Tray type automatic supply and retraction equipment

An automatic feeding and tray-type technology, which is applied to the stacking of objects, the unstacking of objects, and conveyors, can solve the problems of wasting resources, loud noise, and easy to hurt people, so as to achieve automation, intelligence, and reduce Work intensity, the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the scope of protection of the present invention is not limited to the following examples, that is, any simple equivalent changes and modifications made based on the patent scope of the present invention and the content of the description are still within the scope of the patent of the present invention.

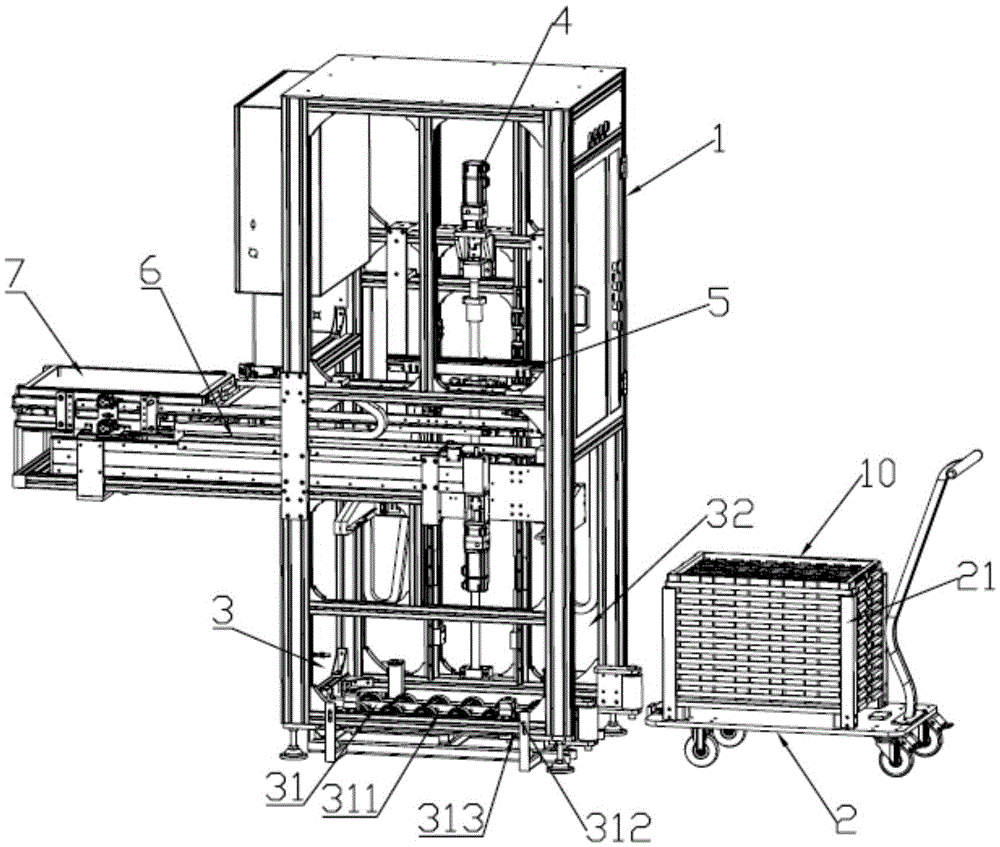

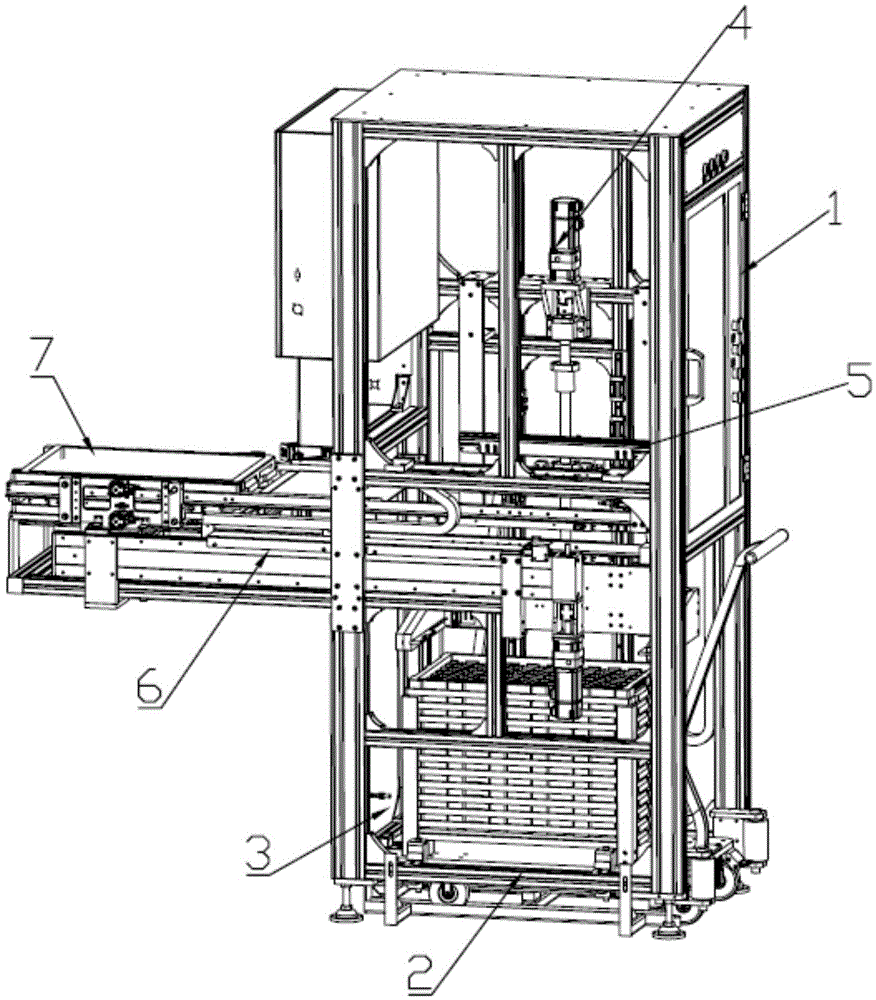

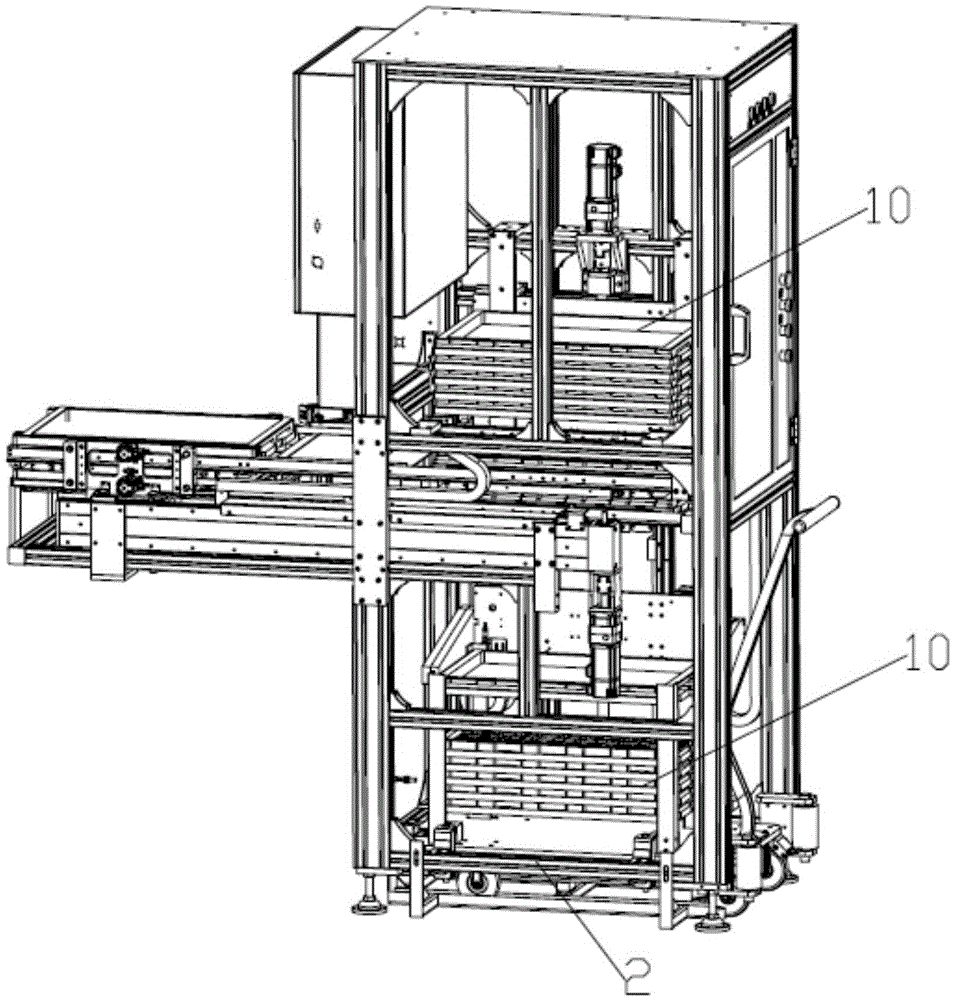

[0051] refer to Figure 1-11 , a kind of tray-type automatic feeding and closing equipment, with the X-direction in the horizontal direction, the Y-direction in the vertical direction, and the Z-direction in the vertical direction, including a frame 1 and several feeding trolleys 2, and the feeding trolley is equipped with There is a tray positioning mechanism 21, which is used to stack and position several trays 10 in sequence.

[0052] A feeding area 3 is formed below the frame, and the feeding area is provided with a trolley pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com