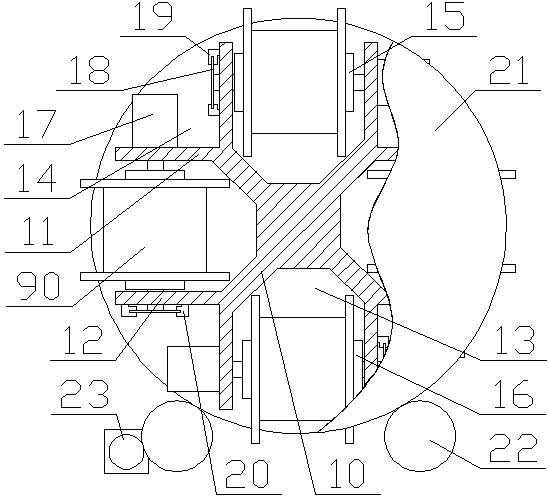

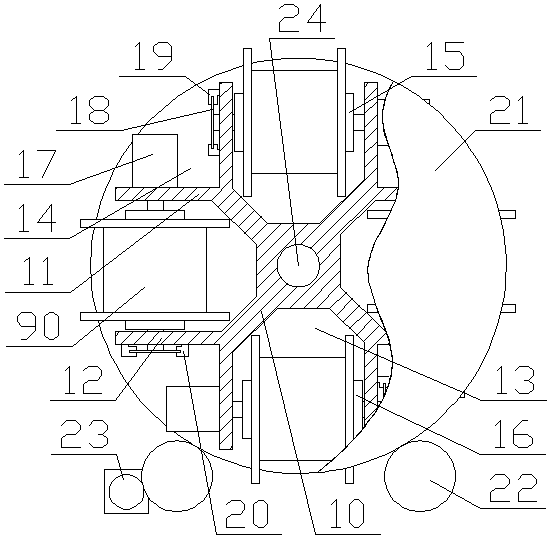

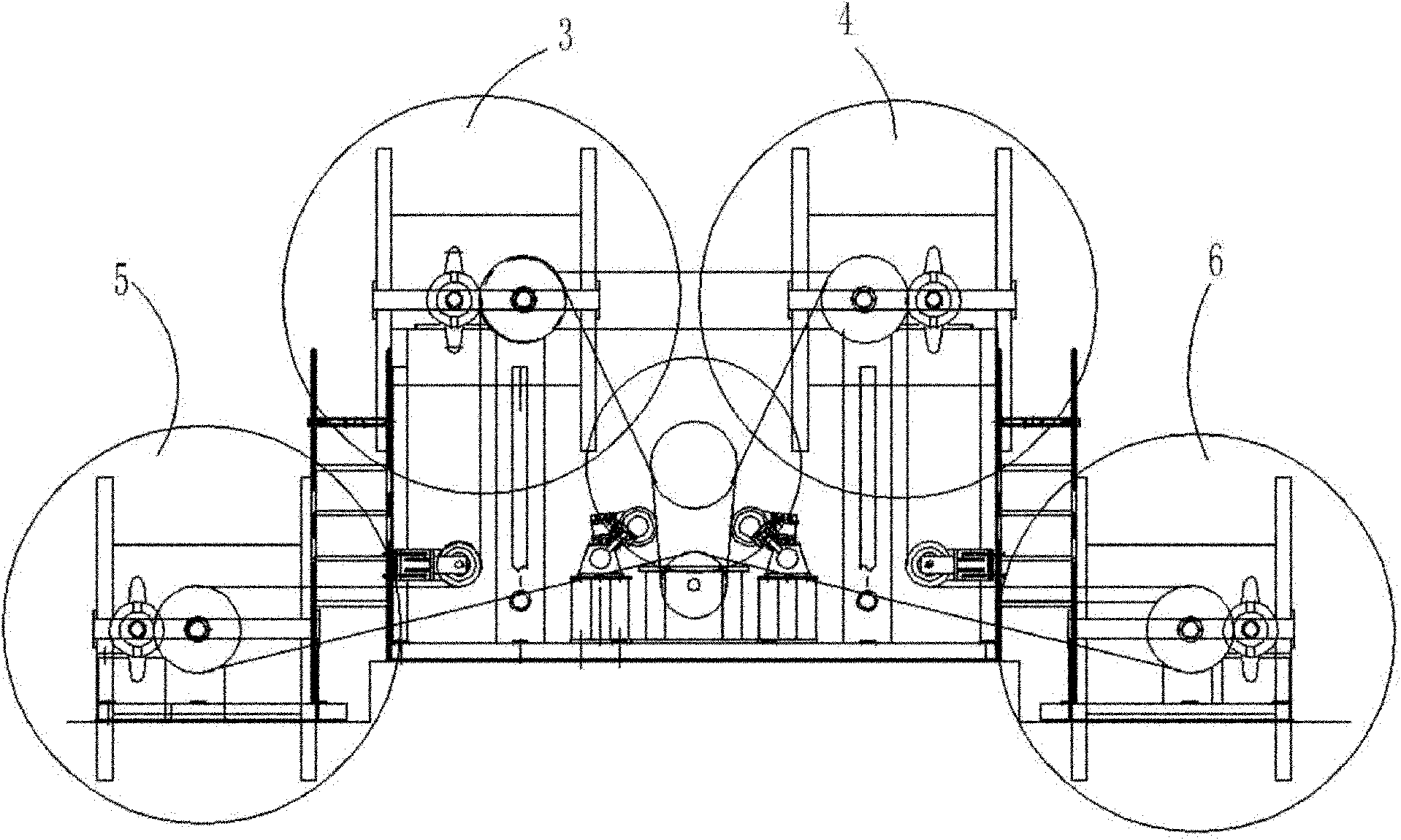

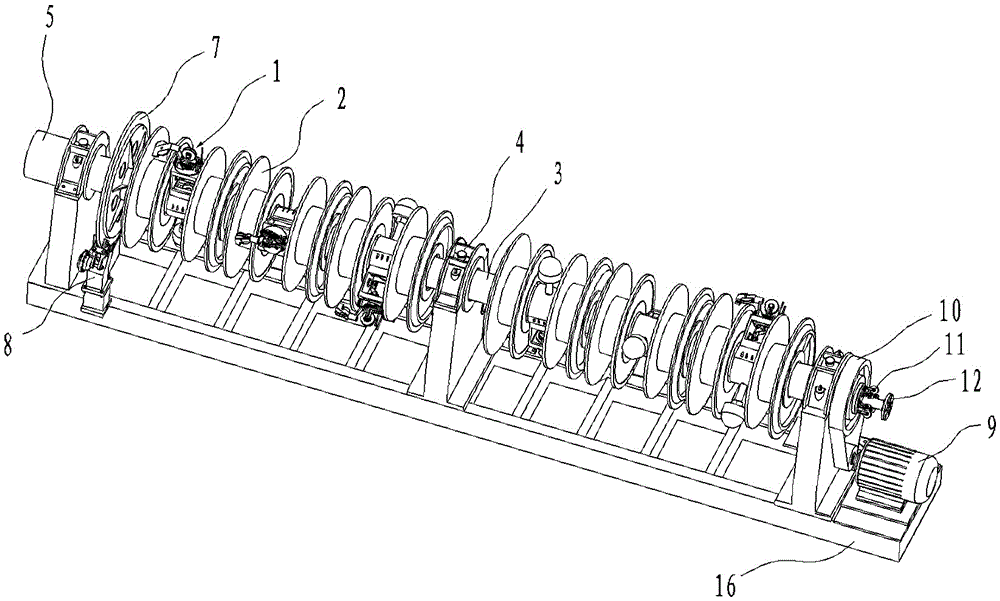

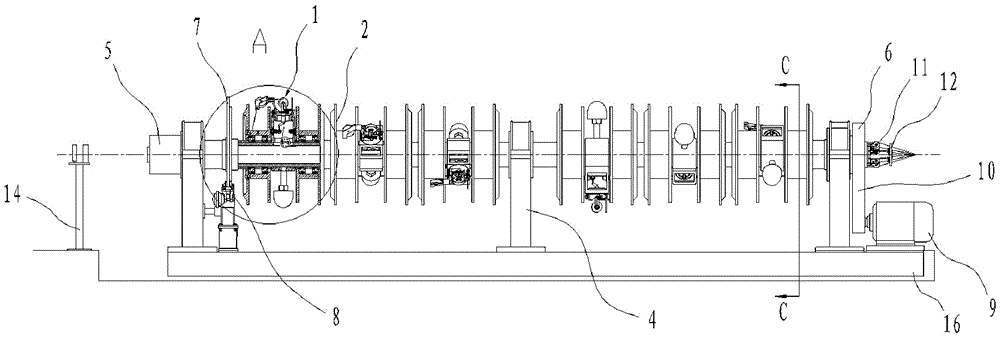

Concentric type wire-stranding machine

InactiveCN103578656AImprove stranding qualityStable pay-off tensionCable/conductor manufactureEngineeringTension control

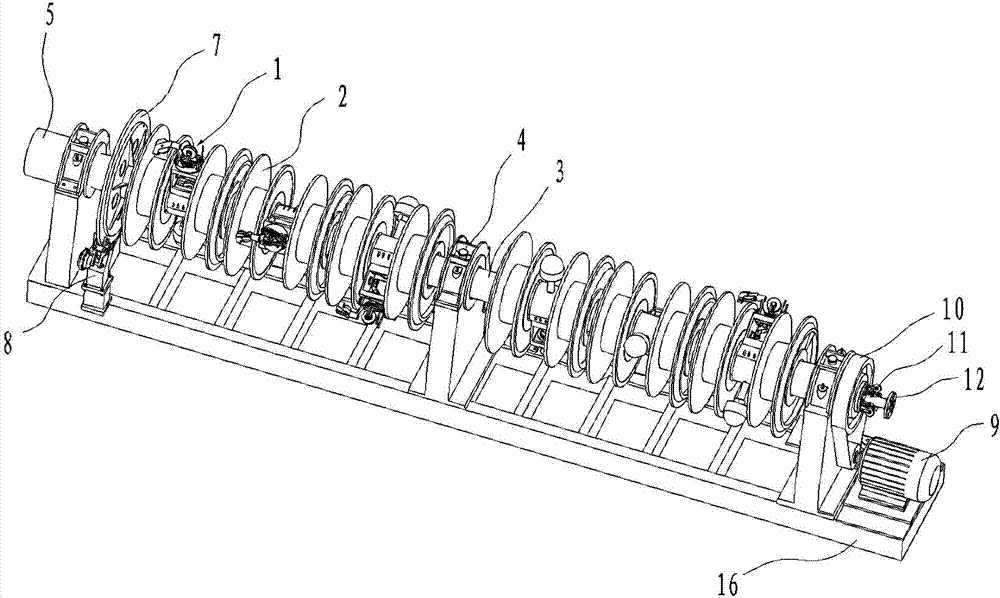

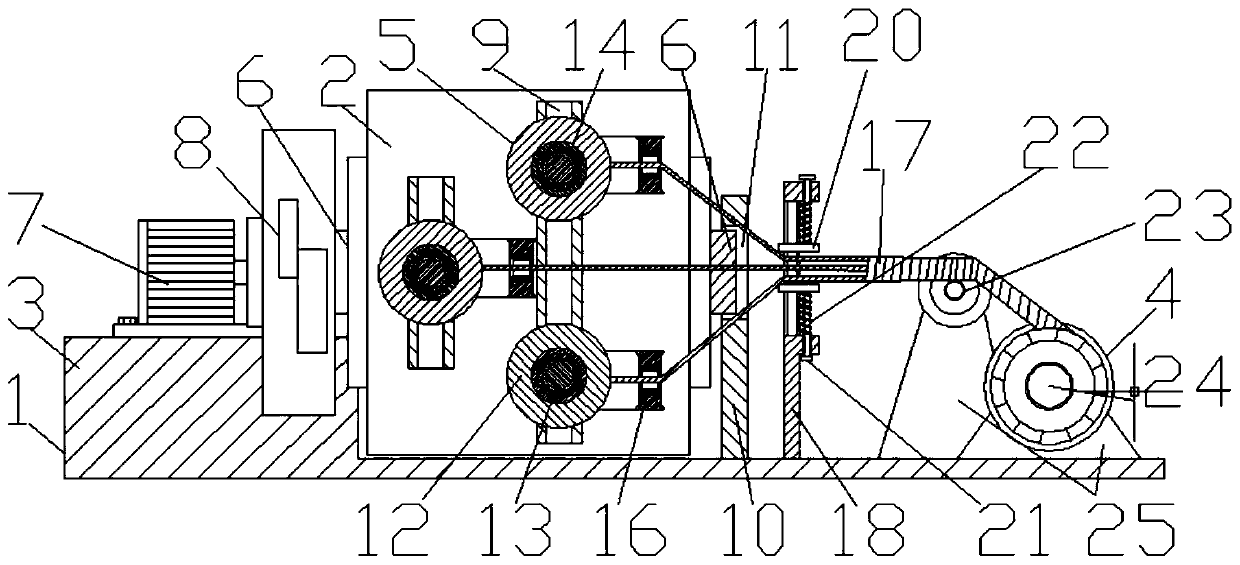

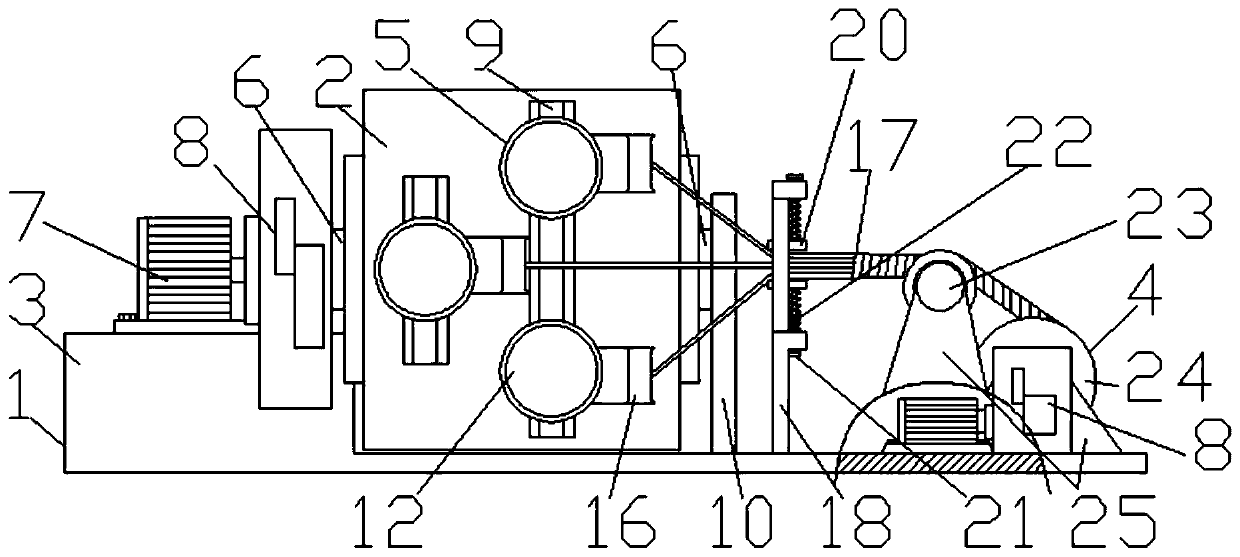

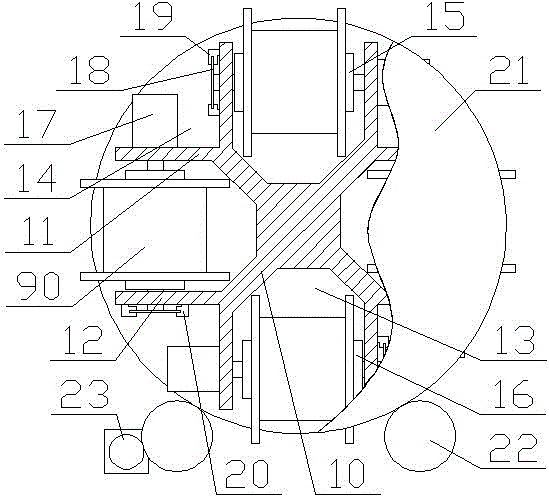

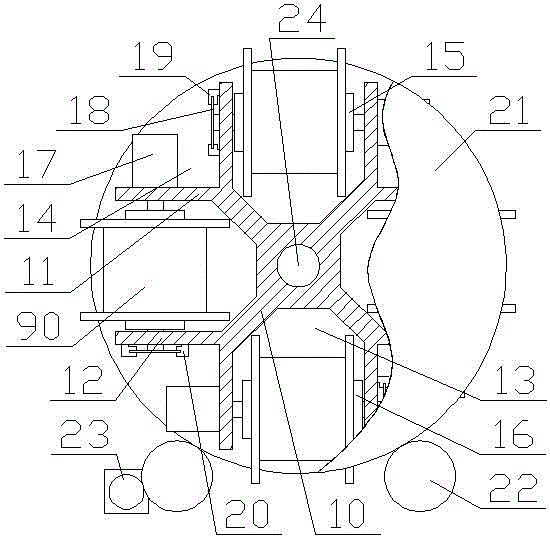

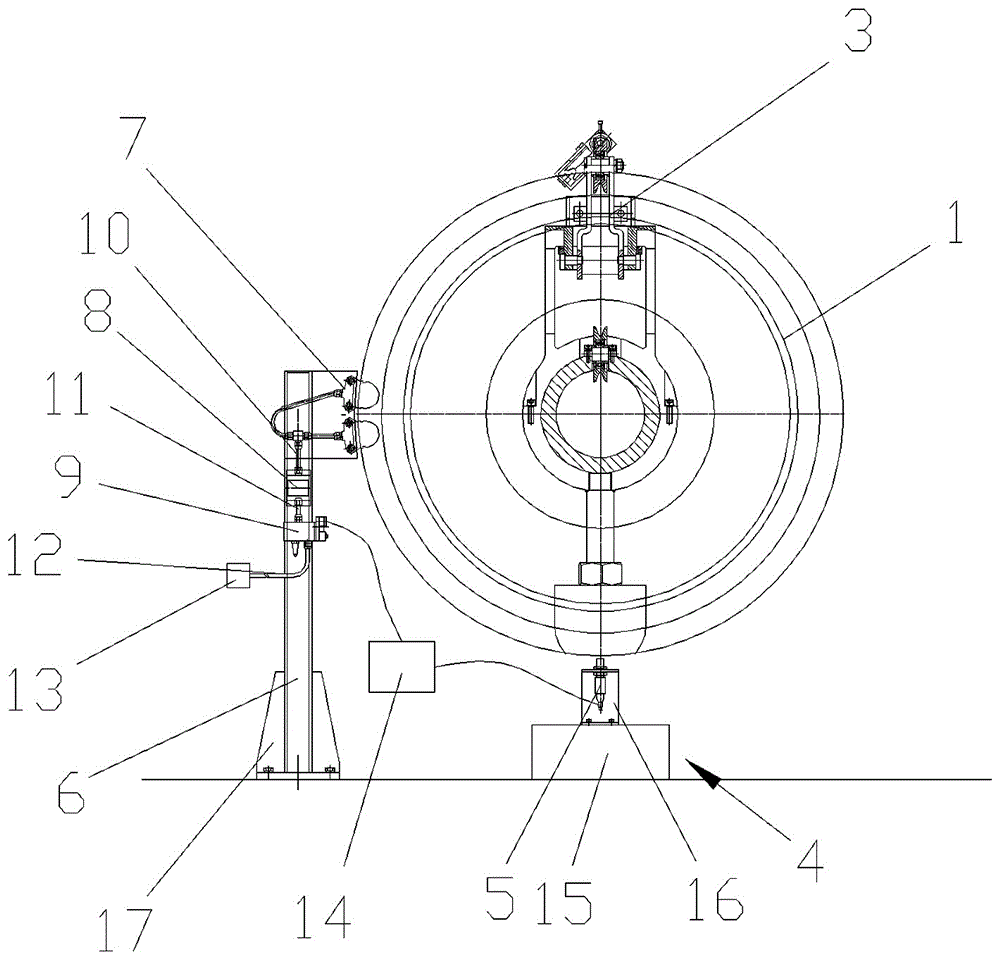

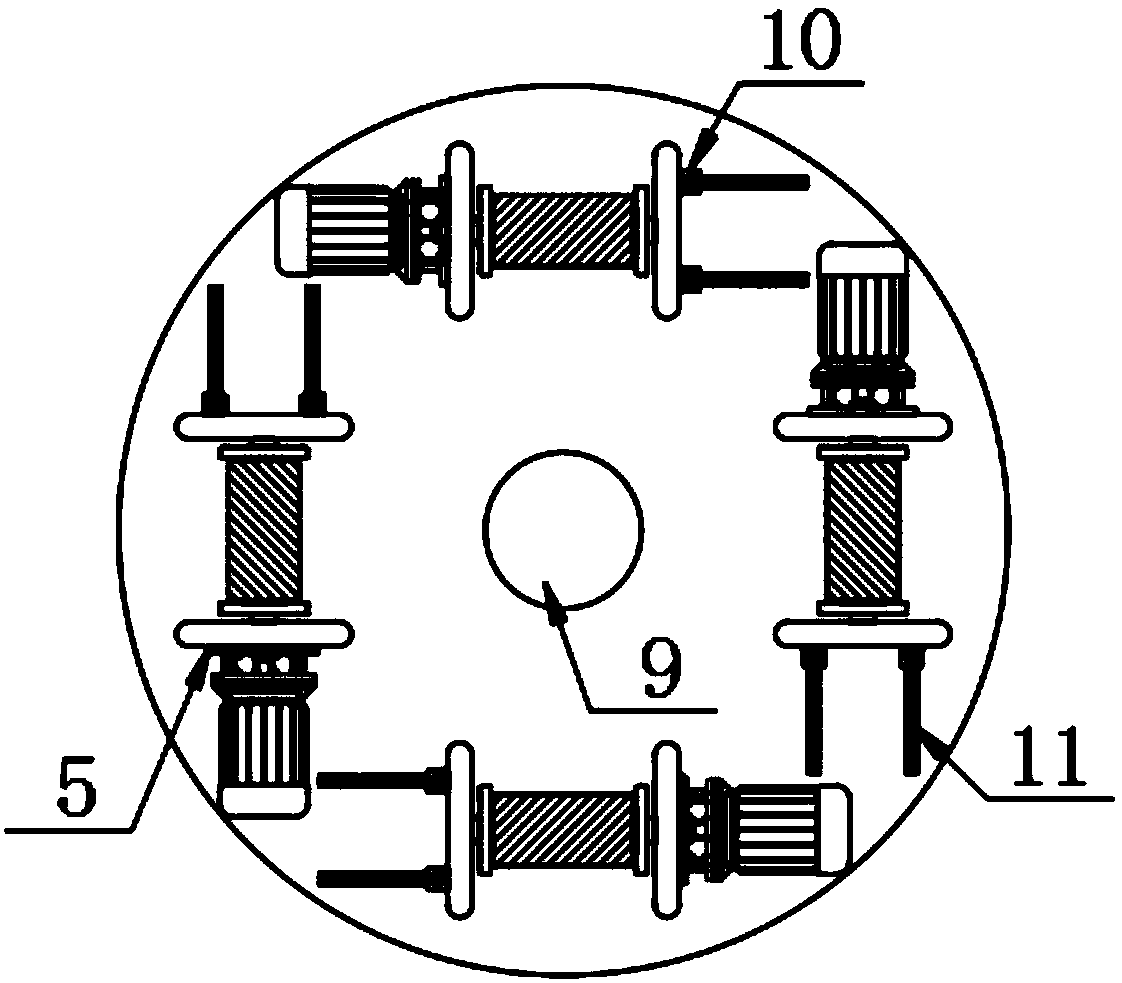

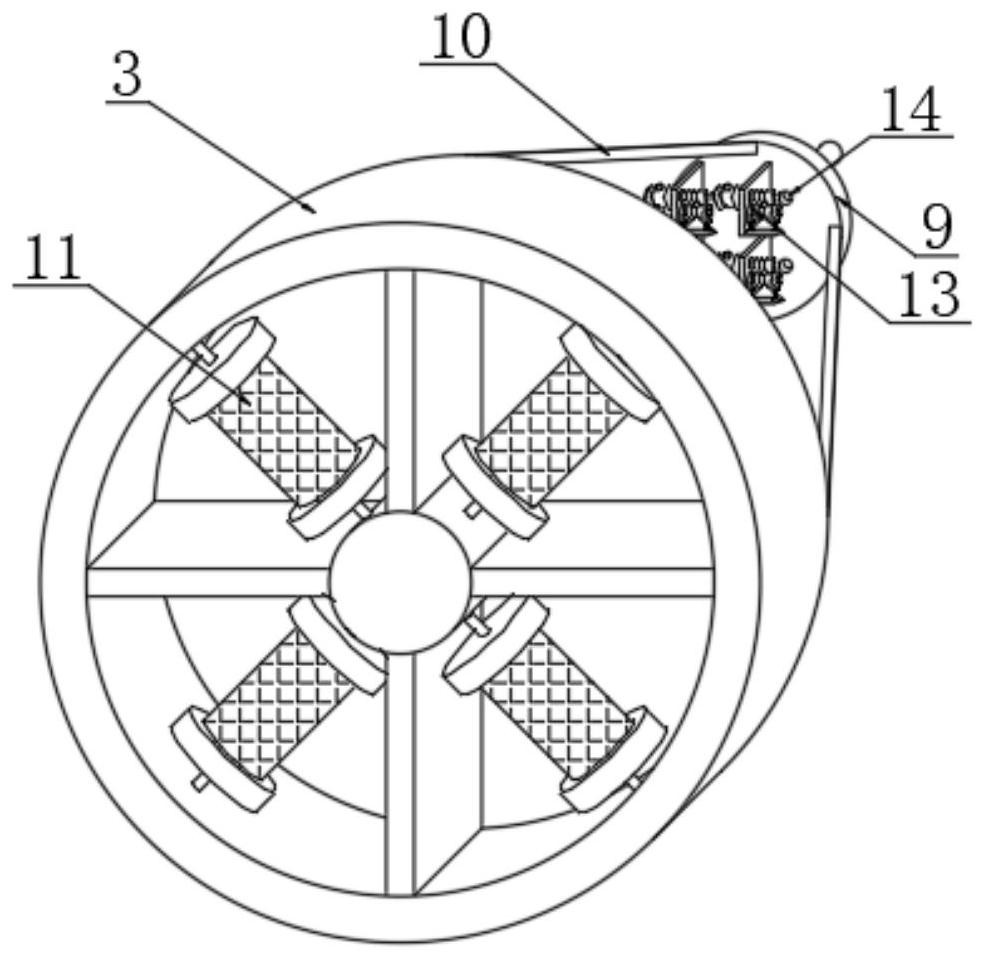

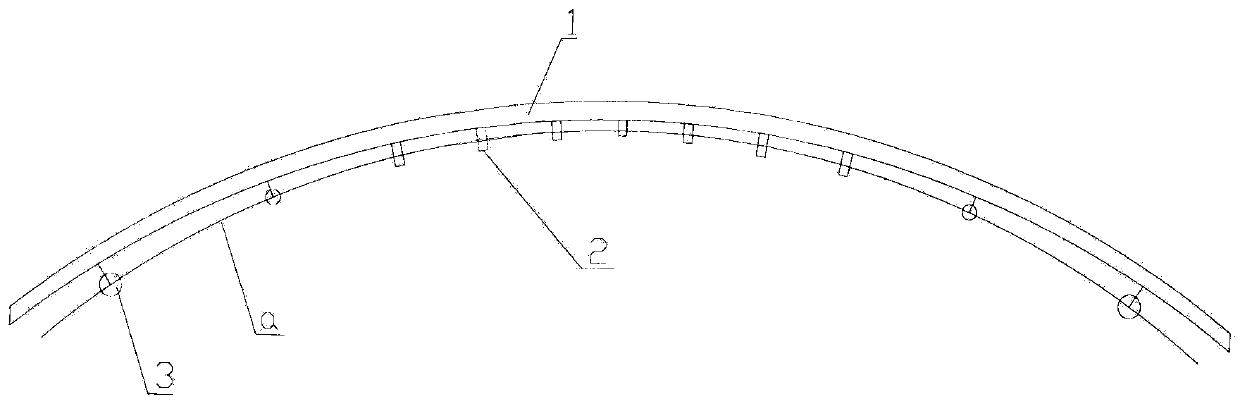

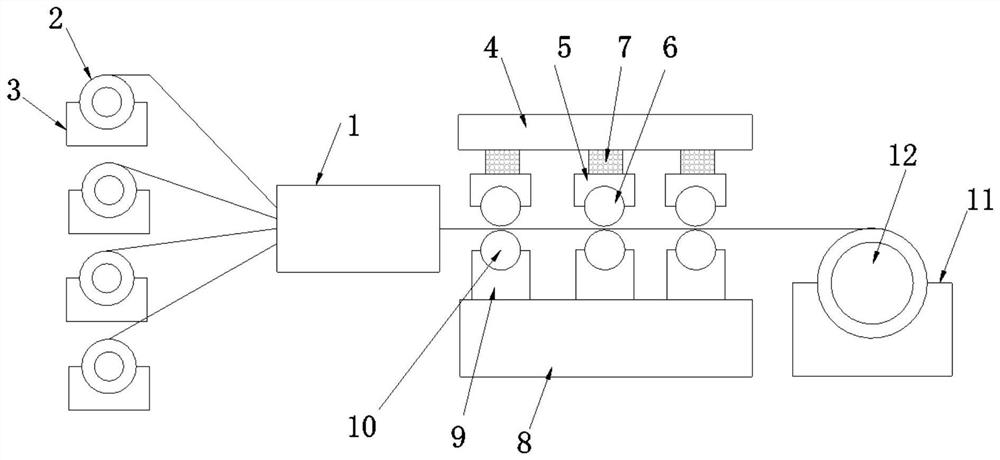

The invention relates to a concentric type wire-stranding machine. The concentric type wire-stranding machine comprises a bottom board (16), wherein the bottom board is connected with a set of machine frames (4) which are connected with a main shaft (3) in a matched mode, the rear end of the main shaft is connected with a branch wire storage reel (12), and the rear end of the main shaft is further connected with a motor (9) through a belt (10). The concentric type wire-stranding machine is characterized in that the main shaft is connected with a set of wire storage reel (2) in a matched mode, tension control devices are arranged on the main shaft respectively at an interval of two wire storage reels, and each tension control device is correspondingly matched with the wire storage reels on two sides of the corresponding tension control device. The concentric type wire-stranding machine has the advantages that the concentric type wire-stranding machine is of an integrated structure, the number of the circulation wire storage reels is reduced, and production cost is saved; rotation inertia is low, and rotating speed of the machine is increased; stranding and rewinding of a cable core can be conducted simultaneously, and operation time is saved; the machine can enable paying-off tension of a wire core to be stable and improve stranding quality of a cable.

Owner:安徽长江精工装备科技有限公司

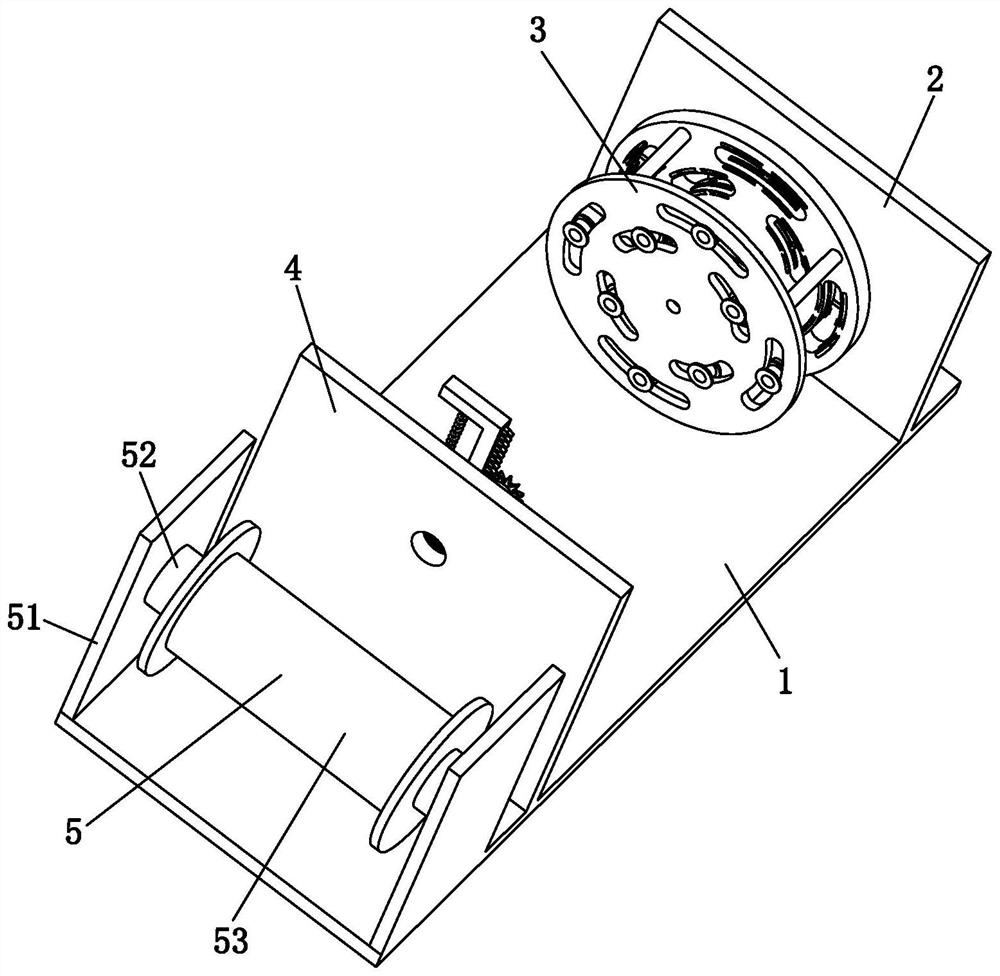

Polyvinyl chloride insulation fireproof power cable cabling stranding machine

InactiveCN110660534ARealize the adjustment functionImprove adaptabilityCable/conductor manufactureRotational axisPower cable

The invention discloses a polyvinyl chloride insulation fireproof power cable cabling stranding machine, which comprises a mounting base, a rotary stranding frame, a take-up device and pay-off devices, wherein the rotary stranding frame is arranged in the middle of the top end surface of the mounting base, the left side of the top end surface of the mounting base is fixedly provided with a boss, the take-up device is arranged on the right side of the top end surface of the mounting base, a plurality of pay-off devices are fixedly arranged on the front and rear end surfaces of the rotary stranding frame, and the left and right end surfaces of the rotary stranding frame are fixedly provided with rotating shafts. According to the invention, the rotary stranding frame is matched with the plurality of pay-off devices to form an integrated automatic stranding structure, and the function of adjusting the stranding position is realized by sliding a fixed rod, so that the adaptability to different stranding strength of different single-stranded cables is facilitated. In addition, a wire guide plate and a collecting device are arranged, so that the single-stranded cable is enabled to have directional output, the friction damage in the stranding process can be well reduced, and the stranding quality is improved. The stranding speed is greatly improved through a wire lapping wheel and a take-up wheel.

Owner:安徽华上电缆科技有限公司

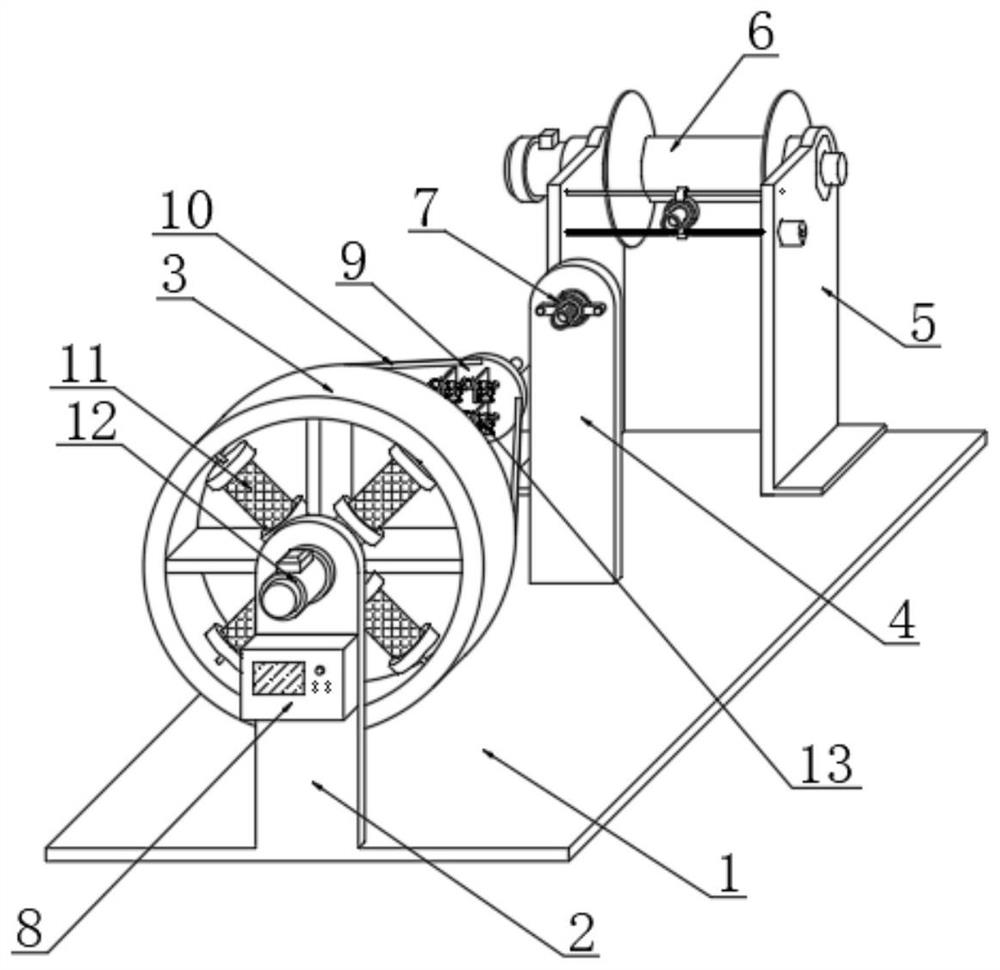

Cable stranding machine

ActiveCN106128641AEasy to produceImprove applicabilityCable/conductor manufactureEngineeringElectrical and Electronics engineering

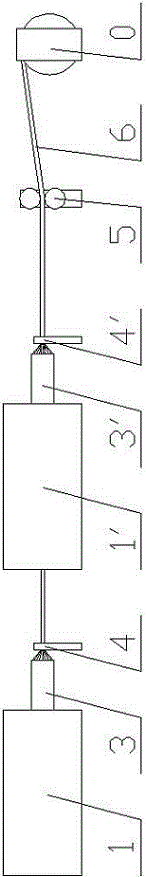

The invention discloses a cable stranding machine. The cable stranding machine comprises at least one wire-releasing and wire-stranding apparatus and a rolling-up apparatus, wherein when the number of the wire-releasing and wire-stranding apparatus is one, the wire-releasing and wire-stranding apparatus comprises a rotary wire-releasing apparatus A, a wire-dividing apparatus A and a wire-stranding apparatus A; when a wire on a wire-releasing reel on the rotary wire-releasing apparatus A passes through the rotary wire-releasing apparatus A, the wire-dividing apparatus A and the wire-stranding apparatus A, the wire is stranded into a cable core; the cable core is connected with the rolling-up apparatus; a driving motor A supplies the driving power to the rolling-up apparatus; and the driving motor A drives the rolling-up apparatus to roll up the stranded wire of the wire-releasing reel. According to the structure of the cable stranding machine, the wires are stranded or stranded in a multilayered manner to form the cable core, so that cables of different specifications can be produced, and the applicability of the equipment is improved.

Owner:江苏南瑞淮胜电缆有限公司

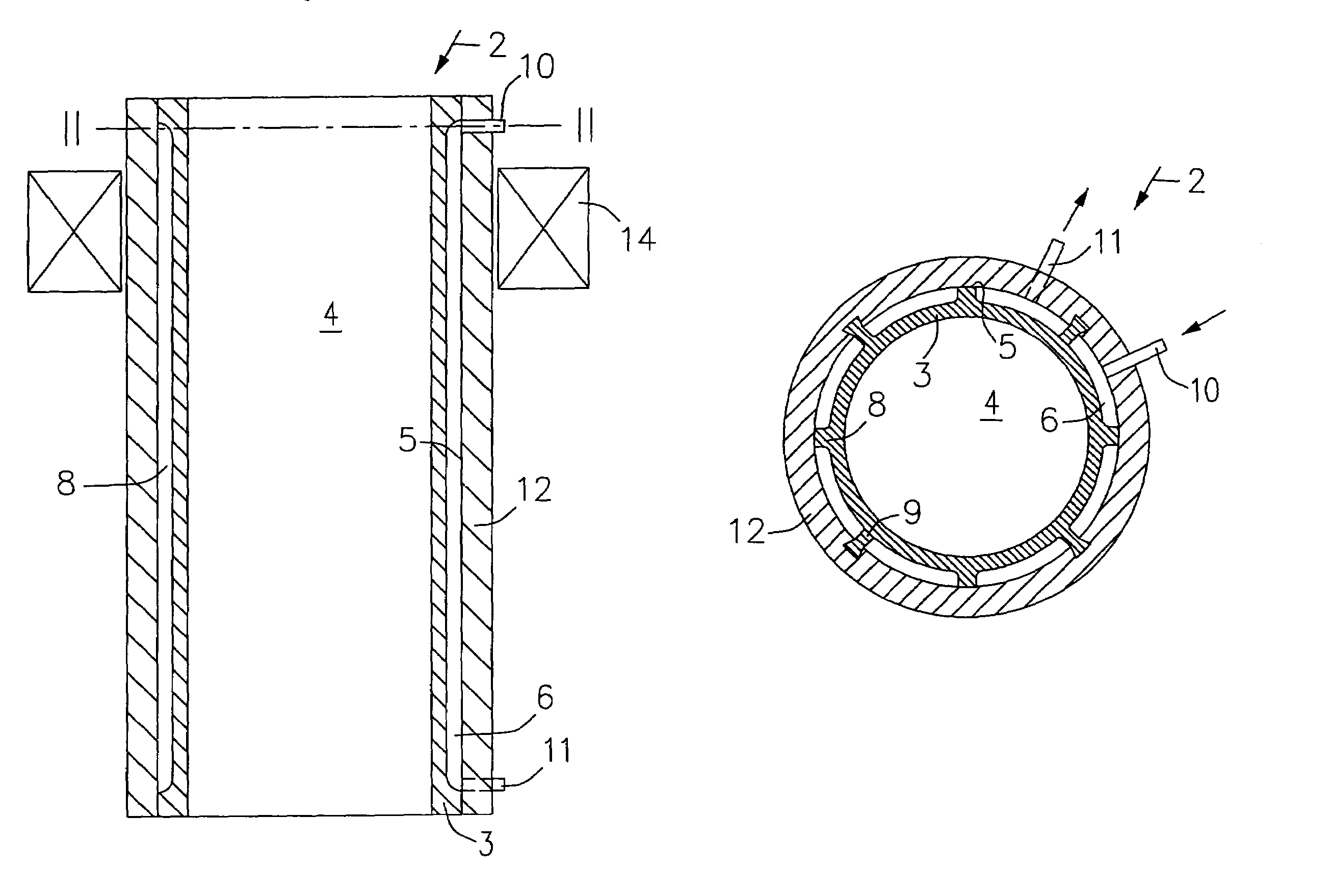

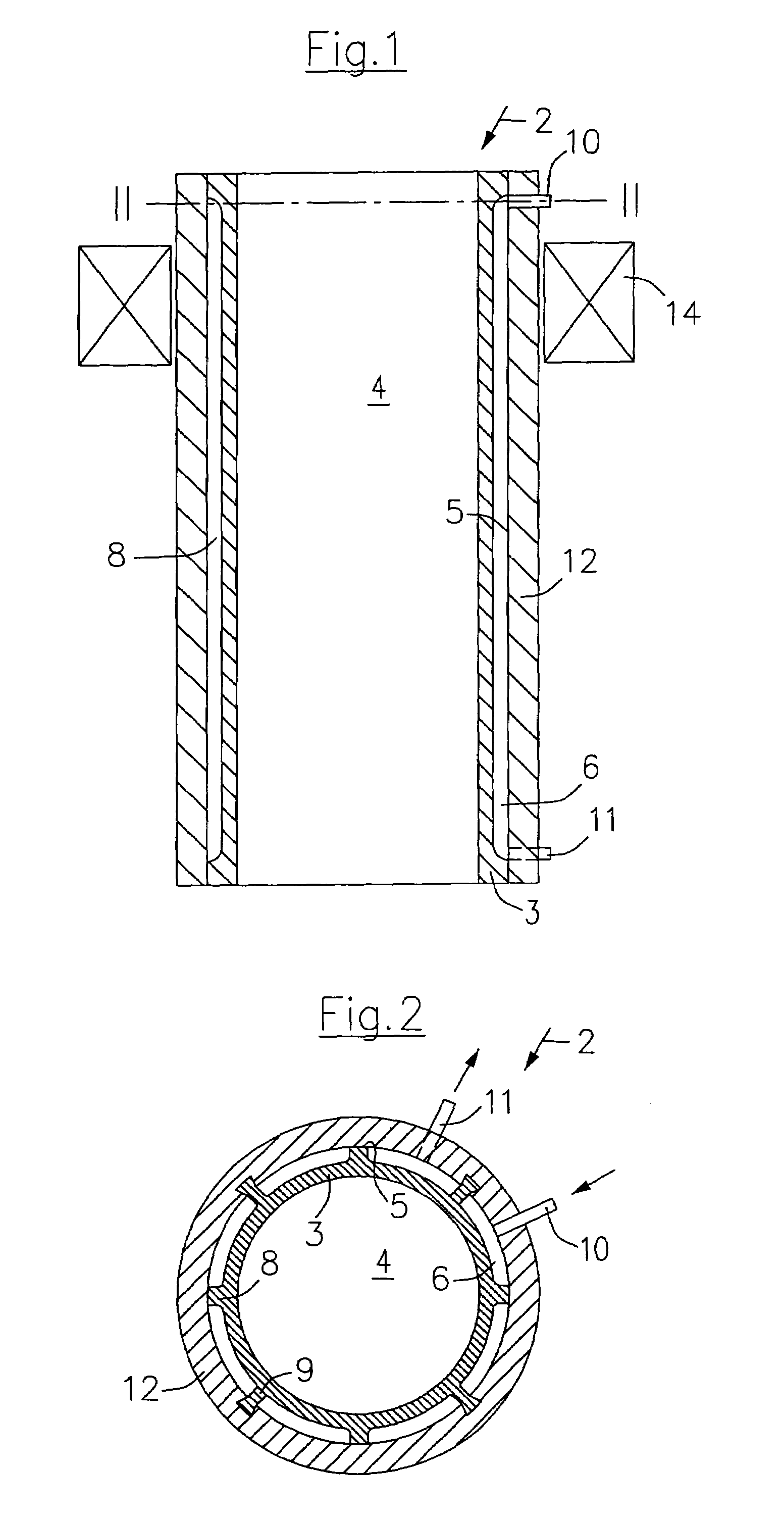

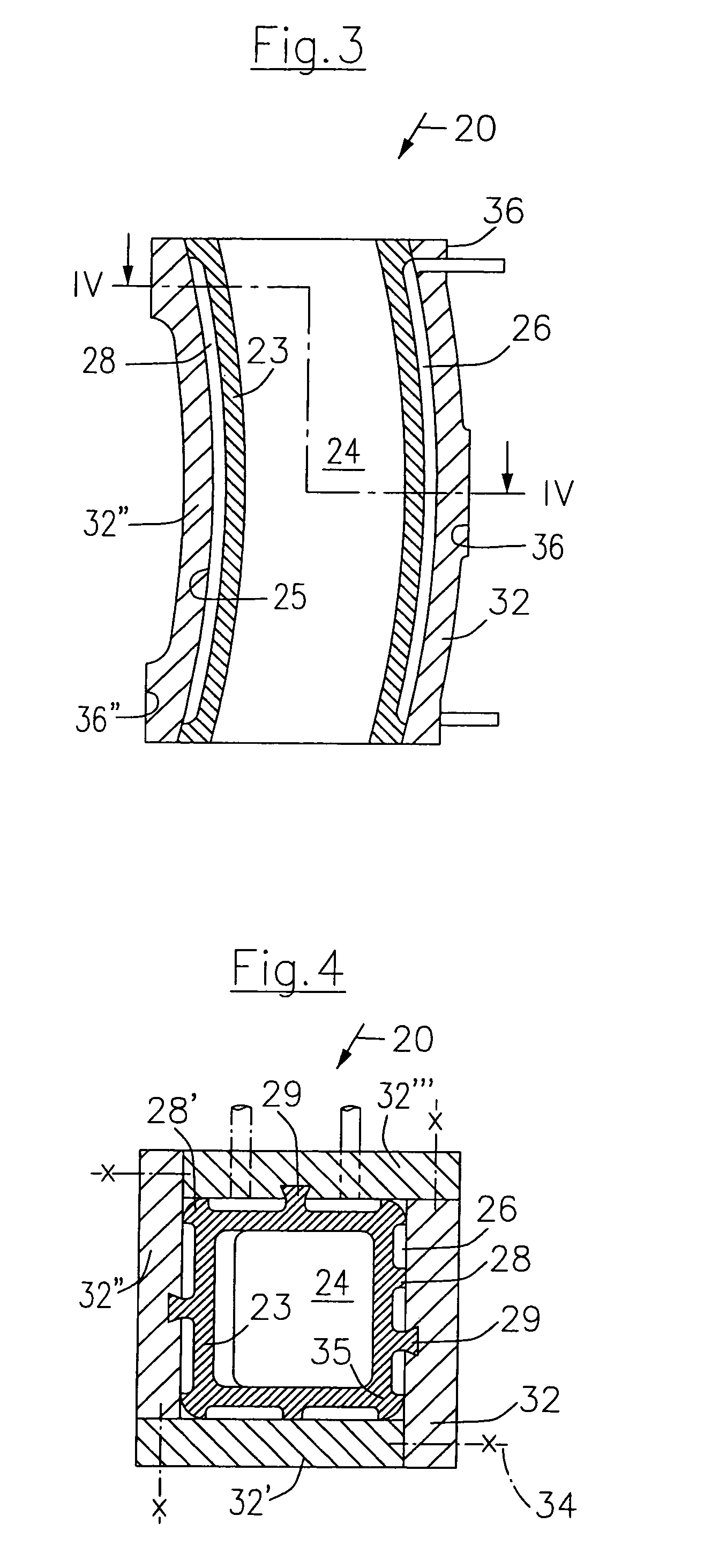

Tubular mould for continuous casting

ActiveUS7422049B2Prevent electrolytic corrosionGood dimensional stabilityPermanent magnetsElectromagnetsWater circulationCooling capacity

In the continuous casting of round or polygonal billet and bloom formats, use is made of moulds the mould cavity of which comprises a copper tube (3) which is intensively cooled by means of water-circulation cooling. In order to increase the cooling capacity on the one hand and the dimensional stability of the mould cavity (4) on the other hand, and also extend the total service life of the copper tube (3), it is proposed to provide the copper tube (3) with a supporting shell (12) or supporting plates over the entire circumference at the tube outer lateral surface (5). For the cooling of the copper tube (3), cooling ducts (6) for guiding the cooling water are arranged on the copper tube (3) or on the supporting shell (12). The cooling ducts (6) are distributed over the entire circumference at the tube outer lateral surface (5) and extend substantially over the entire mould length.

Owner:CONCAST AG

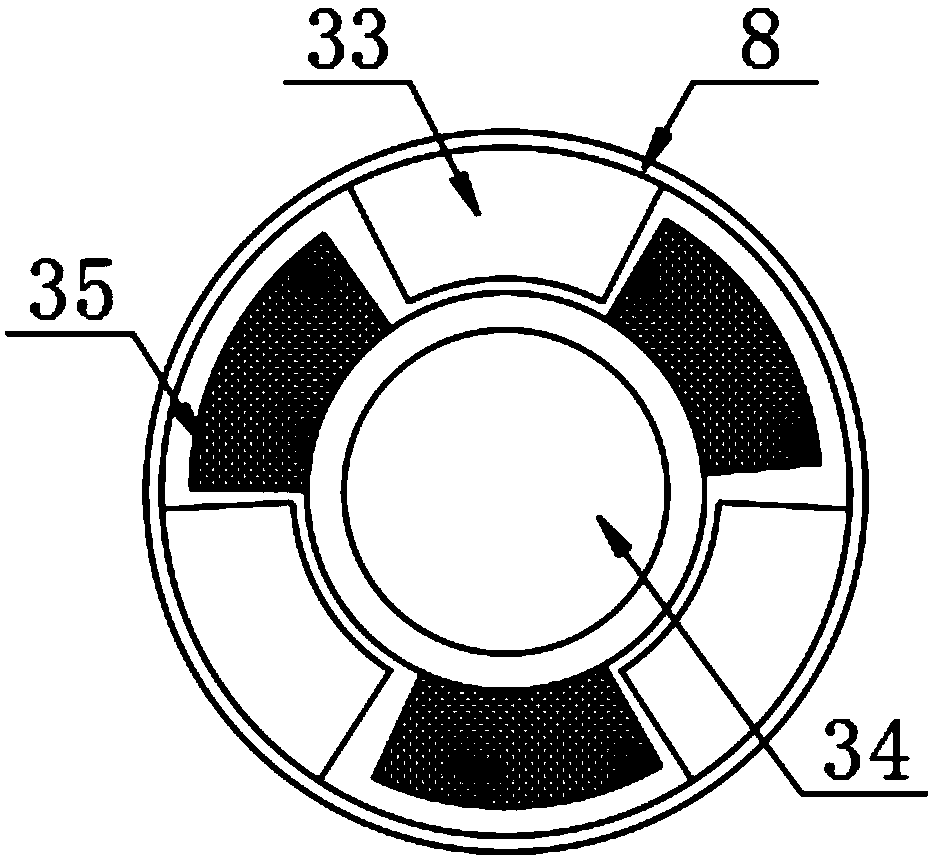

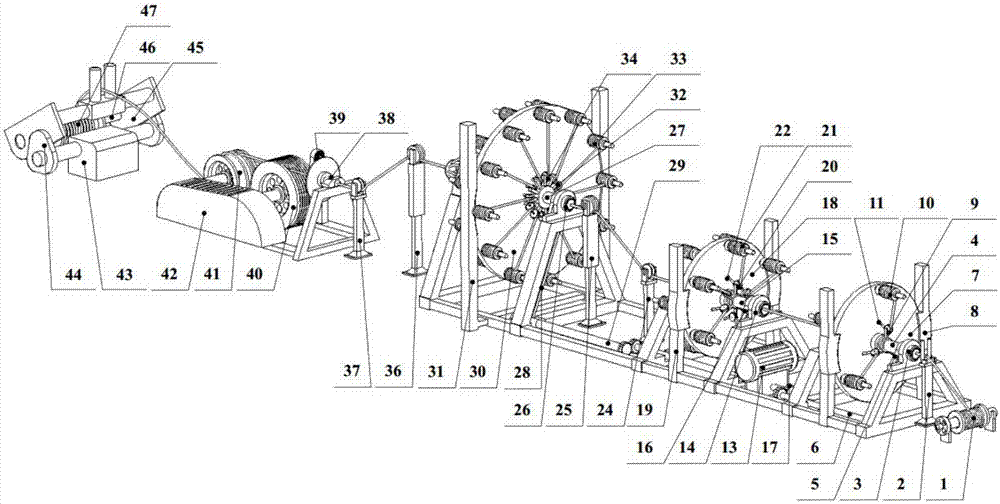

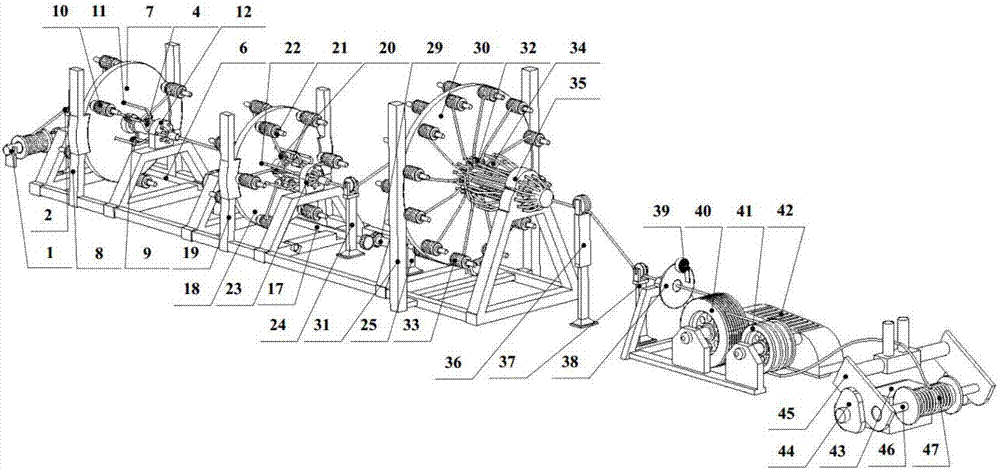

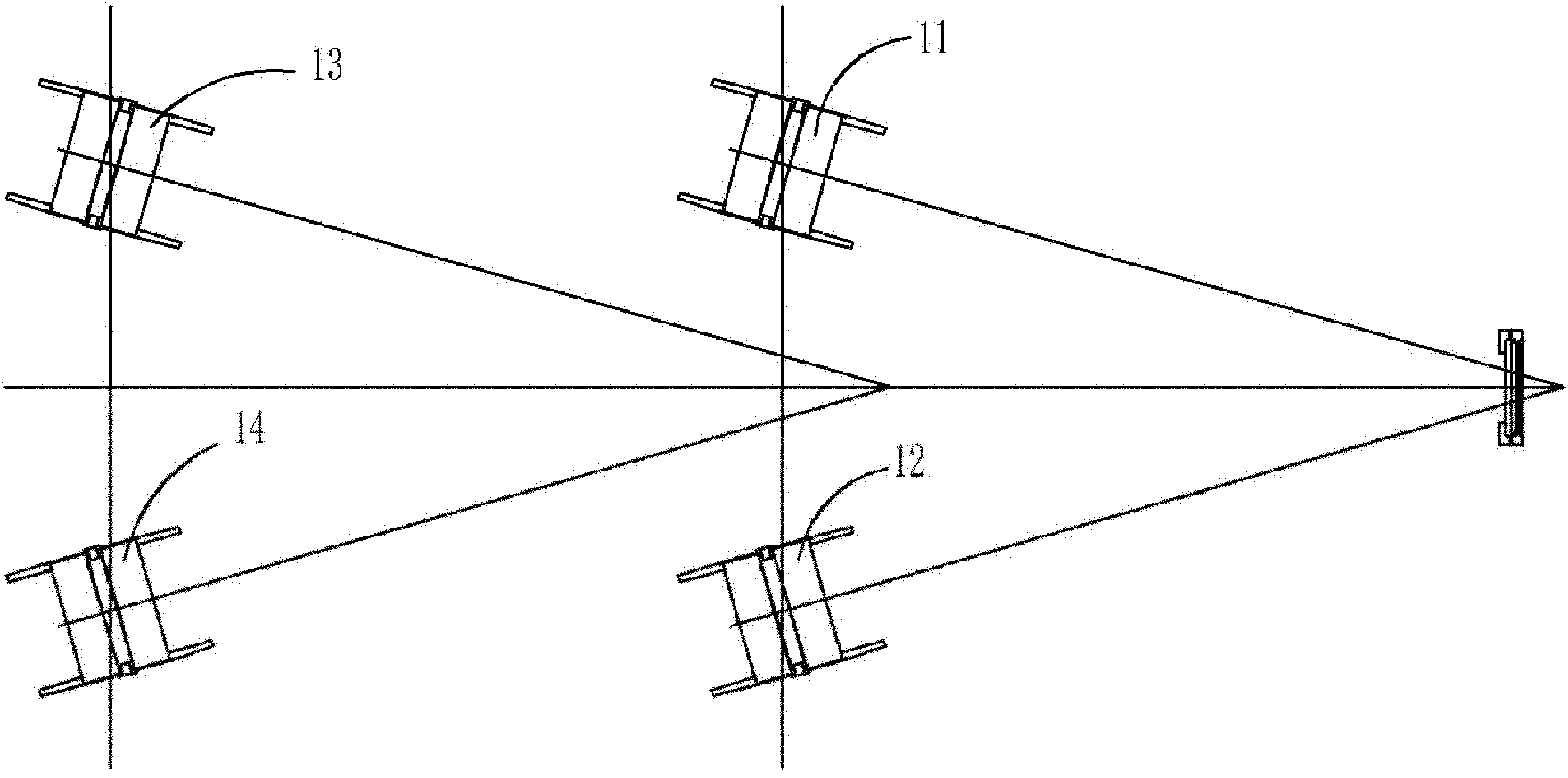

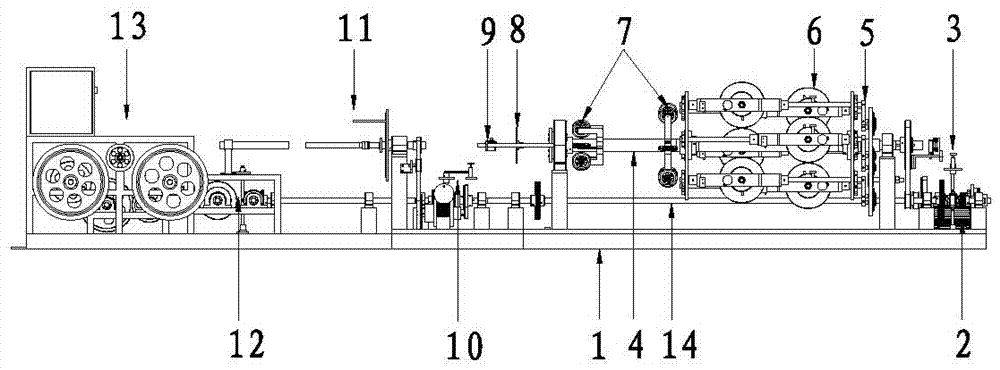

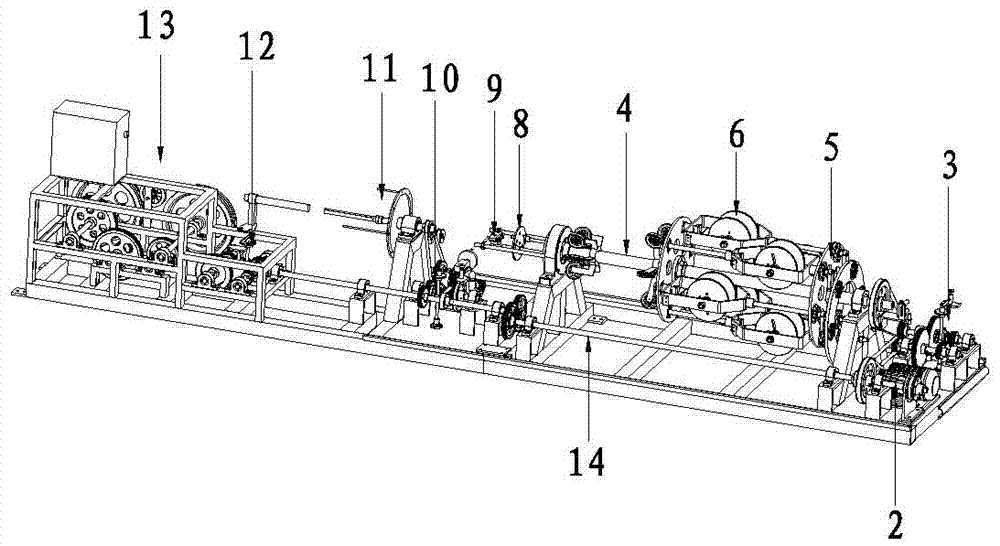

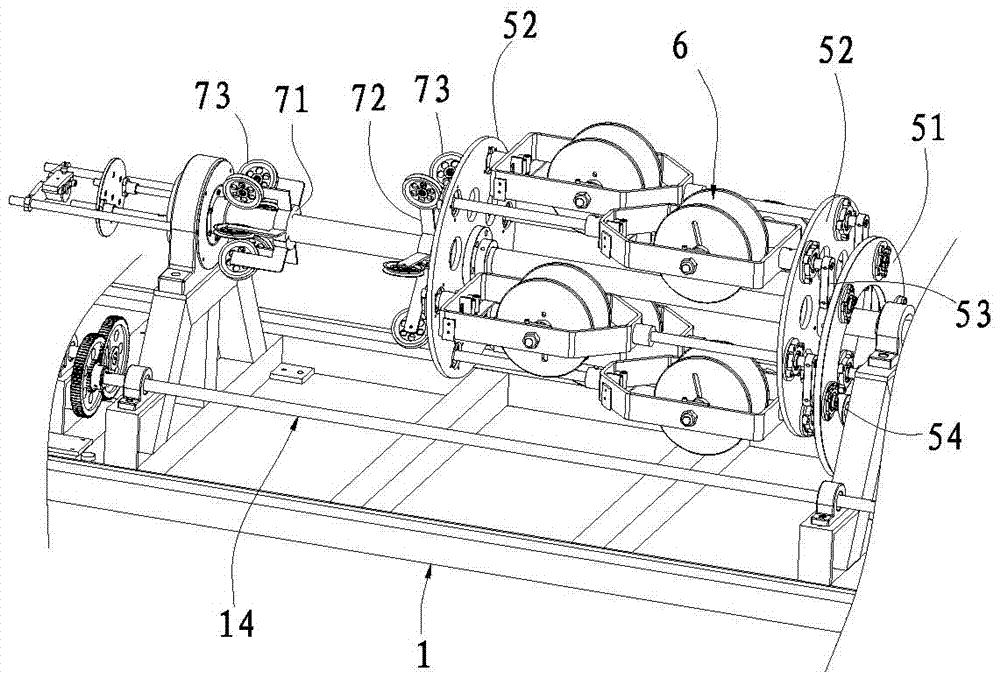

High-speed planetary stranding machine

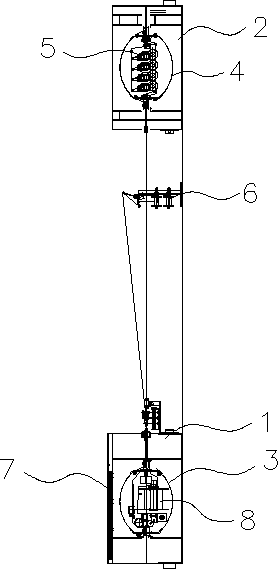

The invention discloses a high-speed planetary stranding machine. The high-speed planetary stranding machine comprises a rack, a main shaft driving device, a main shaft commutation assembly, a main shaft, a cradle frame, tension pay-off devices, a line-passing wheel group, a honeycomb screen plate, an eye mold seat, a paper-wrapping commutation assembly, a paper-wrapping mechanism, a lead-taking commutation assembly and a lead-taking mechanism. According to the high-speed planetary stranding machine, the design is ingenious and reasonable, a center line passes through a central hole of the main shaft, an auxiliary line is respectively arranged on each tension pay-off device, the tension pay-off devices are arranged on the cradle frame and can rotate around the main shaft so that the auxiliary lines and the center line are twisted together, paper wrapping is performed through the paper-wrapping mechanism, and a take-up process is performed through a take-up machine so that the whole stranding process is accomplished; the tension pay-off devices perform pay-off in a passive manner, and the pay-off tension can be adjusted through a permanent magnet damping regulator; the cradle frame can swing during pay-off so that back-twist pay-off is realized, and the stranding quality is effectively improved; besides, the stranding speed is fast, the operation is simple and convenient, labor saving and time saving are achieved, and the work efficiency is high.

Owner:DONGGUAN NEW ENSHIANG MACHINERY ENTERPRISE

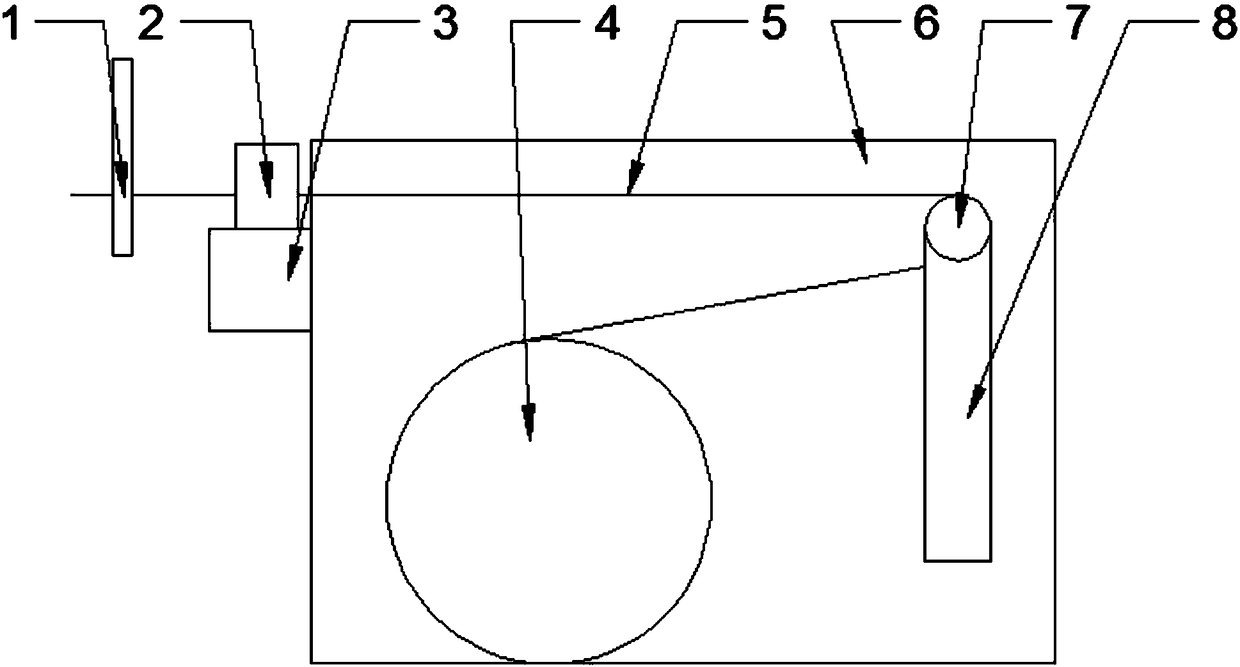

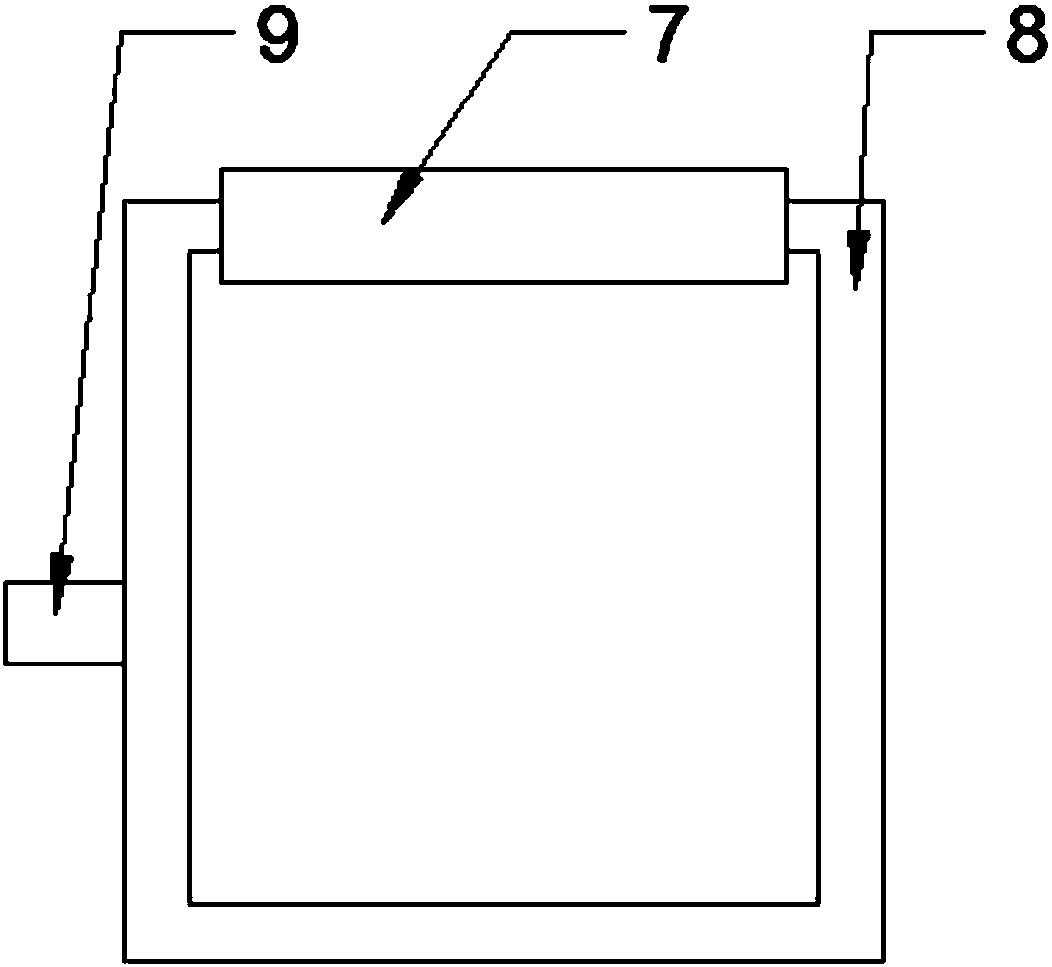

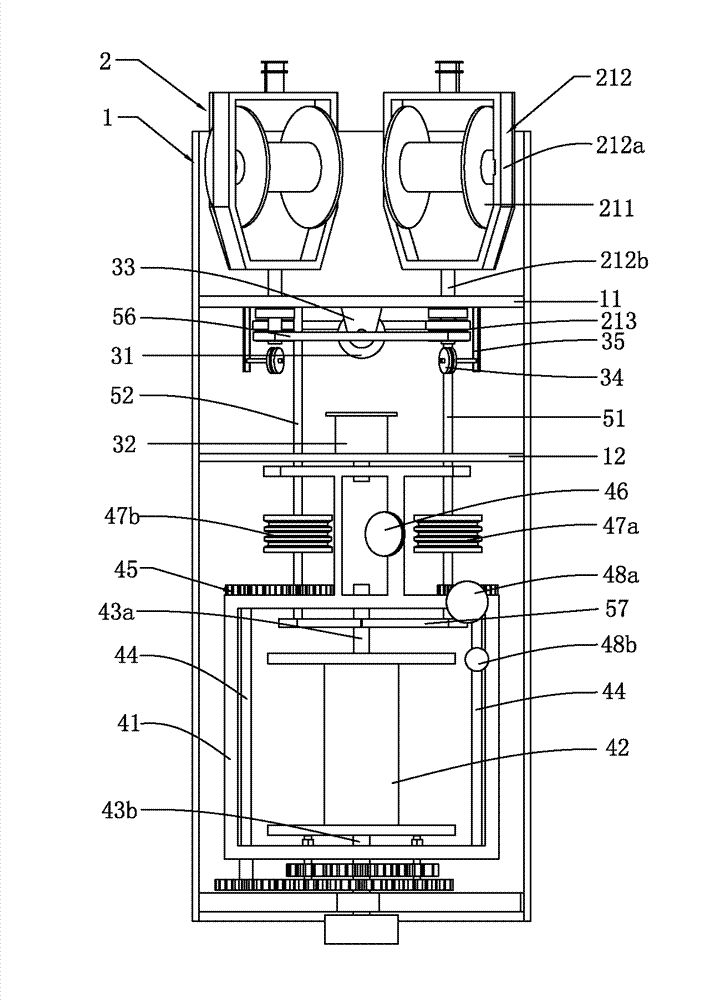

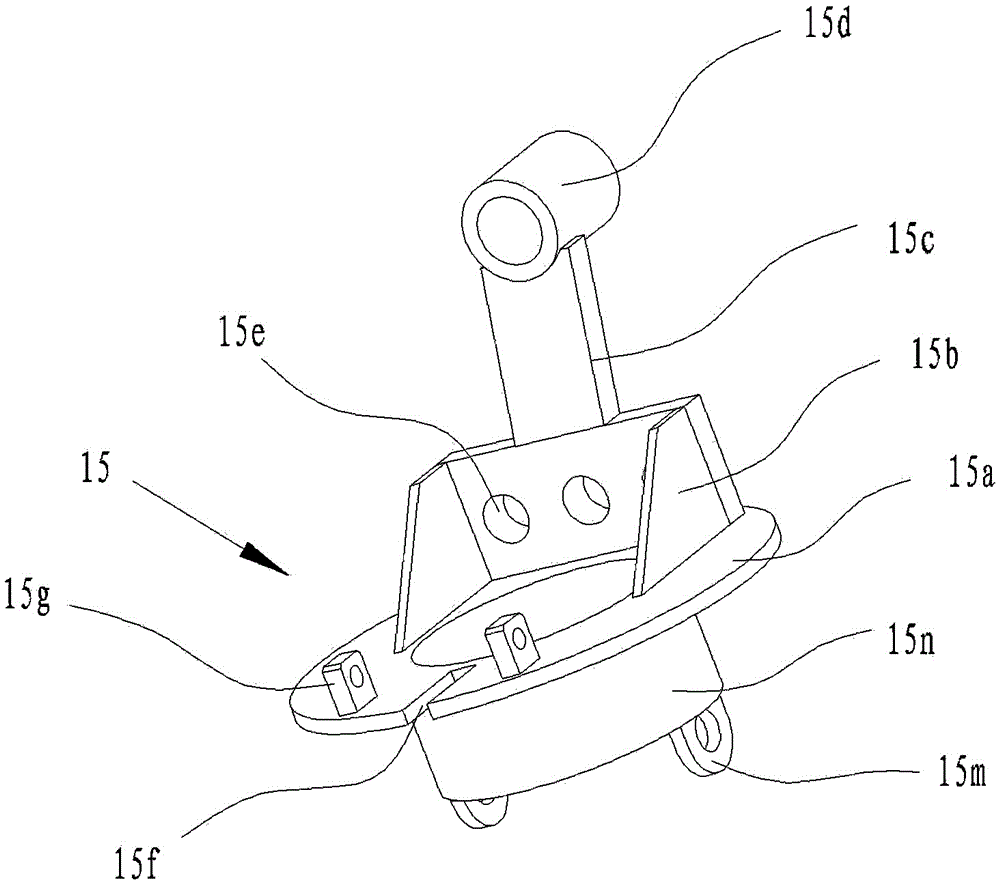

Tension detection control device for center-based stranding machine

InactiveCN106782912AUniform and stable tensionImprove stranding qualityCable/conductor manufactureElectrical conductorSolenoid valve

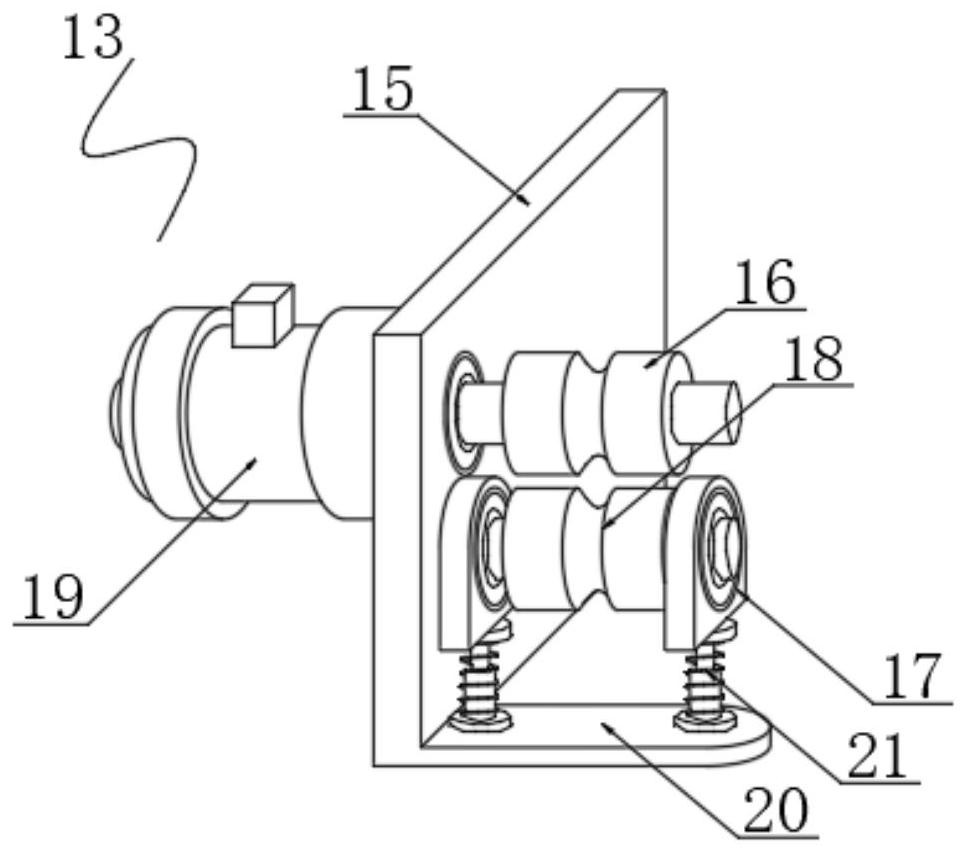

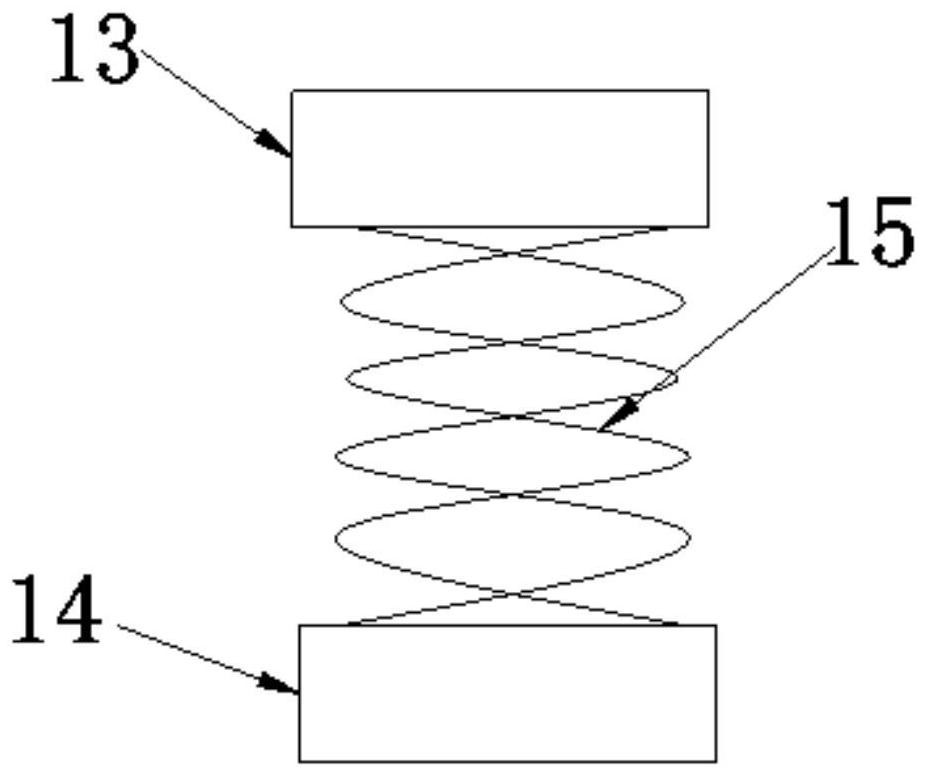

The invention relates to a tension detection control device for a center-based stranding machine, comprising a pay-off spool (1). A cable core (2) is twined and connected on the pay-off spool, a range sensor (5) that is in induction fit with the cable core is arranged below the pay-off spool, one side of the pay-off spool is provided with a brake (7), a proportional pressure valve (8) and a solenoid valve (9) which are mounted through a brake support (6) and connected by a pipeline, and the solenoid valve is connected with an air source (12) through a third pipeline (12); and the tension detection control device further comprises a control device (14) connected with the range sensor and the solenoid valve. The tension detection control device has the advantages that the device is used for detecting the match degree of the change, from a full plate to a shallow plate, of a wire conductor stored in the pay-off spool and the line outgoing speed of a complete machine, matches up with an air pressure disc brake through an inductor detection feedback mode in the process of releasing the conductive cable core, and automatically adjusts the stability of line releasing tension of the wire conductor stored in the pay-off spool, so that the cable releasing tension is guaranteed to be uniform and stable, and the cable stranding quality is improved.

Owner:安徽长江精工装备科技有限公司

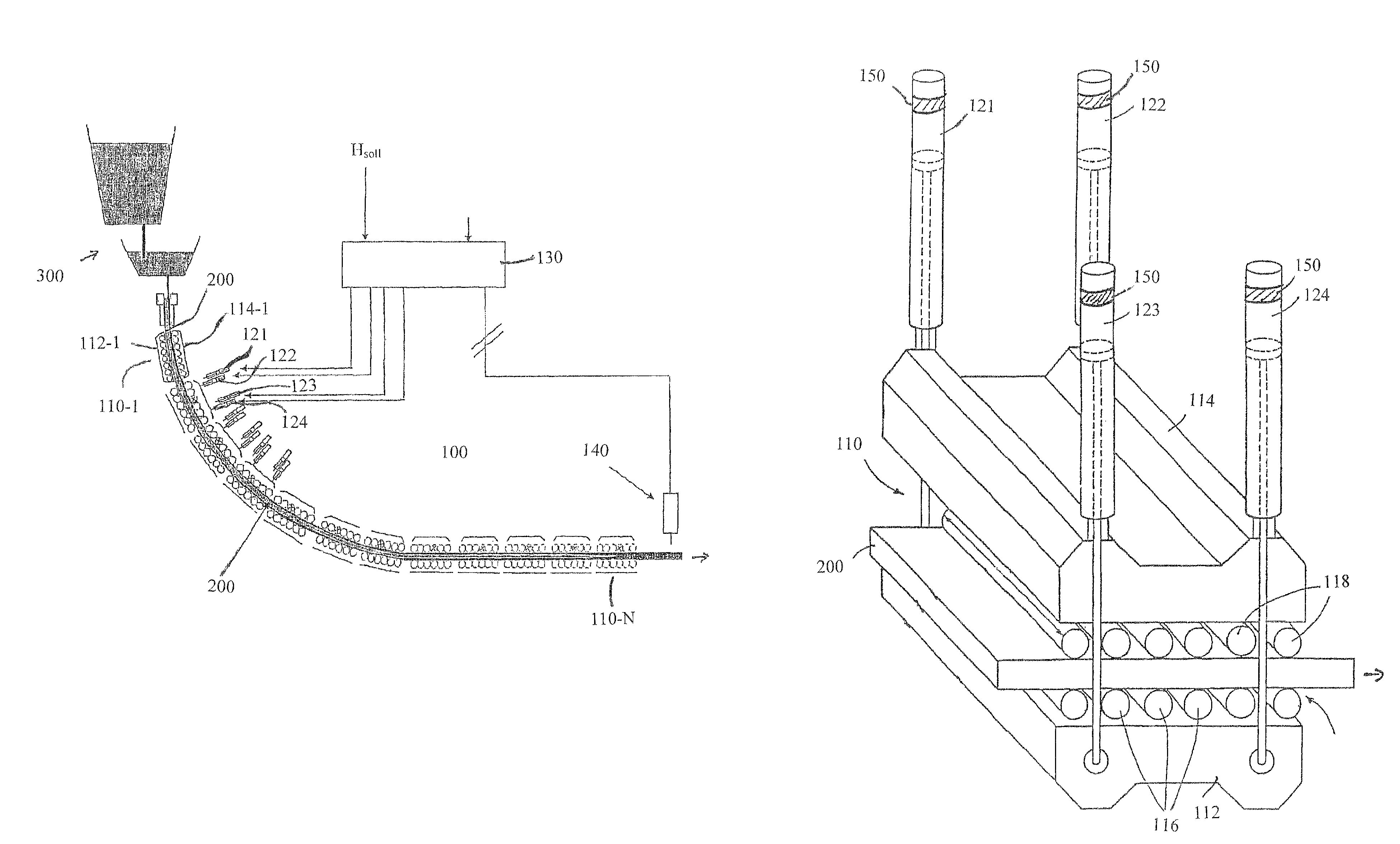

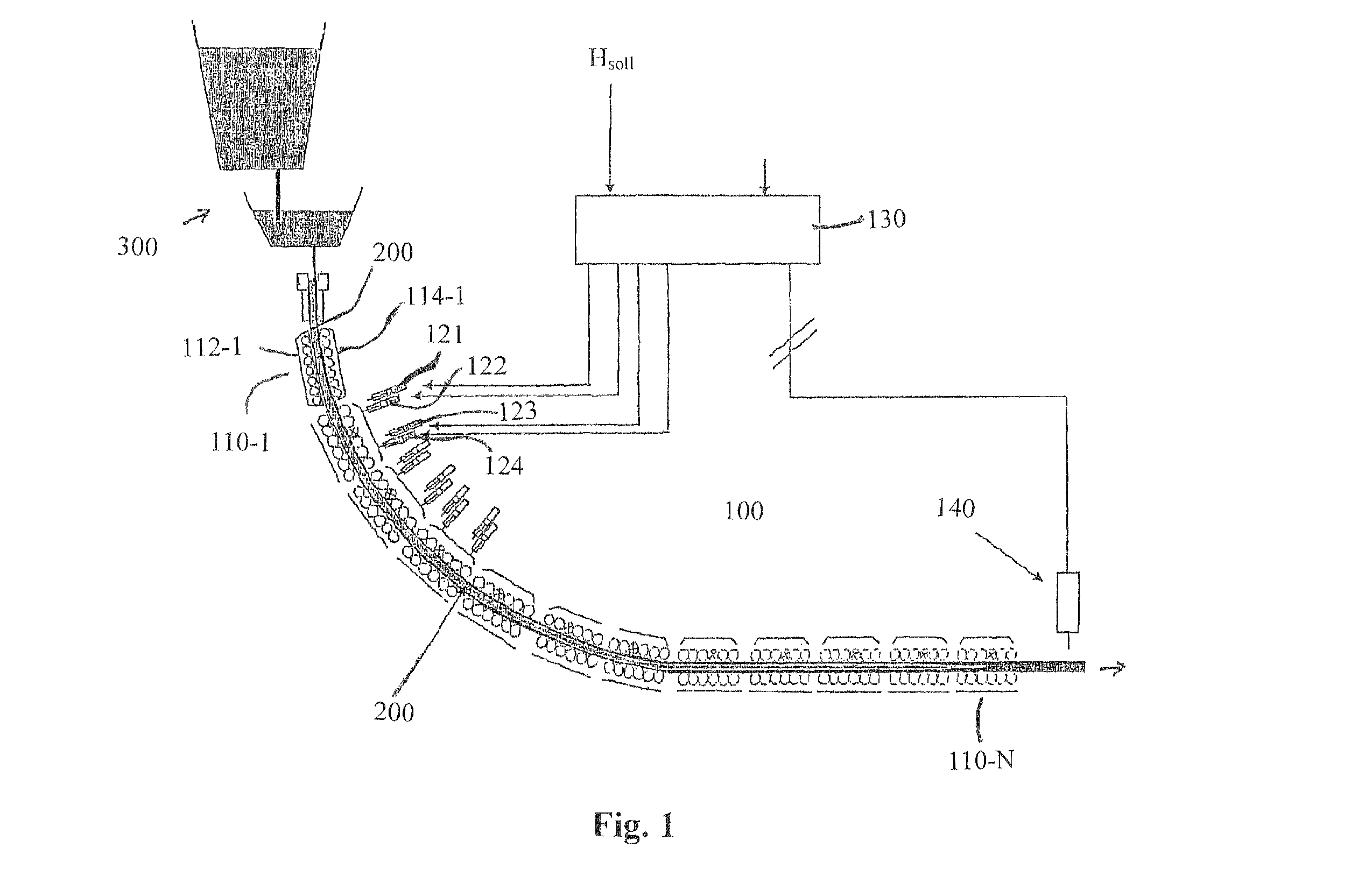

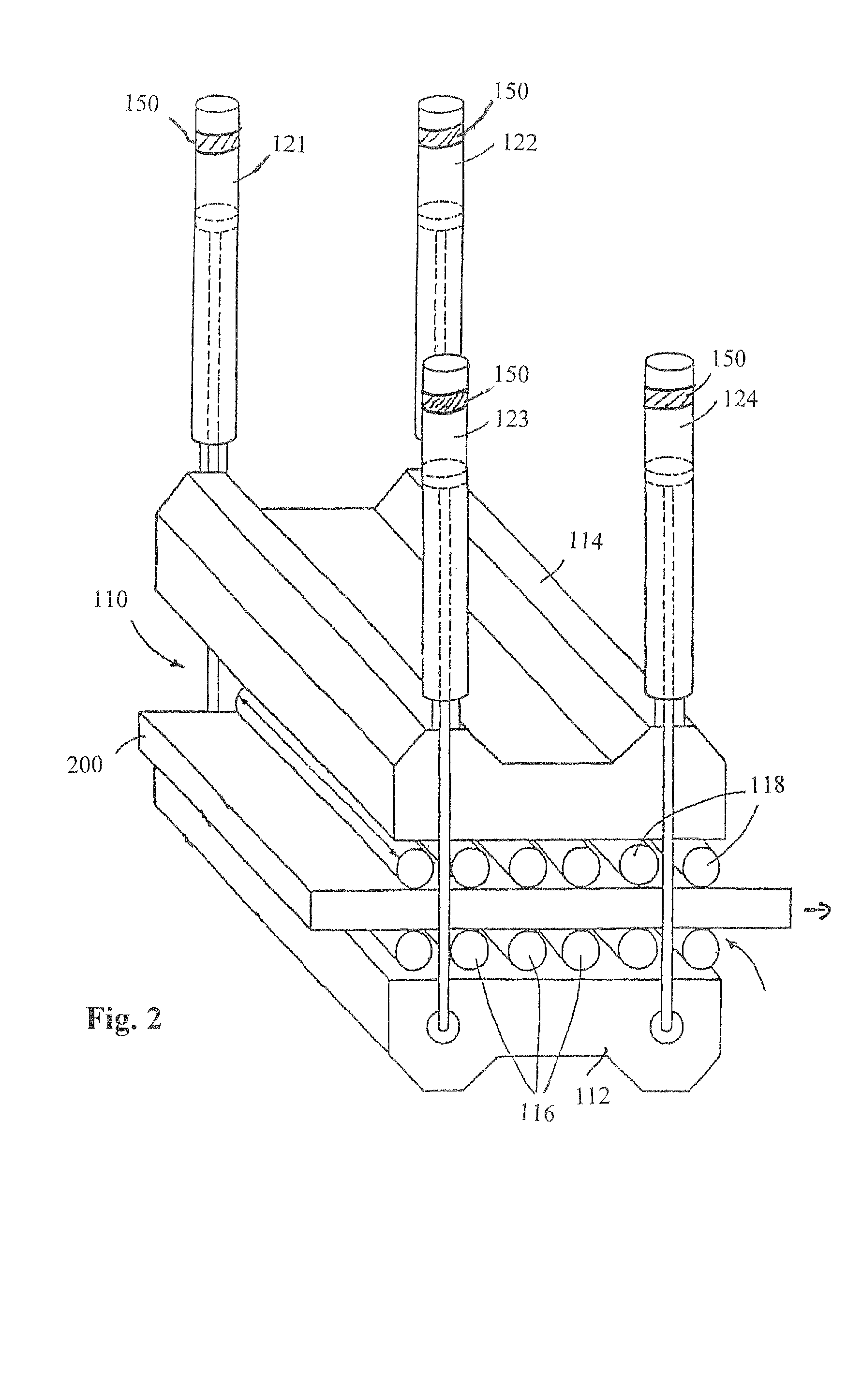

Method and device for positioning at least one roll segment of a strand guiding unit against a strand

ActiveUS20110220315A1Improve stranding qualityQuality improvementRoll force/gap control deviceMoulding machine componentsEngineeringEqualization

Owner:SMS DEMAG AG

Method and device for positioning at least one roll segment of a strand guiding unit against a strand

ActiveUS8205661B2Improve stranding qualityQuality improvementRoll force/gap control deviceCasting safety devicesEngineeringEqualization

A method for adjusting a roll segment of a strand guide of a slab-casting installation against a strand, wherein the roll segment has an upper and a lower roll support that each have an adjusting element for adjusting the two roll supports relative to each other. The method includes individual control of the individual adjusting elements, wherein the actual profile of the strand, including the heights of the right and left lateral edges of the strand, is detected and compared with a set profile that includes a predetermined set height, which is the same for the right and left lateral edges, and the individual adjusting elements of the roll segment are individually controlled based on the control deviation that results from the comparison so that the actual profile is adapted to the set profile, including equalization of the heights of the right and left lateral edges of the strand.

Owner:SMS DEMAG AG

Cable-twisting device

The invention relates to a cable twisting device Including base, A first fixed bracket is arranged on the top of the base, A fixing plate is vertically arranged on the top of the first fixing bracket,One side of the fixing plate is provided with a first wire mechanism, and the other side is provided with a second wire mechanism. The first wire mechanism and the second wire mechanism both comprisea finite position plate group. The position limiting plate group is vertically arranged between the position limiting plate group and the fixing plate, and the position limiting plate group is composed of a left side plate and a right side plate. By passing the side cable to be stranded through the limiting groove and the wire hole on the wire plate in turn, and the center cable passes through the center position of the stranded tube, and the side cable passes through the conductor groove formed between the adjacent spiral guide strips, and then the pitch in the stranding process can be ensured to be a fixed value by using the turntable with the fixing clip in the rotating process and the stranded tube, so as to greatly improve the twisting quality of the cable.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

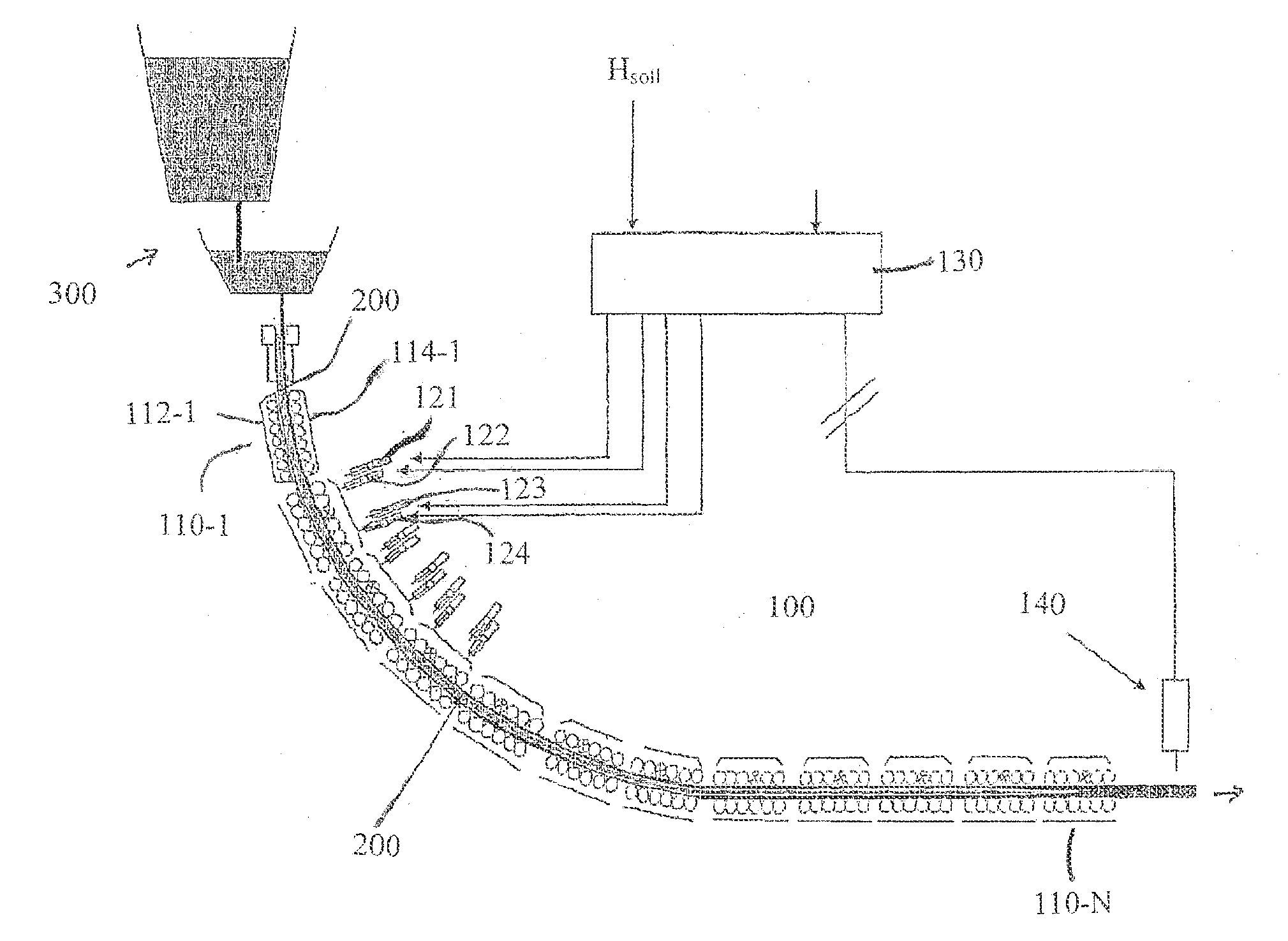

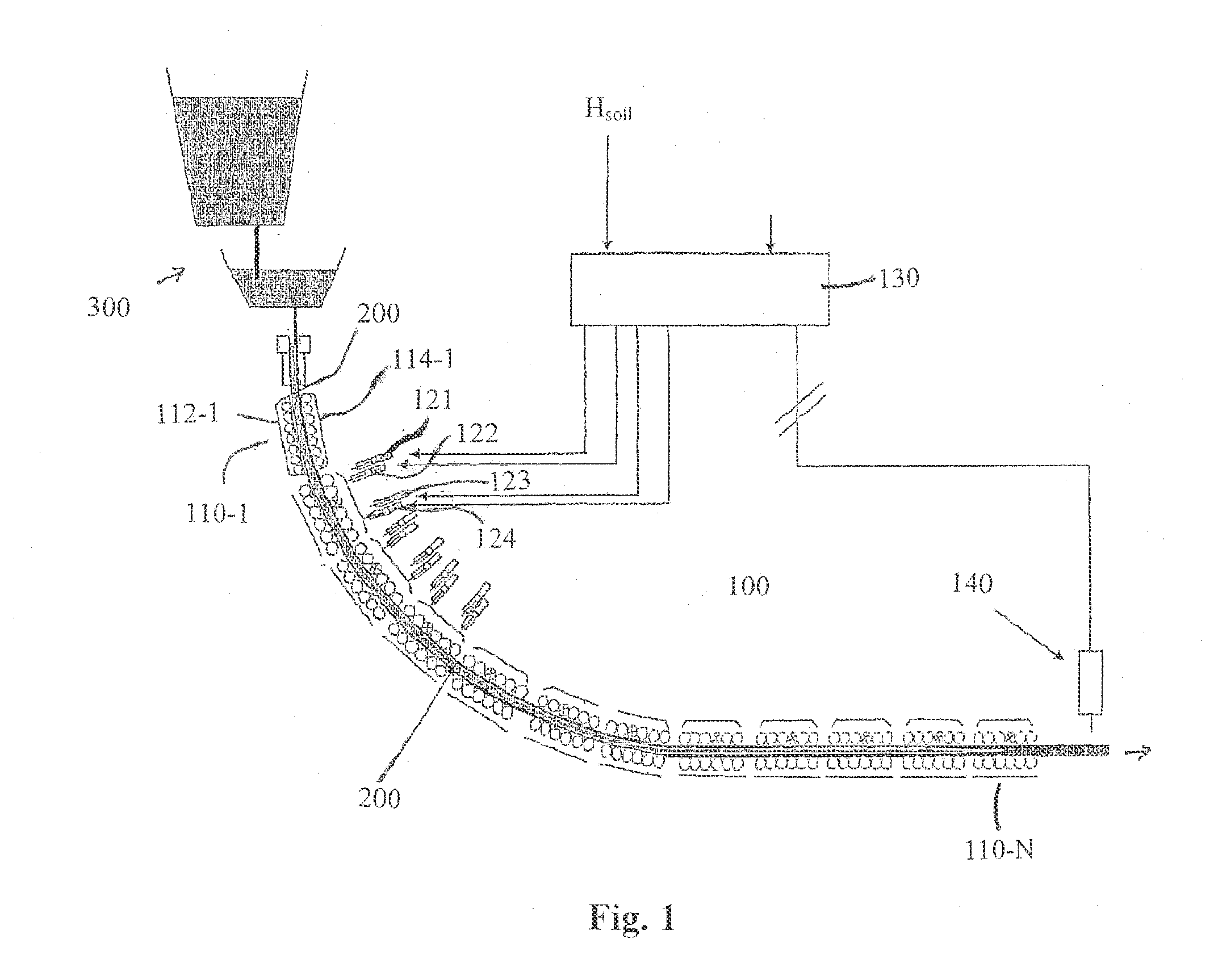

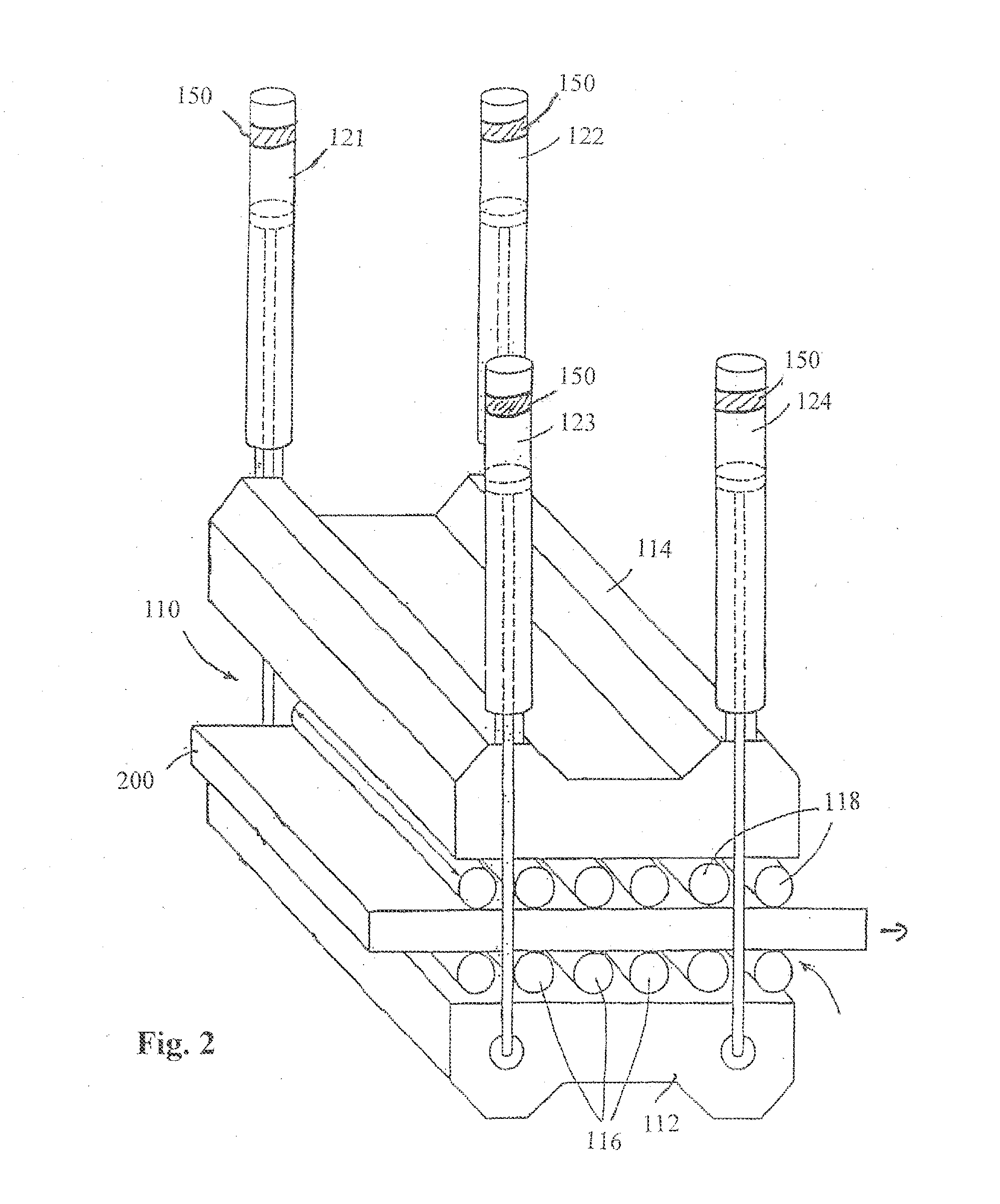

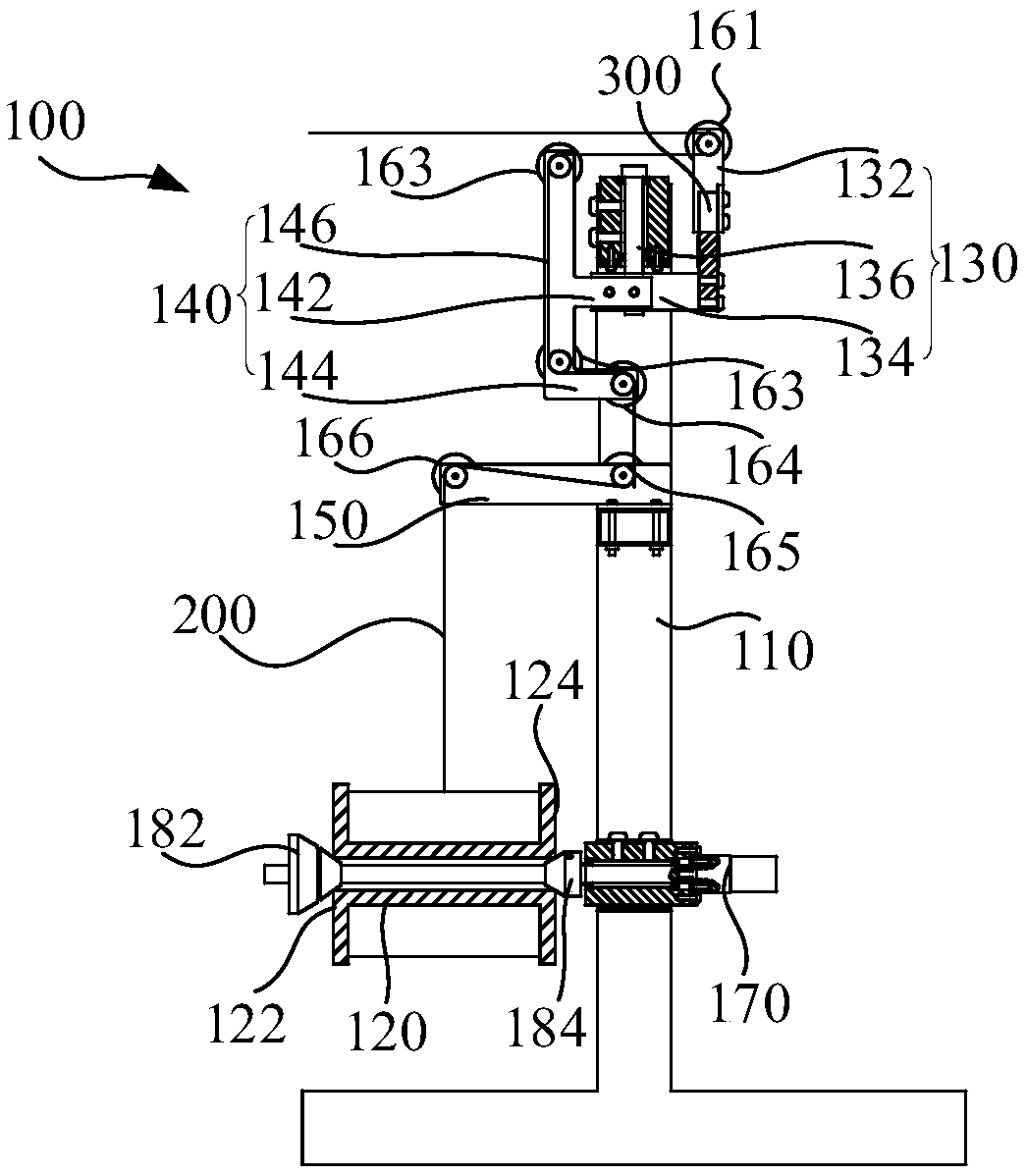

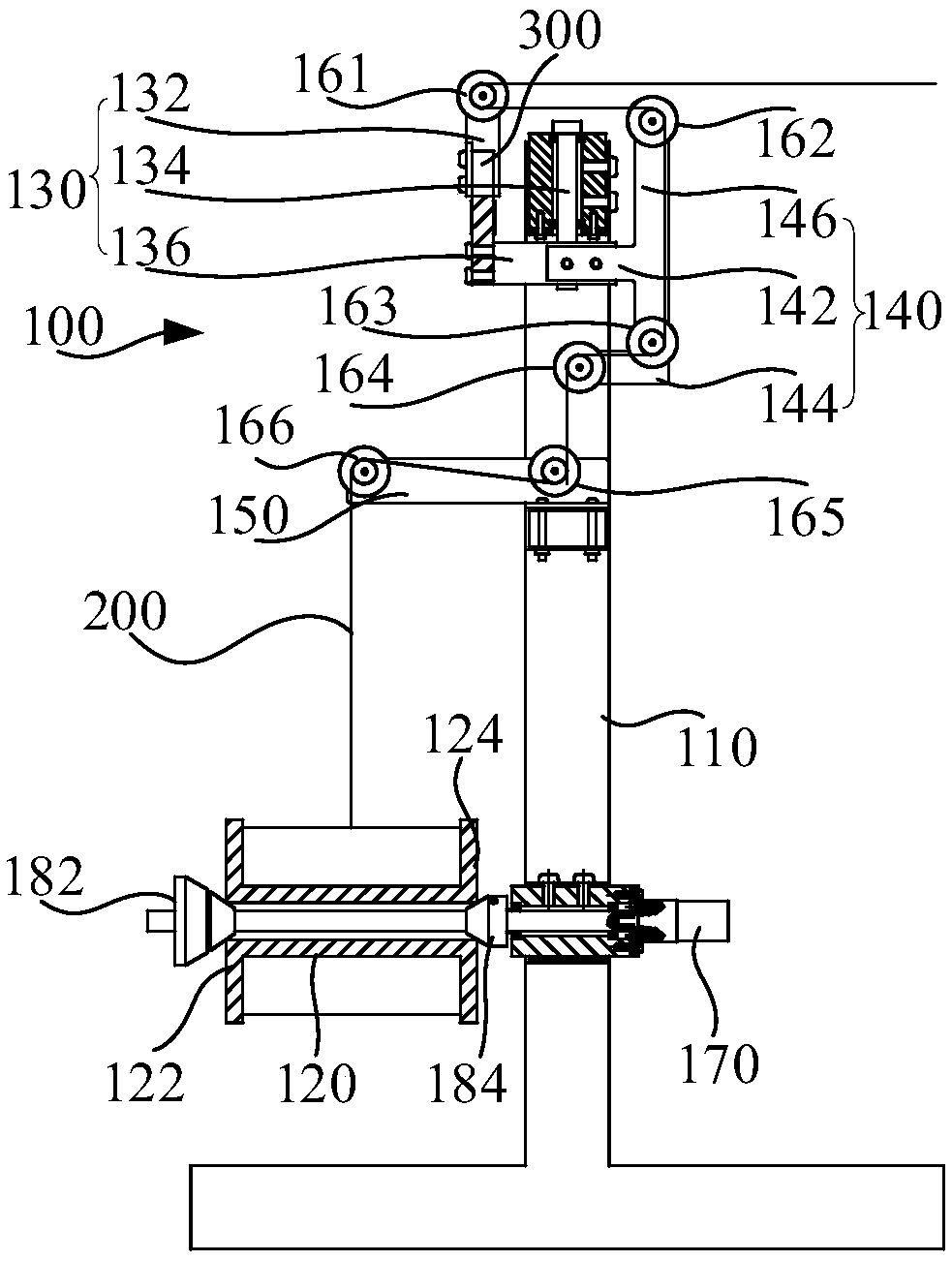

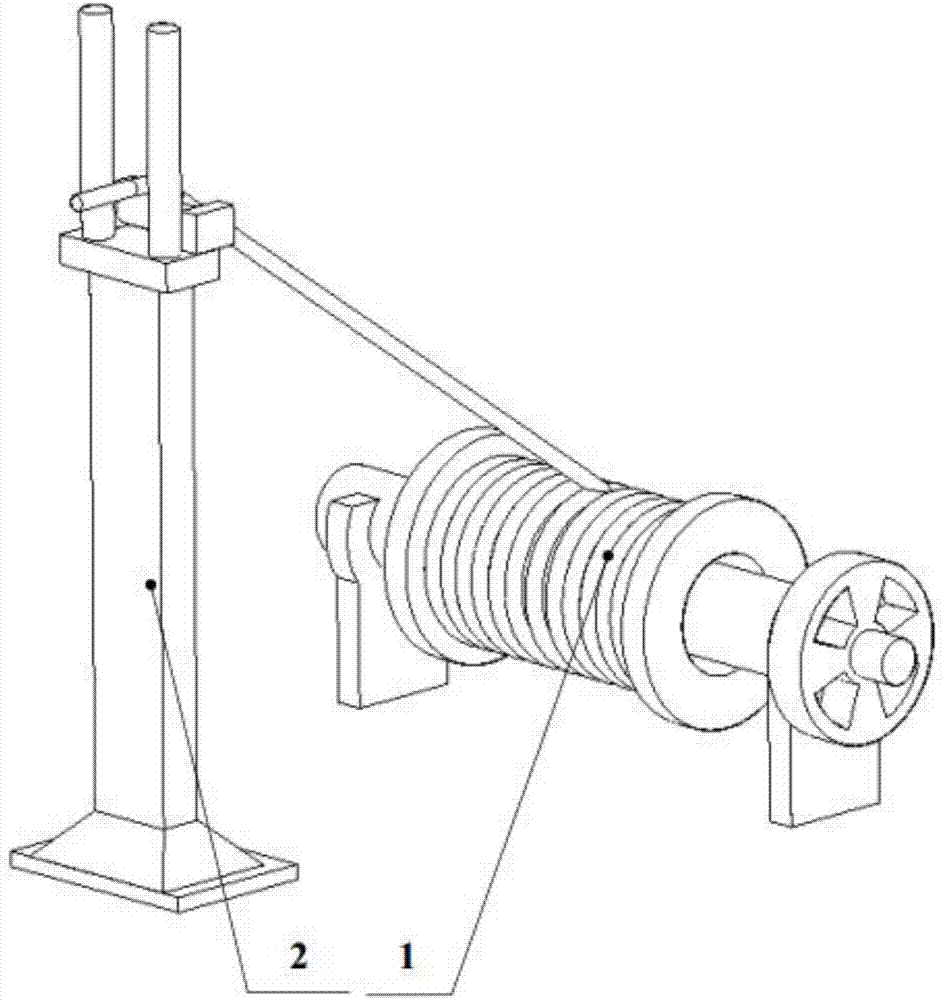

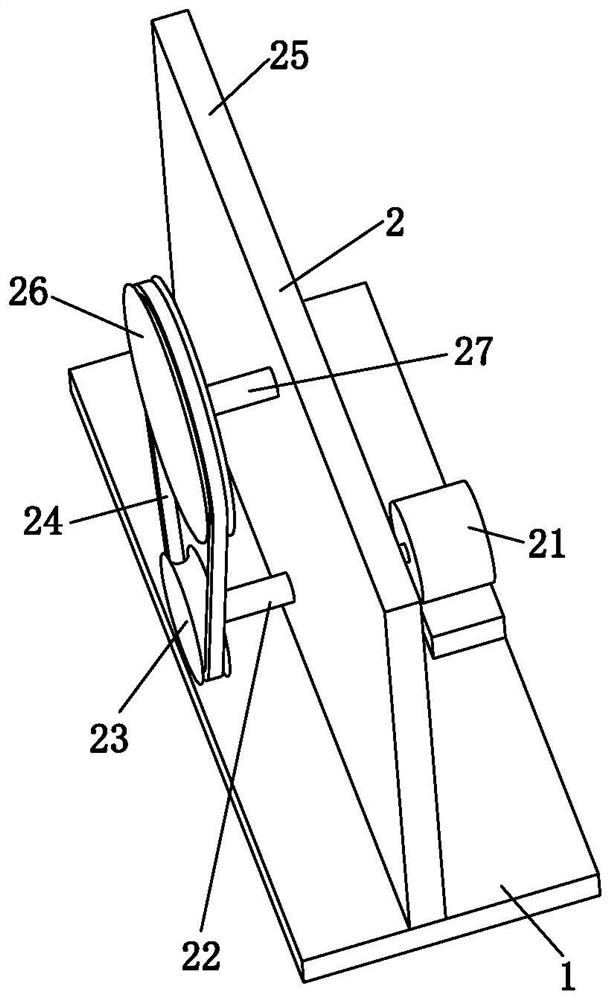

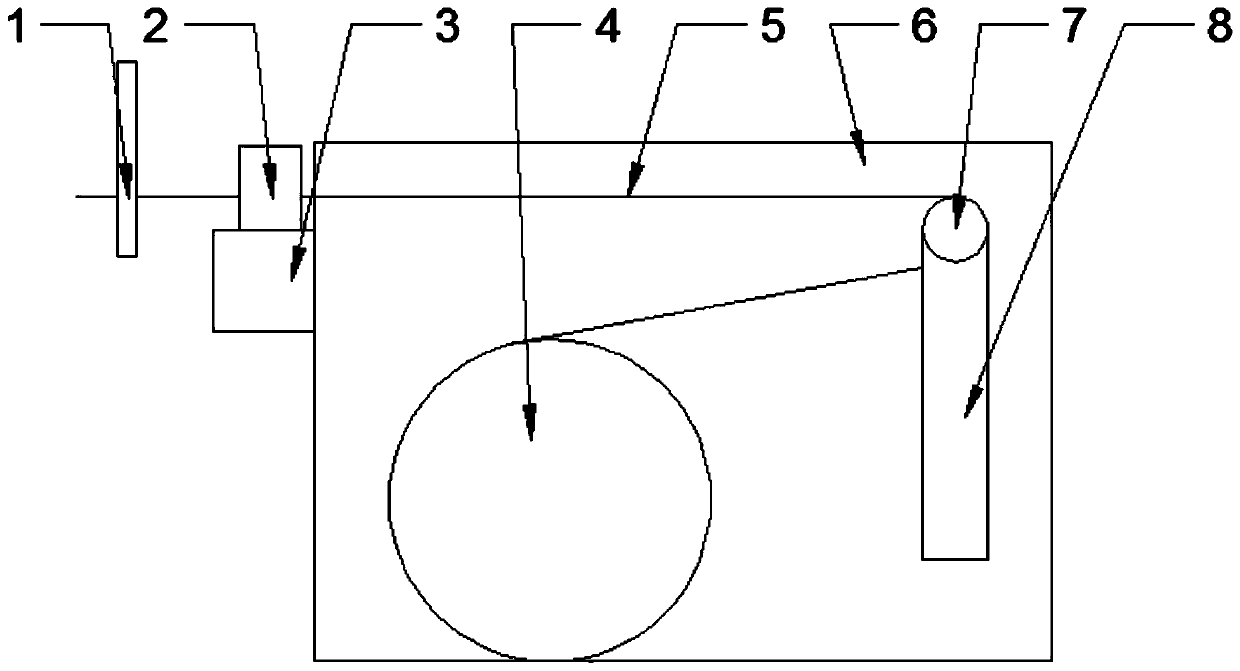

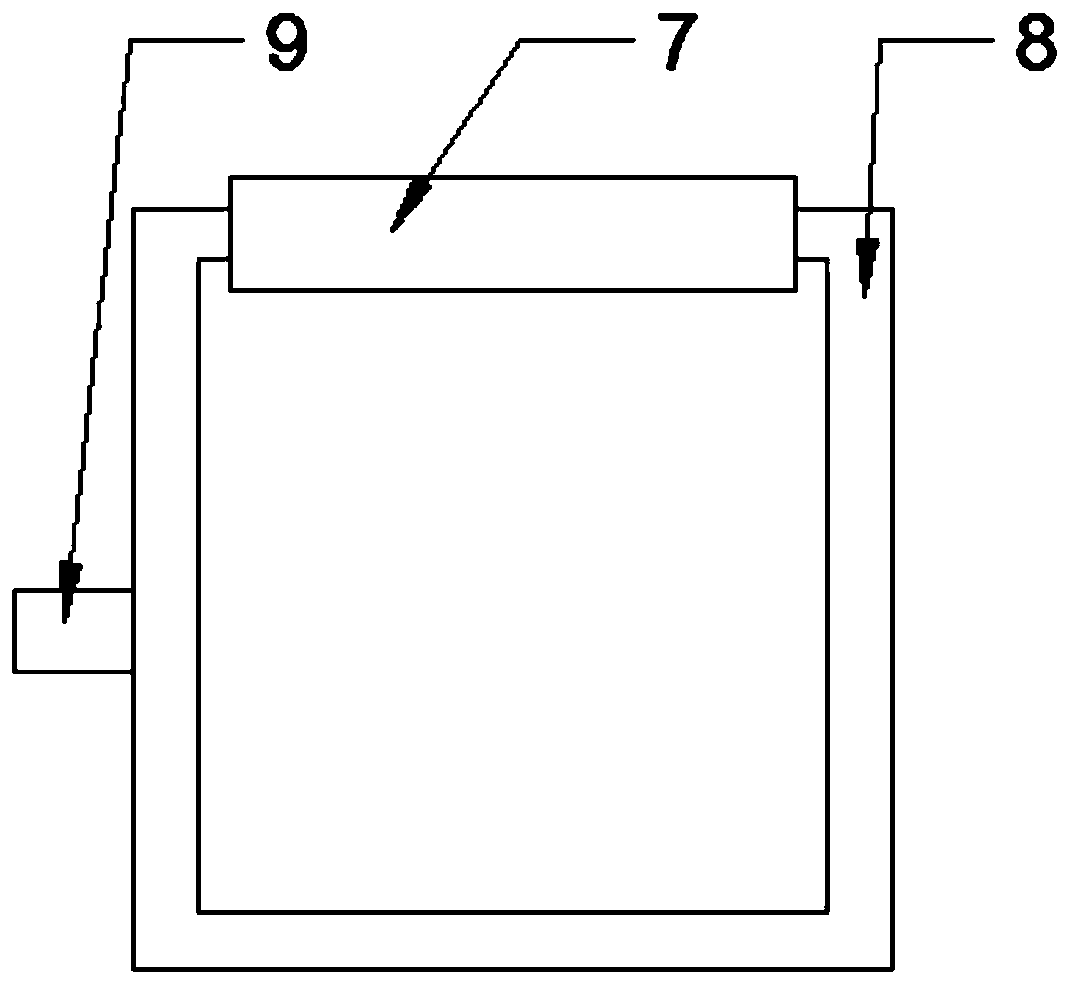

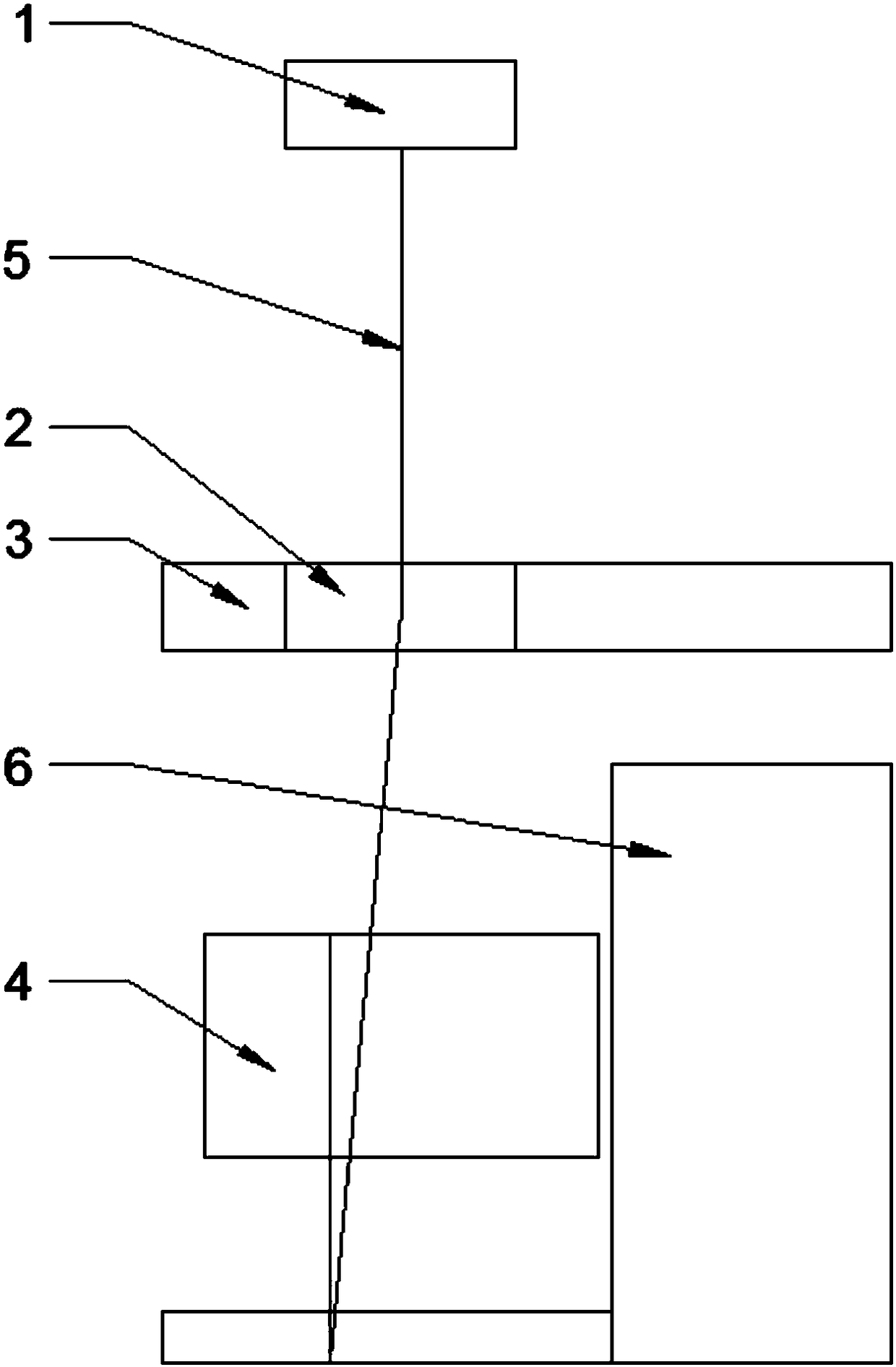

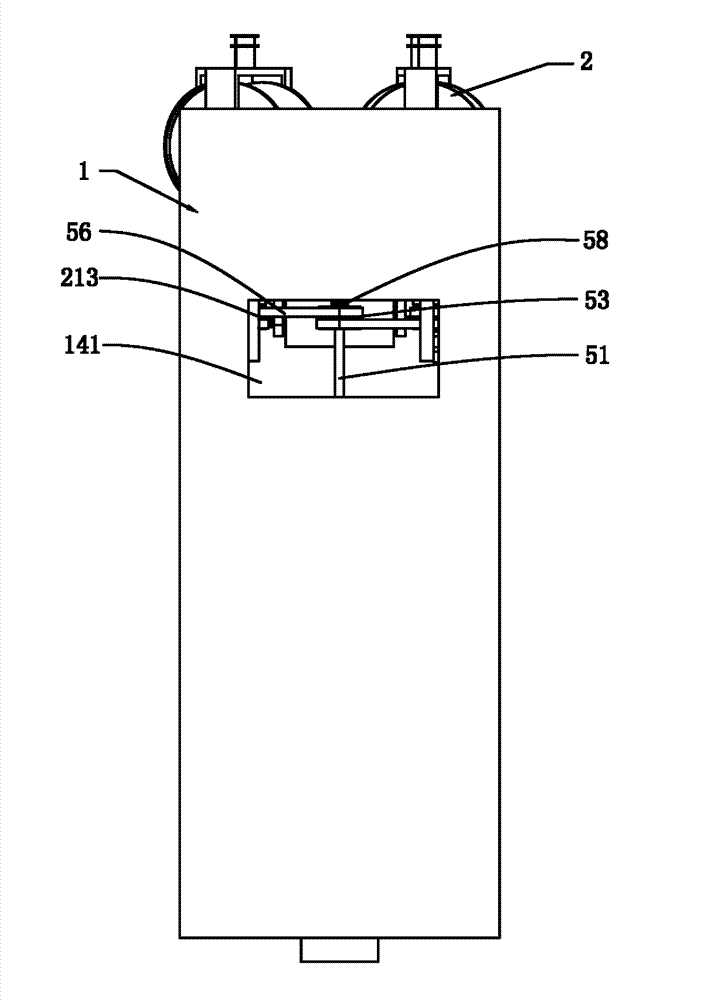

Dereeler, wire stranding system, and wire tension control method

PendingCN108750790AAvoid breakingImprove stranding qualityFilament handlingCable/conductor manufactureWire tensionEngineering

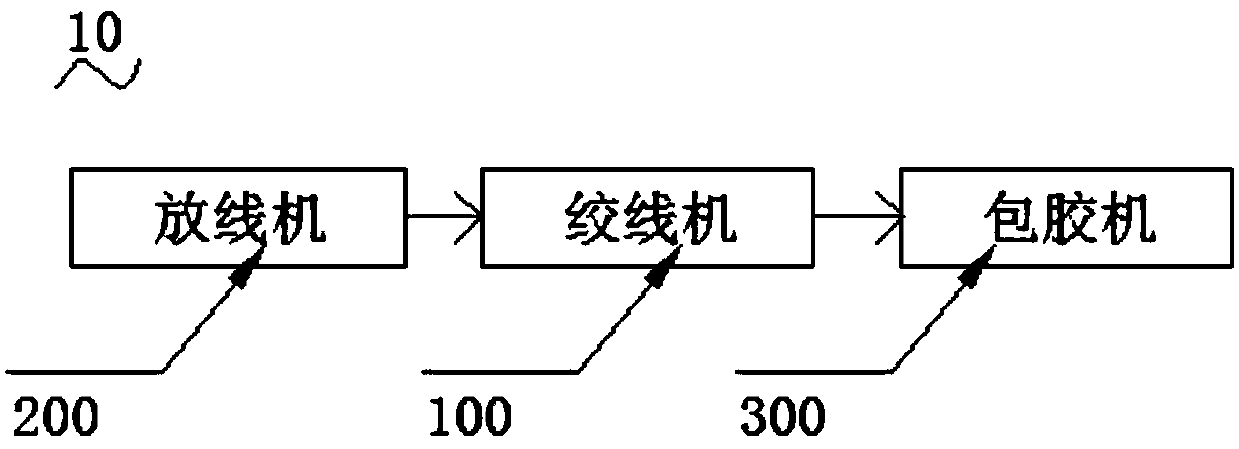

The invention discloses a dereeler, a wire stranding system and a wire tension control method. The dereeler comprises an installation support, a swinging assembly, a wire feeding device, a pressure sensor and a controller. The swinging assembly is provided with a swinging piece and a first rolling body; one end of the swinging piece is rotatably arranged on the installation support; the other endof the swinging piece can swing relative to the installation support and is connected with the first rolling body; the first rolling body is provided with a wire inlet side, a guiding part and a wireoutlet side; the guiding part is arranged between the wire inlet side and the wire outlet side; the wire feeding device comprises a wire feeding piece and a drive piece; the drive piece is used for driving the wire feeding piece, so that the wire feeding piece can convey a wire to a wire stranding device along the wire inlet side, the guiding part and the wire outlet side; the pressure sensor is used for measuring the pressure of the wire applied on the swinging piece through the first rolling body; and the controller is in communication connection with the pressure sensor and the drive piece.The dereeler can enable a tension value of the wire to maintain a preset value.

Owner:GUANGZHOU INST OF RAILWAY TECH

Electric wire and electric cable auger machine

ActiveCN107316717AEliminate splittingImprove stranding qualityCable/conductor manufactureElectronic waste recyclingPhysicsDrive shaft

The present invention belongs to the field of electric cable production equipment, and more particularly relates to an electric wire and electric cable auger machine which comprises a main wire rotating shaft, a positioning frame, wire inlet sleeves at all levels, rotation sleeves at all levels, transmission chains at all levels, transmission shafts at all levels, rotating disks at all levels, rotating disk racks at all levels, directional wheels at all levels, branching wire rotating shafts at all levels, disk holes at all levels, cluster die heads at all levels, a rotating electric motor, a pull-up group of low wheels, a pull-up group of high wheels, a pull-down group of high wheels, a pull-down group of low wheels, package rotating sleeves, non-woven cloth rods, a metering rotary wheel, a tightening rotary wheel, a synchronous steering electric motor, a rotary shaft platform, a support rack platform rod, a wire take-up rod, a sleeve rod and a wire forming rotary shaft. The beneficial effects of the electric wire and electric cable auger machine are that (1) bidirectional twisting can be realized, and branching wire interweaving and non-uniform intertwisting can be prevented; (2) the number of twisting layers can be enlarged and the number of stranded wires can be adjusted; (3) lapping operation can be performed at the same time; (4) accurate metering can be realized, cabled wires can be bundled tight, and convenience of blanking cabled wires can be improved.

Owner:安徽腾飞特种电缆科技有限公司

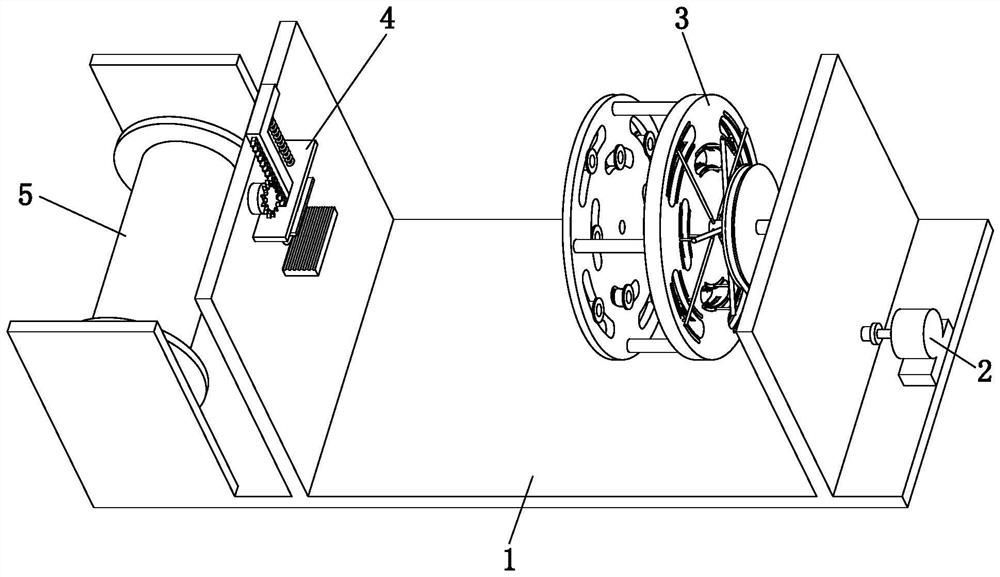

High-strength steel strand producing, manufacturing and stranding processing machine

InactiveCN113279274AImprove stranding qualityAvoid entanglementRope making machinesStructural engineeringManufacturing engineering

The invention relates to a high-strength steel strand producing, manufacturing and stranding processing machine. The high-strength steel strand producing, manufacturing and stranding processing machine comprises a bottom plate, a driving device, a stranding device, a clamping device and a winding device. The stranding processing machine can solve the following problems in the stranding process of steel wires: a, the number of wire harnesses of the steel wires is relatively large, traditional stranding equipment cannot position, install and guide steel wire coils easily, so that the phenomenon that the steel wires are wound easily in the stranding process is caused, consequently, the stranding is blocked or the stranding quality is relatively poor, and the stranded steel strands cannot be put into use; and b, the mounting positions of the steel wire coils are mostly fixed, so that when different strands of steel wires are stranded and adjusted, the mounting positions of the steel wire coils cannot be changed, the included angles between the stranded steel wires are not uniform, the polymerization degree of the stranded steel strands is relatively poor, and the overall performance of the steel strands is reduced.

Owner:武亮

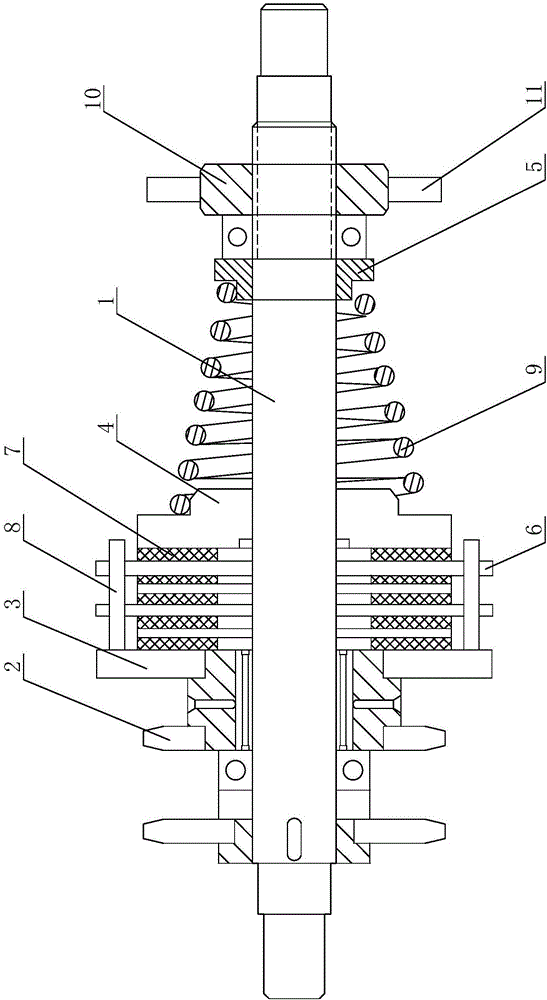

Slipping device for tube type stranding machine take-up mechanism

The invention discloses a slipping device for a tube type stranding machine take-up mechanism. The slipping device comprises a take-up shaft, and a chain wheel is installed on the take-up shaft. The slipping device further comprises a damping device, the damping device comprises a damping wheel, a compression sleeve and a spring seat which are sequentially installed on the take-up shaft, multiple moving pieces and multiple static pieces are arranged between the damping wheel and the compression sleeve and are arrayed alternately, the moving pieces are arranged on the take-up shaft in a sleeving mode and can move relative to the take-up shaft, a positioning pin is fixed to the damping wheel, the moving pieces are connected to the positioning pin in a sliding mode, and the damping wheel is fixed to the take-up shaft; the compression sleeve is installed on the take-up shaft and can move relative to the take-up shaft; a spring is arranged between the spring seat and the compression sleeve, the spring seat is installed on the take-up shaft and can move relative to the take-up shaft, and a driving block for driving the spring seat to move axially is arranged on the take-up shaft. The slipping device is simple in structure, easy to obtain and stable and reliable in transmission in the take-up process and greatly improves stranding quality.

Owner:WUXI UNIVERSAL STEEL ROPE

Cable Stranding Machine

ActiveCN106128641BEasy to produceImprove applicabilityCable/conductor manufactureEngineeringElectric cables

Owner:江苏南瑞淮胜电缆有限公司

Efficient stranding device for cable production and processing

InactiveCN112289514AImprove smoothnessImprove uniformityCable/conductor manufactureStructural engineeringElectric cables

The invention relates to the technical field of cable production, in particular to an efficient stranding device for cable production and processing. The device comprises a supporting plate, a stranding bracket is welded at the front end of the upper surface of the supporting plate, a stranding disc is rotatably mounted at the upper end of the rear surface of the stranding bracket, and a gatheringdisc is arranged at the rear end of the stranding disc. A connecting rod is welded to the joint of the stranding disc and the gathering disc, a control box is installed at the upper end of the frontsurface of the stranding bracket, a material conveying support is welded to a rear position of the stranding bracket on the upper surface of the supporting plate, a tension material conveying component is installed at the upper end of the material conveying support, and a discharging hole is formed in the front surface of the gathering disc. A material conveying device is installed at the position, close to the material conveying support, of the front surface of the gathering disc. The stranding end of the stranding device is not provided with a gathering structure, and is provided with a discharging structure, the tension material conveying component can be replaced, the adaptive diameter of a machined cable is changed, and the device is simple in structure and small in size.

Owner:扬州润中信息科技有限公司

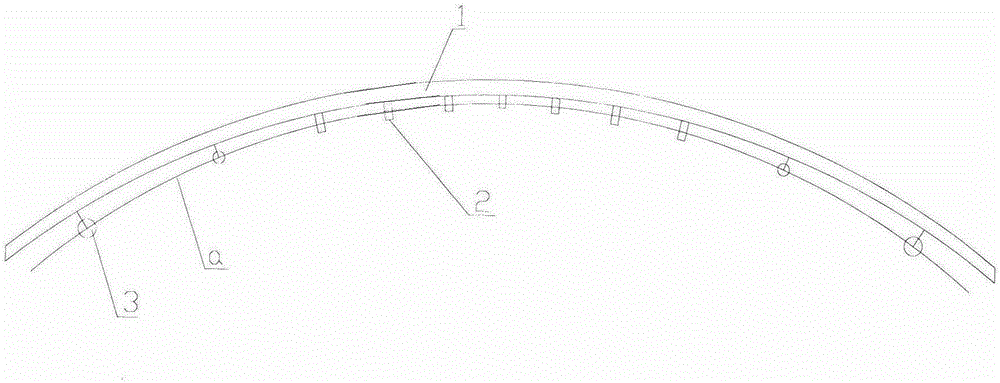

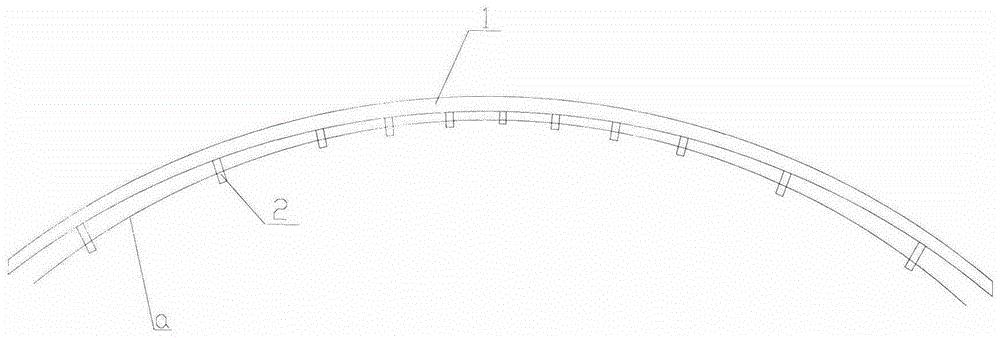

Conductor twisted roundness improving device and method

ActiveCN104376929AImprove stranding roundnessHollow state is goodRope making machinesCable/conductor manufactureCopper wireEngineering

The invention discloses a conductor twisted roundness improving device which comprises a twisting bow. A plurality of magnetic holes are formed in the twisting bow. The radial distance between the magnetic holes in the two ends of the twisting bow and the twisting bow is the maximum, and the radial distance between the twisting bow and the magnetic holes from the two ends to the middle of the twisting bow is gradually decreased, and the distance between the magnetic holes from the two ends to the middle of the twisting bow is gradually decreased. According to the conductor twisted roundness improving device, the copper wire hollow state is kept well, and the twisted conductor quality is the highest.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

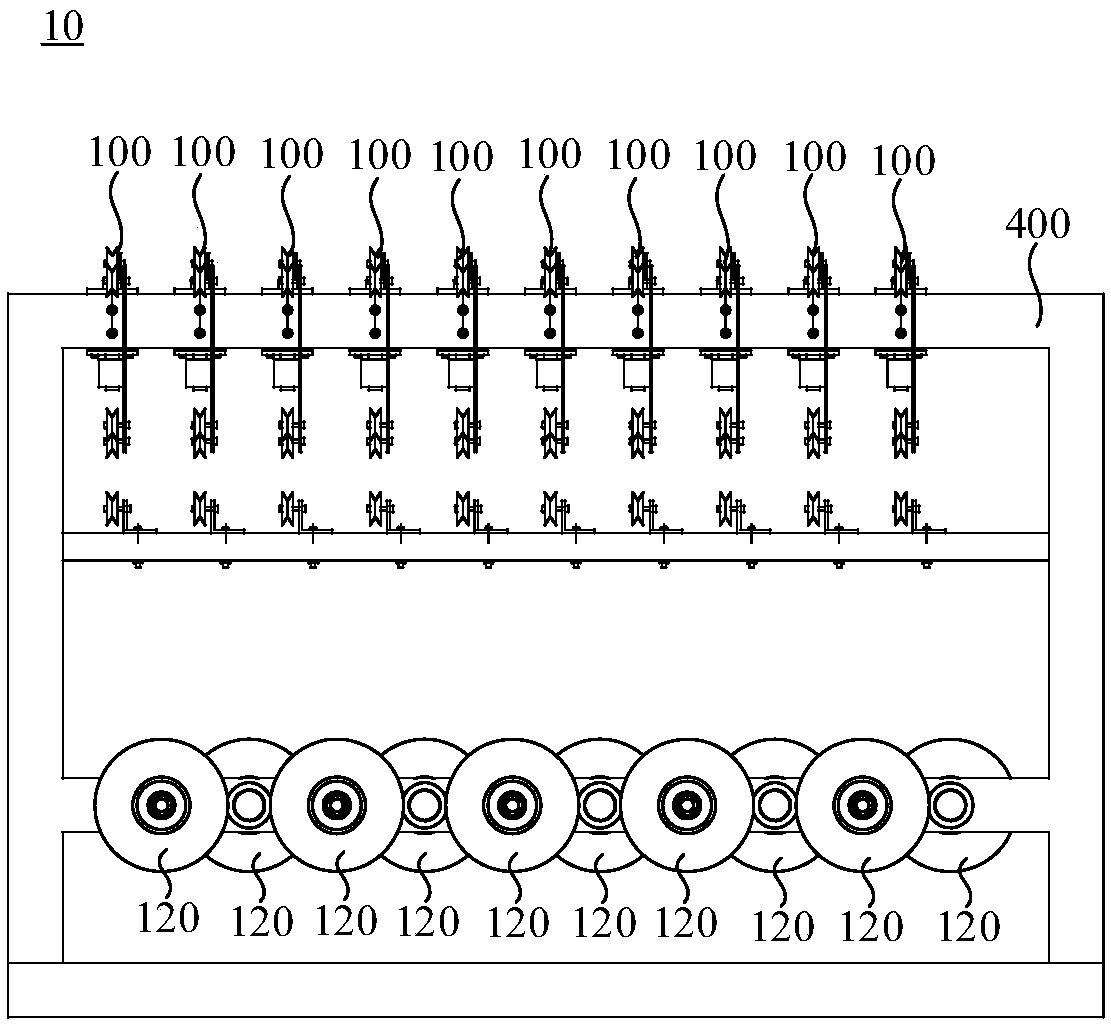

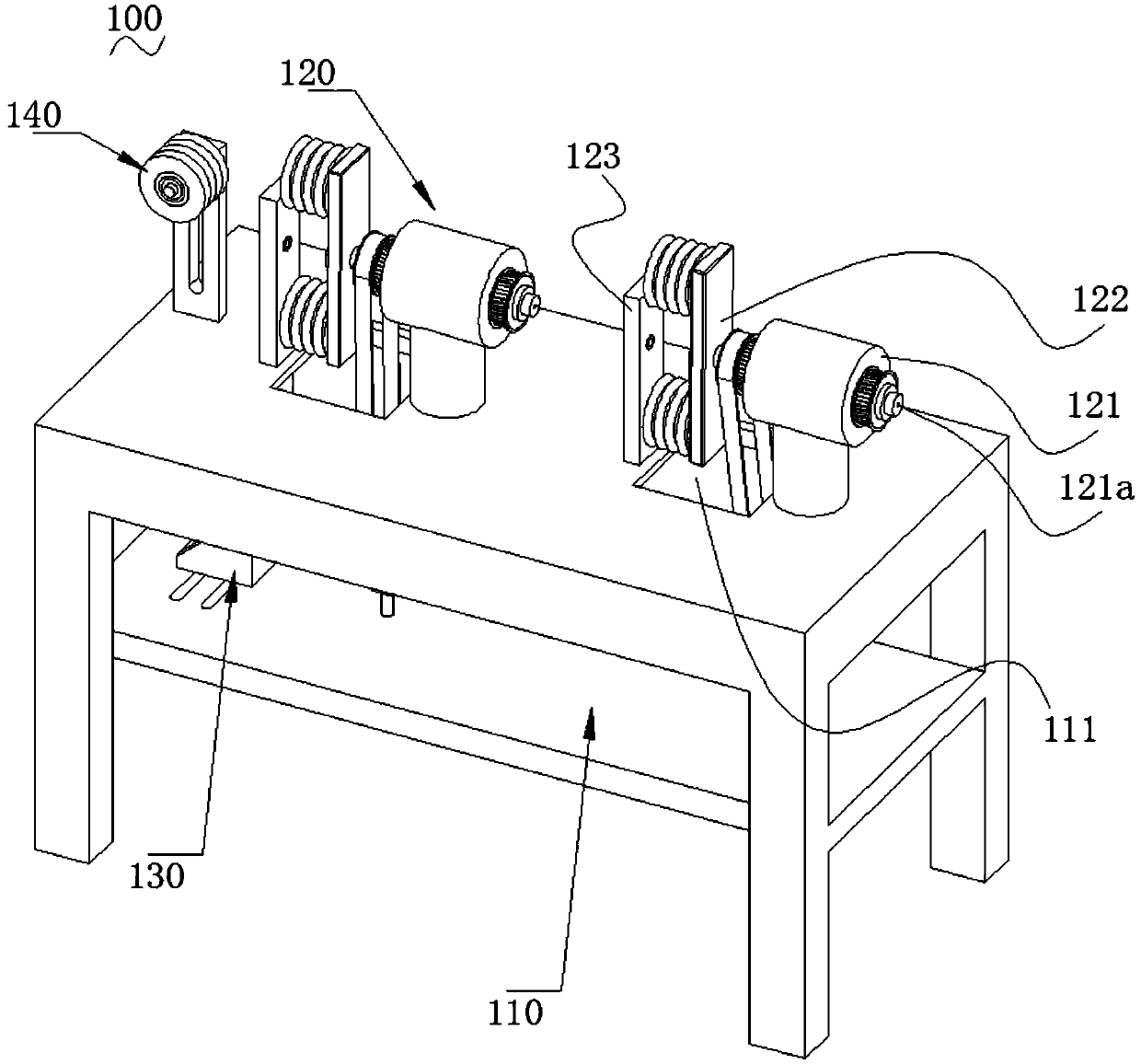

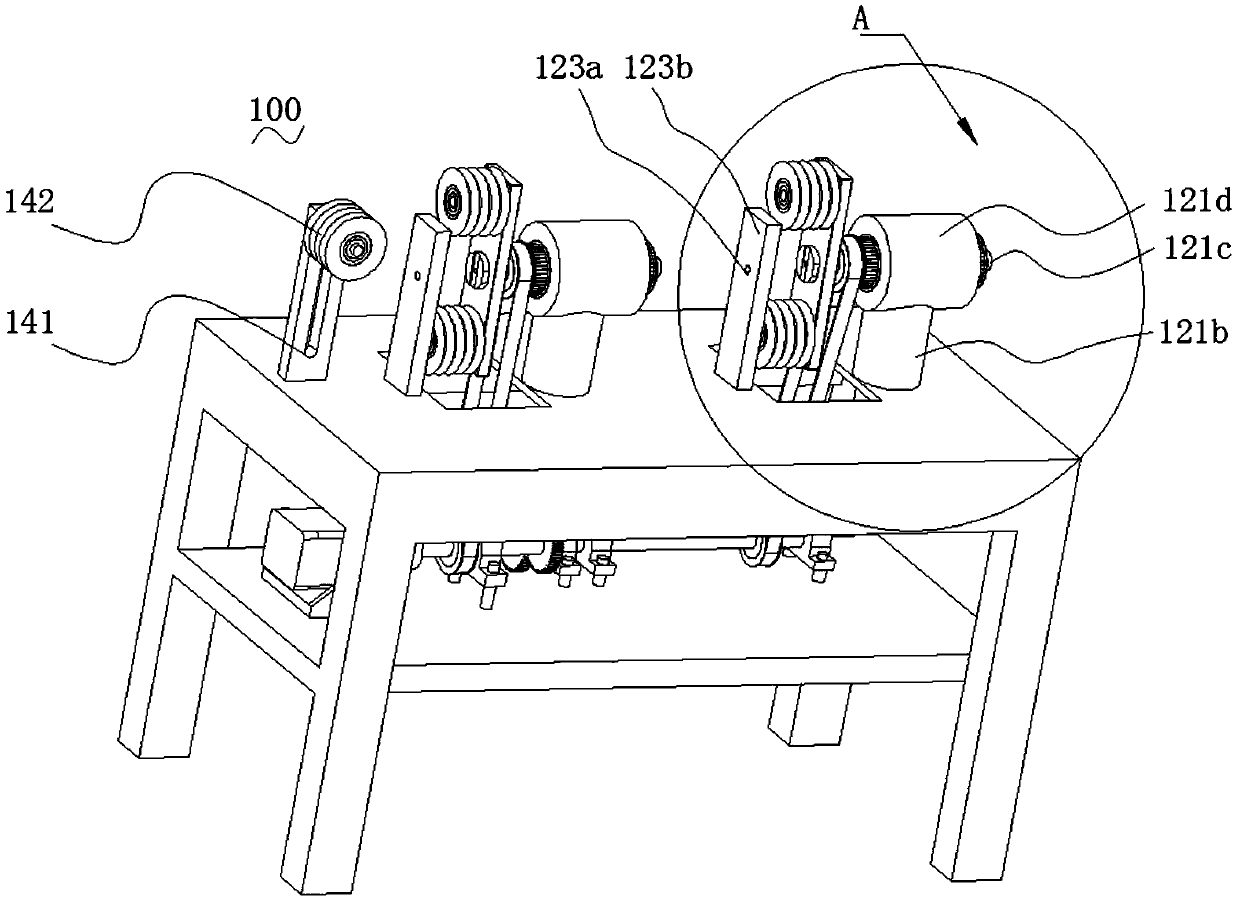

High quality cable production system

ActiveCN107481804BAvoid spreadingWon't call backApparatus for feeding conductors/cablesInsulating conductors/cablesEngineeringSmall footprint

The invention relates to the field of wire twisting machines, in particular to a high-quality cable production system. The system comprises a wire twisting machine which comprises a wire twisting platform, multiple wire twisting mechanisms installed on the wire twisting platform and a power mechanism which is installed below the wire twisting platform and used for providing power for the wire twisting mechanisms, and the wire twisting directions of the two adjacent wire twisting mechanisms are opposite; each wire twisting mechanism comprises a wire inlet unit used for wire incoming, a twisting unit connected to the output end of the wire inlet unit and a wire passing unit which is arranged parallel to the wire inlet unit and located on the side, deviating from the wire inlet unit, of the twisting unit for wire passing after twisting; a wire inlet hole is formed in each wire inlet unit, a wire outlet hole is formed in the portion, corresponding to each wire inlet hole, of the corresponding twisting unit, a wire passing hole is formed in the portion, corresponding to each wire outlet hole, of the corresponding wire passing unit, and wire inlet holes, the wire outlet holes and the wire passing holes are located on a straight line. The wire twisting machine is high in production efficiency, good in wire twisting quality and small in occupied area.

Owner:东莞市卡源电子有限公司

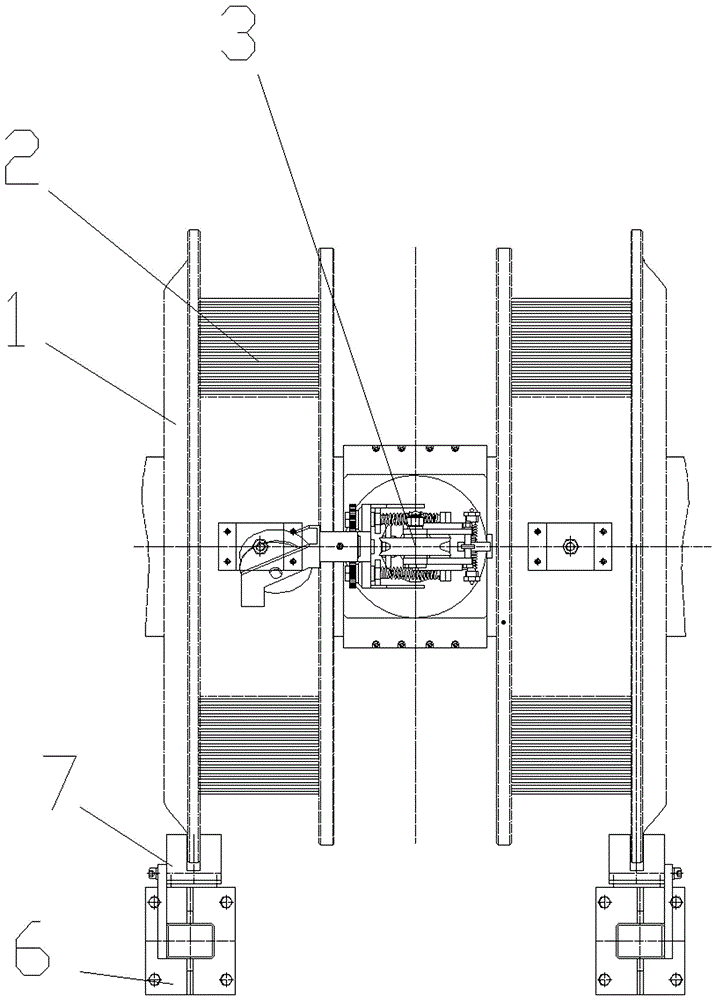

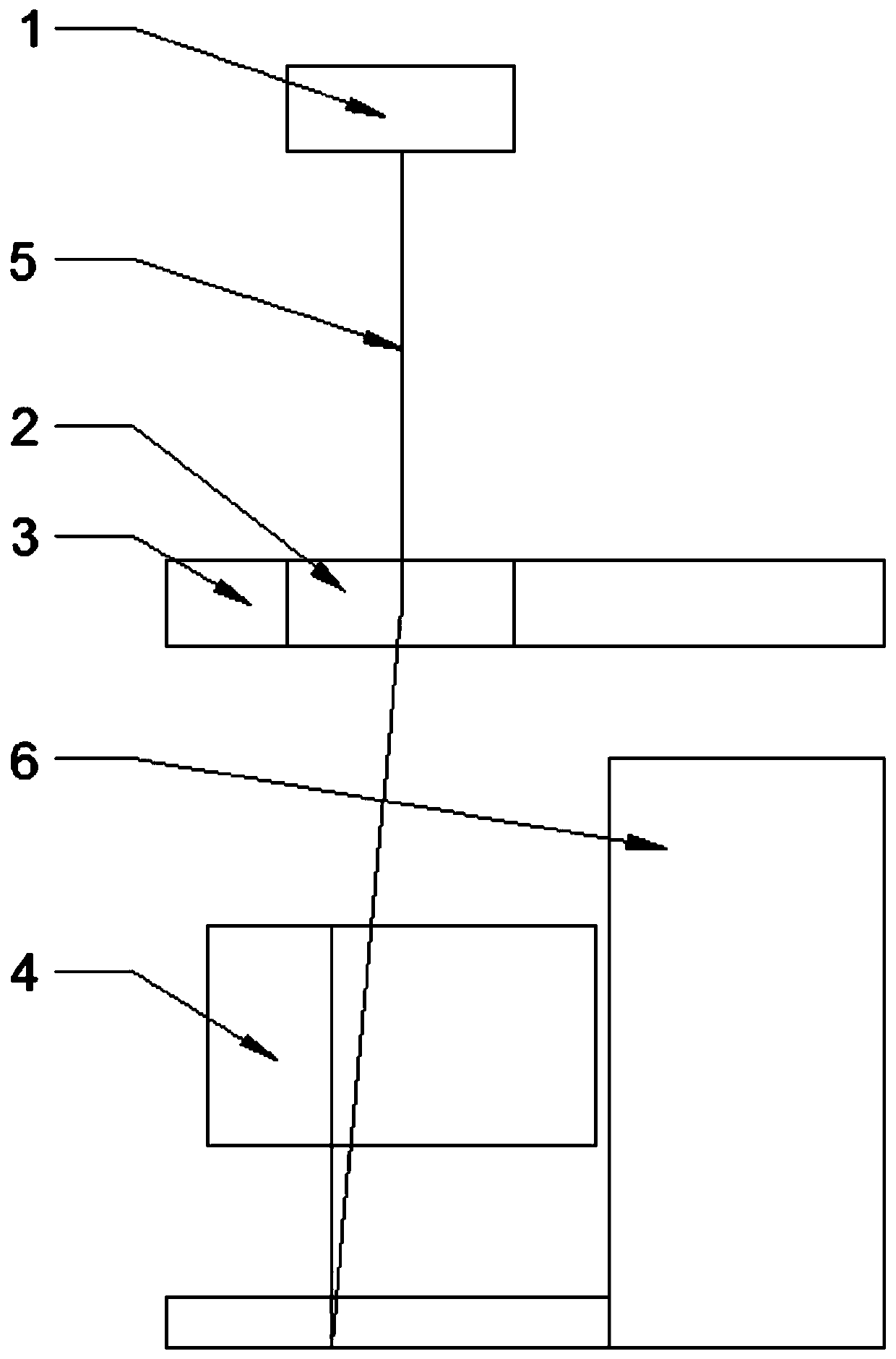

A twisting device for bundled wires and a method for improving the quality of twisted bundles

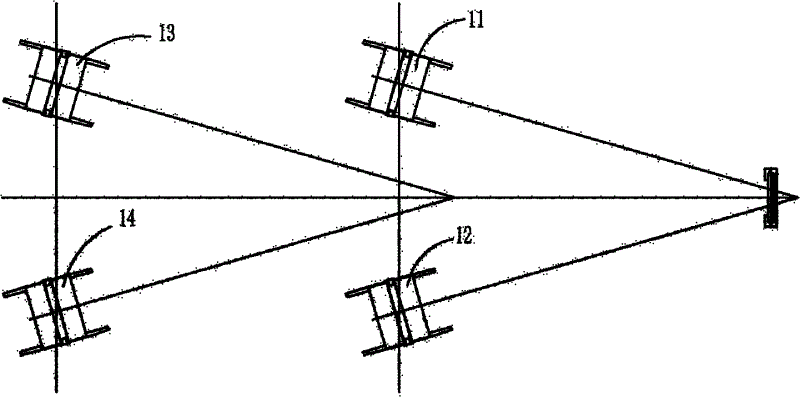

ActiveCN108335804BImprove stranding qualitySimple structureCable/conductor manufactureStructural engineeringElectric wire

The invention discloses a bundled wire twisting device and a method for improving twisting quality of a bundled wire, and relates to the field of cables. The bundled wire twisting device comprises a pay-off rack, a branching rack and a honeycomb plate which are sequentially arranged from front to back. The method for improving the twisting quality of the bundled wire comprises the steps of measurement, analysis and adjustment. The invention discloses the bundled wire twisting device and the method for improving the twisting quality of the bundled wire. By changing a wiring path, the equipmentstability and the twisting quality of the bundled wire are improved.

Owner:成都福斯汽车电线有限公司

Centralized rotary creel stand

ActiveCN102024527AReduce mistakesReduced stranding distanceFilament handlingCable/conductor manufactureSmall footprintEngineering

Owner:HEFEI SMARTER TECH GROUP CORP

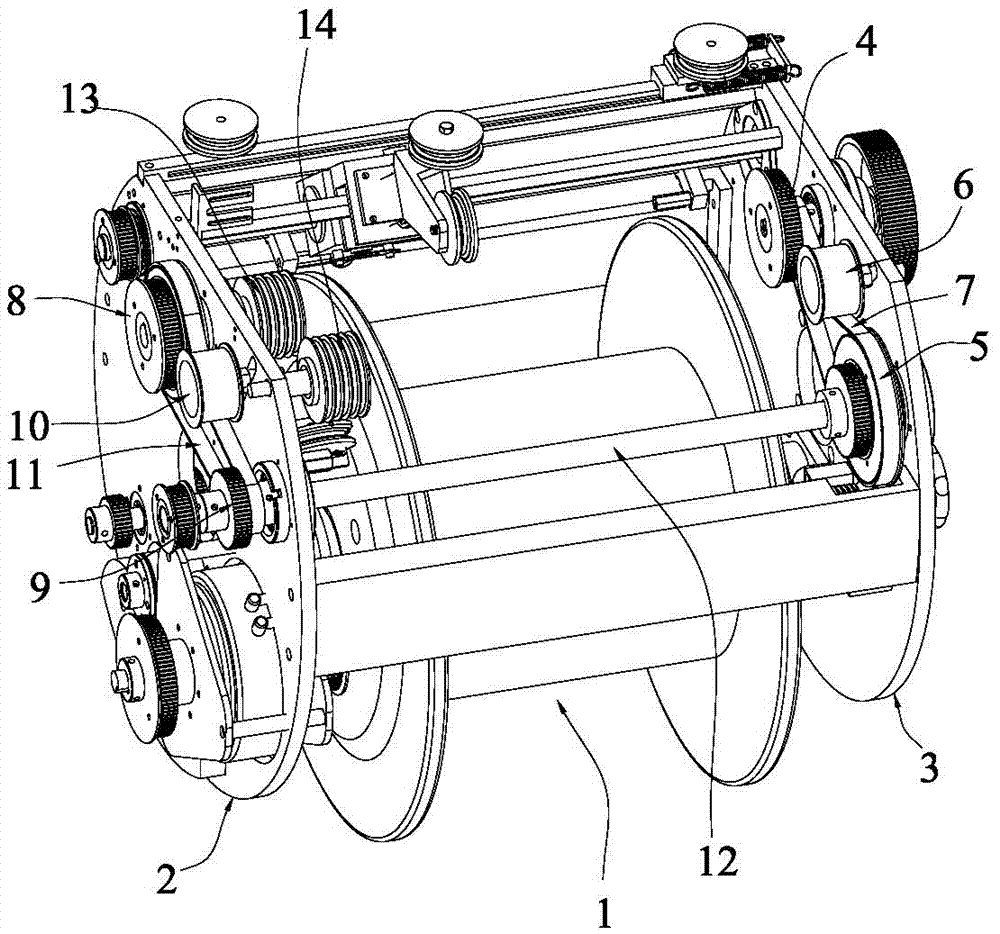

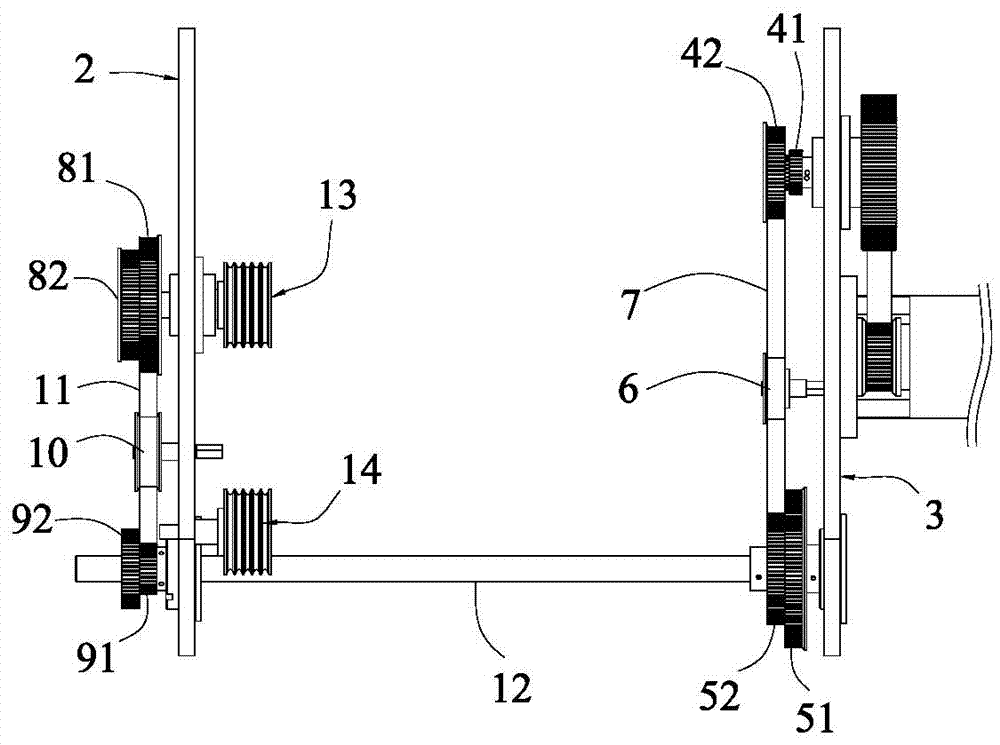

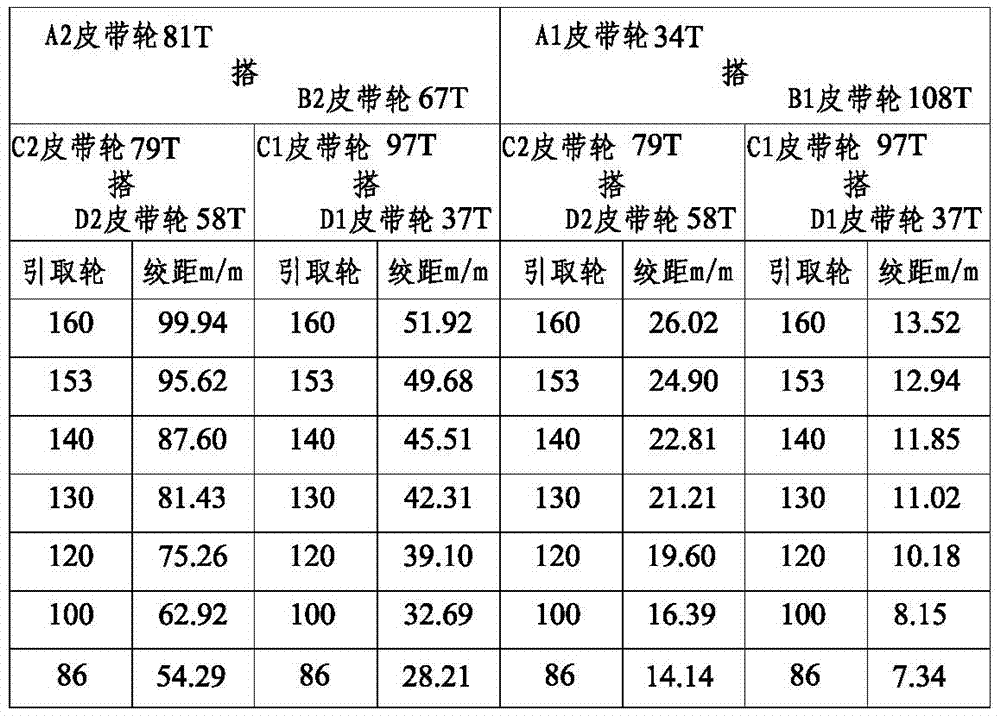

Stranding Machine Pitch Control Mechanism

InactiveCN104376930BIngenious designReasonable designRope making machinesCable/conductor manufactureCircular discBobbin

The invention discloses a pitch control mechanism of a stranding machine. The pitch control mechanism comprises a bobbin, a left disc and a right disc. A right pinch roller, an A group of belt pulley and a B group of belt pulley are arranged on the right disc; a left pinch roller, a C group of belt pulley and a D group of belt pulley are arranged on the left disc. The pitch control mechanism has the advantages that the pitch control mechanism is ingenious and reasonable in design, and belt-pulley transmission is substituted for conventional gear transmission, so that structure is simplified effectively, and simplicity and convenience in operation are achieved; when stranding pitch adjustment is needed, the belt pulleys, with the corresponding tooth numbers, in the A, B, C and D groups of belt pulleys are selected according to stranding pitches as needed, and then left and right belts are tensioned by the left pinch roller and the right pinch roller to complete adjustment, so that adjustment speed is high, flexible matching is achieved, stranding pitch adjustment range is wide, time and labor are saved, a large amount of time and manpower are saved effectively, working efficiency is high, the whole production cycle is shortened, stranding quality is improved, and production cost is reduced; in addition, the pitch control mechanism is simple and compact in overall structure, easy to produce, low in cost, high in working stability and beneficial to wide popularization and application, and has few used parts.

Owner:DONGGUAN NEW ENSHIANG MACHINERY ENTERPRISE

One-time forming type high-speed twisting machine

InactiveCN104200930AAvoid deformationImprove efficiencyCable/conductor manufactureEngineeringMechanical engineering

A one-time forming type high-speed twisting machine comprises a machine set which comprises a reverse twister and a main unit sequentially and technically from front to back. The reverse twister comprises a reverse twisting frame, a plurality of single-strand inner paying-off mechanisms are arranged in a reverse twisting bow which is arranged in the reverse twisting frame, and an outlet of the reverse twisting frame is communicated with an inlet of the main unit; an outer paying-off mechanism connected to the inlet of the main unit is matched with the reverse twister and in linkage with the reverse twister and the main unit. The one-time forming type high-speed twisting machine has the advantages of one-time forming, high efficiency, quickness, high twisting quality, high uniformity and free adjustability in twisting pitch and direction.

Owner:ZHEJIANG BAOLONG MACHINERY

A device and method for improving the roundness of conductor stranding

ActiveCN104376929BImprove stranding roundnessHollow state is goodRope making machinesCable/conductor manufactureElectrical conductorCopper wire

A device for improving the roundness of conductor stranding, including a twist bow, on which several magnetic eyes are arranged; the radial distance between the magnetic eyes at the two ends of the twist bow and the twist bow is the largest, and in the middle, the magnetic eyes and the twist bow The radial distance of the bow is gradually reduced, and the distance between the magnetic eyes is gradually reduced. In the device of the present invention, the hollow state of the copper wire is kept very well, and the quality of the twisted wire is the highest.

Owner:JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

Bundled wire twisting device and method for improving twisting quality of bundled wire

ActiveCN108335804AImprove stranding qualitySimple structureCable/conductor manufactureHoneycombEngineering

The invention discloses a bundled wire twisting device and a method for improving twisting quality of a bundled wire, and relates to the field of cables. The bundled wire twisting device comprises a pay-off rack, a branching rack and a honeycomb plate which are sequentially arranged from front to back. The method for improving the twisting quality of the bundled wire comprises the steps of measurement, analysis and adjustment. The invention discloses the bundled wire twisting device and the method for improving the twisting quality of the bundled wire. By changing a wiring path, the equipmentstability and the twisting quality of the bundled wire are improved.

Owner:成都福斯汽车电线有限公司

High speed planetary stranding machine

Owner:DONGGUAN NEW ENSHIANG MACHINERY ENTERPRISE

Back twist strander

ActiveCN102354583BEliminate torsional stressThere will be no jumping phenomenonCable/conductor manufactureGear wheelTransmitted power

The invention relates to the technical field of stranders, in particular to a back twist strander capable of eliminating torsion stress. The back twist strander comprises a stand, a feeding device, a stranding device, a transmission device and a coiling device, wherein the stand is provided with a first working plate and a second working plate which divide the stand into three working chambers. The back twist strander provided by the invention achieves the aim of eliminating torsion stress generated in the total stranding process of wires through controlling the rotating speed of a feeding end to be consistent with the rotating speed at a coiling end by using the same transmission device. The transmission device of the back twist strander transmits power through a synchronous transmission rod as well as a synchronous gear and a synchronous belt which are in the same specification. The back twist strander is simple and compact in structure, capable of totally stranding a plurality of wires, varied in stranding way and high in stranding quality, and no jumping phenomenon is caused in the total stranding process of the wires.

Owner:HUBEI YINGTONG ELECTRONICS +1

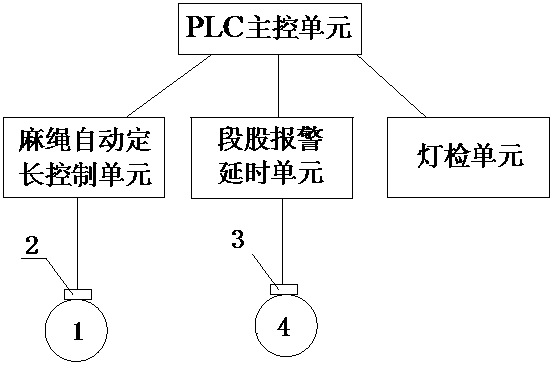

Intellectualized control system of novel two-in-one four-strand rope machine

InactiveCN107558274AControl self-shutdownReduce labor intensityRope making machinesHair removalDelayed periods

The intelligent control system of the new two-in-one four-strand rope machine includes: automatic length-fixing control unit for hemp rope, section-strand alarm delay unit, light inspection unit, and PLC main control unit; the automatic length-fixing control unit for hemp rope, The section strand alarm delay unit, the hair removal motor control unit, the main motor control unit and the PLC main control unit are respectively connected; the hemp rope automatic fixed-length control unit is used to set the fixed length during automatic operation; the section strand The alarm delay unit is used to automatically stop the system and give an alarm when the strand is broken; the light detection unit is used to detect the running indicator lights in the whole system. The intelligent control system of the novel two-in-one four-strand rope machine provided by the present invention can effectively control the automatic shutdown of the machine, greatly relieve the labor intensity of workers, and improve the quality of strands.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE

A concentric stranding machine

InactiveCN103578656BImprove stranding qualityStable pay-off tensionCable/conductor manufactureRotary inertiaOperating time

The invention relates to a concentric stranding machine, which comprises a bottom plate (16), on which a group of frames (4) are connected, on which a main shaft (3) is matched and connected, and a wire storage reel is connected to the rear end of the main shaft (12), the rear end of the main shaft is also connected to the motor (9) through a belt (10), which is characterized in that: a group of wire storage reels (2) are connected to the main shaft, and between two wire storage reels every interval A tension control device is arranged on the main shaft, and the tension control device cooperates correspondingly with the wire storage reels on both sides of it. The advantages of the present invention: the device has an integral structure, which reduces the turnover of the wire storage reel and saves production costs; the moment of inertia is small, which improves the speed of the equipment; and the twisting and rewinding of the cable core can be carried out simultaneously, saving operation Time; this device can stabilize the tension of the wire core and improve the quality of the cable stranding.

Owner:安徽长江精工装备科技有限公司

Multi-strand stranding device and processing method thereof

InactiveCN112002492ANovel structural designEasy to operateCable/conductor manufactureStructural engineeringMechanical engineering

The invention discloses a multi-strand stranding device and a processing method thereof. The device comprises a pay-off mechanism, a stranding cylinder, a shaping assembly and a winding assembly, wherein the pay-off mechanism comprises a plurality of pay-off assemblies, each pay-off assembly comprises a pay-off cylinder and a first mounting rack, the pay-off cylinder is mounted on the first mounting rack, and the stranding cylinder is mounted between the pay-off mechanism and the shaping assembly. The stranding device is novel in structural design and convenient to operate, multi-strand stranding can be achieved, the stranded wires can be wound after being shaped, and stranding quality is improved; and the adopted shaping assembly can shape wires with different thicknesses, the shaping efficiency is high, and the stranding quality is further improved.

Owner:常宁市隆源铜业有限公司

Centralized rotary creel stand

ActiveCN102024527BReduce mistakesReduced stranding distanceFilament handlingCable/conductor manufactureEngineeringSmall footprint

Owner:HEFEI SMARTER TECH GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com