Rope feeding device for ship

A rope-feeding and marine-use technology, which is applied to ships and other directions, can solve the problems of easy loosening and confusion of cables, manual retrieval of cables, time-consuming and labor-intensive problems, etc., and achieves the effects of convenient use, knot prevention, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

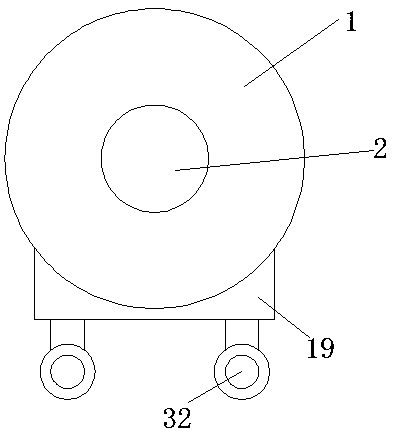

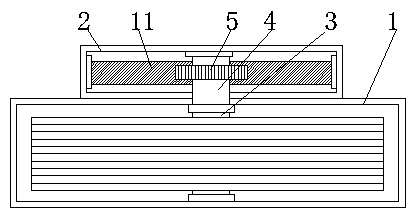

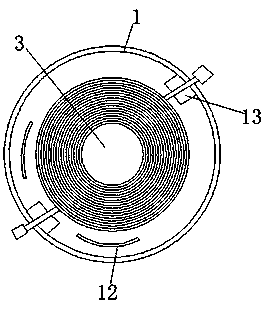

[0025] An embodiment of the present invention provides a marine rope feeding device, such as Figure 1-7 Shown, comprise rope box 1, and control box 2 is installed on the surface of rope box 1, and the inside of rope box 1 is movably connected with rotating shaft rod 3, and the surface of rotating shaft rod 3 is sheathed with thick rope, and the surface of rotating shaft rod 3 is provided with The groove 35 matched with the thick rope is provided with the groove 35 to prevent the thick rope from being twisted when it is set out or taken up, so that the thick rope can be set out or taken up in an orderly manner, and the top of the rotating shaft rod 3 runs through the rope box 1 and extends to the inside of the control box 2, the top of the rotating shaft rod 3 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com