A junction box capable of storing wires

A junction box and electric wire technology, applied in the field of junction boxes, can solve the problems of insufficient utilization of the use effect and lack of junction boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

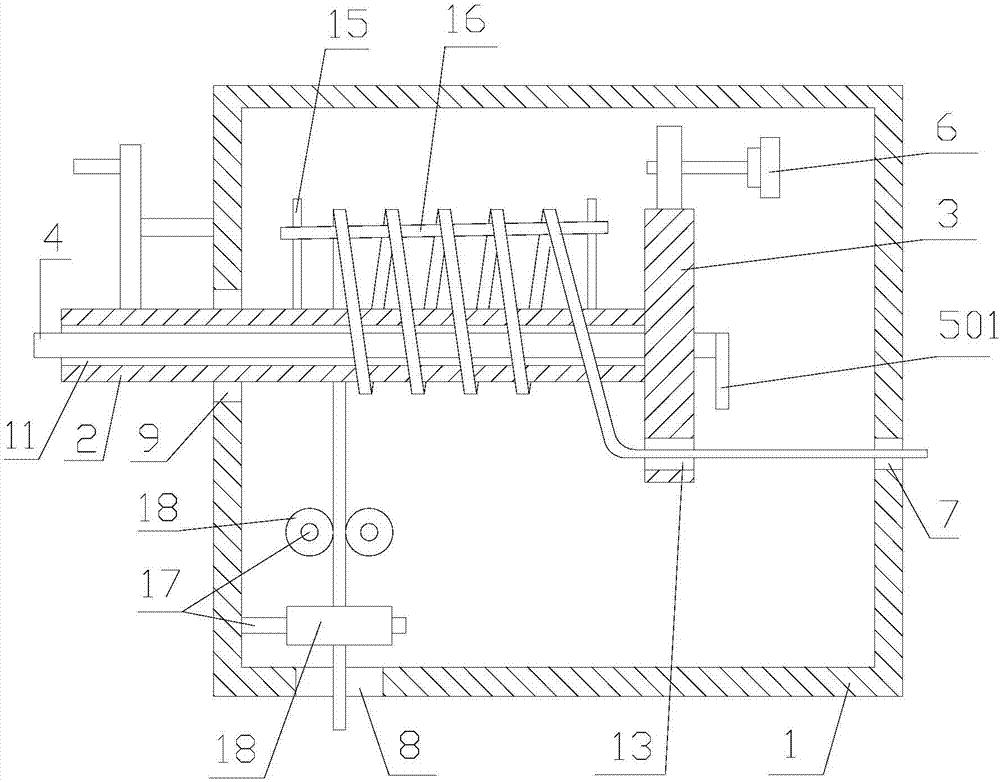

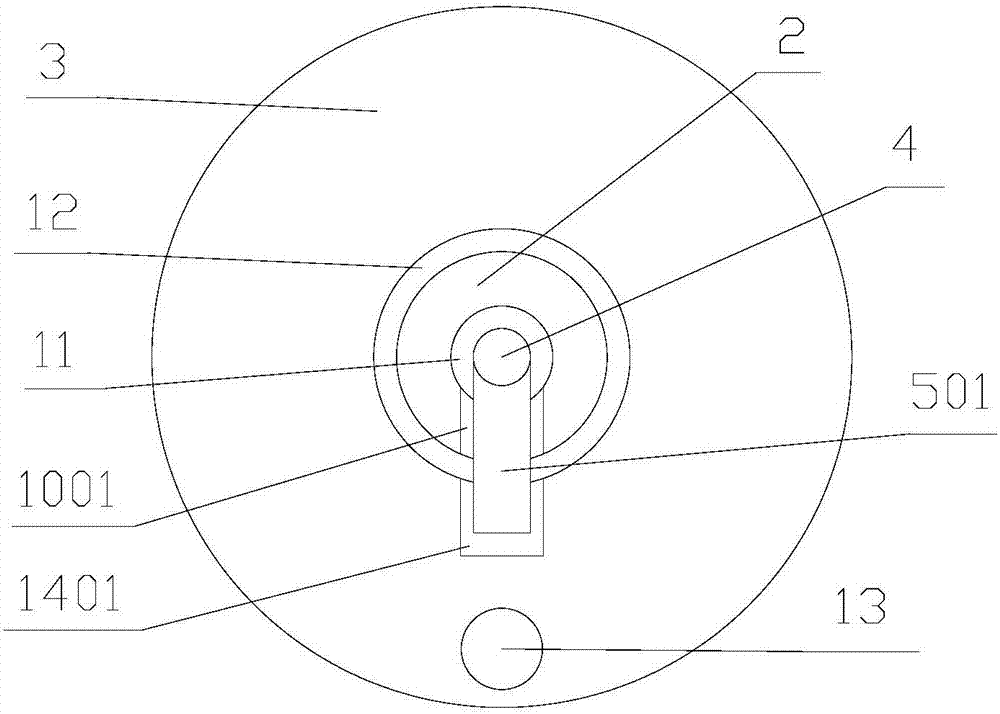

[0031] Reference figure 1 , 2 :

[0032] A junction box capable of storing wires provided by the present invention includes a box body 1, a rotating shaft 2, a rotating wheel 3, a connecting rod 4, a connecting plate 501, a driving mechanism 6, and a plurality of limit units.

[0033] The box body 1 is provided with an inlet hole 7, an outlet hole 8, and a through hole 9. The inlet hole 7 and the through hole 9 are respectively placed on two opposite side walls of the box body 1, and the axis of the inlet hole 7 is connected to the through hole. The axis of the hole 9 is parallel.

[0034] The rotating shaft 2 is placed in the through hole 9, and the rotating shaft 2 is rotatably connected with the through hole 9. The first end of the rotating shaft 2 is placed inside the box body 1 and close to the wire inlet 7, and the first end surface of the rotating shaft 2 is provided with a receiving groove 1001 The second end of the rotating shaft 2 is placed outside the box body 1; the axis...

Embodiment 2

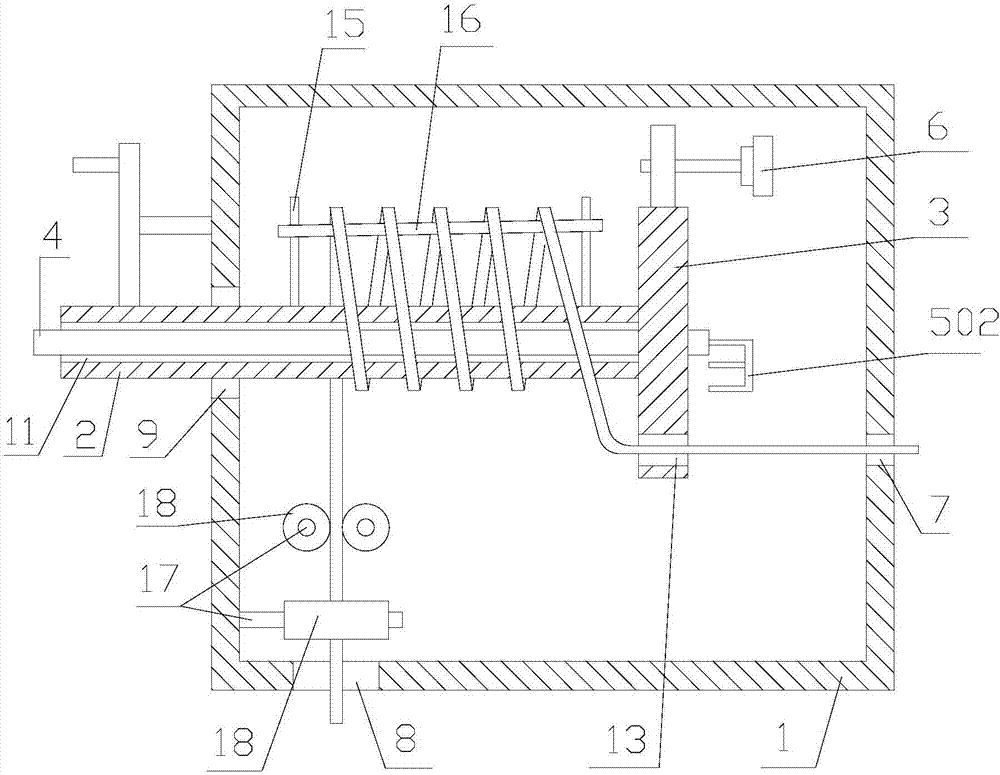

[0049] Combine image 3 , 4 :

[0050] A junction box capable of storing wires provided by the present invention includes a box body 1, a rotating shaft 2, a rotating wheel 3, a connecting rod 4, a connecting plate 502, a driving mechanism 6, and a plurality of limit units.

[0051] The box body 1 is provided with an inlet hole 7, an outlet hole 8, and a through hole 9. The inlet hole 7 and the through hole 9 are respectively placed on two opposite side walls of the box body 1, and the axis of the inlet hole 7 is connected to the through hole. The axis of the hole 9 is parallel.

[0052] The rotating shaft 2 is placed in the through hole 9, and the rotating shaft 2 is rotatably connected with the through hole 9. The first end of the rotating shaft 2 is placed inside the box body 1 and close to the wire inlet 7, and the first end surface of the rotating shaft 2 is provided with a receiving groove 1002 The second end of the rotating shaft 2 is placed outside the box body 1; the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com