Sand shooting mechanism and sand shooting method of sand shooting machine

A technology of sand shooting machine and sand shooting board, which is applied to the parts of the molding machine, the molding machine, the equipment for loosening the model, etc. problems, to reduce labor intensity, avoid high temperature burns, save maintenance costs and electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

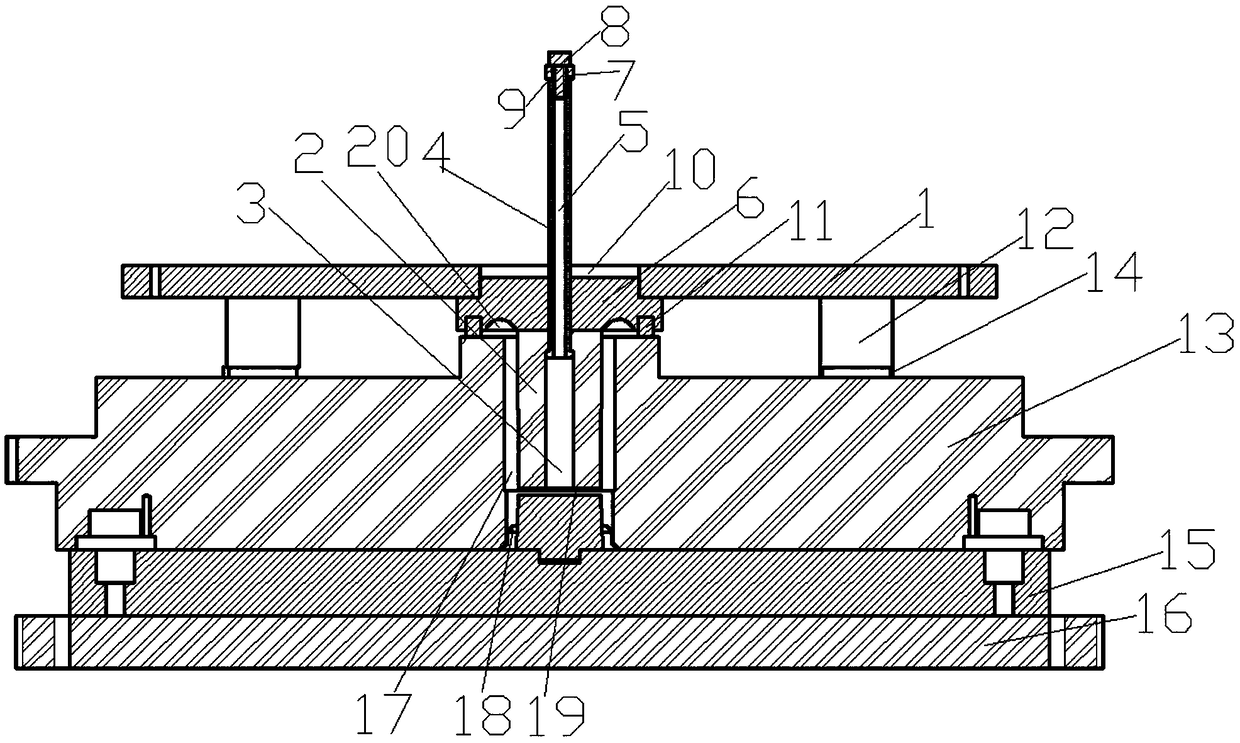

[0025] Such as figure 1 Shown is a schematic structural view of the sand shooting mechanism of the sand shooting machine of the present invention; a sand shooting mechanism of the sand shooting machine of the present invention includes an upper mold 13, a template 15 arranged at the bottom of the upper mold 13, and a mold plate 15 arranged at the top of the upper mold 13 A sand-shooting board 1, a sand core molding cavity is formed between the upper mold 13 and the mold plate 15, and a cavity 17 that penetrates up and down is provided in the middle of the upper mold 13. The sand-shooting board 1 is provided with a The sand-shooting nozzle 12 connected to the sand core forming cavity, the casting riser column 18 and the filter screen 19 extending into the cavity 17 are arranged on the mold plate 15, and the sand-shooting curing device is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com