Chromatoghraph line antiforge method chromatograph line antiforge paper

A technology of anti-counterfeiting paper and chromatography, which is applied in the field of commodity anti-counterfeiting methods and anti-counterfeiting paper, can solve the problems that the speed of the paper machine cannot be fast, it is not suitable for high-speed production, and the production is difficult, so as to achieve good anti-counterfeiting effect, low scrap rate and high production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Such as figure 1 As shown, printing and dyeing a chromatographic line (or printing a film, and then cutting into very narrow thin lines as chromatographic lines).

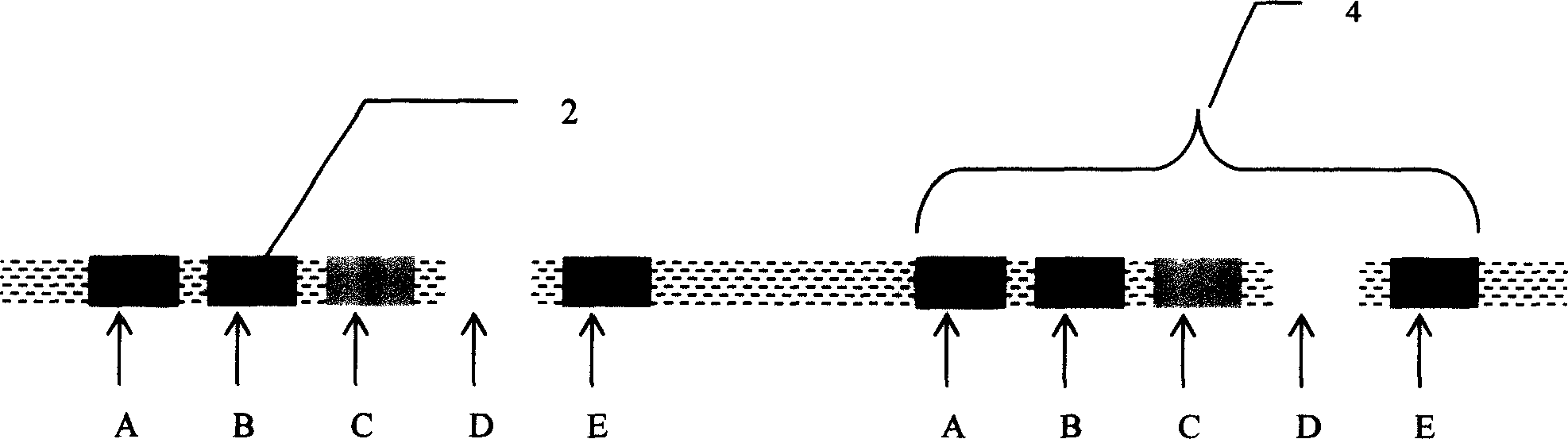

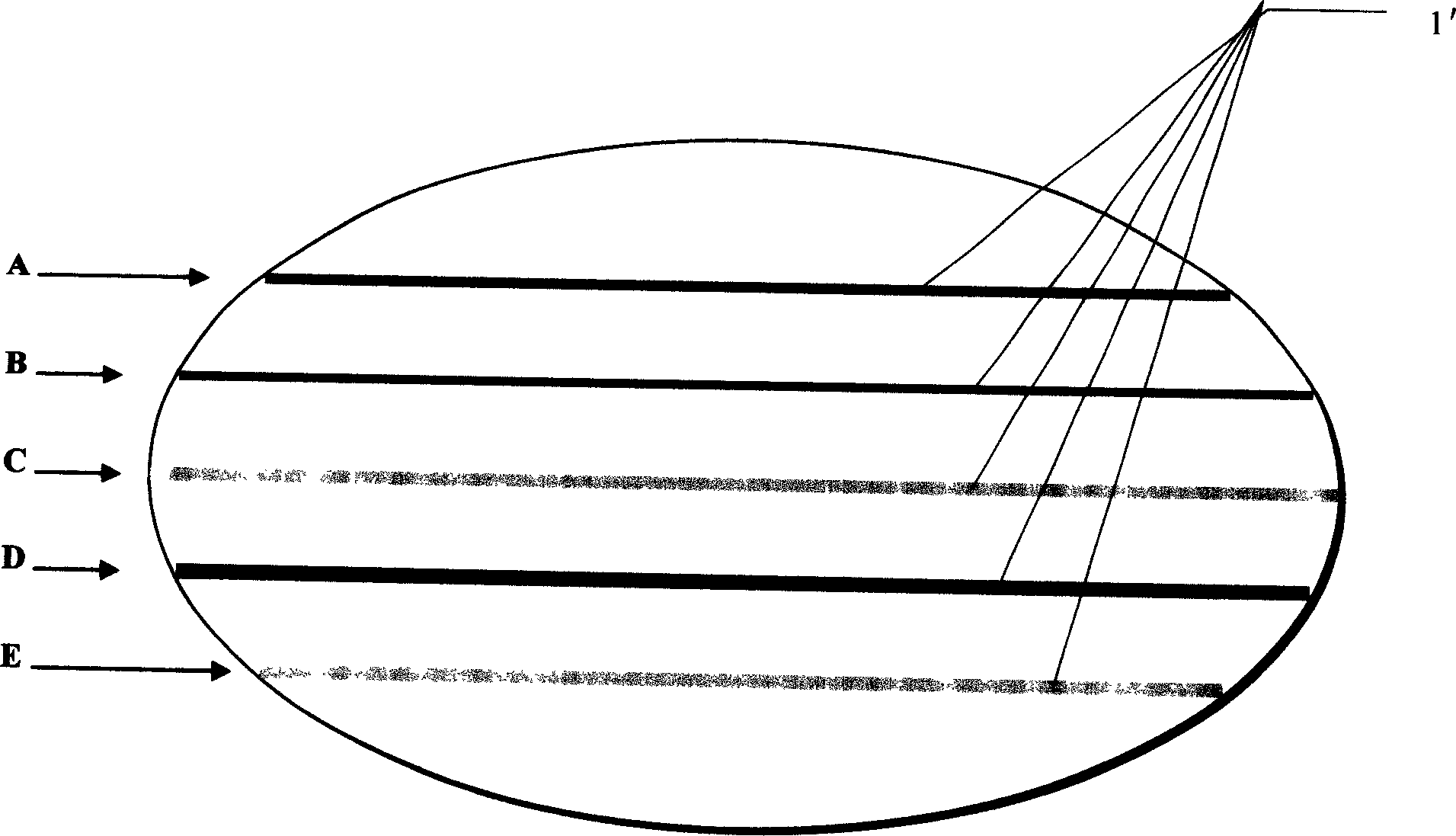

[0024] Select a 20-count white polyester yarn, and use a segment dyeing machine to print and dye some color segments (2) with each color segment length of 3mm on it, choose black (A), red (B), yellow (C), green (D), blue (E) color segment (2), according to the arrangement order of black (A), red (B), yellow (C), green (D), blue (E), each interval is 10mm It is printed and dyed on polyester yarn to form a chromatographic thread (1). Since the color segments (2) of the above five colors are arranged in groups according to a fixed order, the color sequence characteristics of each group must be the same. If 5 color segment lengths are used as a set of anti-counterfeiting information, and they are arranged and combined in different orders, the above five colors can have 3125 permutations and combinations. In ot...

Embodiment 2

[0026] Such as figure 2 , Figure 4 As shown, a chromatographic line anti-counterfeit paper and its chromatographic line anti-counterfeit medicine box are manufactured.

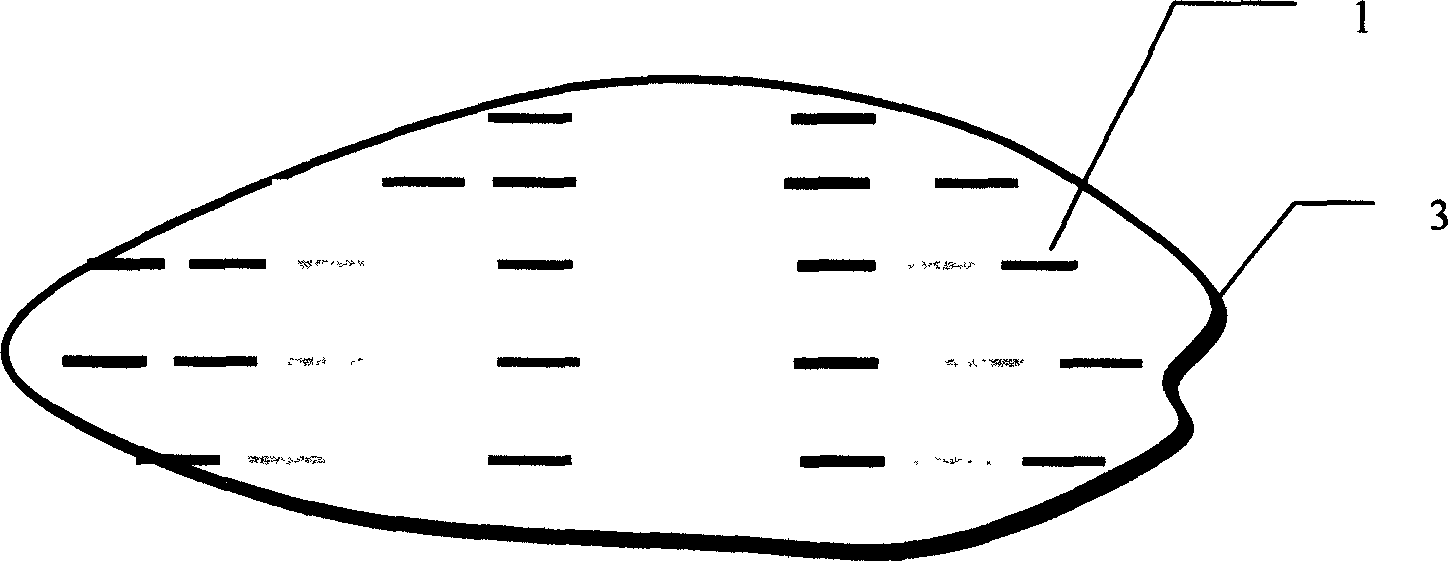

[0027] The first step is to spread the chromatographic lines (1) made in the above example in parallel and evenly in the paper at a distance of 30 mm; increase the transparency of the surface paper layer as much as possible so that the color segments (2) can see through It can be directly seen by the naked eye through the paper surface; according to 230g / m 2 The standard copying out chromatographic line anti-counterfeiting paper (3) is standby (referring to figure 2 ).

[0028] In the second step, adopt the above-mentioned chromatographic line anti-counterfeiting paper (3) to print out the chromatographic line anti-counterfeiting medicine boxes of 105mm * 150mm one by one (see Figure 4 ). And the anti-counterfeiting feature (color sequence feature) statement: "This medicine box is printed on the speci...

Embodiment 3

[0030] Such as Figure 5 As shown, a 20-micron transparent film is selected, and some color segments (2) with each color segment length of 2 mm are printed on it, and black (A), red (B), yellow (C), green (D) are selected. ), blue (E) five color segments (2), in the order of 'black, red, yellow, green and blue', print them on the transparent film at intervals of 3 mm, and then cut them into 0.4 mm wide and 10 mm long Thin lines whose color sequence is characterized by 'black, red, yellow, green and blue (ABCDE)' constitute a special chromatographic line (1).

[0031] The prepared chromatographic lines (1) are added into the pulp during papermaking and stirred evenly, so that the anti-counterfeit paper with randomly distributed chromatographic lines can be produced. Only providing the anti-counterfeiting paper with the same color sequence feature to the same user can play a very good anti-counterfeiting effect.

[0032] Using the chromatographic line anti-counterfeit paper (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com