Pay-off mechanism for electric power construction

A technology of electric construction and rotating mechanism, which is applied in cable laying equipment, overhead line/cable equipment, and arrangement using take-up reel/photosensitive drum, etc. problems, to achieve the effect of smooth pay-off process, improved pay-off efficiency, and easy sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

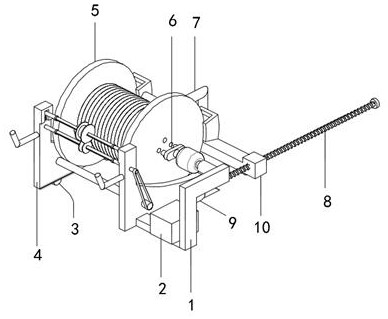

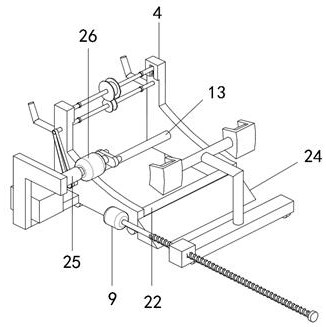

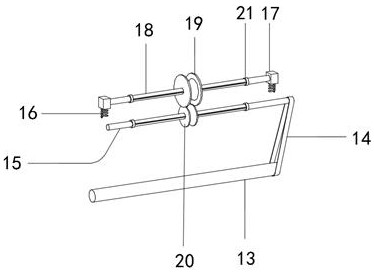

[0029] refer to Figure 1-4 , a pay-off mechanism for electric power construction, comprising a wire reel 5, a universal wheel 3, a slant plate 24, a base 4 and a movable plate 10, the outer wall of one side of the base 4 is connected with a first support rod 13 and a second support through a bearing Rod 22, one end of the first supporting rod 13 penetrates through one side of the outer wall of the base 4 and is sleeved with a track 14, and the top of one side of the outer wall of the base 4 is connected with a first rotating shaft 15 through a bearing, and the first rotating shaft 15 and the first supporting rod 13 pass through The crawler belt 14 is connected, the outer wall of the first rotating shaft 15 is sleeved with a small wire feeding wheel 20, one side outer wall of the base 4 is provided with a chute, the bottom inner wall of the chute is fixed with a spring 16 by screws, and the top of the spring 16 is fixed with a screw. The base block 17, the outer wall of one si...

Embodiment 2

[0037] refer to Figure 5, a pay-off mechanism for electric power construction. Compared with Embodiment 1, this embodiment also includes the outer walls on both sides of the wire reel 5, which are fixed with limiting blocks 27 by screws.

[0038] In the present invention, the inner walls of both sides of the bracket 11 are provided with locking grooves 28 .

[0039] In the present invention, the limiting block 27 is engaged with the locking groove 28 .

[0040] During use, when the cable on the reel 5 is paid out, continue to rotate the reel 5 so that the limit block 27 partly rotates to the inner wall of the slot 28 of the bracket 11, then close the second motor 26, and start the electric push rod 25 to retract Piston rod, start the first motor 9 again to drive the screw mandrel 8 to rotate, and the screw mandrel 8 rotates to drive the movable plate 10 to drive the support 11 to move away from the direction of the swash plate 24. At this time, the support 11 pulls the wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com