Cable-twisting device

A twisted wire and cable technology, which is applied in the field of cable processing equipment, can solve the problems of inaccurate control of pitch, unstable power or information transmission process, etc., and achieve the effect of improving twisting quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

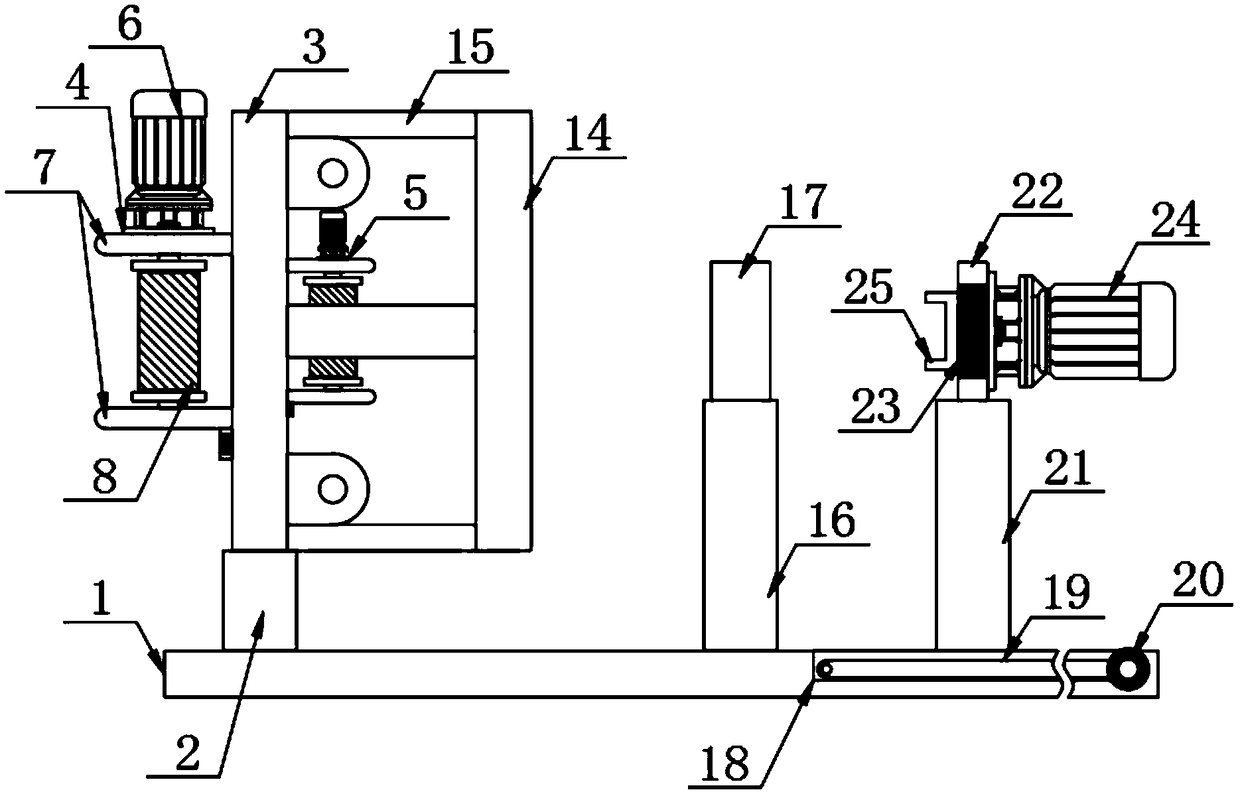

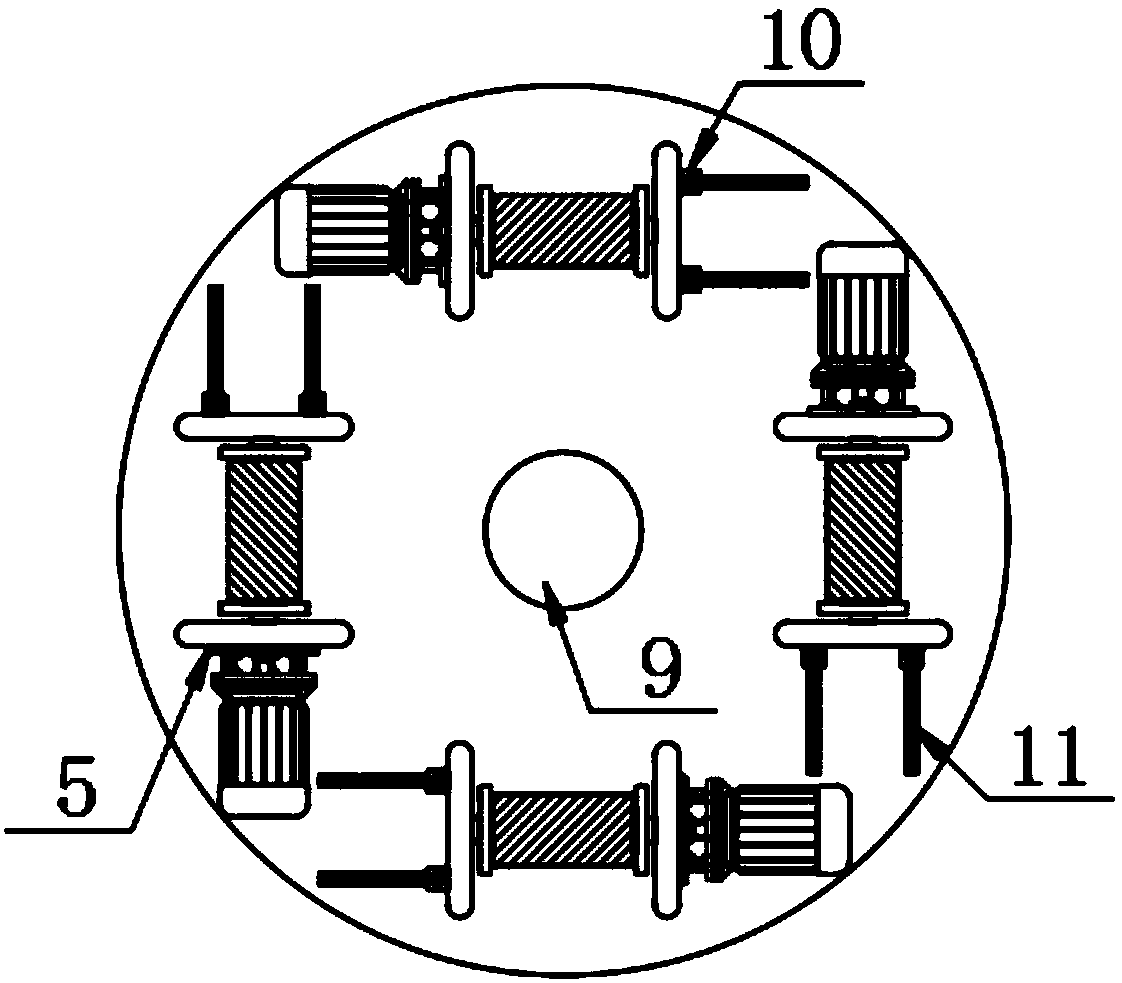

[0029] The present invention provides such as Figure 1-9 The shown cable twisting device includes a base 1, the top of the base 1 is provided with a first fixed pallet 2, and the top of the first fixed pallet 2 is vertically provided with a fixed plate 3, and the fixed plate 3 One side is provided with a first guide wire mechanism 4 and the other side is provided with a second guide wire mechanism 5, the first guide wire mechanism 4 and the second guide wire mechanism 5 both include a limiting plate group 7, and the limiting plate group 7 Set vertically between the fixed plate 3, the limiting plate group 7 is composed of a left side plate and a right side plate, the two ends of the outer side of the left side plate are fixed with locking blocks 10 and the outer center of the right side plate is provided with The first motor 6, a wire barrel 8 is arranged between the left side plate and the right side plate, the center position of the wire barrel 8 is provided with a rotating ...

Embodiment 2

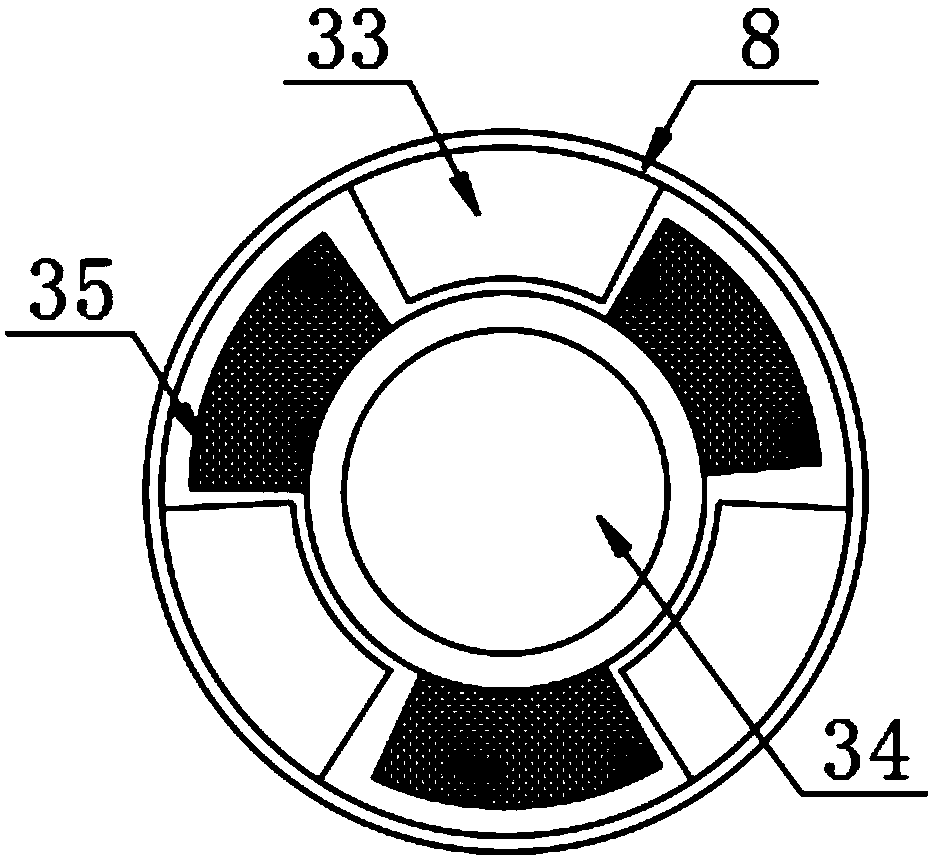

[0036] Further, in the technical solution of Embodiment 1, a gear 35 is fixedly sleeved on the rotating rod 34, and a second gear 33 is arranged inside the wire barrel 8, and the gear 35 meshes with the second gear 33 , when the cable on the spool 8 is used up, you only need to loosen the locking screw on the locking block 10, and then slide the left side plate along the strip thread groove 11 until it is far away from the rotating rod 34 When a certain distance is reached, the spool 8 is removed, and the spool 8 wrapped with a cable is replaced to be set on the rotating rod 34, and then the left side plate is used to limit the spool 8 to carry out the next round. stranded wire.

[0037] Further, in the technical solution of Embodiment 1, there are rollers 26 movably connected in the groove of the limiting groove 15 through connecting rods, and there are multiple rollers 26, and the plurality of rollers 26 are evenly distributed in the limiting groove 15, the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com