Anti-slip denoising device of shell vibration machine

A vibrating shell machine and anti-skid technology, which is applied in the direction of loosening the equipment of the model, can solve the problems of potential safety hazards, easy slipping of workpieces, troubles, etc., and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

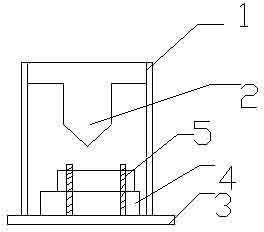

[0010] Such as figure 1 , 2 and 3, the vibration shell machine with anti-skid and noise reduction device mainly has a frame 1, a freely movable vibrating hammer 2 connected to the frame, a base 3 fixed on the bottom of the frame, and placed on the base The rubber pad 4 on the seat 3 is formed by the antiskid steel plate 5 placed on the rubber pad. In this device, a rubber pad 4 with a raised pattern or a concave pattern is placed on the base 3. The rubber pad can play a good anti-slip effect during work. The anti-skid steel plate 5 of pattern or concave pattern is further fixed on the base 3 by screws on the four corners of the anti-skid steel plate 5, which improves the safety performance of the workpiece like this. In this way, during the working process, the rubber pad and the anti-skid steel plate can have a good anti-skid and noise reduction effect, and at the same time reduce the possibility of the workpiece falling off, thereby providing conditions for safe production....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com