Stranding Machine Pitch Control Mechanism

A technology of control mechanism and stranding machine, which is applied in the auxiliary device of rope making, cable/conductor manufacturing, textile and paper making, etc., which can solve the problem of not being able to meet the needs of rapid and diversified markets, increase production costs, and replace processes. Complicated problems, to achieve the effect of shortening the production cycle, easy to implement, and flexible collocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

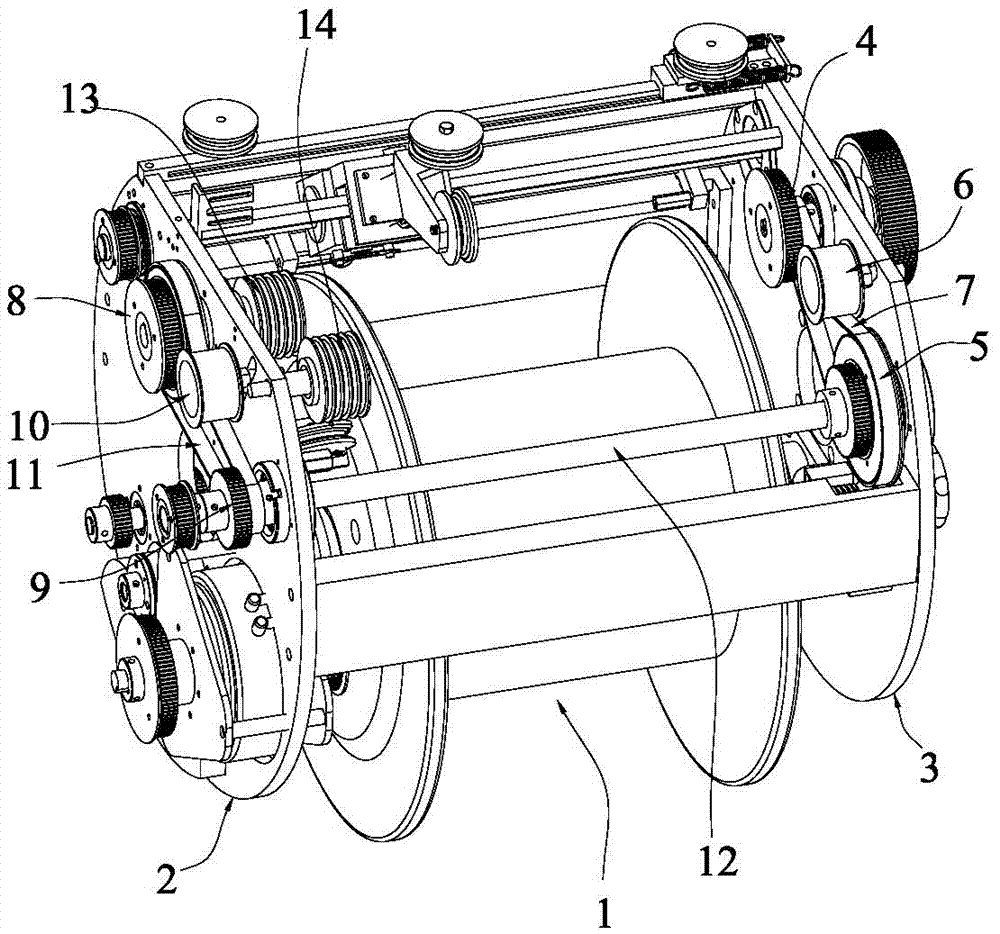

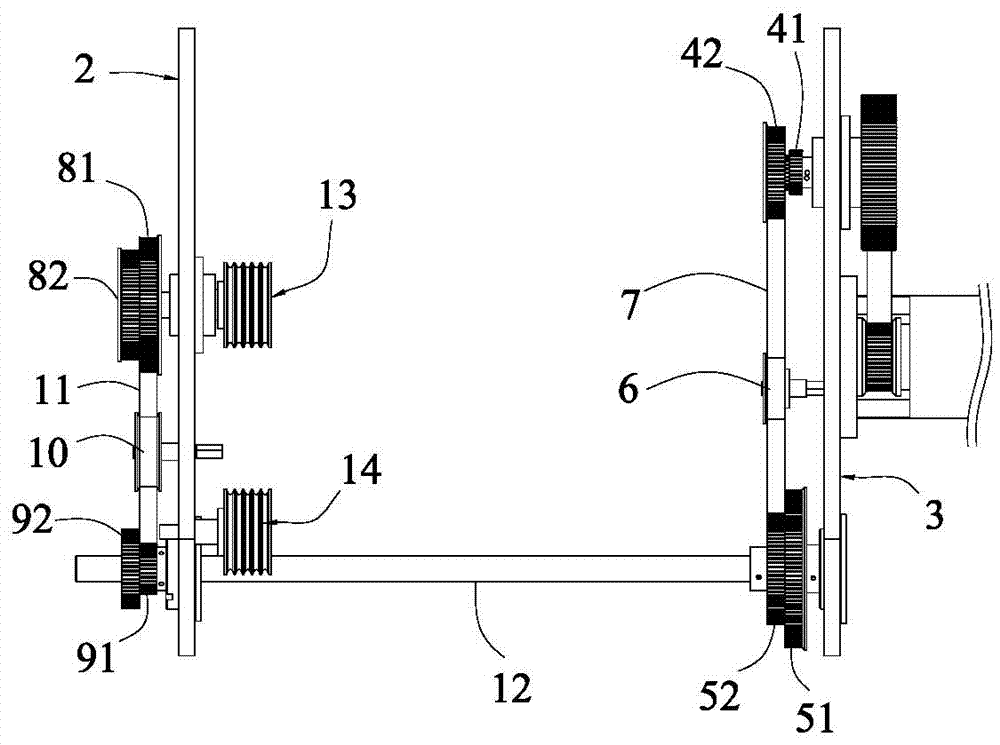

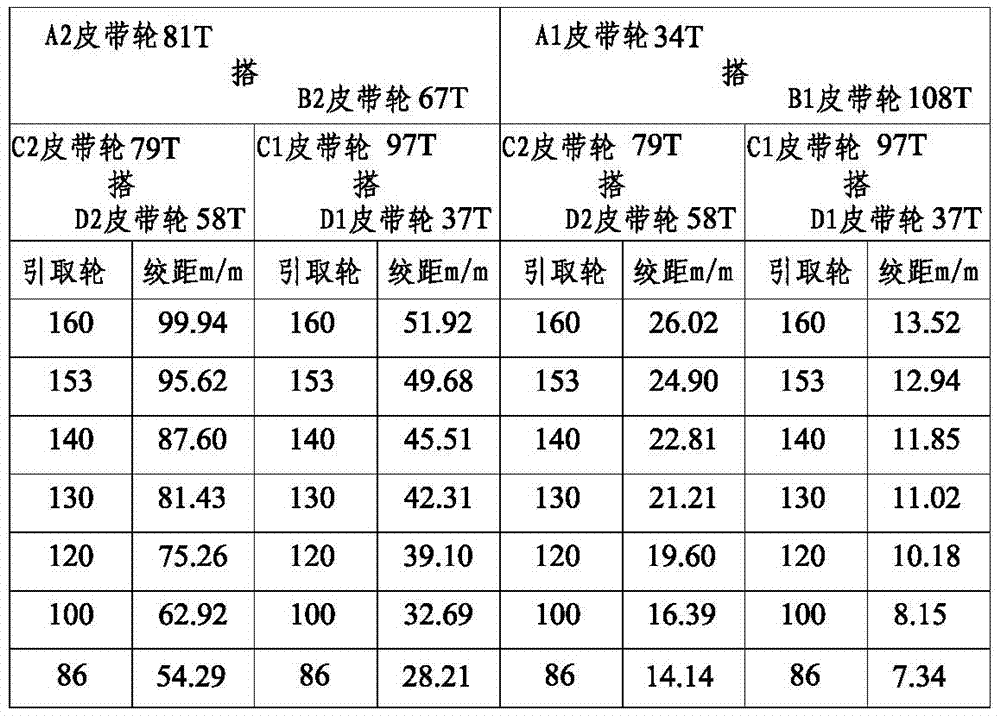

[0019] see figure 1 and figure 2 , a stranding machine pitch control mechanism provided in this embodiment, which includes a bobbin 1 and a left disk 2 and a right disk 3 arranged on both sides of the bobbin 1, and the right disk 3 is provided with a group A pulley 4. The pulley 5 of group B and the right pressure pulley 6, the pulley 4 of group A is connected with the pulley 5 of group B through the right belt 7, the right pressure pulley 6 is located between the pulley 4 of group A and the pulley 5 of group B, and the top pressure On the right belt 7; the left disc 2 is provided with a C group pulley 8, a D group pulley 9 and a left pressure pulley 10, and the D group pulley 9 communicates with the B group pulley 5 through a transmission shaft 12 Connection, the D group pulley 9 is connected with the C group pulley 8 through the left belt 11, the left pressure pulley 10 is located between the C group pulley 8 and the D group pulley 9, and presses on the left belt 11. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com