Centralized rotary creel stand

A rotary pay-off and centralized technology, applied in the field of pay-off racks, can solve the problems of complex structure of pay-off racks, limit production efficiency, and extend stranding speed, so as to reduce stranding distance, improve stranding quality, and improve The effect of traction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

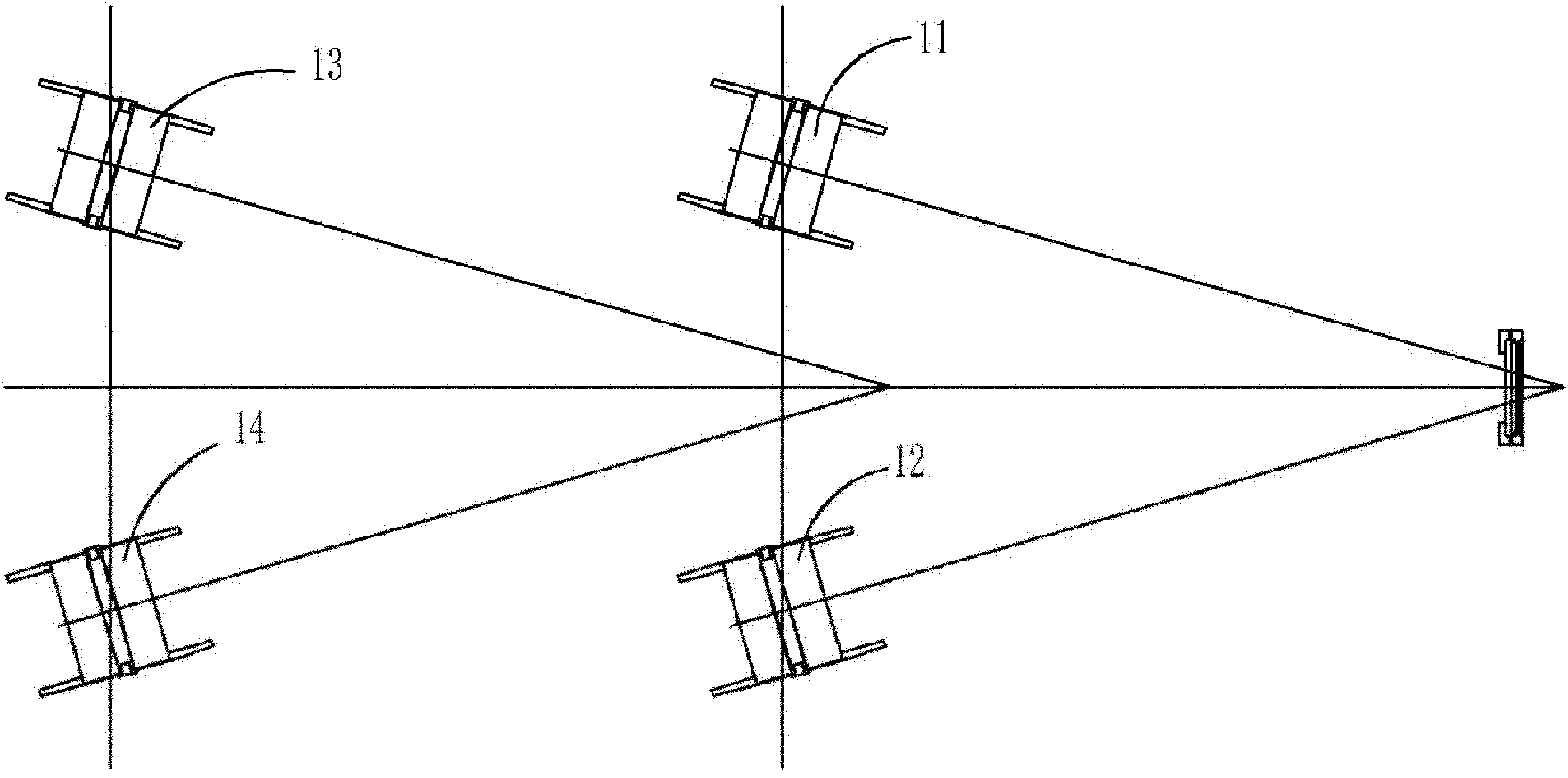

[0020] The setting of the pay-off frame is a double-layer frame structure with an upper frame and a lower frame parallel to each other concentrated on the same axial position; each wire frame is distributed on the upper frame and the lower frame respectively to form the spatial distribution of the wire frame; In the upper frame and the lower frame, each wire reel in the same layer is centered on the outlet of the floor, and the axes of each wire reel are fan-shaped to each other, and the wire reels in different layers are not in the same vertical position. On a straight plane, this form can effectively avoid the interference between the wire reels.

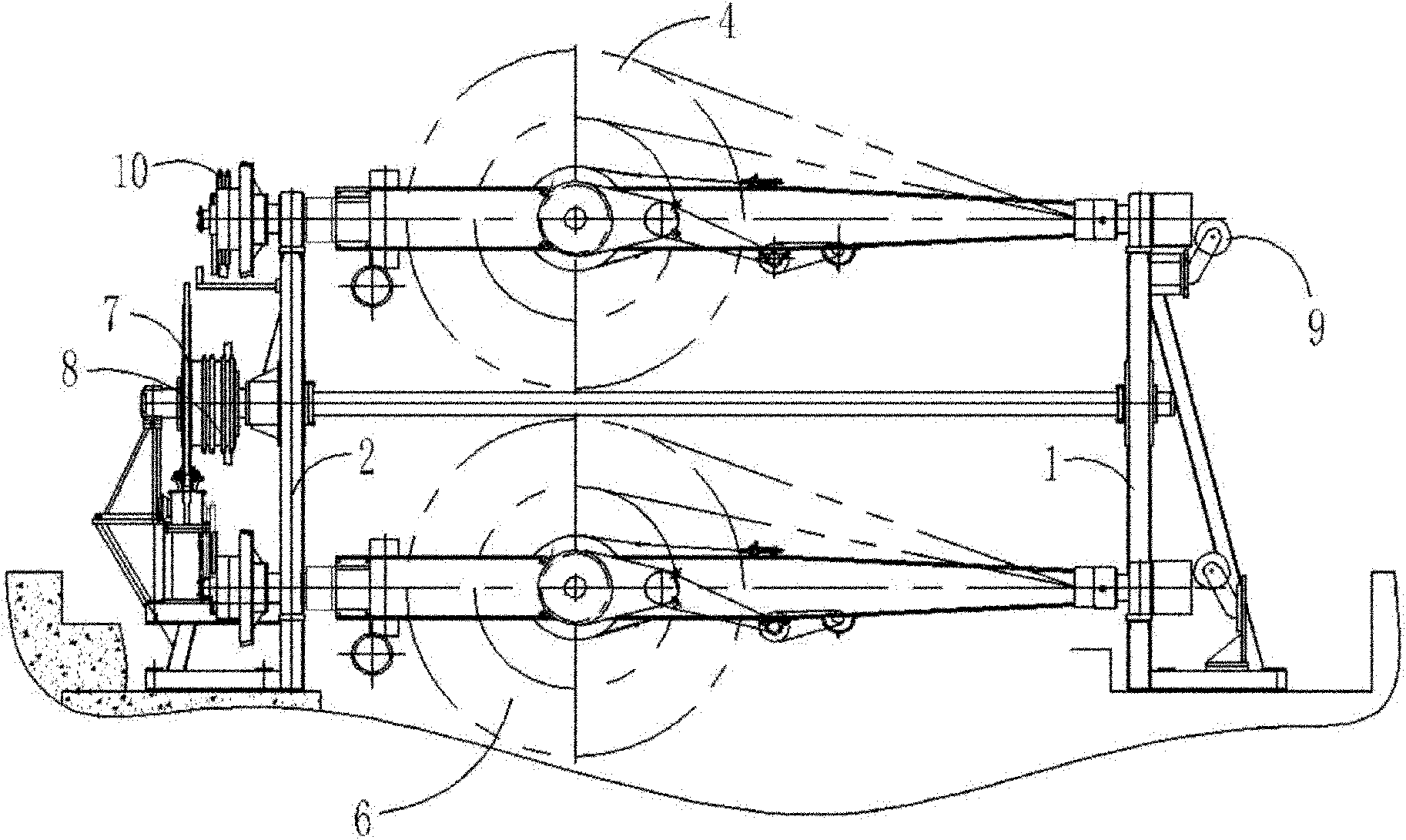

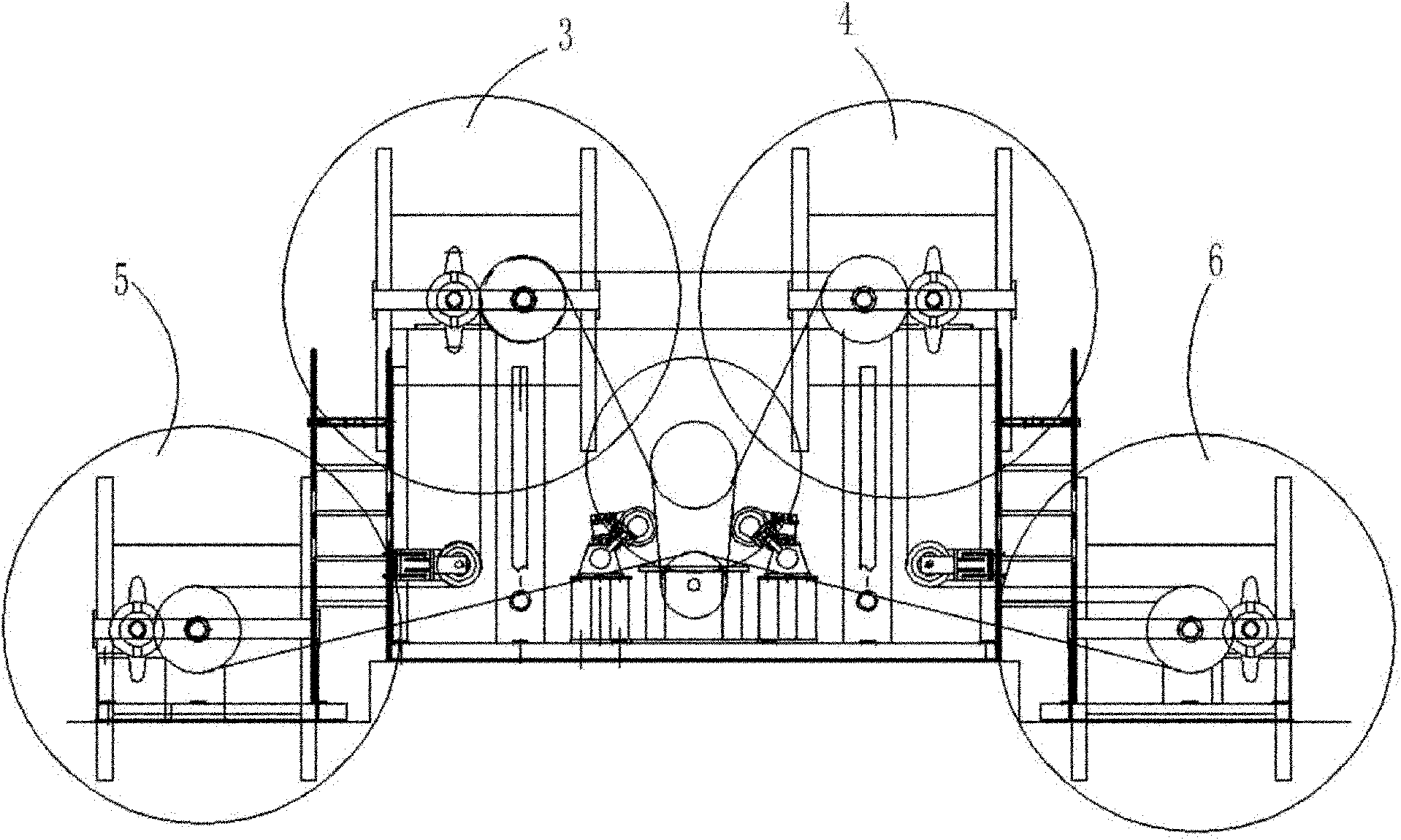

[0021] see figure 2 , image 3 and Figure 4 , in the present embodiment, setting pay-off frame is the double-layer structure that has upper shelf and lower shelf that is made up of front supporting frame 1 and rear supporting frame 2 jointly, the upper layer left wire tray frame 3 and the upper layer right wire tray in the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com