Threading device for measuring three-dimensional coordinates of pipe

A technology of three-dimensional coordinates and measuring pipes, which is applied in the field of threaders, can solve the problems of inconvenient carrying, unsafe, large size, etc., and achieve the effect of convenient carrying, convenient operation and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

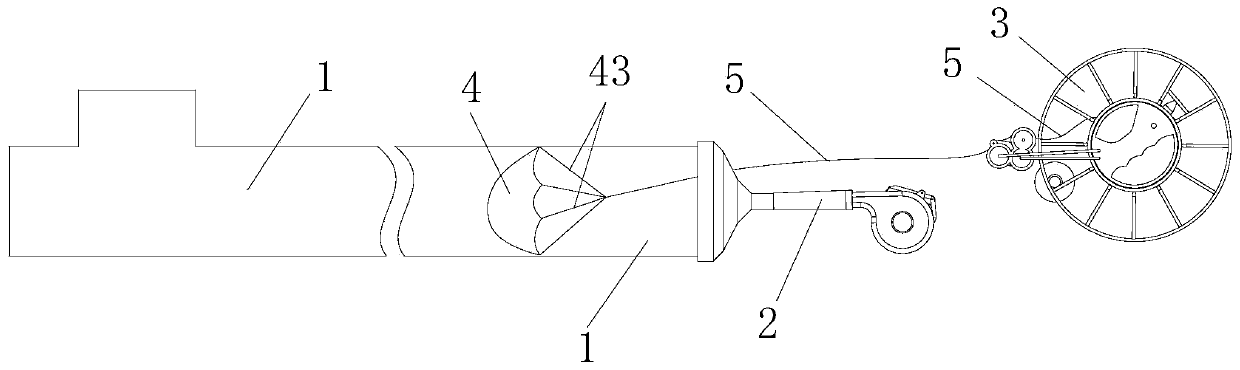

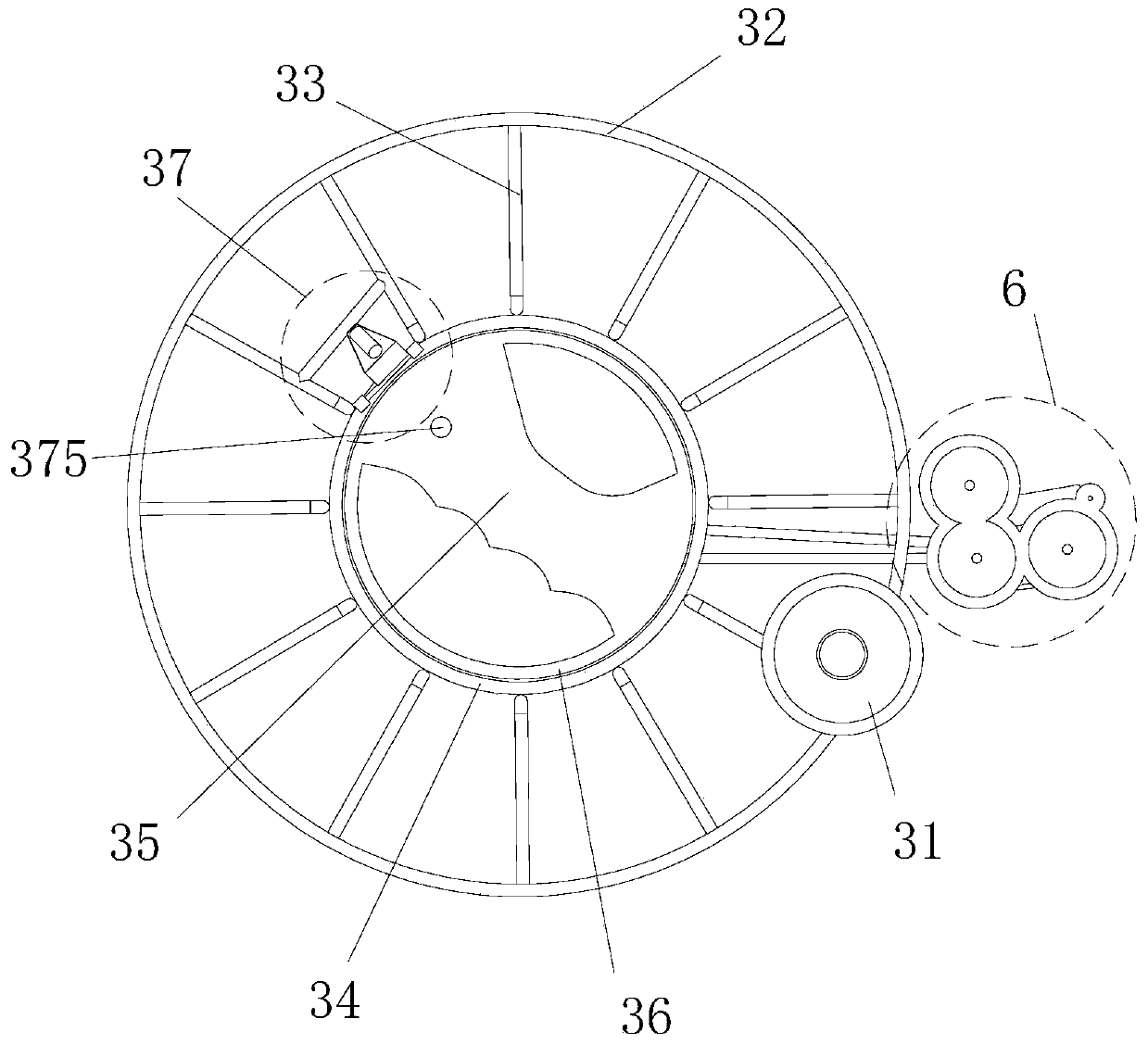

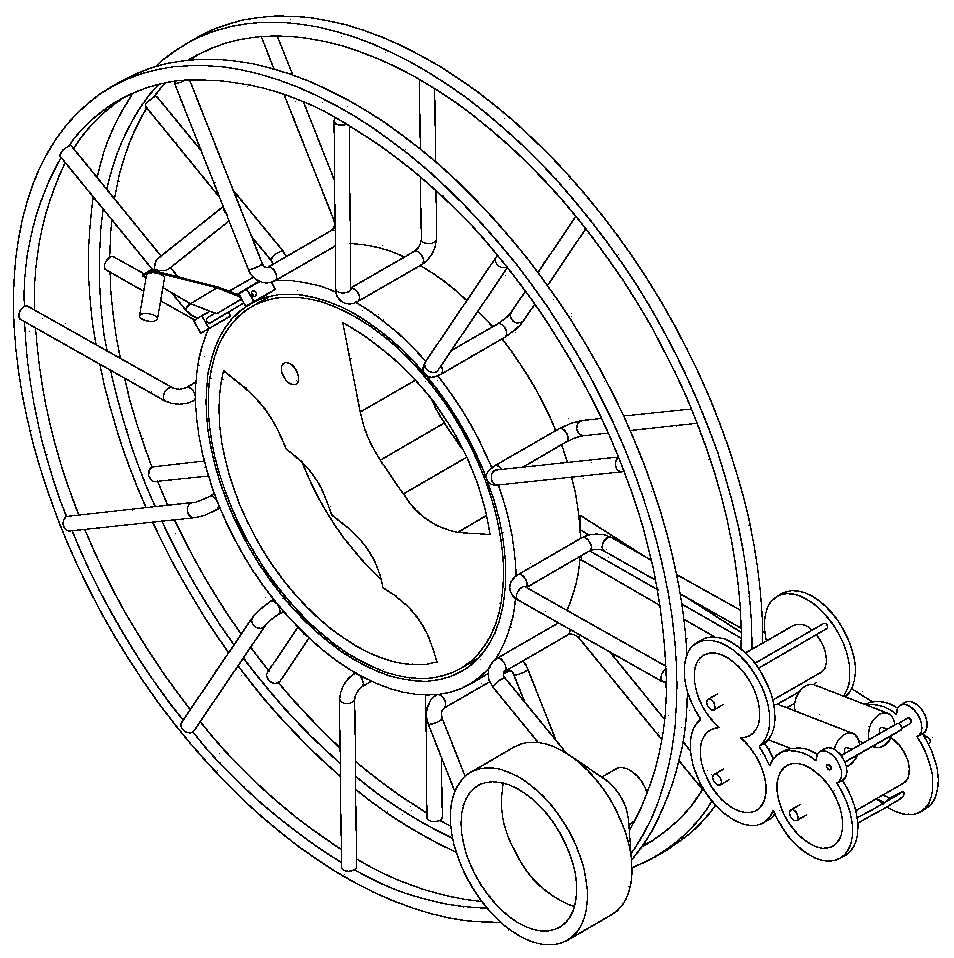

[0063] Such as figure 1 As shown, this embodiment discloses a threader for measuring three-dimensional coordinates of a pipeline, the threader mainly includes an air blast device 2 for blowing air to the pipeline to be measured, a lead wire 5, and a traction device 4 for bearing directional wind , and a wire reel 3 for receiving and releasing the lead wire 5 . One end of the lead wire 5 passes through the blower device 2 and is fixedly connected to the traction device 4 , and the other end is spirally wound in the winding reel 3 . The traction device 4 is put into one end of the pipeline to be tested, and the head of the blower device 2 is sleeved on the end of the pipeline to be tested, blowing air to the other end of the pipeline to be tested, and simultaneously with the reel 3 to set off the wire, the The pulling device 4 and the lead wire 5 are blown to the other end of the pipeline to be tested together.

[0064] Specifically, the pulling device 4 is set as an ordinary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com