One-time forming type high-speed twisting machine

A stranding machine, high-speed technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of single-layer twisted wire extrusion, hidden dangers in stranding quality, and complicated processes, and achieve high stranding quality, Good consistency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

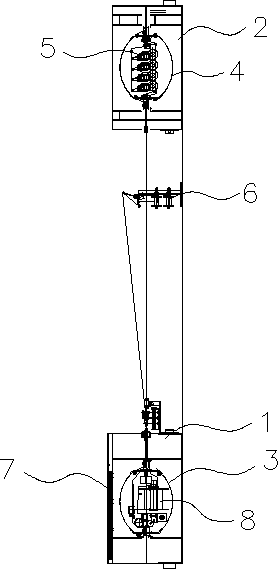

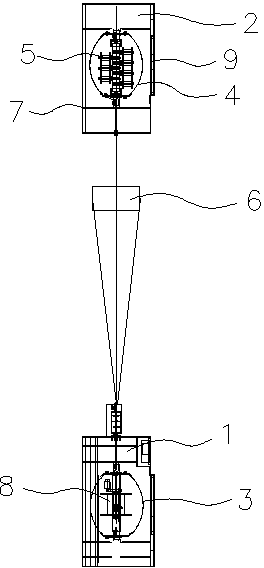

[0025] The high-speed stranding machine for one-time forming includes a unit. The unit includes a reverse twisting machine 2 and a main engine 1 in sequence along the process; For the single-strand inner pay-off mechanism 5, all the inner pay-off mechanisms 5 are distributed along the axial direction of the reverse twist bow 4; The host 1 includes a main twisting bow 3, and the twisting directions of the reverse twisting bow 4 and the main twisting bow 3 are opposite. The outlet of the reverse gallows is communicated with the inlet of the host 1; the outlet of the host 1 is also connected with an external pay-off mechanism 6, which is a multi-strand pay-off mechanism. The external pay-off mechanism 6 is matched with the reverse twist machine 2 and is linked with the reverse twist machine 2 and the host 1 . The main machine 1 and the anti-twisting bow 4 are respectively provided with a casing 7, and each casing 7 is respectively provided with a safety door 9. The safety door 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com