Automatic mold release mechanism for engine casting complex sand core mold

A sand core mold and automatic demoulding technology, applied in the field of casting, can solve the problems of increasing the cost of mold manufacturing and maintenance, increasing the labor intensity of on-site operators, increasing the complexity of mold design, etc., to achieve easy use of the mold, simple structure, The effect of fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

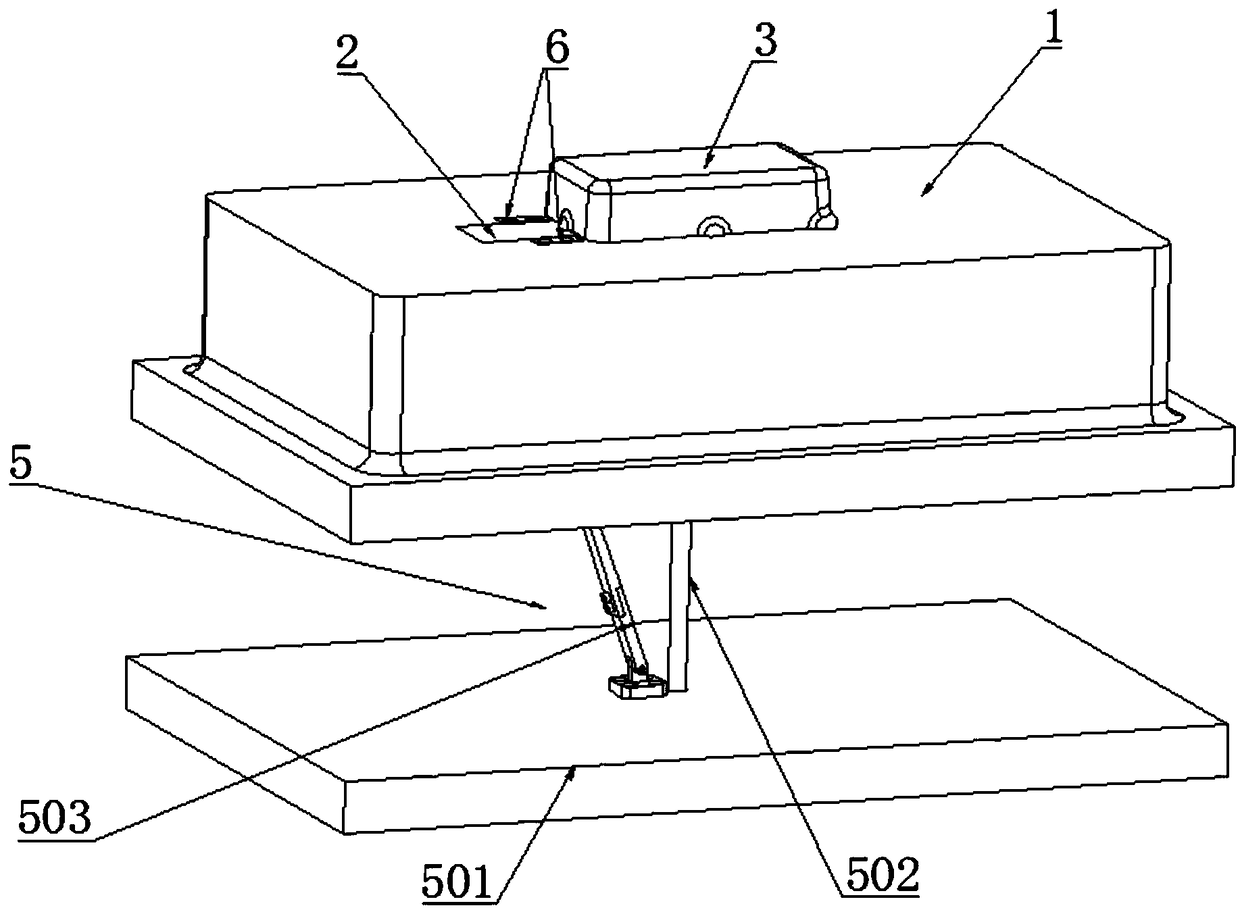

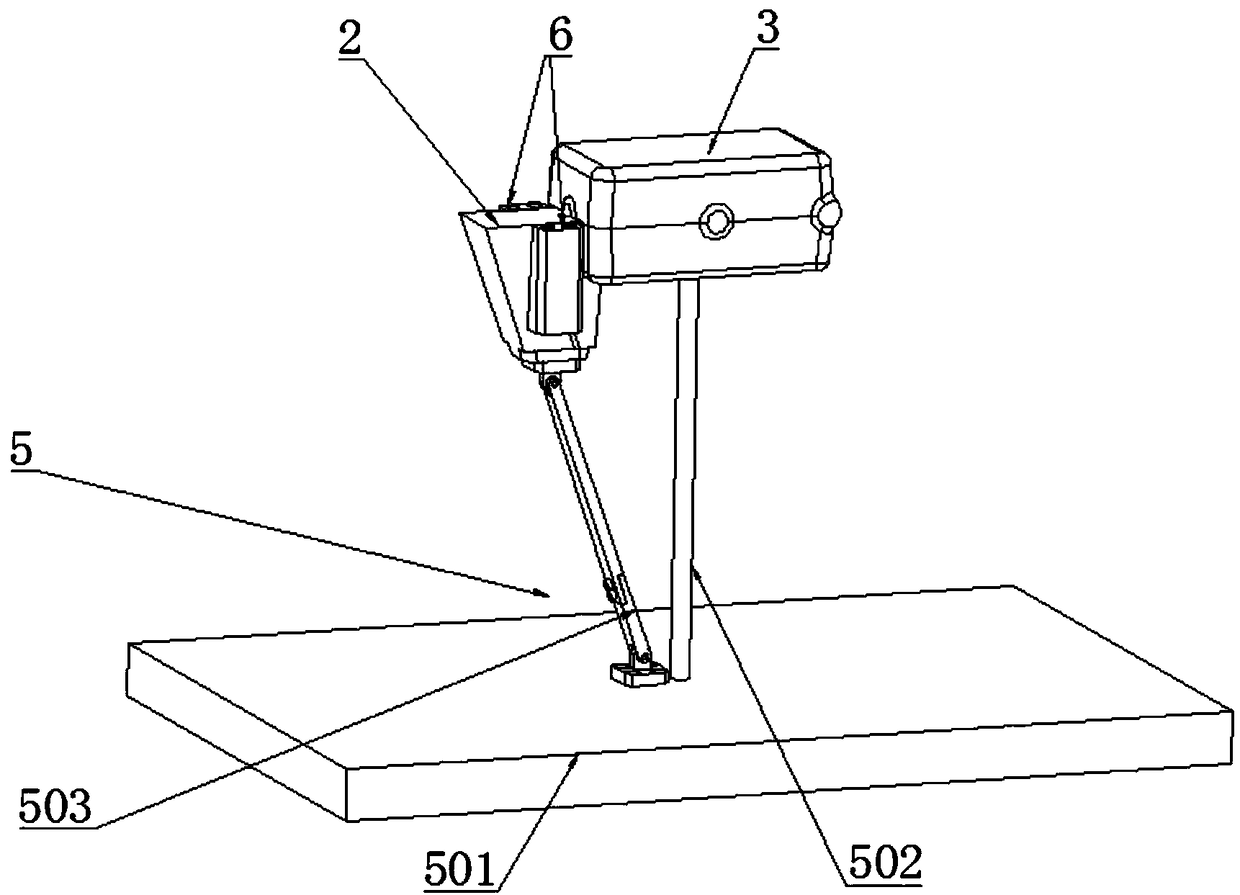

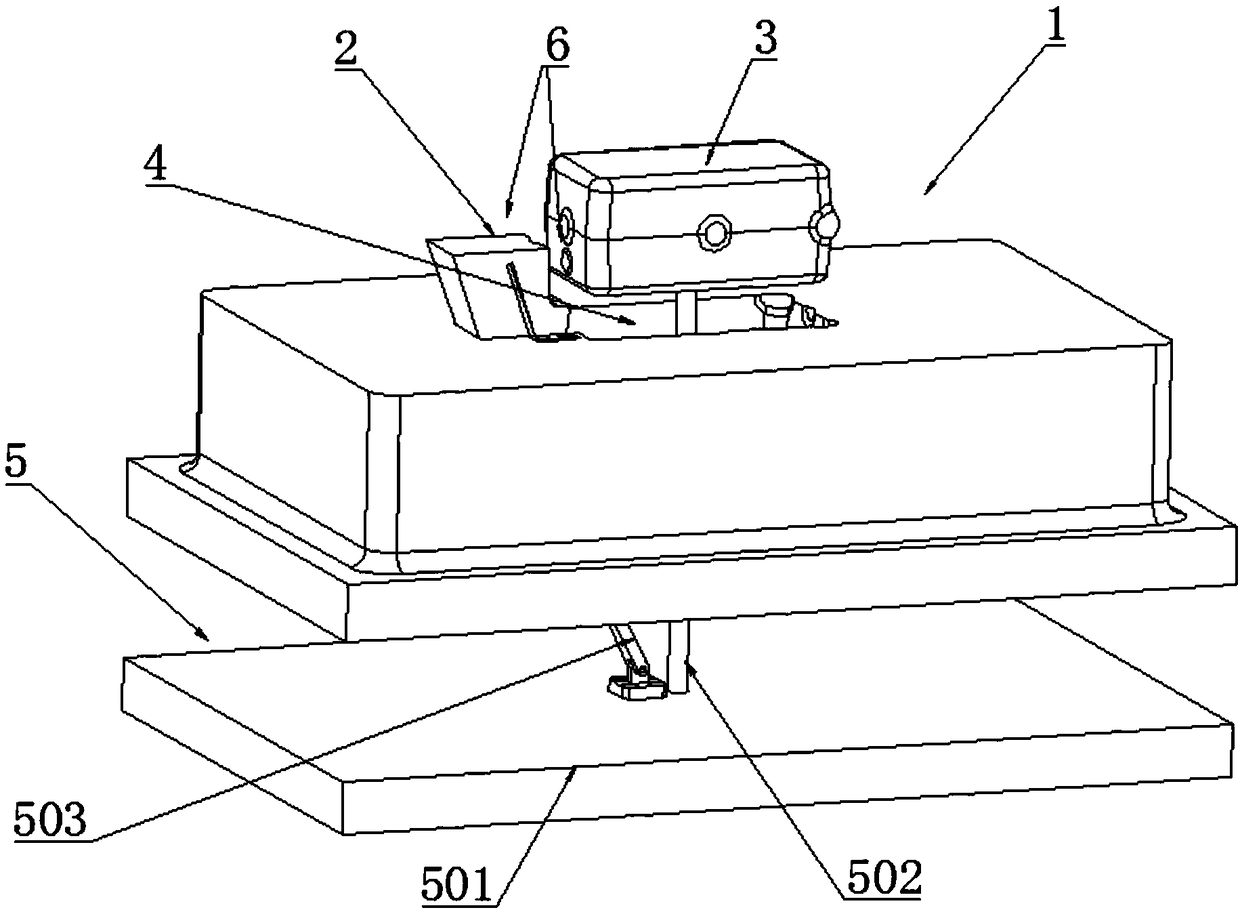

[0033] The specific embodiment of the present invention is like this: as Figure 1-7 As shown, an automatic demoulding mechanism for a complex sand core mold for engine casting, including a lower core box 1 and a cavity 4 adapted to the outer contour of the lower part of the sand core 3 on the lower core box 1, and the lower structure of the sand core 3 A movable block 2 is provided to slide up and down in the cavity 4 of the lower core box 1 to protrude or sag to one side, and the movable block 2 and the cavity 4 form a cavity suitable for the outer contour of the lower part of the sand core 3. The bottom of the core box 1 is provided with a jacking and demoulding mechanism 5 capable of jacking up the movable block 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com