Injection molding feeding machine for vertical hook of jacquard machine assembly

A component and injection molding technology, which is applied in the direction of coating, etc., can solve the problems of increased defect rate, low manual operation efficiency and production capacity, and high operation intensity, so as to ensure the qualified rate and consistency, efficient and compact operation process, and reduce the production cost. The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

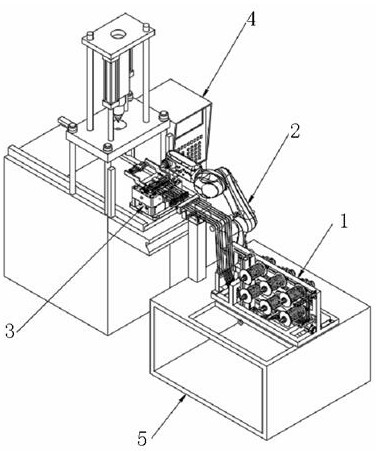

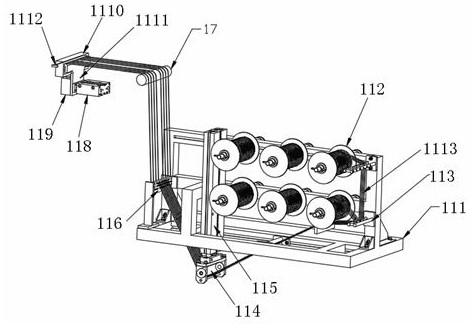

[0031] A jacquard machine assembly vertical hook injection molding material loading machine, including an equipment frame body 5, a wire cutting mechanism 1, a robot assembly 2, an injection molding machine 4 and a mold assembly 3, wherein the injection molding machine 4 is located on one side of the equipment frame body 5 , the wire cutting mechanism 1 and the robot assembly 2 are installed on the equipment frame 5, the mold assembly 3 is installed on the injection molding machine 4, and the equipment frame 5 contains related electronic components and pneumatic components.

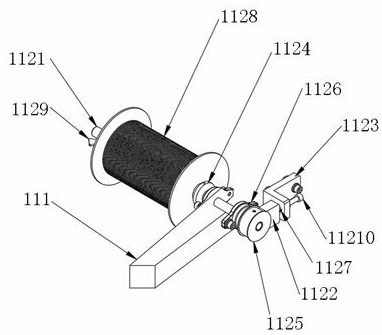

[0032]The harness cutting mechanism 1 is used to cut the harness wound continuously on the harness disc into a harness segment with a certain length; it includes a roller assembly 112, a first clamping flat push assembly, a push-down assembly, Cutting assembly and guide roller assembly. The supporting roller assembly 112 is used to install the wire reel, and its structure includes a wire reel shaft 1121 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com