Preparation method of adhesive assorted with liquid crystal coated optical cable

A technology for adhesives and optical cables, applied in the directions of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of insufficient low temperature resistance of adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

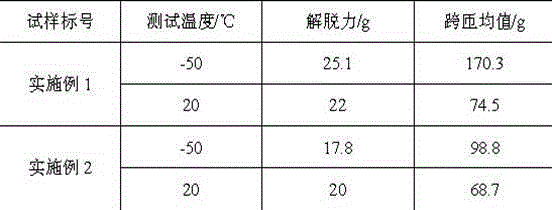

Embodiment 1

[0025] Dry the reactive end-group liquid silicone rubber and silicon dioxide, weigh 100g of α, ω-terminated hydroxyl polymethyl vinyl phenyl silicone rubber (8% phenyl content), 10g of precipitation method Silica ULTRASIL? VN3 and 20g of fumed silica AEROSIL? R106 were prepared according to the above steps, and then 6g of ethyl orthosilicate, 8g of γ-aminopropyltriethoxysilane, and 0.5g of dilauric acid were added Dibutyltin, stir evenly to prepare the required adhesive.

Embodiment 2

[0027] Dry the reactive end-group liquid silicone rubber and silicon dioxide, weigh 100g of αα, ω-terminated hydroxyl polydimethyldiethylsiloxane (7% ethyl content), 10g of precipitation method II Silica ULTRASIL? VN3 and 20g of fumed silica AEROSIL? R106, prepare the base rubber according to the above steps, then add 6g of tetraethyl orthosilicate, 8g of γ-aminopropyltriethoxysilane, 0.5g of di Dibutyltin laurate, stir evenly to prepare the required adhesive.

Embodiment 3

[0029] Dry the reactive end-group liquid silicone rubber and silica, weigh 100g of α, ω-terminated hydroxyl polymethylvinylphenyl silicone rubber (8% phenyl content), 50g of G-CC glue Adhesive-specific nano-calcium carbonate was prepared according to the above steps, and then 2g of triethoxysilane, 10g of γ-glycidyloxypropyltrimethoxysilane, and 0.3g of dioctyltin dilaurate were added, and the mixture was prepared by stirring evenly. Adhesive is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com