Device for taking out loose piece of sand core of sand mold for large casings and using method of device

A technology for large castings and loose blocks, which is applied in the field of devices for taking loose blocks from sand cores of large castings. It can solve the problems of fragile model loose blocks, time-consuming, and inability to persist in use, and achieves improved surface quality, significant surface quality, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

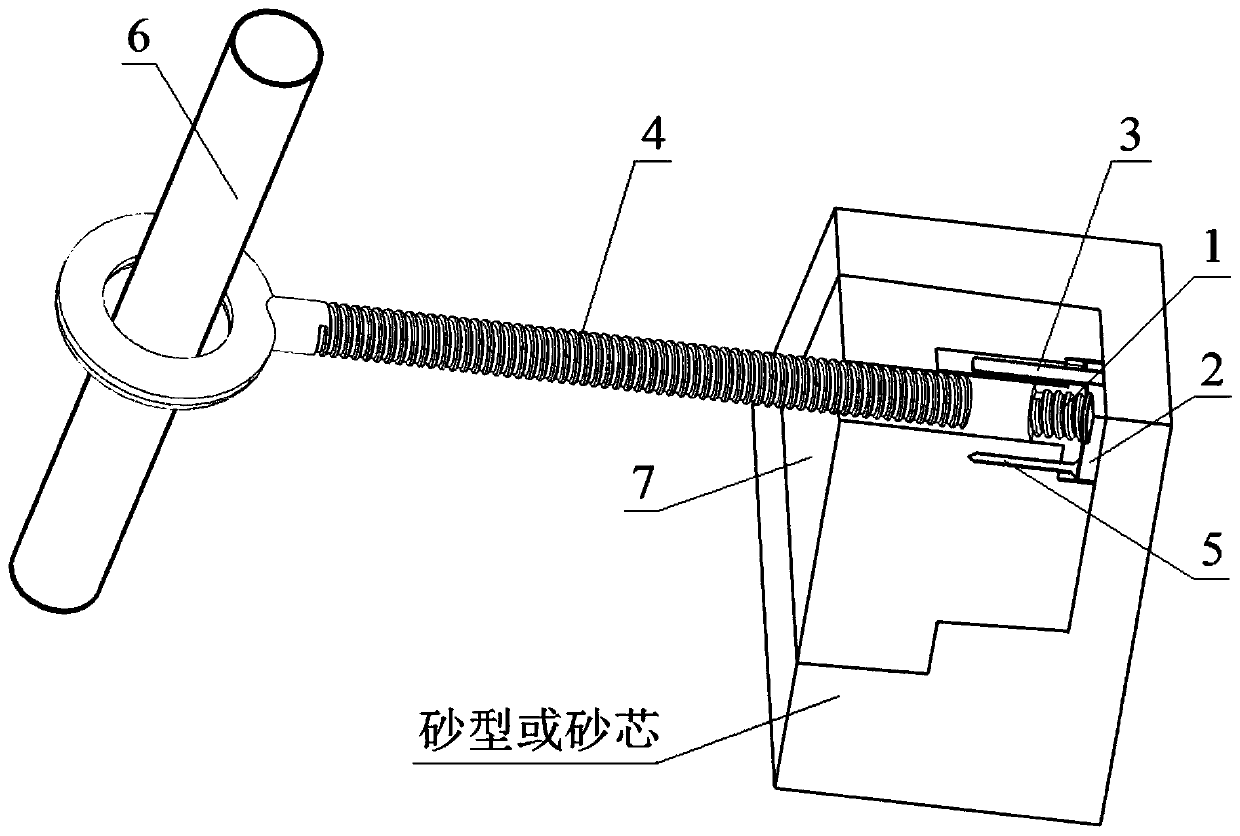

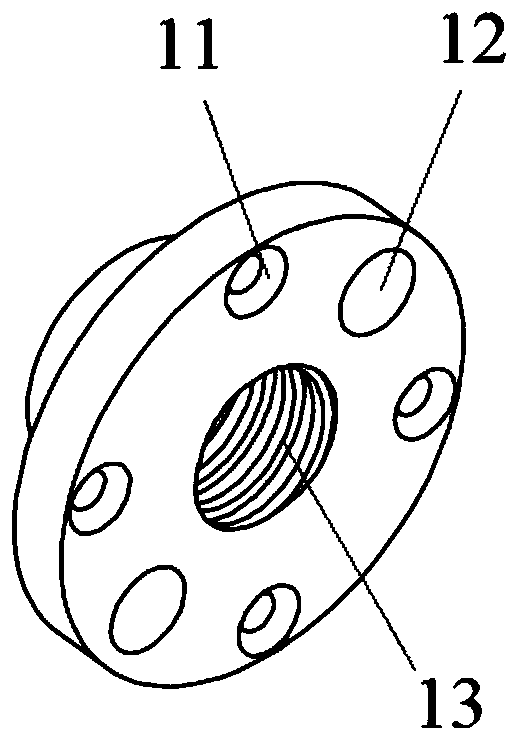

[0119] The device for taking loose blocks from sand cores of large-scale castings mainly includes: an embedded top screw 1 placed in the mounting seat hole 71 of the model loose block 7, a cover plate 2 positioned on one side of the embedded top screw 1, and a positioning screw 3 , the lead screw mandrel 4 that links to each other with embedded top screw 1, fastening screw 5 and torque bar 6. The mounting seat hole 71 is opened from one end face of the model movable block 7 .

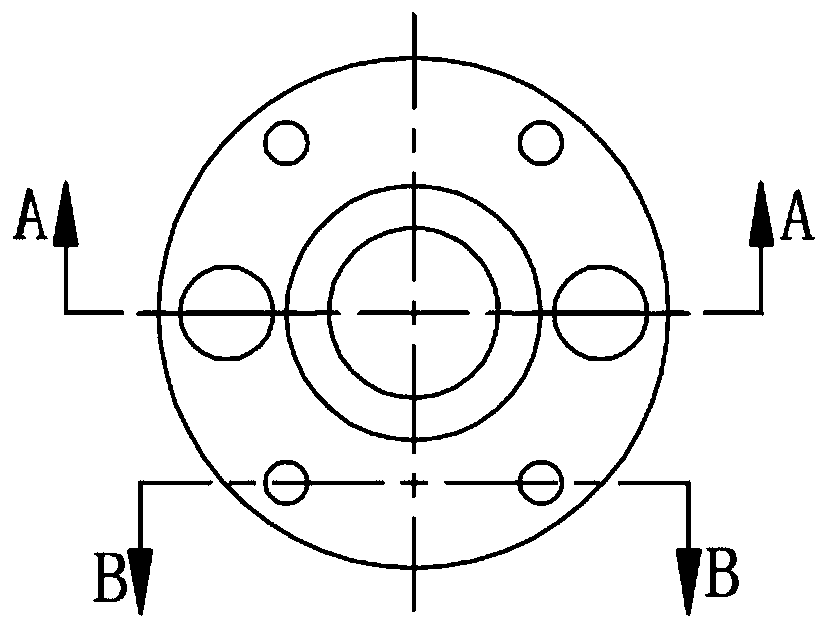

[0120] The center of the bottom of the mounting seat hole 71 is provided with a connected long hole 72, the mounting seat hole 71 and the through long hole 72 are in a tapered stepped structure, and run through the entire model block 7 in the thickness direction, the mounting seat hole 71 The diameter is greater than the diameter of the long hole 72; the bottom of the mounting seat hole 71 is provided with 2 first through holes 73 and 4 second through holes 74 distributed at intervals in the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com