Cable Stranding Machine

A technology for stranding machines and cables, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., and can solve problems such as troublesome operation, loose cable cores, and poor quality of finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

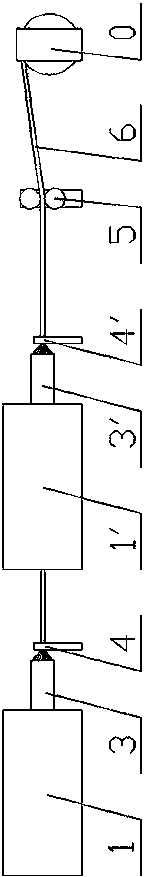

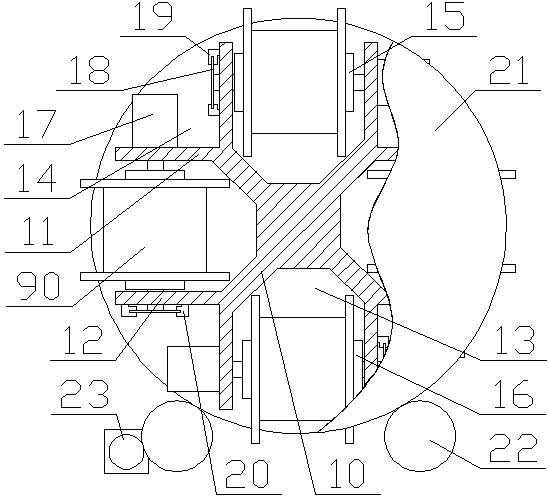

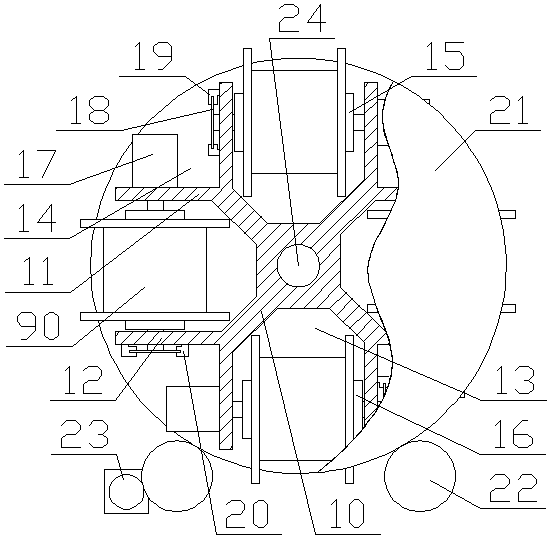

[0078] combine Figure 1~Figure 10It can be seen that the present invention includes a pay-off and twisting device and a winding device. There is at least one pay-off and twisting device. Wire device A1, wire splitting device A3 and twisting device A4, the wire 61 of the pay-off reel 90 on the rotary pay-off device A1 passes through the rotary pay-off device A1, the wire splitting device A3 and the twisting device A4 in sequence, and then is twisted into a cable core 6, and connected through the winding device 0, the winding device 0 provides driving force through the driving motor A, and the driving motor A drives the winding device 0 to wind the wire 61 of the pay-off reel 90 before winding;

[0079] When the number of pay-off and twisting devices is greater than 1, the pay-off and twisting devices include a rotary pay-off device A and a rotary pay-off device B, the rotary pay-off device A is the first pay-off and twist device, and the rotary pay-off device A is the first pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com