A twisting device for bundled wires and a method for improving the quality of twisted bundles

A bundle twisting and twisting technology, which is applied in the field of bundle twisting device, achieves good effect, improves twisting quality, and improves stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

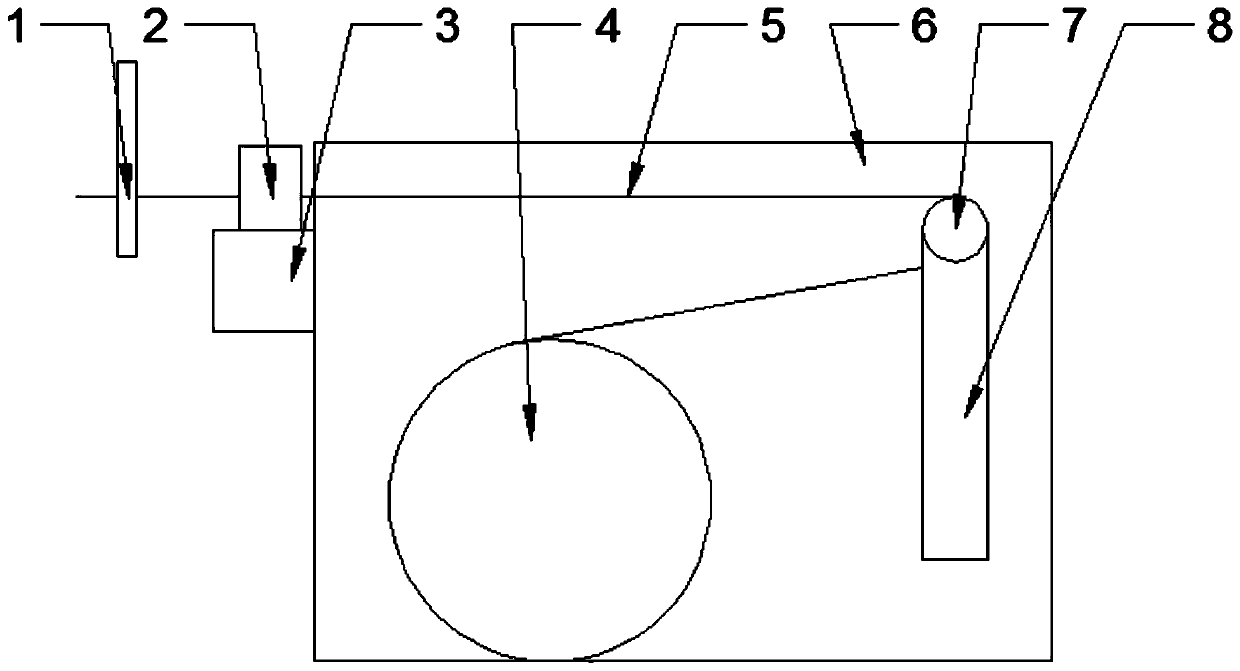

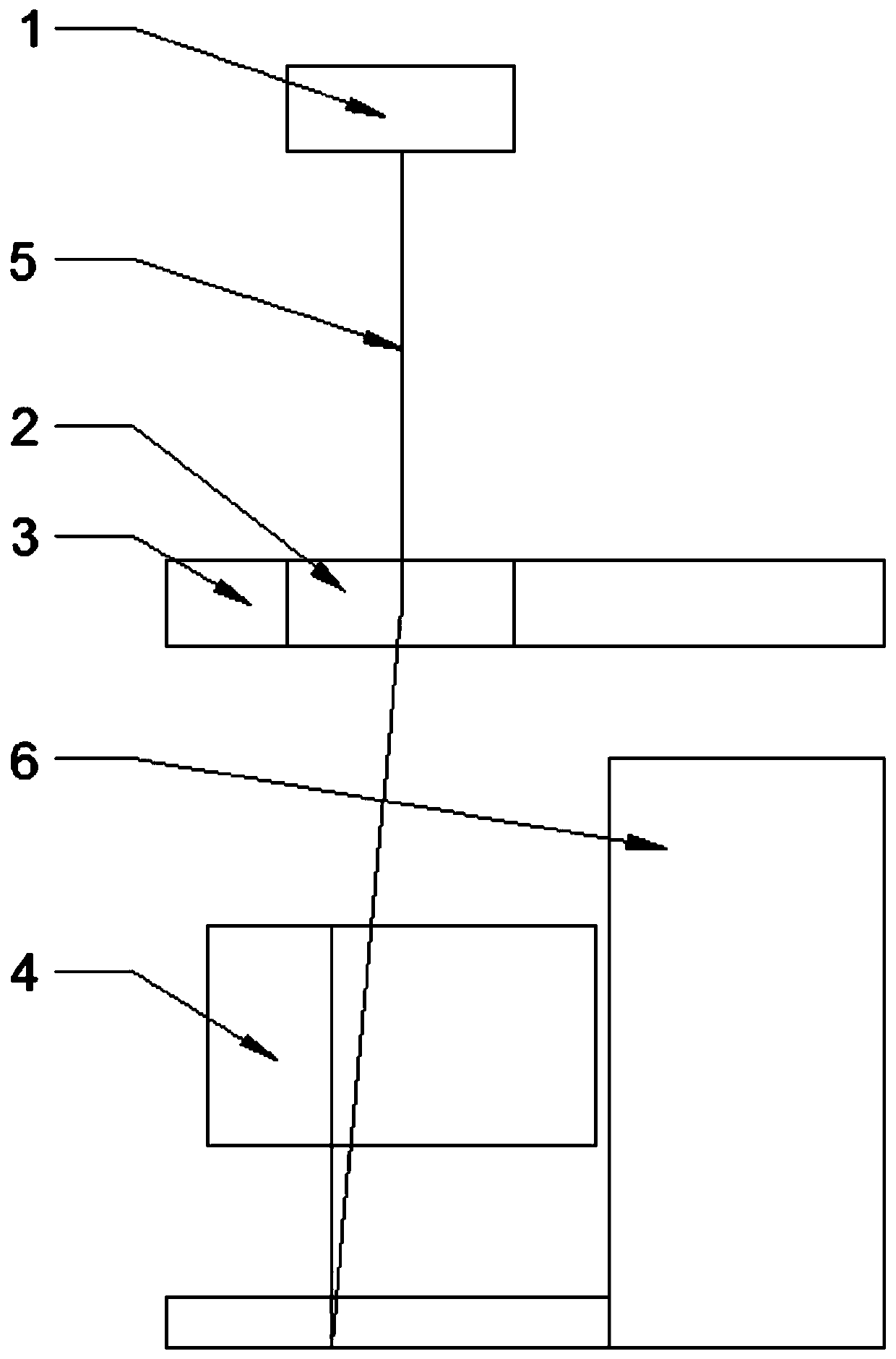

[0029] This example figure 1 As shown, a bundle twisting device includes a pay-off frame 6, a wire-distributing frame 3 and a honeycomb board 1 arranged in sequence from front to back, and the wire-distributing frame 6 is a tension pay-off frame 6; The top bar of the frame 3 is arranged horizontally and perpendicular to the pay-off frame 6, and the wire distribution frame 3 is provided with a comb-shaped plate 2 that can slide along the top bar of the wire distribution frame 3; The pay-off rack 6 protrudes and bifurcates to form a plurality of doubling wires 5 , and all the doubling wires 5 reach the honeycomb board 1 through the comb-shaped board 2 .

Embodiment 2

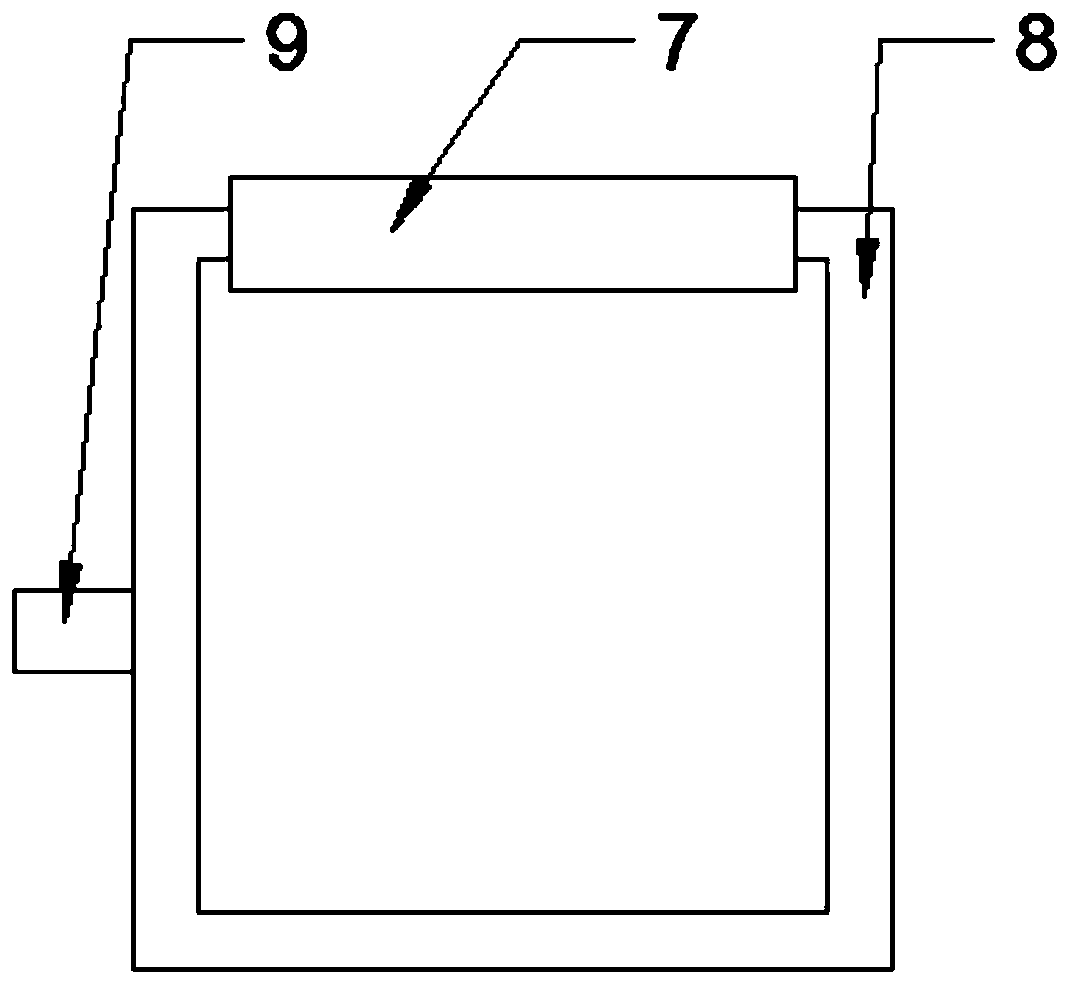

[0031] This embodiment is based on embodiment one, combined with image 3 As shown, one side of the pay-off frame 6 is sequentially provided with a tension roller 7 and a pay-off roller 4 from front to back, and the bundle of stranded wires stretches out from the pay-off roller 4 and wraps around the tension roller 7 and forks to form multiple and Wire sub-line 5.

Embodiment 3

[0033] This embodiment is based on embodiment one, such as Figure 4 As shown, both sides of the pay-off frame 6 are sequentially provided with a tension roller 7 and a pay-off roller 4 from front to back, and the bundle of stranded wires stretches out from the pay-off roller 4 and wraps around the tension roller 7 and forks to form a plurality of Parallel thread and branch line 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com