Tension adjusting method for fiber traction laying

A technology of tension adjustment and optical fiber, which is applied in the direction of optical fiber/cable installation, etc., can solve the problems of increased fiber damage and breakage, optical cable surge, damage, etc., to avoid looping and surge, tension is always stable, and improve use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

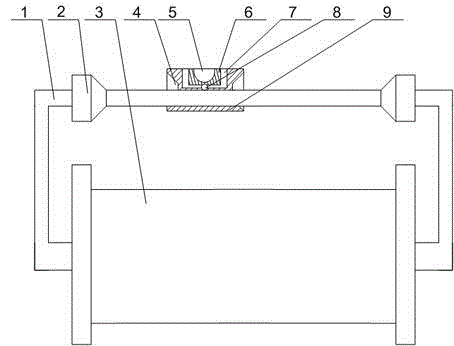

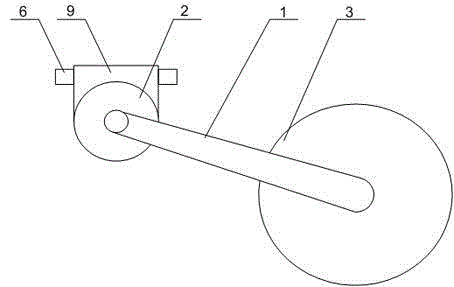

[0025] Such as figure 1 and figure 2 As shown, this embodiment includes the following steps,

[0026] (A) Place the cable head on the cable reel 3 in the wire slot 5, and start laying the predetermined line of the optical cable through the wire slot 5. The optical cables on the cable drum 3 are distributed layer by layer, so the traction of the optical cable follows the axis of the cable drum 3 The direction starts to be pulled out layer by layer;

[0027] (B) Slide the adjusting block 9 on the connecting rod 1, and the adjusting block 9 starts to slide on the connecting rod 1 along with the outlet direction of the optical cable on the cable reel 3. By adjusting the outlet of the optical cable, the optical cable is further reduced. The phenomenon that the axial direction of disk 3 swings greatly;

[0028] (C), the adjusting block 9 is eccentric relative to the connecting rod 1, that is, the center of gravity of the adjusting block 9 is not on the connecting rod 1, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com