Connection row pulley for large-section cable paying off

A large cross-section, pulley technology, applied in the direction of cable laying equipment, etc., can solve the problems of single pulley fixing the ground, ground contact damage, and difficulty in cable laying, so as to save rivets and workload, prevent loosening, and facilitate transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

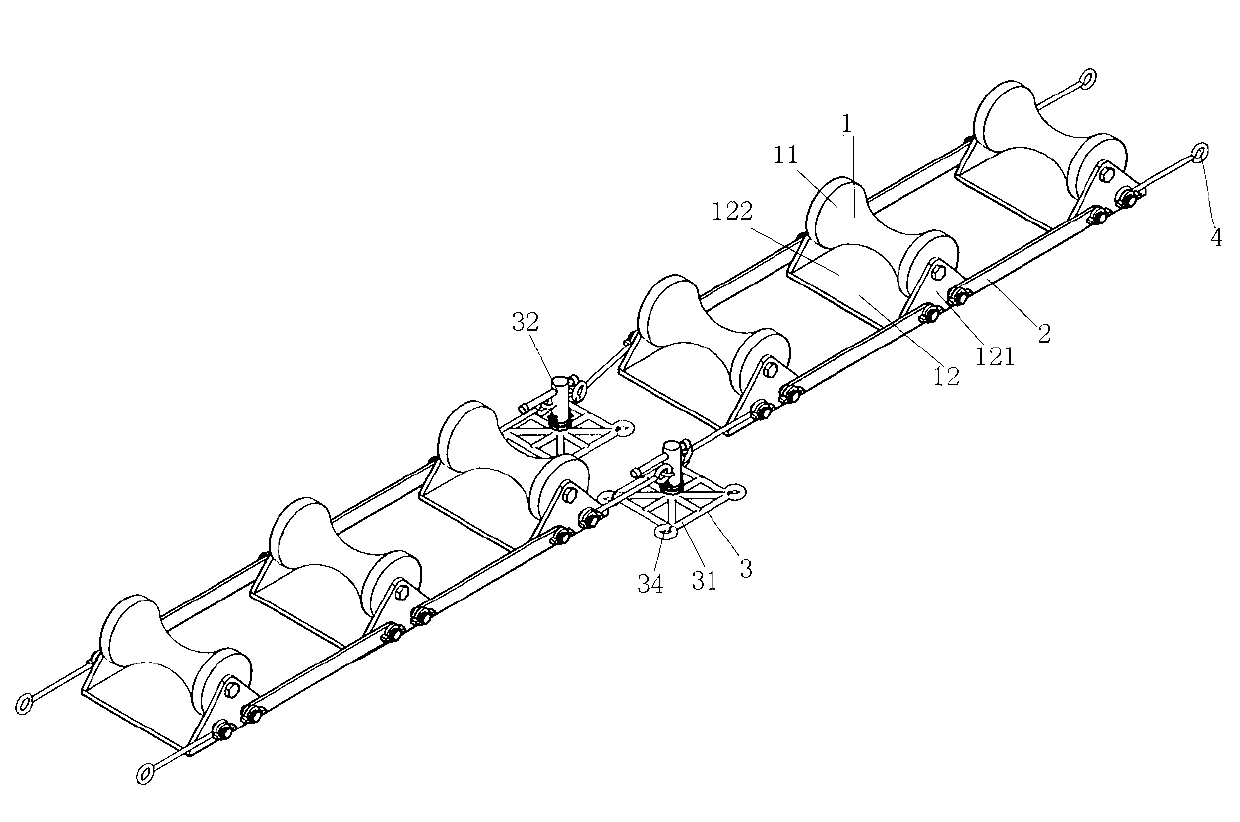

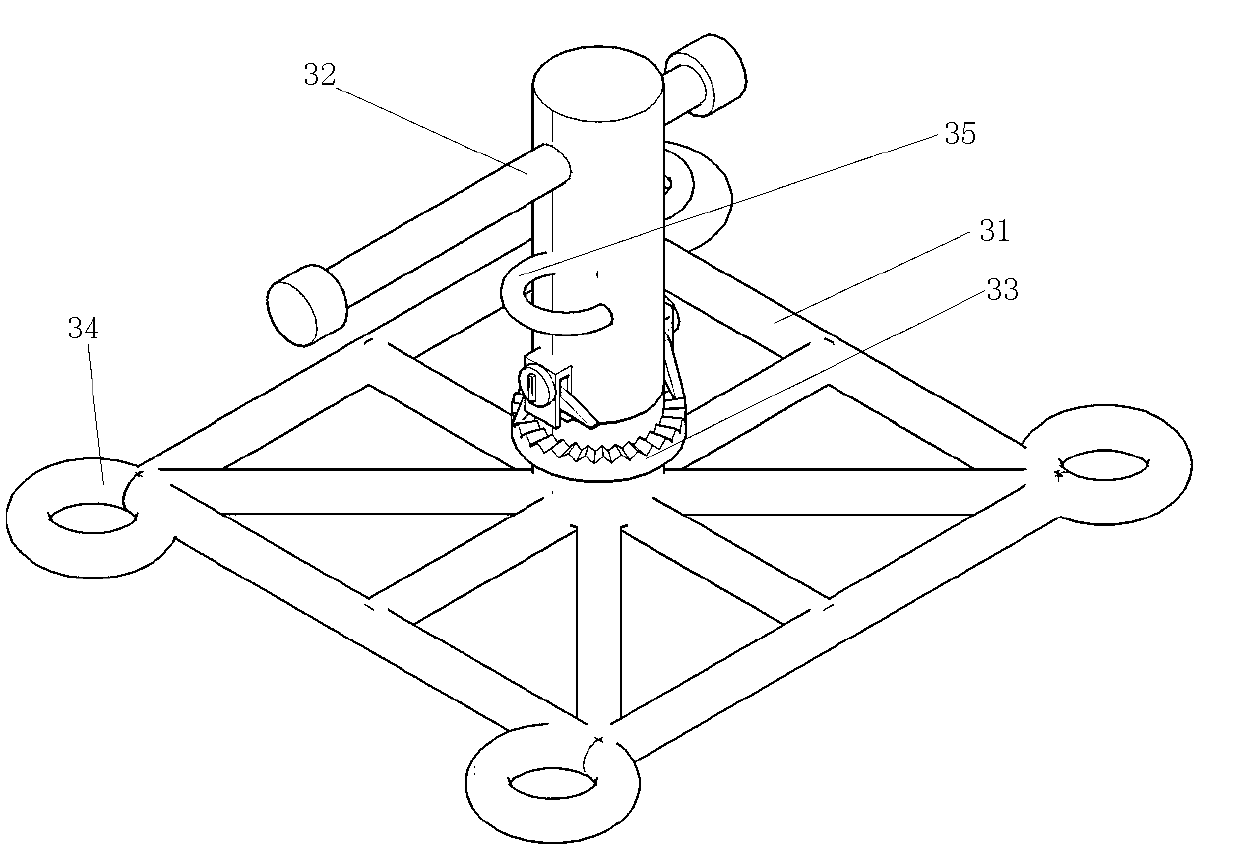

[0016] Such as figure 1 As shown, the row blocks for large-section cable payout of the present invention include several individual blocks 1, and the individual blocks 1 are connected in series, and the adjacent individual blocks 1 are connected by a steel block fixing plate. 2 are connected to each other, and the single tackle 1 at both ends is connected with two steel rope sleeves 4 respectively. The single block 1 includes a pulley 11 and a supporting iron plate 12, the supporting iron plate 12 is composed of two triangular side plates 121 and a rectangular bottom plate 122, and the two triangular side plates 121 are welded on the rectangular bottom plate 122 Two triangular side plates 121 are connected to the pulley 11 by bolts on both sides of the pulley. Both ends of the tackle fixing plate 2 are provided with screw holes, and the tackle fixing plate 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com