Electric wire and electric cable auger machine

A technology of electric wire and cable and auger, which is applied in the field of cable production equipment, can solve the problems of difficulty in adjusting the number of twisted wires, fewer twisted layers, and uneven twisting, so as to simplify the production process, expand the number of twisted layers, Effect of improving stranding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

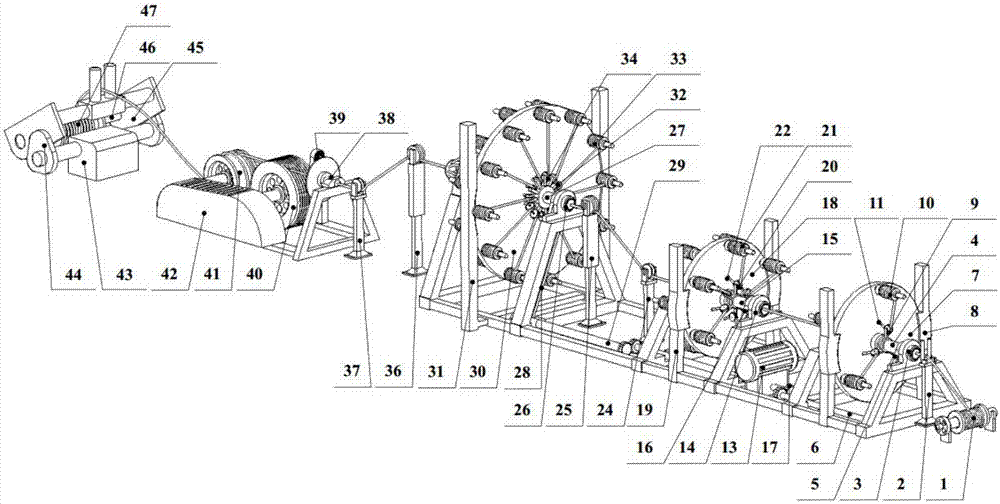

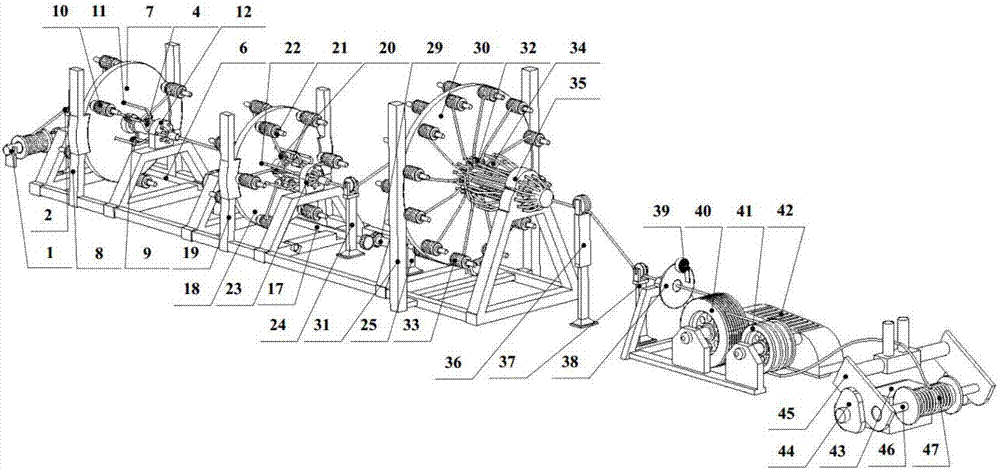

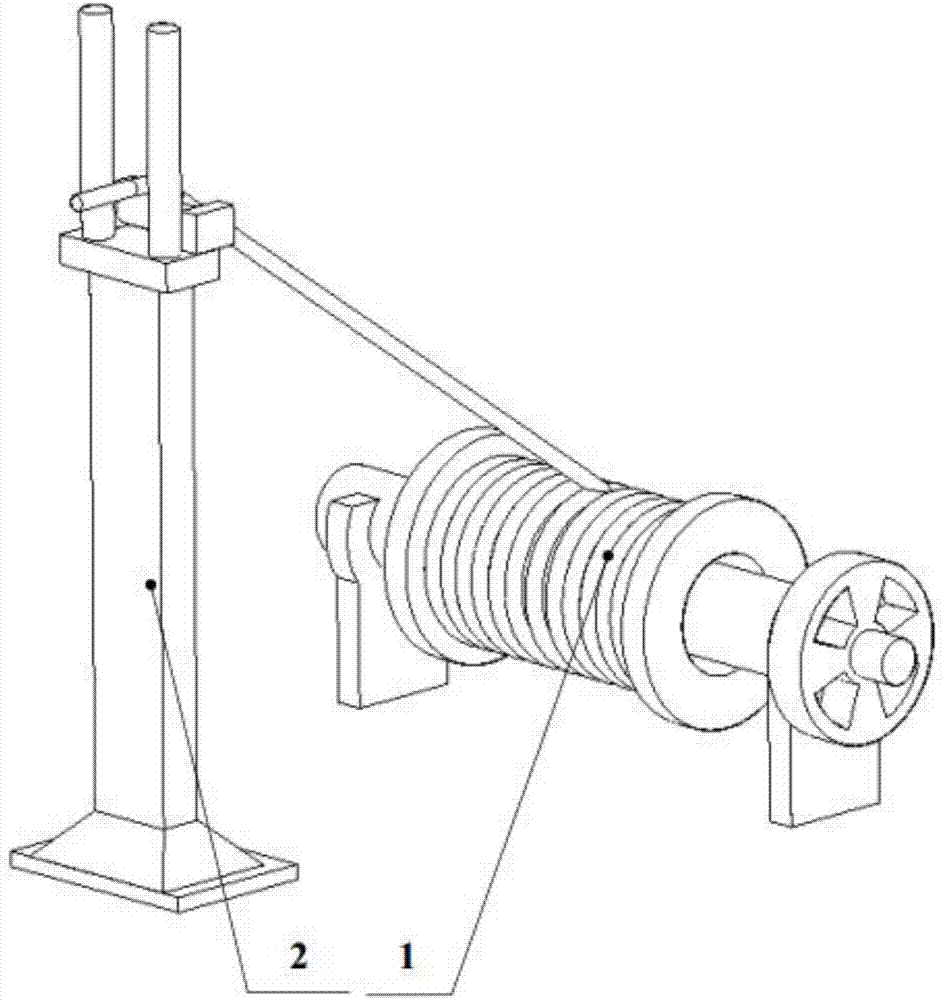

[0034] see Figure 1-13, a wire and cable wringer of this embodiment is characterized in that it includes a main line shaft 1, a positioning frame 2, a first-level wire sleeve 3, a first-level rotary sleeve 4, a first-level transmission chain 5, and a first-level transmission shaft 6 , first-level turntable 7, first-level turntable frame 8, first-level directional wheel 9, first-level splitting shaft 10, first-level disc hole 11, first-level cluster die head 12, rotating motor 13, second-level wire inlet sleeve 14, two-level Secondary rotary sleeve 15, secondary transmission chain 16, secondary transmission shaft 17, secondary turntable 18, secondary turntable frame 19, secondary directional wheel 20, secondary branch line shaft 21, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com