High-angle rotation wire feeding device of bucket wheel machine

A bucket wheel machine, large-angle technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of large twist angle and stretch length of cables, unsatisfactory rotation on the line, affecting material passing capacity, etc., to achieve system optimization, The effect of saving control cables and installation costs and increasing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing and embodiment, embodiment is intended to illustrate the present invention rather than to the further limitation of the present invention, as not departing from the design spirit of the present invention, those of ordinary skill in the art make various solutions to the present invention Deformation, improvement, and retouching all fall within the scope defined by the claims of the present invention.

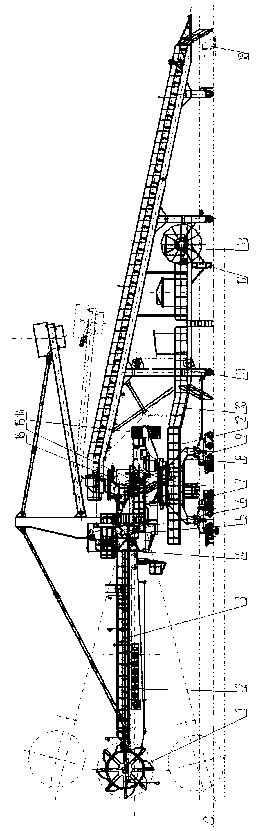

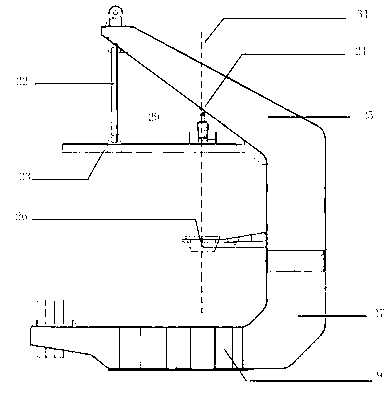

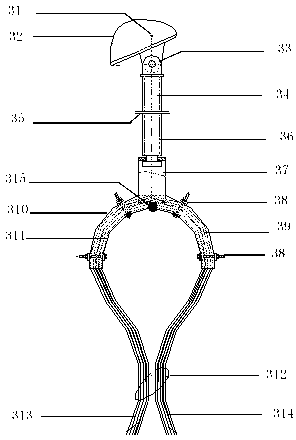

[0024] The following is only one of the exemplary embodiments, such as figure 1 , figure 2 , image 3 As shown, a bucket wheel machine with a fixed single-tail car or trailer structure consists of a bucket wheel mechanism (1), a front arm frame (2), an arm frame belt conveyor (3), a cab (4), and an upper structure parts (5), pitching mechanism (6), traveling trolley (7), door seat (8), slewing mechanism (9), tail car (10), electrical (11), lubrication system (12), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com