Sewing thread spool

A sewing thread and shaft technology, which is applied to sewing equipment, sewing machine components, hand sewing tools, etc., can solve the problems of cumbersome operation, thread breakage, and inability to unwind, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

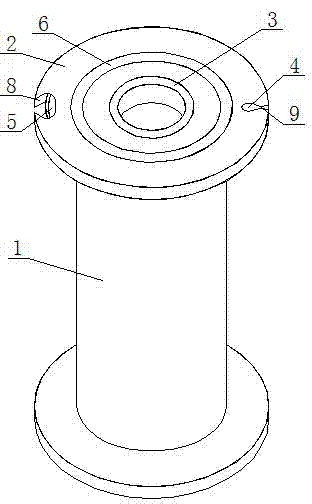

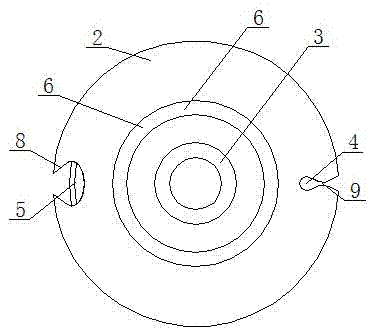

[0022] refer to figure 1 , image 3 and Figure 4 , the sewing bobbin in this embodiment includes a cylindrical shaft body 1, a baffle plate 2 and a magnetic inner ring 3, the two ends of the shaft body 1 are provided with a baffle plate 2 integrally formed with the shaft body 1, and the middle of the two baffle plates 2 The opening communicates with the inner cavity of the shaft body 1, and the surface of one of the baffles 2 is provided with a color identification ring 6, and the baffle 2 is provided with a threading hole 4 and a groove 8 near the edge, and the threading hole 4 and the groove 8 are located in the shaft body On the same diameter of 1, the edge of the baffle plate 2 is provided with a wire inlet 9 communicating with the threading hole 4, the wire inlet 9 is V-shaped, the groove 8 is provided with a blade 5, and the blade 5 is covered with a protective cover. The both sides of groove 8 are provided with chute, and protective cover is provided with the groove ...

Embodiment 2

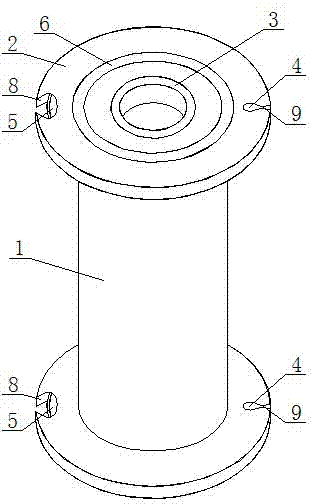

[0024] refer to figure 2 , image 3 and Figure 5 , the sewing bobbin in this embodiment includes a cylindrical shaft body 1, a baffle plate 2 and a magnetic inner ring 3, the two ends of the shaft body 1 are provided with a baffle plate 2 integrally formed with the shaft body 1, and the middle of the two baffle plates 2 The opening communicates with the inner cavity of the shaft body 1, and the two baffles 2 are provided with threading holes 4 and grooves 8 near the edges, and the surfaces of the two baffles 2 are respectively provided with color identification rings 6 . The threading hole 4 and the groove 8 are located on the same diameter of the shaft body 1, and the edge of the baffle plate 2 is provided with an inlet 9 communicating with the threading hole 4, and the inlet 9 is V-shaped. Blade 5 is provided in groove 8, and blade 5 is covered with protective cover, and the both sides of groove 8 are provided with chute, and protective cover is provided with the groove ...

Embodiment 3

[0026] refer to figure 1 , image 3 and Figure 6 In the sewing thread reel in this embodiment, the surfaces of the baffles 2 at both ends of the shaft body 1 are respectively provided with color identification rings 6, and the remaining parts are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com