Conductor twisted roundness improving device and method

A technology of roundness and conductor, which is applied in the auxiliary device of rope making, cable/conductor manufacturing, textile and paper making, etc. It can solve the problems of not feeling very smooth and affecting the roundness of copper wire twisting, etc.

Active Publication Date: 2015-02-25

JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The position and distance between the twisted bow and the magnetic ring are fixed, and each magnetic ring is connected into a section of string, which makes the operation feel not very smooth, and will greatly affect the roundness of the twisted copper wire.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

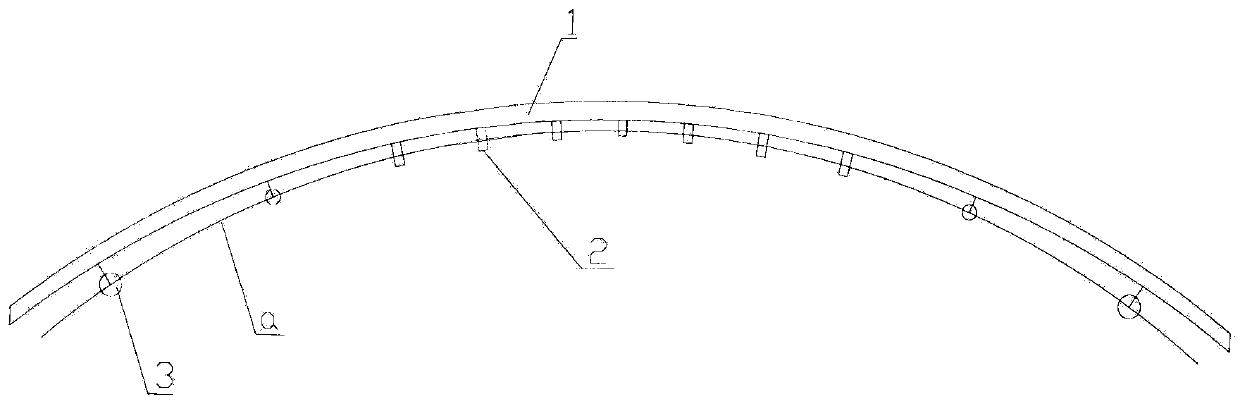

The invention discloses a conductor twisted roundness improving device which comprises a twisting bow. A plurality of magnetic holes are formed in the twisting bow. The radial distance between the magnetic holes in the two ends of the twisting bow and the twisting bow is the maximum, and the radial distance between the twisting bow and the magnetic holes from the two ends to the middle of the twisting bow is gradually decreased, and the distance between the magnetic holes from the two ends to the middle of the twisting bow is gradually decreased. According to the conductor twisted roundness improving device, the copper wire hollow state is kept well, and the twisted conductor quality is the highest.

Description

technical field The invention belongs to the field of cable processing, and in particular relates to a device and method for improving the roundness of conductor stranding. Background technique The conductor stranded wire is realized by the twisted single wire rotating around the axis of the stranded wire at an equal angular velocity and the stranded wire moving forward at a uniform speed. The single copper wire on the pay-off reel passes through the distribution reel through two to three rows of guide wheels, and then passes through Take up the line through the twisted bow to the take-up reel. In the processing of small round wire conductor cross-section wires, stranded wires are generally divided into two types: normal stranded and irregular stranded (ie bundle stranded). Regular twisting means that the single wire takes the center line of the twisted wire as the axis, and is layered and orderly twisted around it. The directions of adjacent twisted layers are opposite. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01B13/02

CPCD07B3/10D07B7/021

Inventor 罗跃中田凤军王永录

Owner JIANGSU HENGTONG ELECTRONICS CABLE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com