Intellectualized control system of novel two-in-one four-strand rope machine

A control system and two-in-one technology, applied in the field of rope making machines, can solve the problems of large floor space, low roundness, and inability to meet tensile force, etc., and achieve the effect of alleviating labor intensity and improving the quality of strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

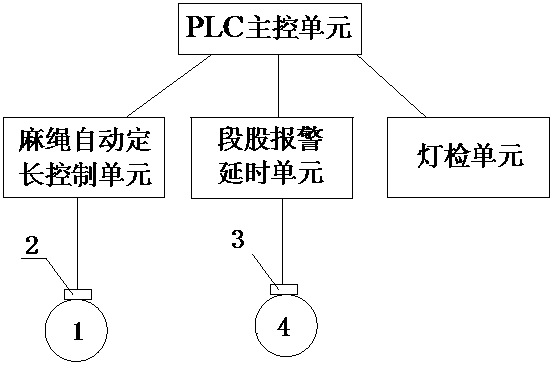

[0011] The intelligent control system of the new two-in-one four-strand rope machine includes: automatic length-fixing control unit for hemp rope, section-strand alarm delay unit, light inspection unit, and PLC main control unit; the automatic length-fixing control unit for hemp rope, The section alarm delay unit, the hair removal motor control unit, the main motor control unit are respectively connected with the PLC main control unit.

[0012] The automatic fixed-length control unit of the hemp rope is used to set the fixed-length length during automatic operation; by setting the position sensor 2 on the meter wheel 1, the position sensor 2 is connected with the automatic fixed-length control unit of the hemp rope, and the hemp rope is automatically fixed-length. The length of the rope is obtained by multiplying the number of turns of the meter wheel by the circumference of the meter wheel.

[0013] The segmental strand alarm delay unit is used to make the system automaticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com