Concentric type wire-stranding machine

A stranding machine and concentric technology, applied in the field of stranding machines, can solve the problems of low production efficiency, a large number of turnover storage reels, and long auxiliary operation time, so as to achieve stable pay-off tension and reduce turnover storage reels , Improve the effect of stranding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

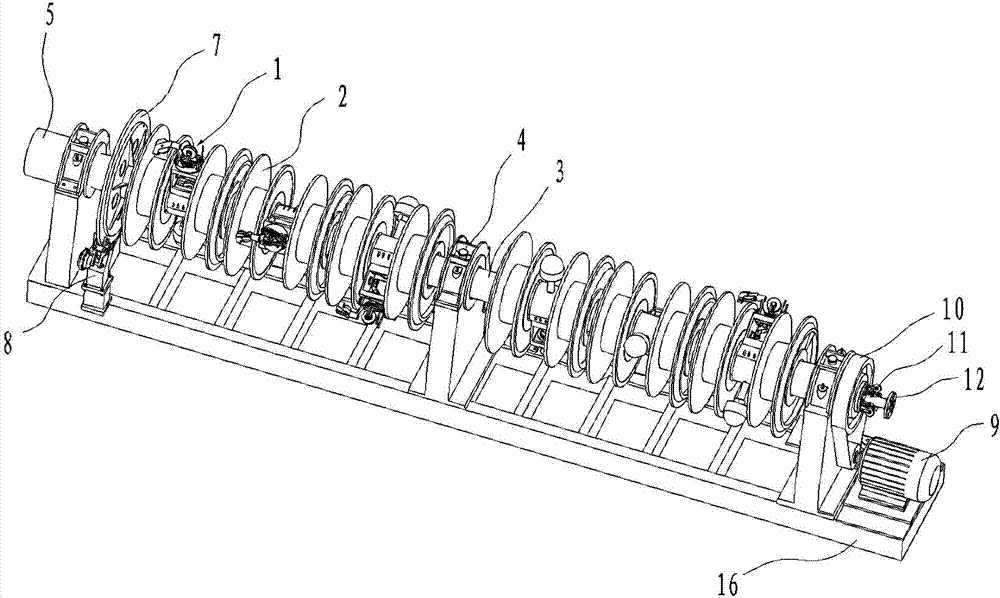

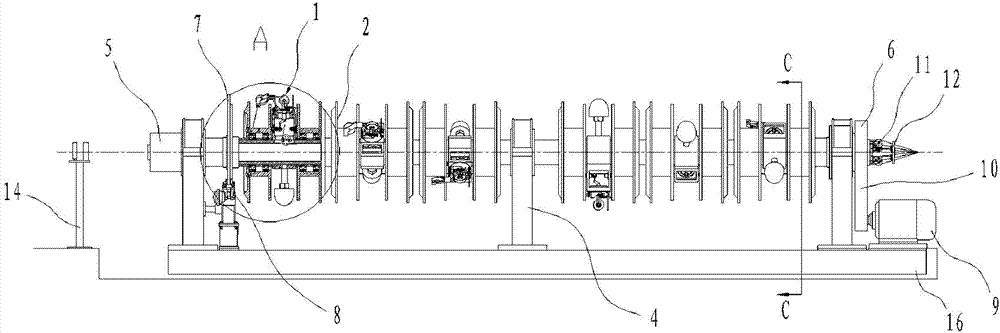

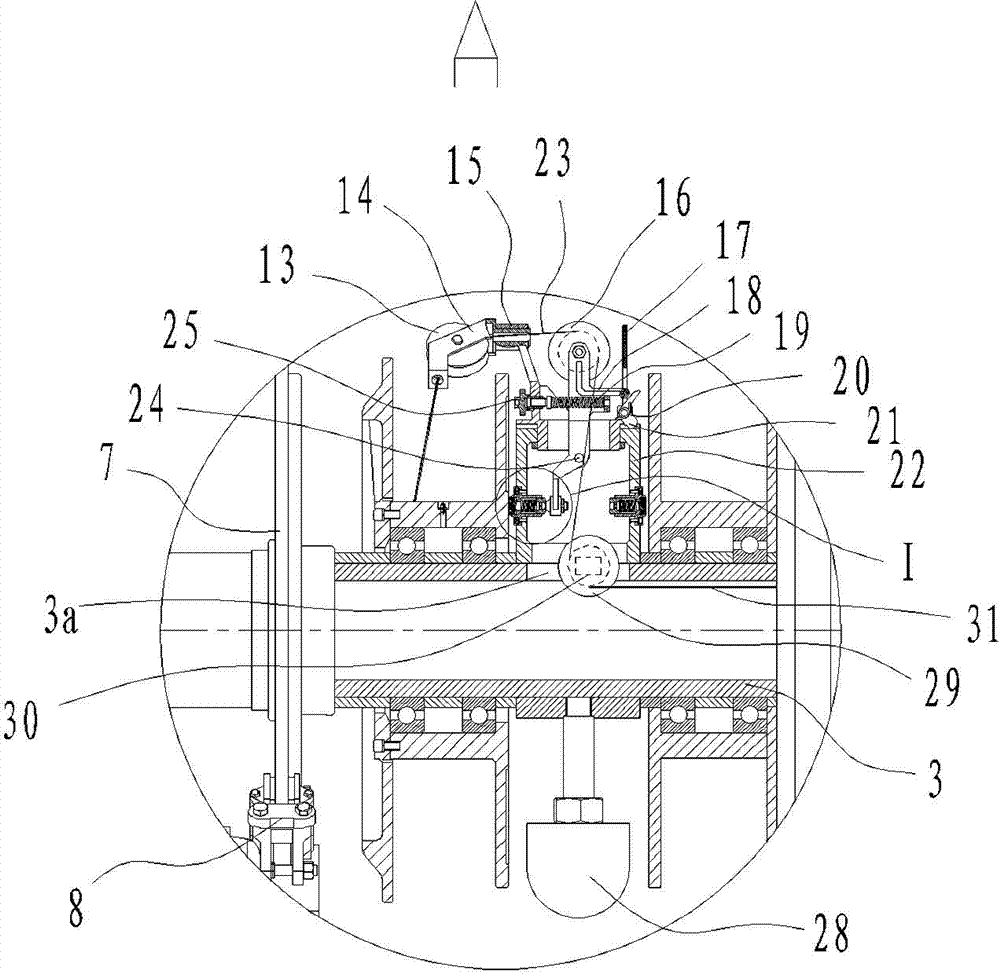

[0023] Such as figure 1 and figure 2 As shown, a kind of concentric stranding machine provided by the present invention comprises a base plate 16, the front side, the middle and the rear side of the base plate 16 are respectively connected to the frame 4, and the main shaft 3 is connected to the frame 4. The rear end is connected to the sub-storage reel 12, and the rear end of the main shaft 3 is connected to the pulley 6, and the pulley 6 is connected to the motor 9 through the belt 10. It is characterized in that: twelve concentric wire storage reels 2 are connected on the main shaft 3, and each A tension control device 1 is arranged on the main shaft spaced between the two wire storage reels 2, and each tension control device 1 is all correspondingly matched with the wire storage reels 2 on both sides thereof. Also be provided with six openings 3a on the main shaft 3, be respectively provided with a symmetrical support block on the both sides of each opening 3a, connect a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com