High-speed planetary stranding machine

A planetary and stranding machine technology, which is applied in the field of stranding machines, can solve the problems of high production cost, high labor intensity, and low stranding efficiency, and achieve the goals of saving time and manpower, reducing production costs, and improving stranding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

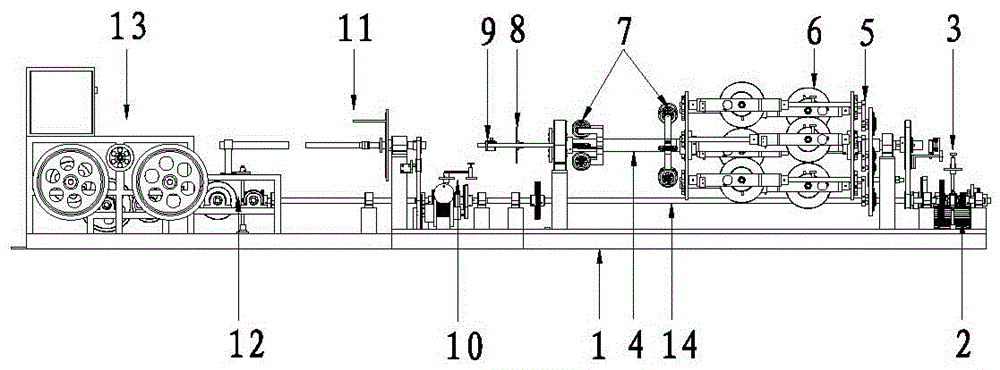

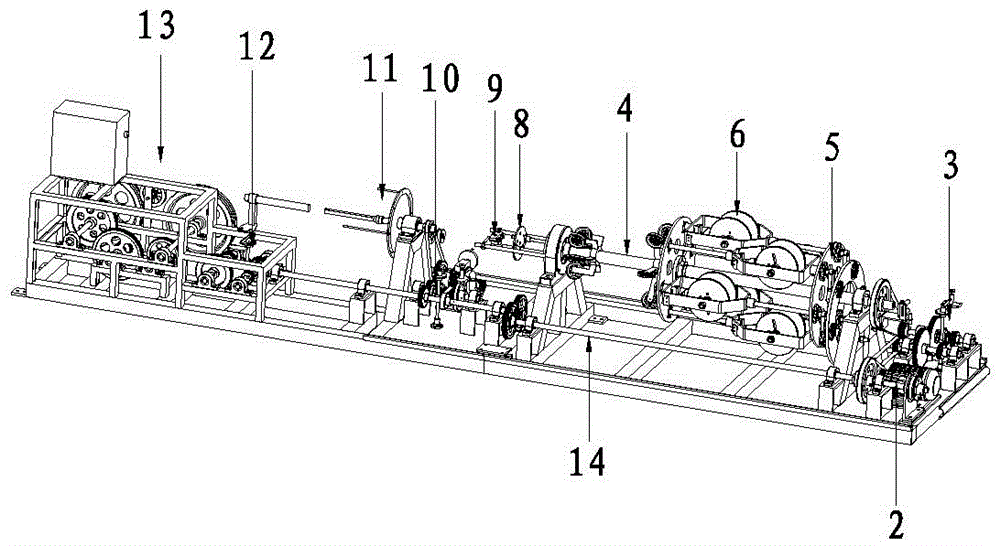

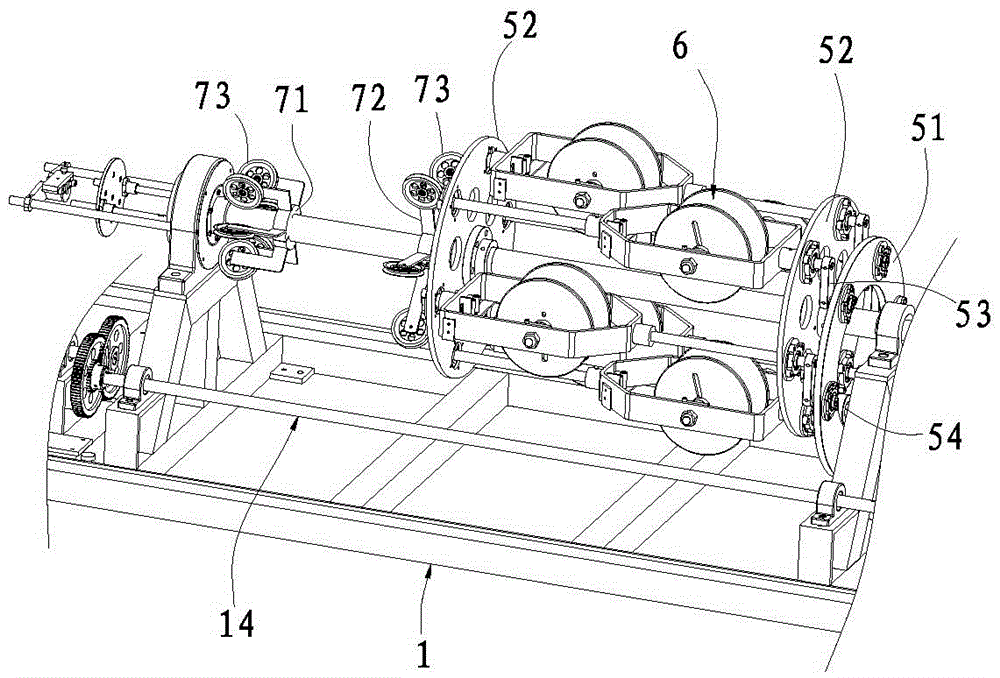

[0022] see Figure 1 to Figure 5 , a high-speed planetary stranding machine provided in this embodiment, which includes a frame 1, a main shaft driving device 2, a main shaft reversing assembly 3, a main shaft 4, a cradle frame 5, a tension pay-off device 6, and a wire passing wheel set 7 , honeycomb mesh plate 8, eye mold base 9, paper wrapping reversing assembly 10, paper wrapping mechanism 11, drawing and fetching reversing assembly 12 and drawing mechanism 13, the main shaft 4, paper wrapping mechanism 11 and drawing mechanism 13 are arranged from front to back The last sequence is arranged on the frame 1 in turn, and the cradle frame 5, the wire passing wheel group 7, the honeycomb mesh plate 8 and the eye mold seat 9 are arranged on the main shaft 4 in sequence from front to back, and multiple tension The pay-off device 6 is evenly arranged on the peripheral position of the cradle frame 5, and the main shaft driving device 2 is arranged on the front end position of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com